Lathe fixture

A lathe jig and jig technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of low pass rate, increase of unqualified products, difficult clamping, etc., to save labor costs, improve production efficiency, and meet positioning requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further elaborated below according to the drawings and in conjunction with the embodiments.

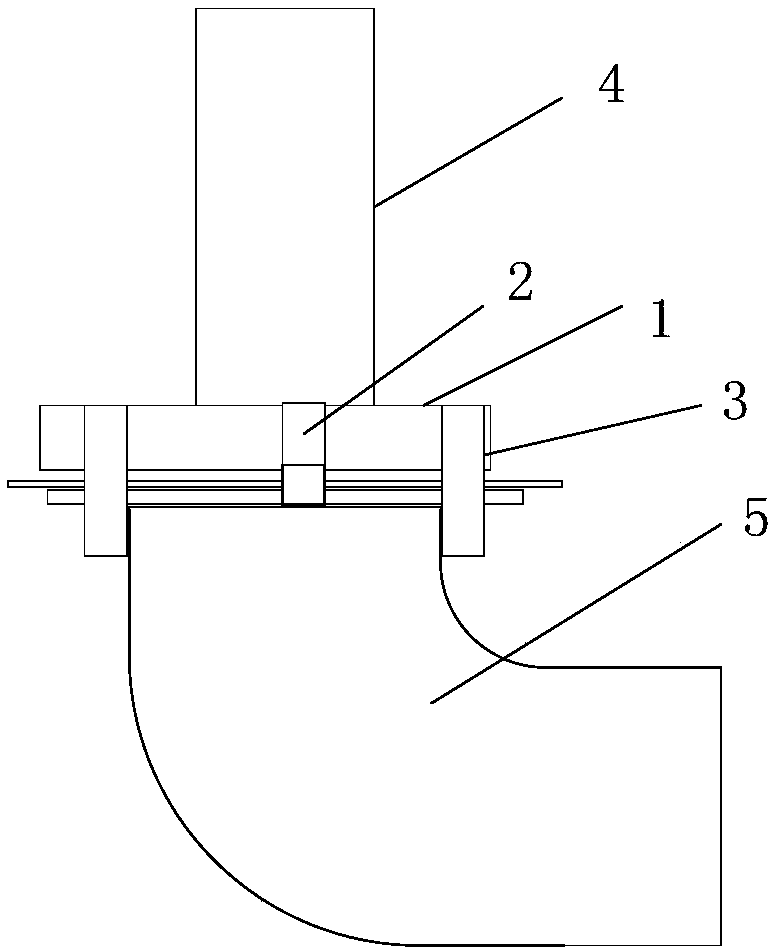

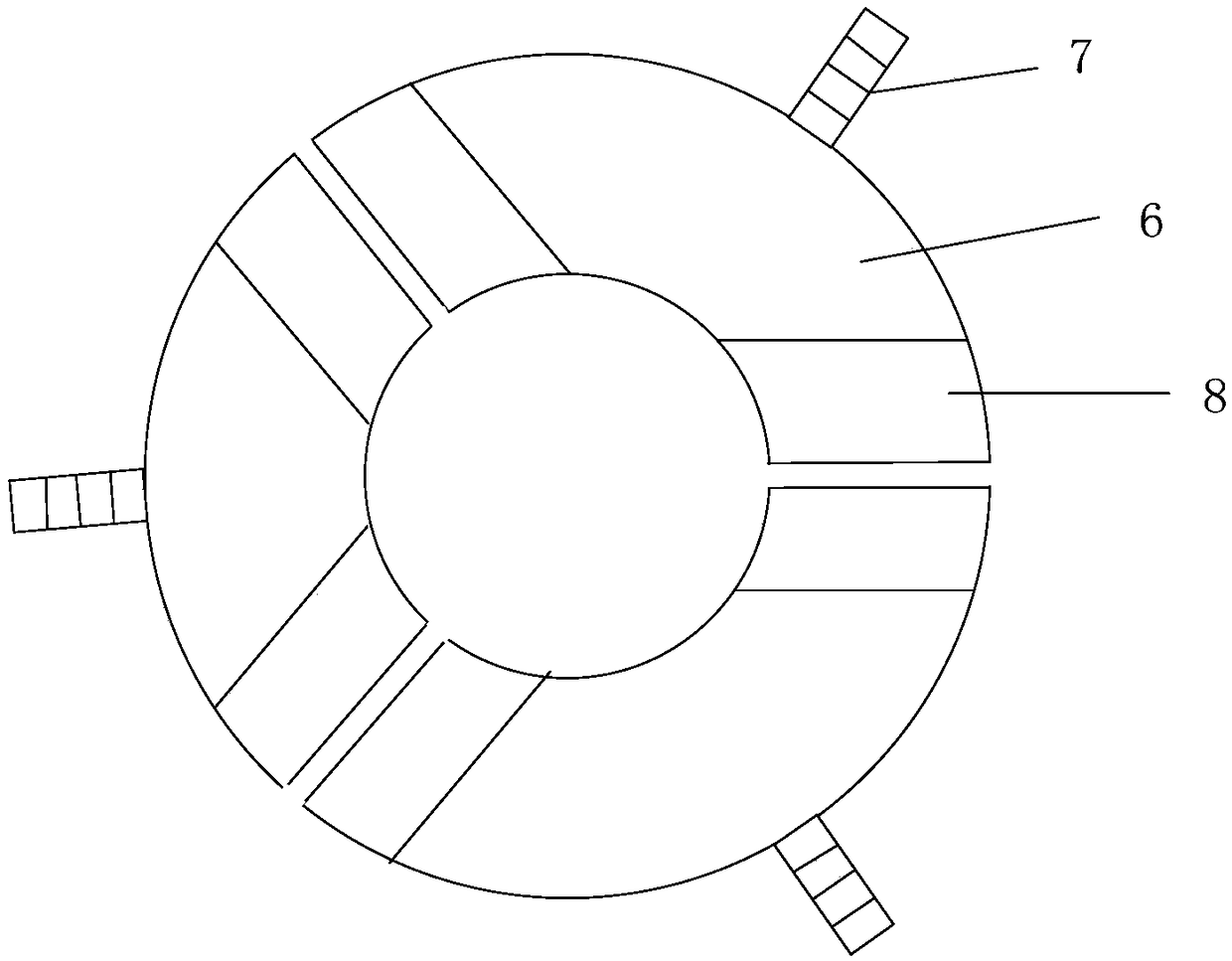

[0014] figure 1 It is a structural schematic diagram of the feeding fixture of the embodiment of the present invention, figure 2 It is a structural schematic diagram of a lathe fixture according to an embodiment of the present invention. A lathe fixture includes a feeding fixture and a processing fixture, wherein the feeding fixture includes a base 1, claws 2 and a limit rod 3, and the base 1 of the feeding fixture is connected to the feeding rod 4. The claw 2 is connected to the circumference of the base 1, and is used to fix the workpiece 5. The limit rod 3 is fixed on the circumference of the base 1; the processing fixture is a cylindrical structure as a whole, and the cylindrical structure is divided into three parts according to the circular axis The clamp 6 is obtained, the clamp 6 is connected with the lathe thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com