Connected ceramic core

A ceramic core and conjoined technology, applied in tobacco and other directions, can solve the problems of not meeting market demand, low heating power, and small calorific value, and achieve the effect of increasing the amount of smoke, increasing the heating power, and increasing the amount of atomization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

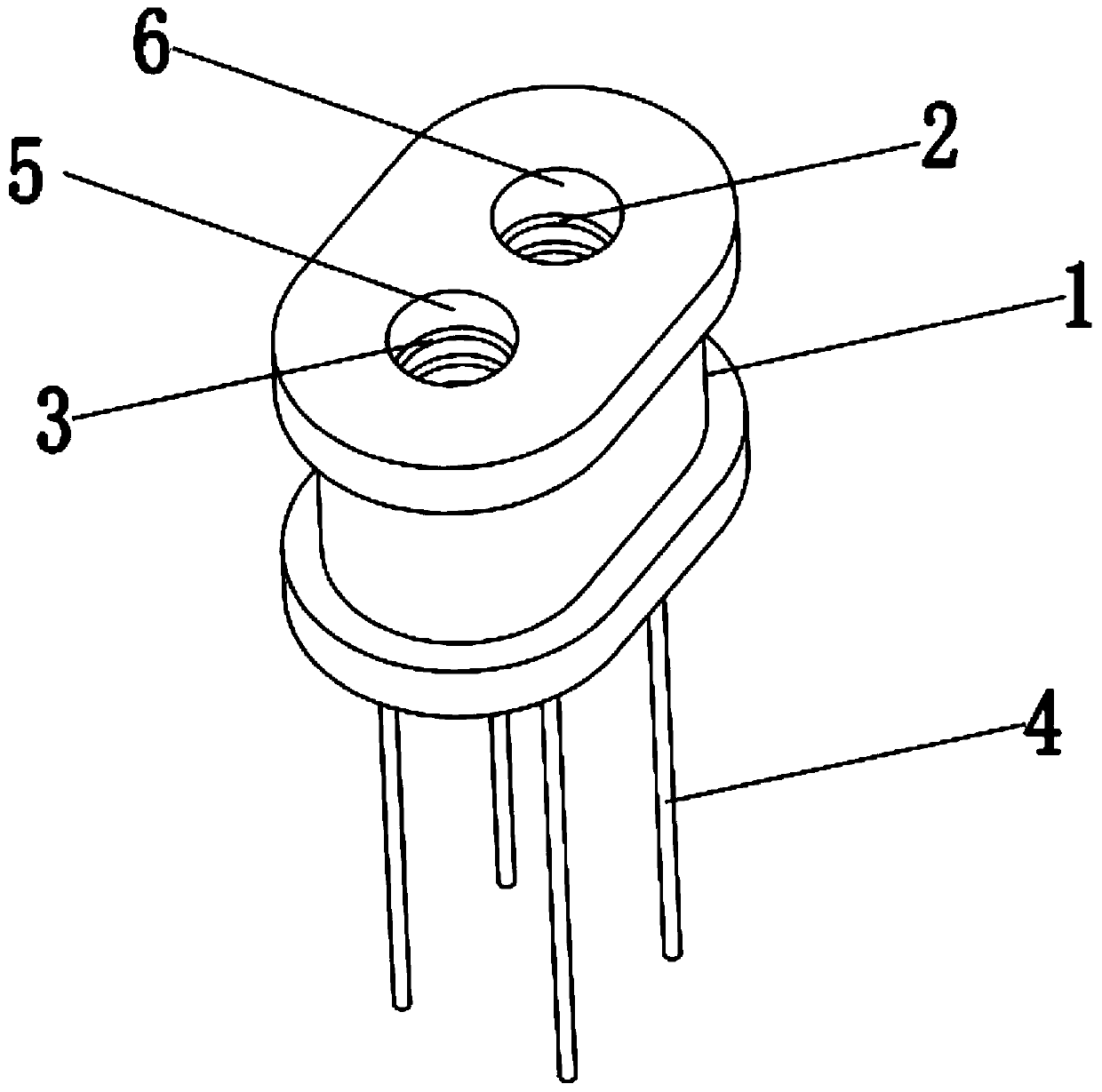

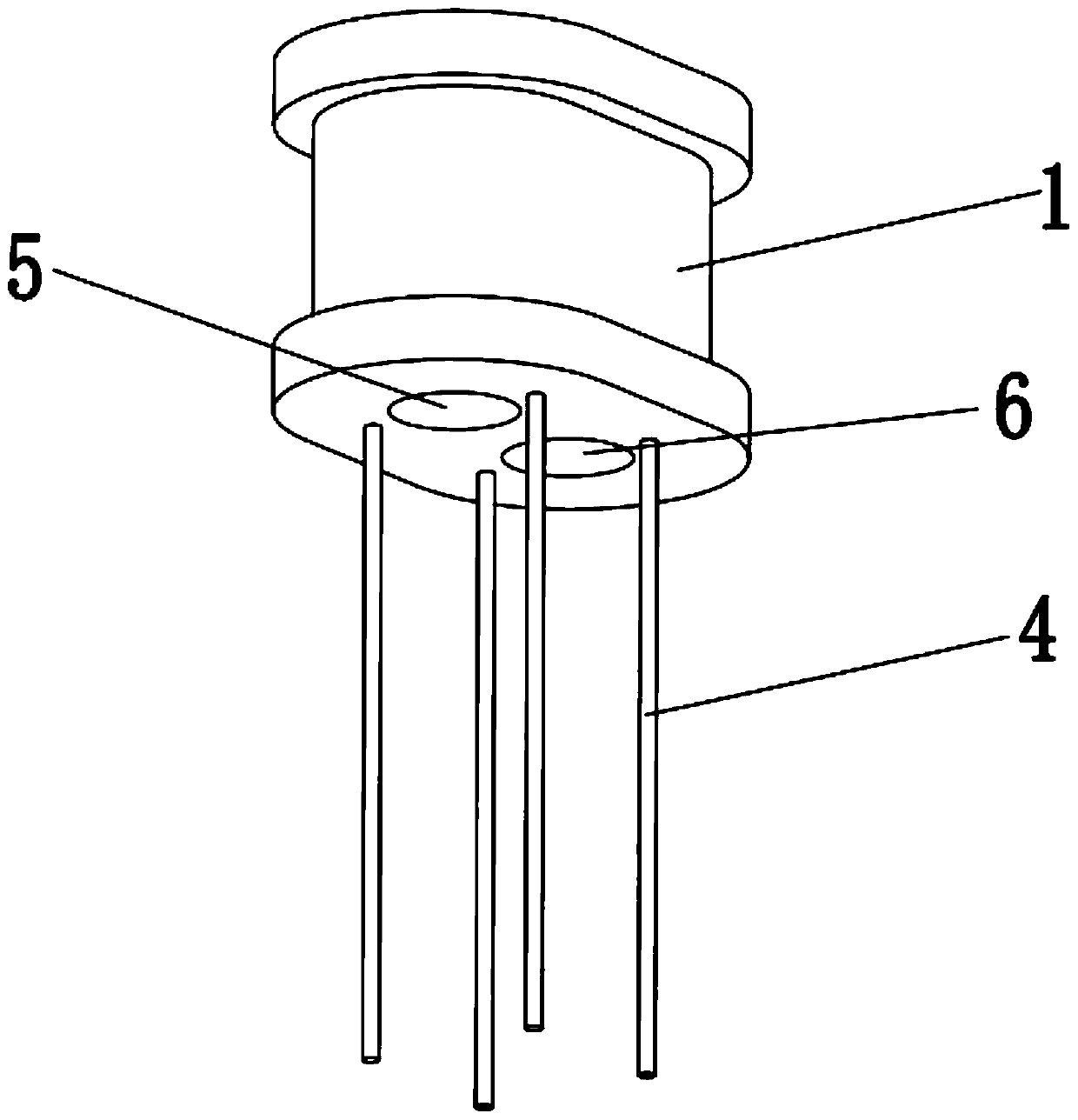

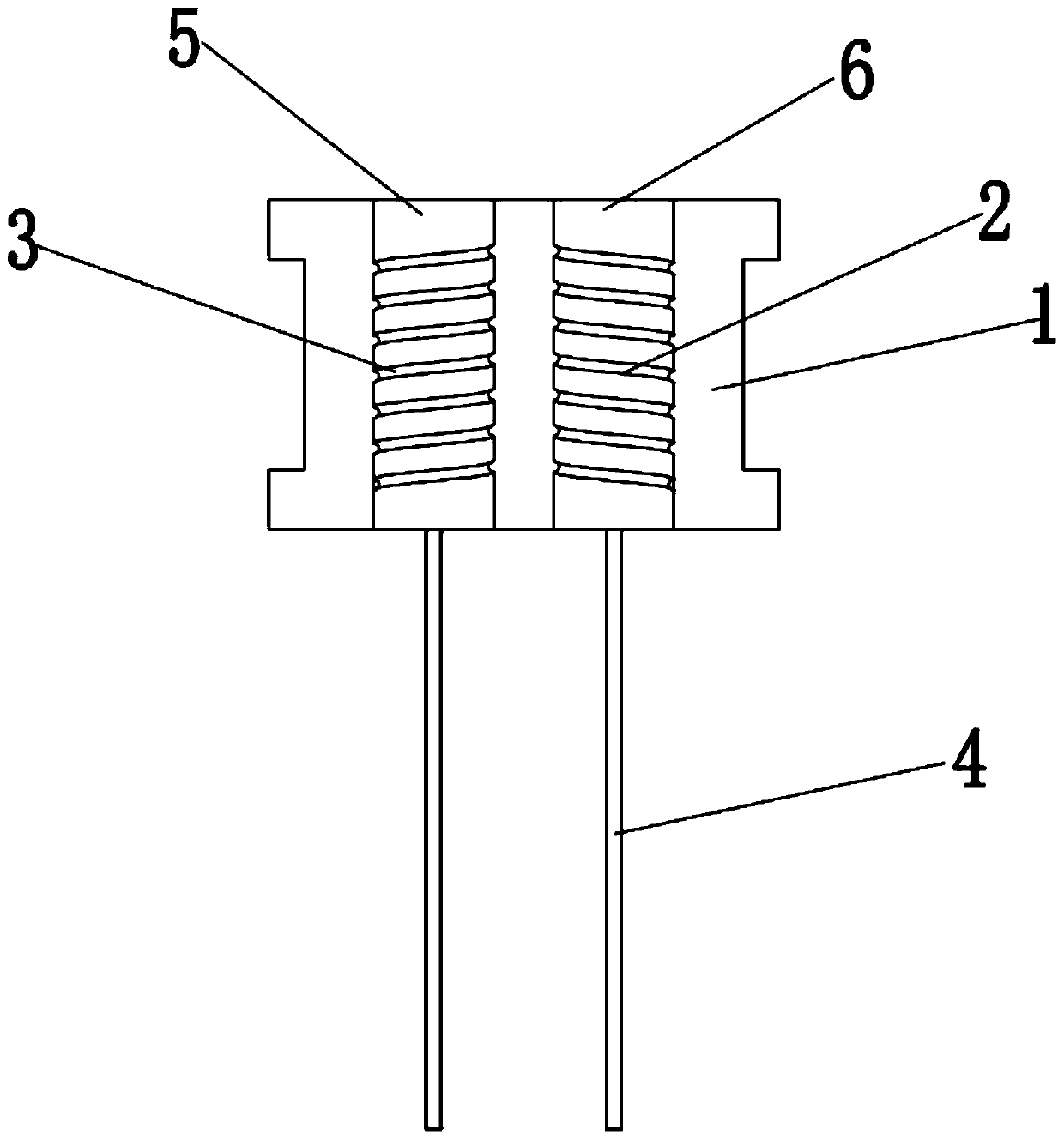

[0015] Specifically, in one embodiment, the shape of the ceramic core (1) is I-shaped, and the heating element (3) and the heating element (2) are connected in parallel, respectively placed in the vertical through holes (5) of the ceramic core (1). In the vertical through hole (6), there are four heating wires (4), which are fixed on the bottom of the ceramic core (1), extend vertically downwards, and are bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com