Plug-free hydrogen-rich negative ion concentration stable and long-lasting generating device

A negative ion concentration and generation device technology, which is applied in the field of plug-free hydrogen-rich negative ion concentration stable and long-lasting generation devices, can solve the problems of product failure, water can not be mixed with fillers, and has no functionality, so as to avoid uneven water concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

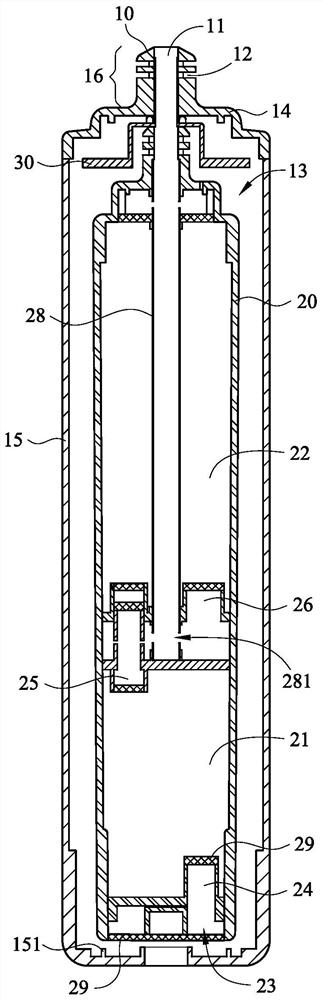

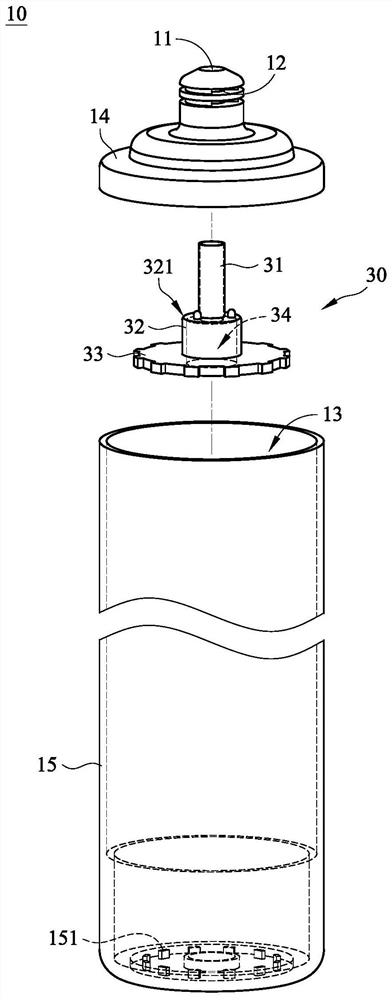

[0053] see Figure 5 As shown, a raw water C is poured from the second water inlet and outlet ports 12, flows into the accommodating space 13, flows to the bottom of the outer shell 10, and passes through the first water inlet and outlet 23 of the inner shell 20 and the first water inlet and outlet channel 24. Into the first manufacturing chamber 21 of the inner shell 20, these filter membranes 29 are provided at the first water inlet and outlet 23 and the first water inlet and outlet 24 to filter impurities in the water and prevent the solute 40 from flowing out. The raw water C is mixed with the solute 40 in the first manufacturing chamber 21 to become a mixed water M, and the mixed water M flows from the second inlet and outlet channel 25 to the second manufacturing chamber 22, and the second inlet and outlet channel 25 These filter membranes 29 are respectively provided at both ends of the chamber, the mixed water M enters the second manufacturing chamber 22 and mixes with...

Embodiment 2

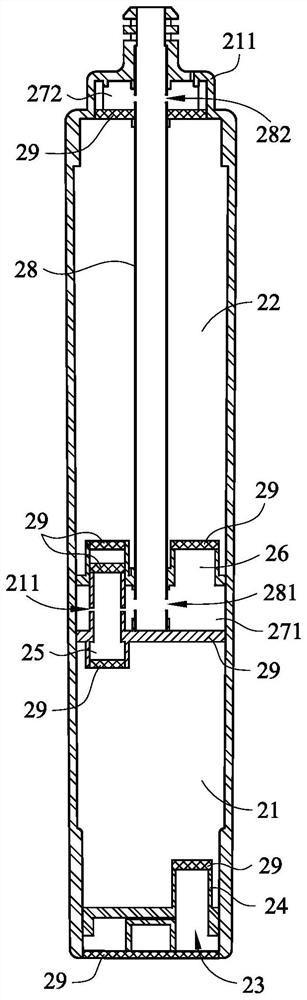

[0055] see Figure 6 As shown, in this embodiment, the raw water C is poured from the first water inlet and outlet 11, directly flows into the water pipe 28 of the inner shell 20, and flows into the first air chamber 271 through the water inlet and outlet holes 281, Affected by the water pressure, water flows from the first air chamber 271 into the second manufacturing chamber 22 to mix with the solute 40 to form the mixed water M, and then the mixed water M flows into the first manufacturing chamber 21 through the second inlet and outlet channels 25 mixed with the solute 40 of the first manufacturing chamber 21, and flow into the accommodation space 13 of the housing 10 from the first water inlet and outlet 23 through the first water inlet and outlet channel 24, and the mixed water M fills the accommodation space After 13, it flows out from the second water inlet and outlet 12 under the influence of water pressure.

[0056] In Embodiment 1, the raw water C enters from the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com