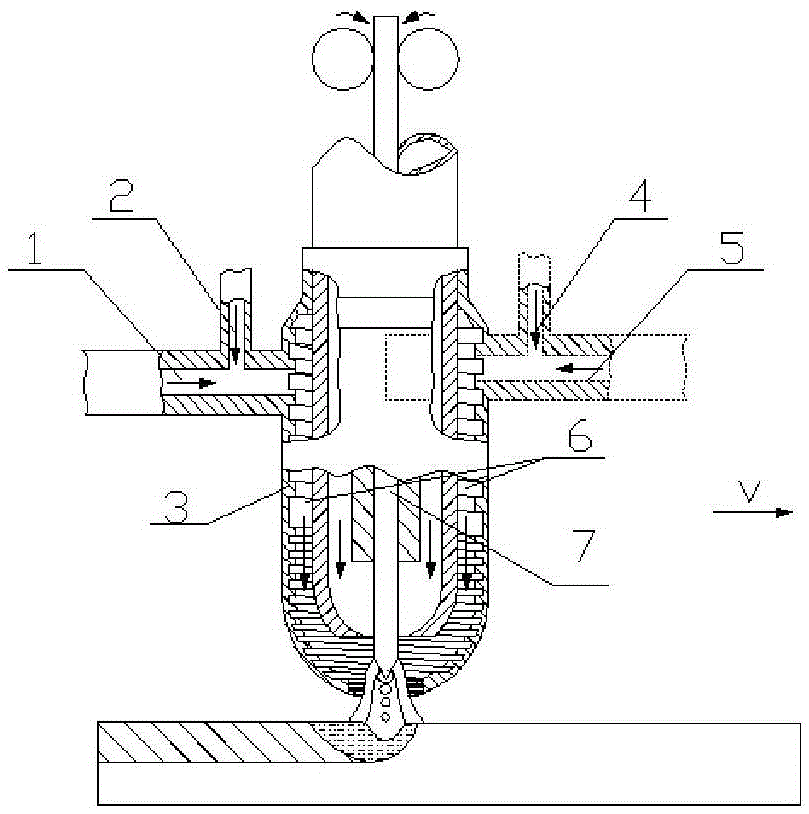

Wire-powder-gas-arc coaxial 3D printing device

A 3D printing, coaxial technology, applied in the direction of arc welding equipment, welding media, welding/welding/cutting items, etc., can solve the problem that the product composition cannot be designed, and achieve the goal of improving printing efficiency, reducing losses, and saving preprocessing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

