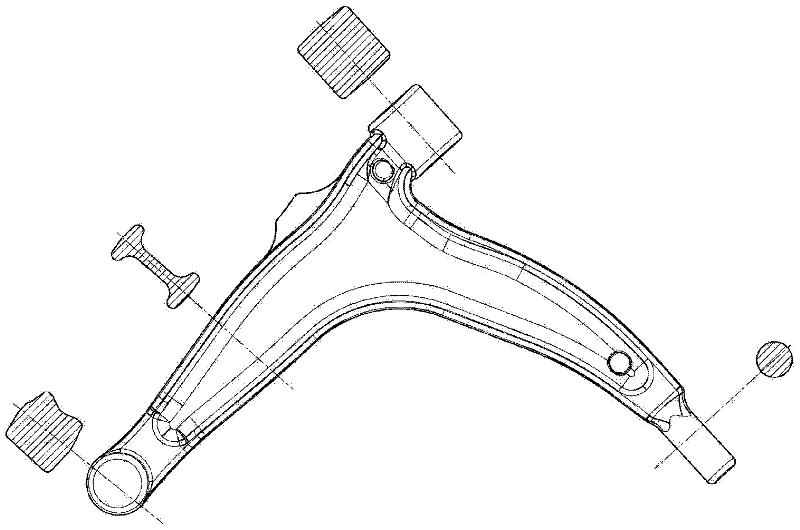

Manufacturing process for lambdoidal control arm

A manufacturing process and control arm technology, applied to railway car body parts, transportation and packaging, vehicle parts, etc., can solve the problems of long processing time, affecting product production efficiency, affecting product forming performance, etc., to shorten the total production time, guaranteed performance, and the effect of saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

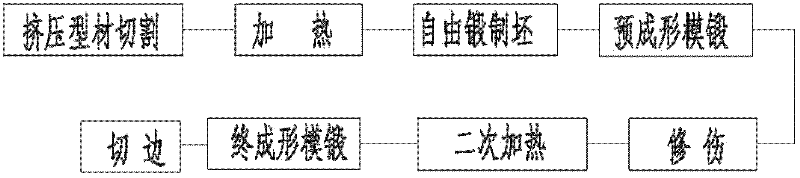

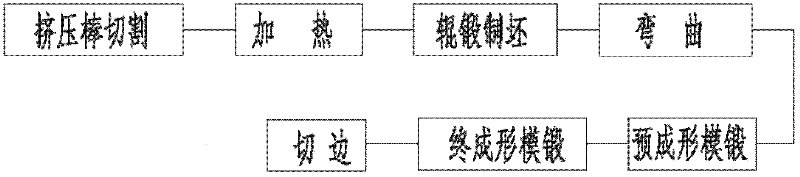

[0032] Such as figure 2 As shown, the manufacturing process of the herringbone control arm includes the following steps: extruded bar sawing-heating-roll forging billet-bending forming-pre-forming die forging-final forming die forging-trimming; specific processes for:

[0033] (1) Extruded bar is sawed, and the aluminum alloy extruded bar is selected as the raw material. The structure of the aluminum alloy extruded bar is as follows Figure 4 Extruded bars are sawn into billets using a high-speed circular saw as shown;

[0034] (2) heating, the billet sawed into is heated by a medium frequency induction heating furnace, and the controlled heating temperature is 440°C;

[0035] (3) Roll forging billets, use a roll forging machine to roll forge the heated billets; use two passes of roll forging; control the roll forging speed to control the billet temperature after roll forging is 420 ° C, roll forging After the blank such as Figure 5 shown;

[0036] (4) Bending and formi...

Embodiment 2

[0043] Such as figure 2 As shown, the manufacturing process of the herringbone control arm includes the following steps: extruded bar sawing-heating-roll forging billet-bending forming-pre-forming die forging-final forming die forging-trimming; specific processes for:

[0044] (1) Extruded bar is sawed, and the aluminum alloy extruded bar is selected as the raw material. The structure of the aluminum alloy extruded bar is as follows Figure 4 Extruded bars are sawn into billets using a high-speed circular saw as shown;

[0045] (2) heating, the billet sawed into is heated by an intermediate frequency induction heating furnace, and the controlled heating temperature is 480°C;

[0046] (3) Roll forging billets, use a roll forging machine to roll forge the heated billets; use two passes of roll forging; control the roll forging speed to control the temperature of the billets after roll forging is 460 ° C, roll forging After the blank such as Figure 5 shown;

[0047] (4) Be...

Embodiment 3

[0054] Such as figure 2 As shown, the manufacturing process of the herringbone control arm includes the following steps: extruded bar sawing-heating-roll forging billet-bending forming-pre-forming die forging-final forming die forging-trimming; specific processes for:

[0055] (1) Extruded bar is sawed, and the aluminum alloy extruded bar is selected as the raw material. The structure of the aluminum alloy extruded bar is as follows Figure 4 Extruded bars are sawn into billets using a high-speed circular saw as shown;

[0056] (2) heating, the billet sawed into is heated by a medium frequency induction heating furnace, and the controlled heating temperature is 460°C;

[0057] (3) Roll forging billets, use a roll forging machine to roll forge the heated billets; use two passes of roll forging; control the roll forging speed to control the temperature of the billets after roll forging is 440 ° C, roll forging After the blank such as Figure 5 shown;

[0058] (4) Bending a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com