Easy-to-clean material mixing device used for production of bagged mini breads

A mixing device and bread technology, applied in the direction of mixing/kneading, application, dough mixer, etc. with vertical installation tools, can solve the problems that are difficult to meet the high-quality production requirements, the production quality is difficult to be effectively guaranteed, and the wheat flour is difficult to fully Mixing and other issues to achieve the effect of improving efficiency, ensuring production quality, and ensuring full mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

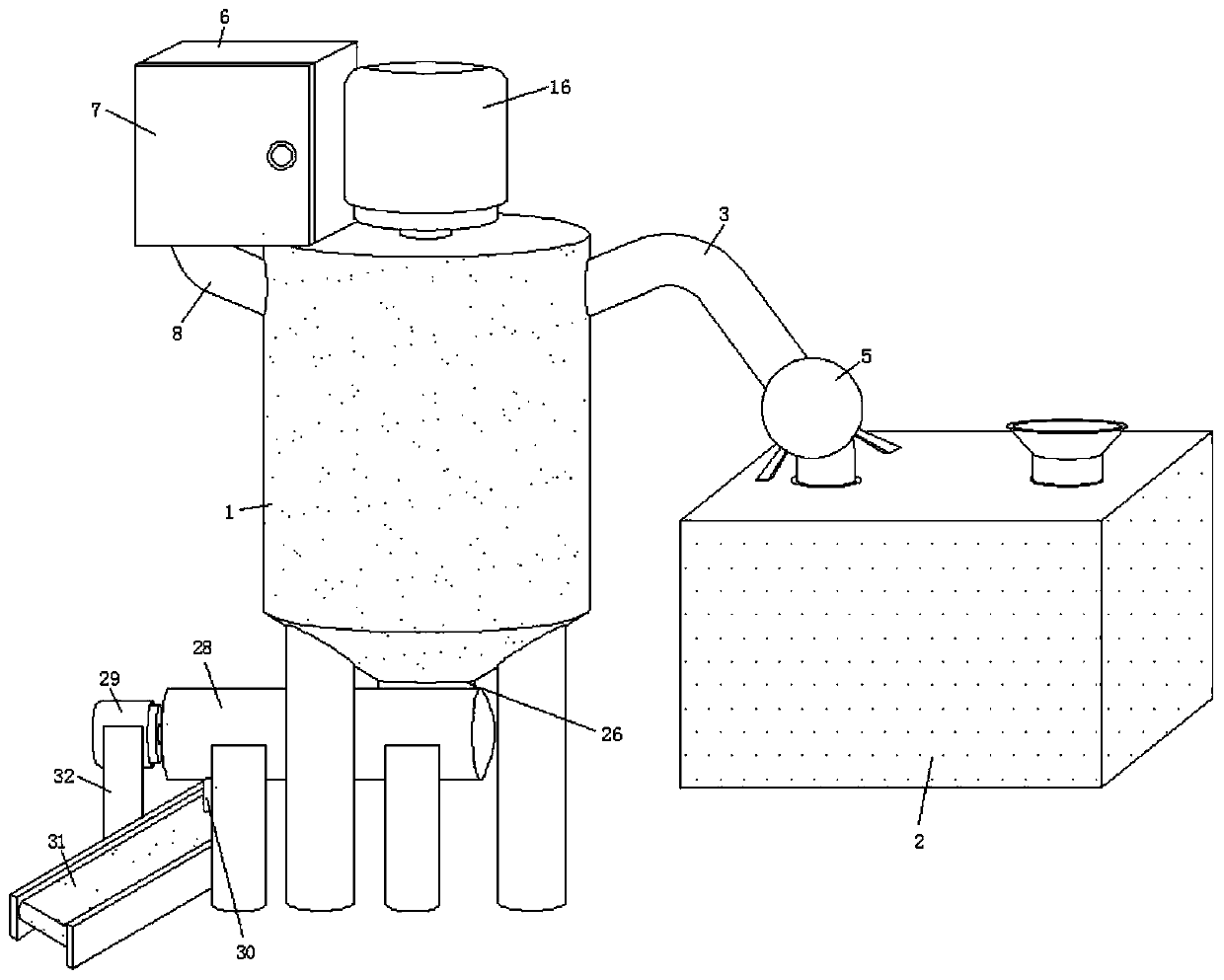

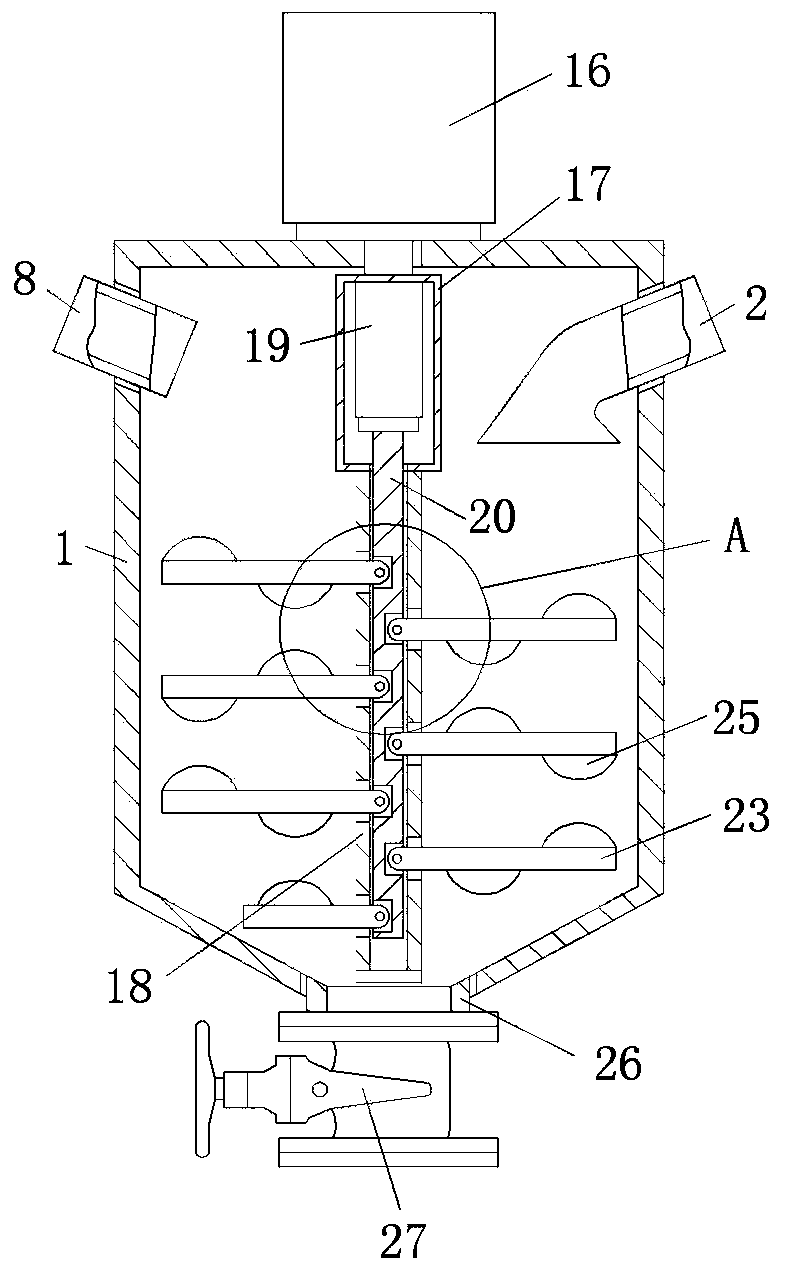

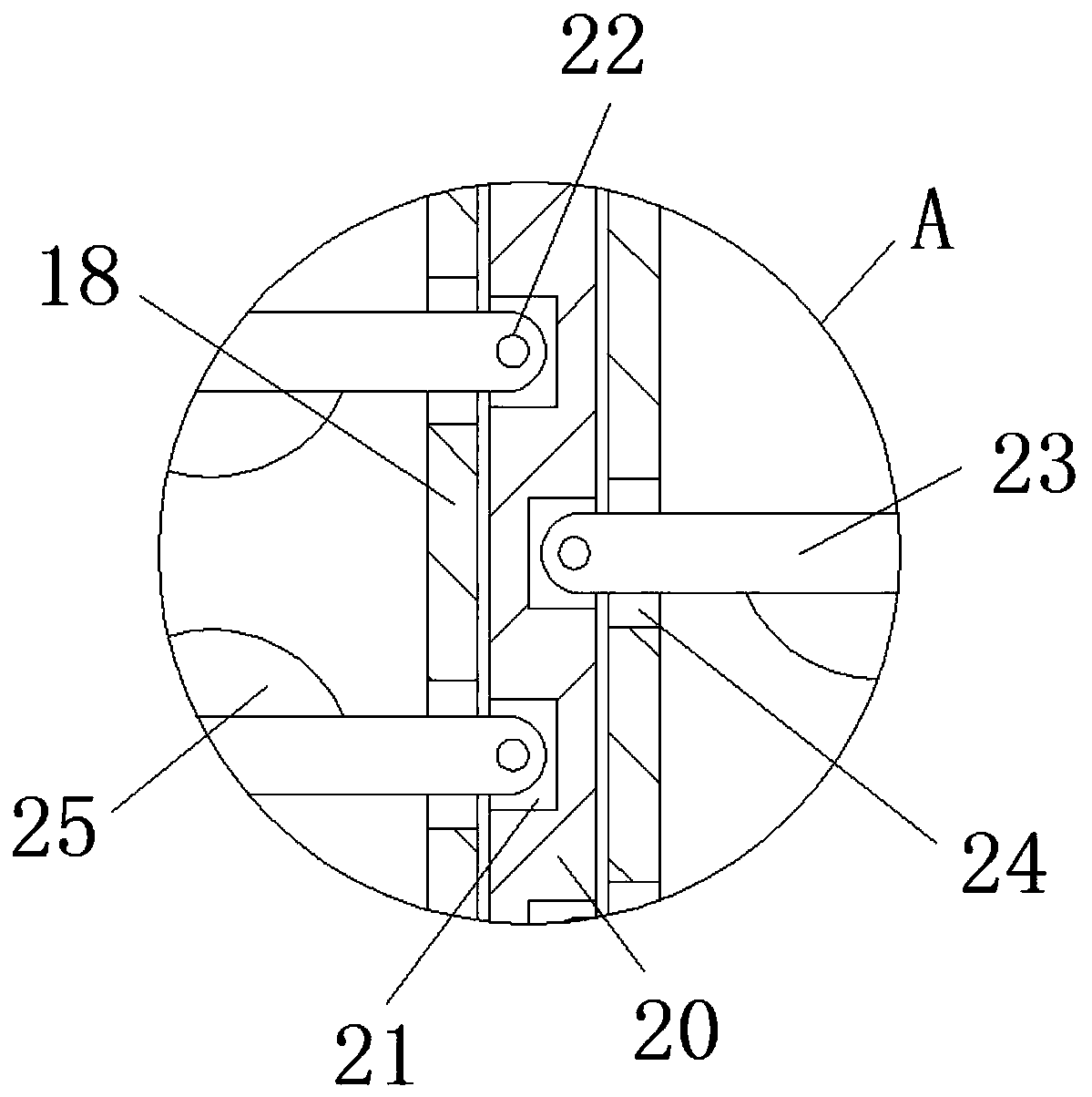

[0029] refer to Figure 1-5 , a mixing device for pocket bun production that is easy to clean, comprising a mixing tank 1, a wheat flour storage component 2 is arranged on one side of the mixing tank 1, and the wheat flour storage component 2 includes a wheat flour storage dish 201, a wheat flour storage vessel 201 The inner wall is slidingly connected with a partition 202, and the inner bottom of the wheat flour storage dish 201 is away from the side of the mixing tank 1. A servo motor 203 is fixedly connected by