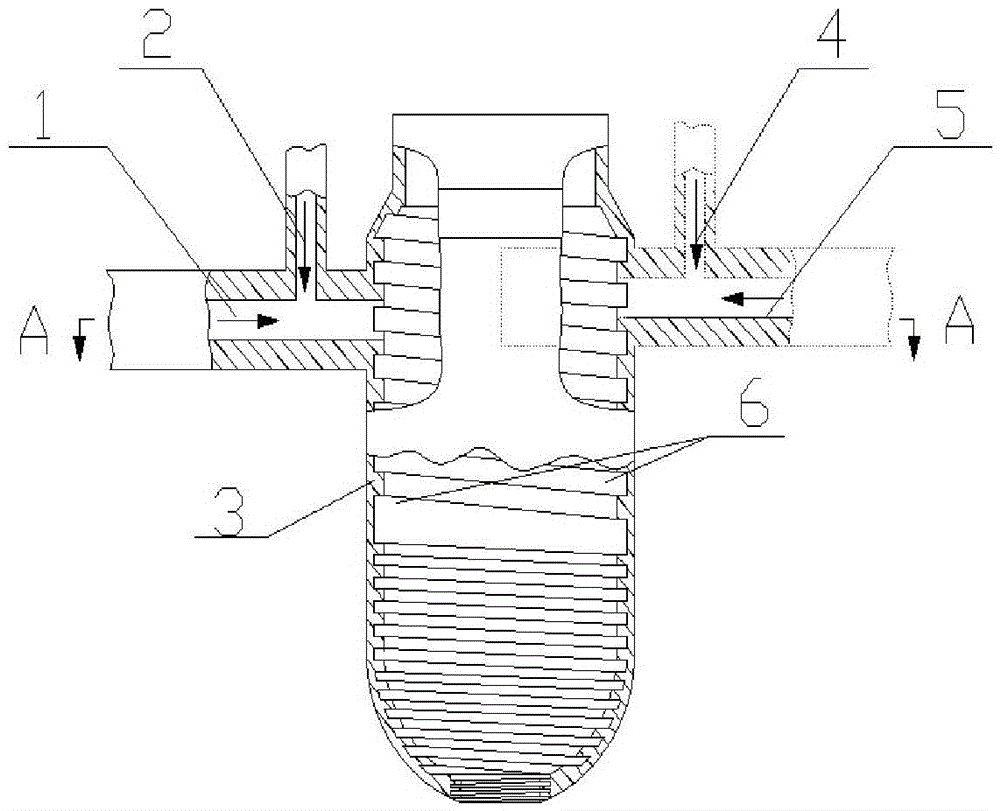

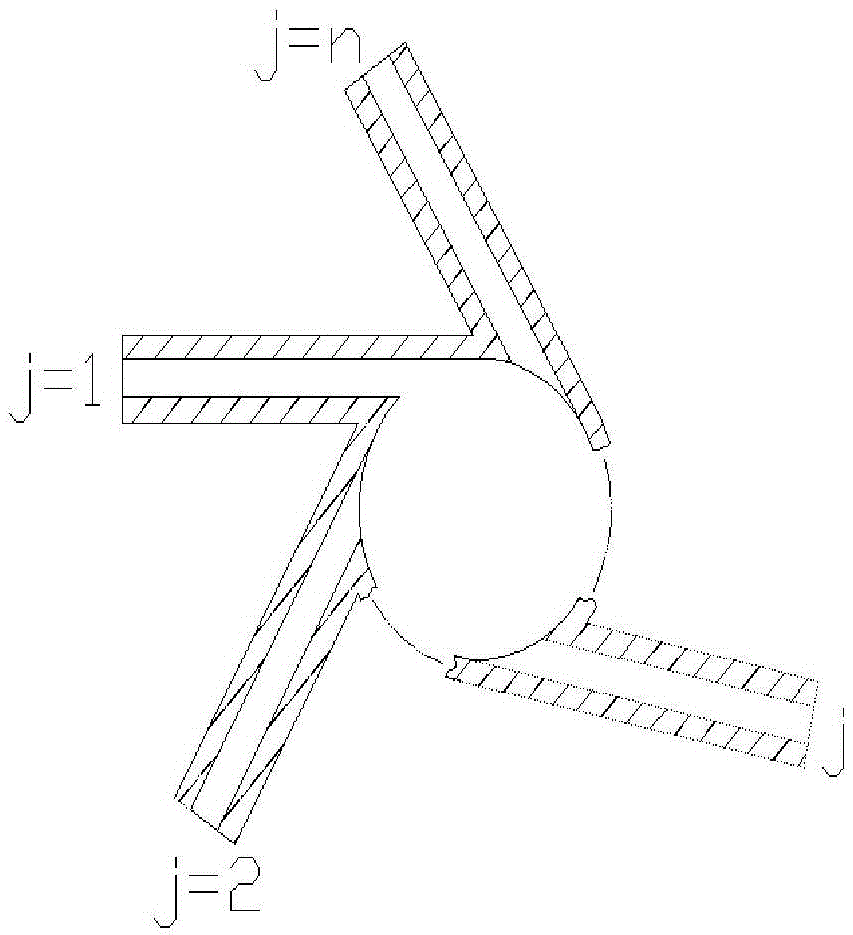

Method used

Image

Examples

Embodiment 1

[0061] Using the above-mentioned device, the method of 3D printing high-nitrogen steel products using nitrogen arc and nitride is used to prepare high-nitrogen steel components. Its size is 100mm×100mm×40mm, composed of 20 surfacing layers, each layer is 2mm high, and each layer is welded. The seam consists of 7 welds.

[0062] Table 1 The chemical composition requirements of target high nitrogen steel (%)

[0063] chemical composition

N

Mn

Cr

Mo

Si

C

Fe

Standard Specification

0.8-2.4

12-18

18-23

1.0-2.5

≤1

≤0.1

Margin

[0064] Table 2H08Mn2SiA welding wire chemical composition (%)

[0065]

[0066] A nitrogen arc wire feeding additive manufacturing method is used to carry out the surfacing forming of the high nitrogen steel of the set layer, and at the same time the nitrogen powder feeding is used to add nitride alloy powder to the molten pool. By controlling the parameter matching of 3D printing, high nitrogen steel printing layers with different nitrogen content can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com