Heating wire assembly, atomizer and electronic cigarette

A heating wire and atomizer technology, applied in the field of electronic cigarettes, can solve the problems of low heat generation, peculiar smell of glass fiber rope, uneven heat generation, etc., so as to increase the amount of atomization, improve the uniformity of heat generation, and meet the large amount of smoke the effect of the demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those of ordinary skill in the art to more clearly understand the purpose, technical solutions, and advantages of the present invention, the present invention will be further described below with reference to the accompanying drawings and embodiments.

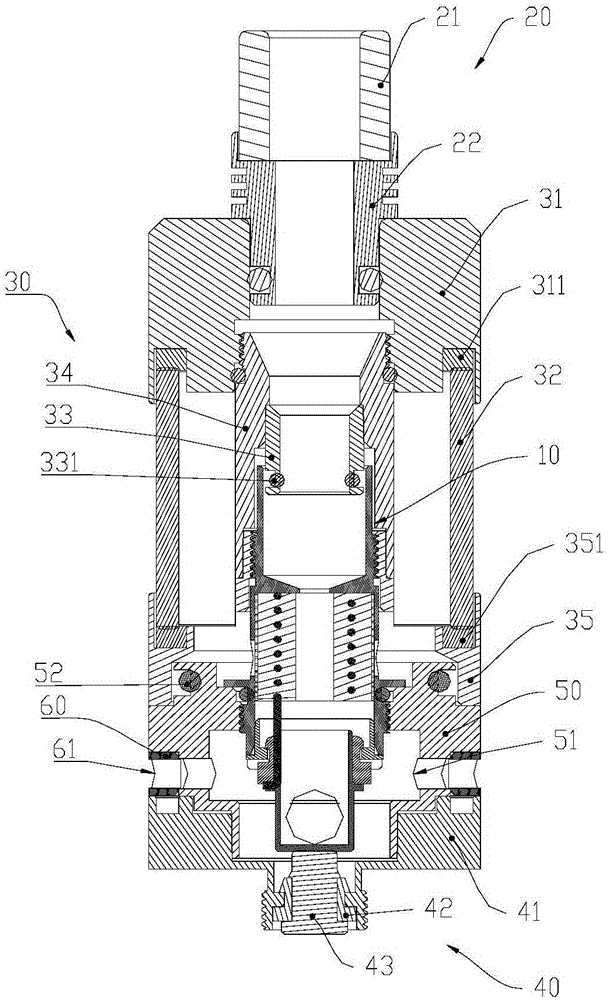

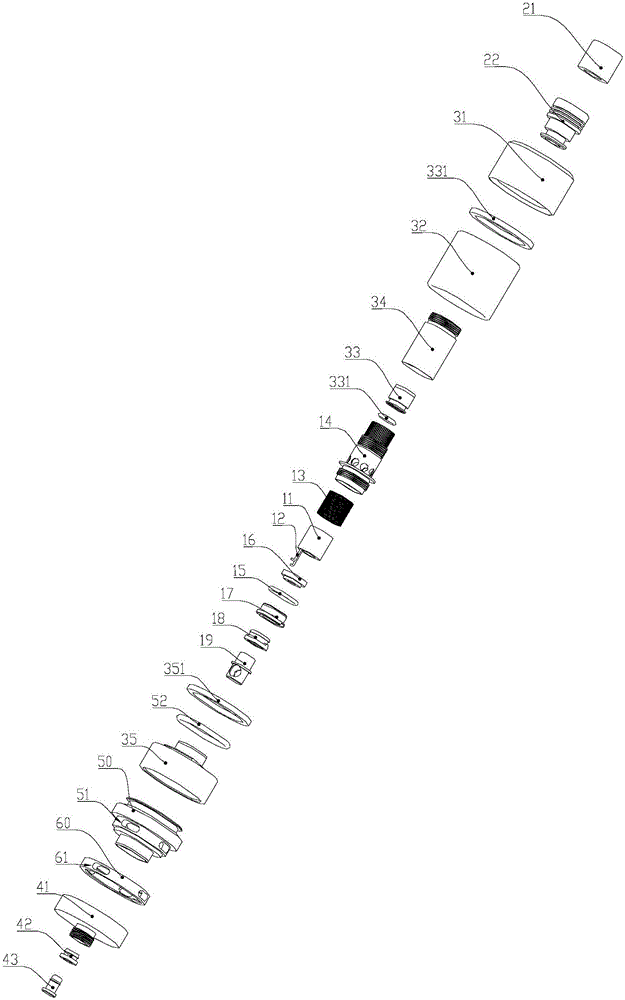

[0024] Please see figure 1 , Electronic cigarette generally includes two parts: atomizer 1 and cigarette rod 2 (including battery and various electronic circuits), please refer to figure 2 In some embodiments, the atomizer 1 includes a base assembly 40 from bottom to top, a connector 50 with a bottom inner sleeve on the base assembly 40, an adjustment ring 60 jacketed near the middle of the connector 50, and placed above the connector 50 The e-liquid bin 30, the atomizing core 10 passing through the e-liquid bin 30, the connecting member 50, the base assembly 40 in turn, and the suction nozzle assembly 20 placed on the top and connected to the e-liquid bin 30; wherein, the atomizing core 10 Including heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com