screws, and the output end of the servo motor 203 is fixedly connected with a screw rod 204 through a coupling. The rod outer wall of the rod 204 is threadedly connected with an adjustment block 205, and balls 206 are also installed on both sides of the upper end of the adjustment block 205. The bottom surface of the dividing plate 202 is also provided with a rolling groove 207, and the balls 206 are slidably connected in the rolling groove 207. The upper end of 201 ...

Embodiment 2

[0032] Such as figure 1As shown, this embodiment is basically the same as Embodiment 1. Preferably, the discharge mechanism includes a discharge barrel 28, and the lower end of the discharge pipe 26 is connected through the discharge barrel 28, and one side of the discharge barrel 28 is provided with three servo motors. 29. The output end of the servo motor 3 29 passes through the discharge barrel 28 and is fixedly connected with a conveying auger. The side of the discharge barrel 28 away from the mixing barrel 1 is also connected with a connecting pipe 30, and the lower side of the connecting pipe 30 is provided with Conveyor belt 31.

[0033] In this embodiment, by being provided with a discharge mechanism at the lower end of the mixing bucket 1, the conveying auger can be driven to rotate under the action of the servo motor 3 29, thereby facilitating the stable conveying of the mixed bun raw materials, greatly improving the The efficiency of small bread production.

Embodiment 3

[0035] Such as figure 1 and 5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the front end side of the feeding chamber 6 is connected to the door body 7 through hinge rotation, and the bottom surface of the feeding chamber 6 and the side wall of the mixing tank 1 are connected through a door body 7 . Feeding pipe 8, the middle part of the inner wall of the feeding chamber 6 is also fixedly connected with a mounting plate 9, and one side of the upper end of the mounting plate 9 is fixedly connected with a measuring cylinder 10, and the middle part of the bottom surface of the measuring cylinder 10 is also connected with a drain pipe 11, and the drain pipe 11 is also installed. There is a check valve-12, and an electronic scale 13 is also fixed on the other side of the upper end face of the mounting plate 9. A weighing dish 14 is placed on the electronic scale 13, and a discharge pipe 11 side is also provided with a material guide pipe 15.

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com