Specially-shaped part clamping equipment of numerically-controlled lathe

A CNC lathe and special-shaped technology, which is applied in the field of tooling and fixtures, can solve the problems of inability to directly clamp special-shaped parts, difficult to ensure production accuracy, and reduce production quality, and achieve the effect of firm clamping, reliable production quality, and guaranteed production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

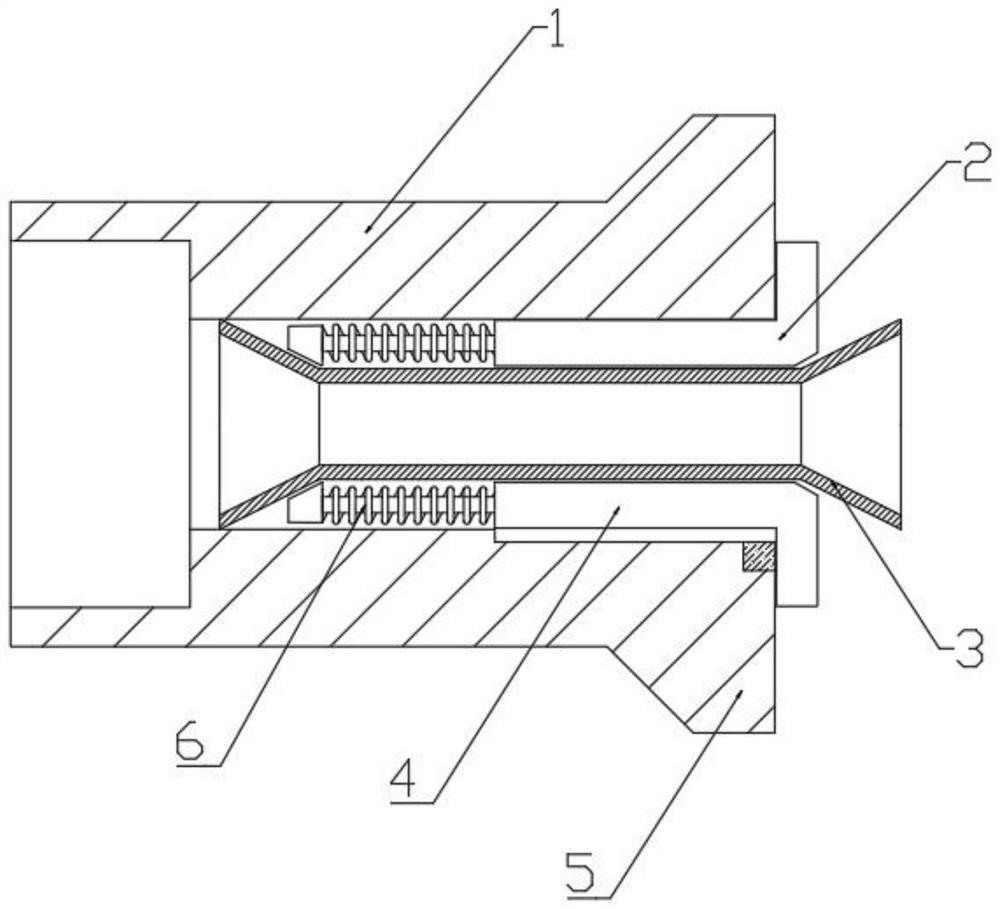

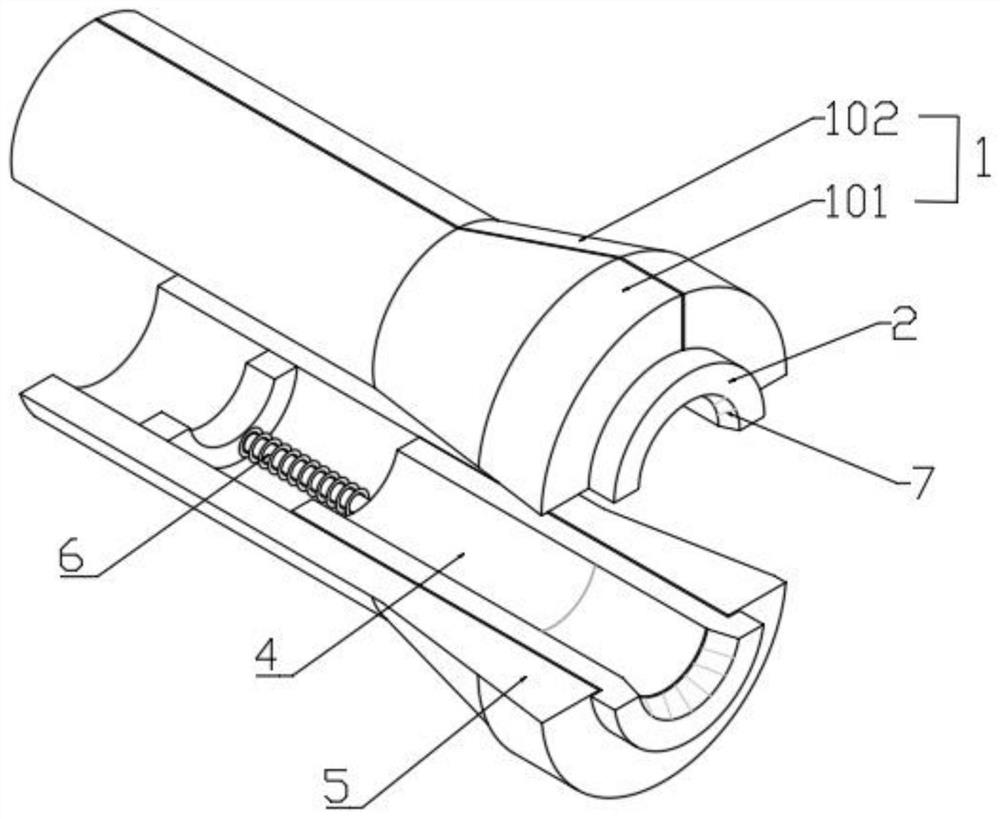

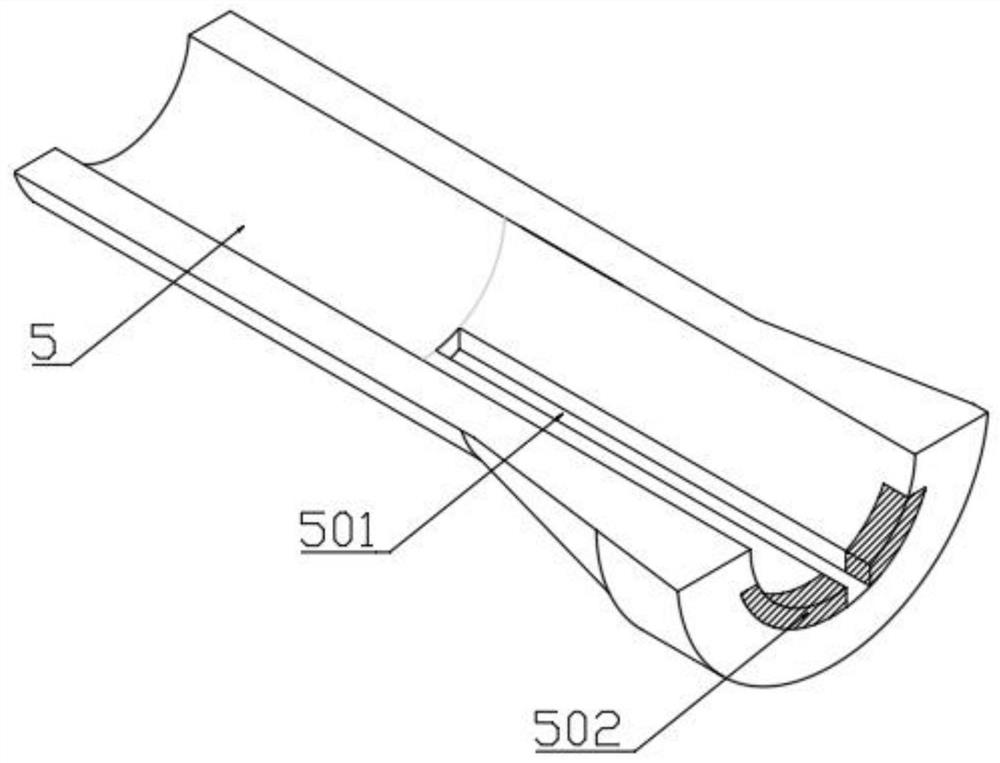

[0028] as attached figure 1 to attach Figure 4 Shown:

[0029] The invention provides a clamping device for special-shaped parts of a CNC lathe, which includes an upper splint 1, the upper splint 1 and the lower splint 5 both have a half-cylindrical tubular structure, and the front ends of the upper splint 1 and the lower splint 5 are both half-shaped A trumpet-shaped distribution; the upper clamping plate 1 includes a first clamping piece 101 and a second clamping piece 102, the first clamping piece 101 and the second clamping piece 102 are quarter ring structures, when the upper clamping plate 1 and the lower clamping plate 5 are paired When the special-shaped casing part 3 is clamped, the first clamping piece 101 and the second clamping piece 102 are in a tight fit state; the upper splint 1 is provided with an upper spacer 2 inside a half cylindrical lumen; the lower splint 5 two There is a lower block 4 inside the one-third cylindrical lumen; the upper block 2 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com