Method for detecting content of 3-monochloropropanol-1, 2-diol ester in edible oil

A technology of propylene glycol ester and propylene glycol palmitate diester is applied in the field of detecting the content of 3-chloro-1,2-propylene glycol ester in edible oil, and can solve the problems of polluting a gas chromatography-mass spectrometer, complicated processing steps, affecting analysis efficiency and the like, Achieve the effect of avoiding instrument maintenance, low instrument contamination, and avoiding cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

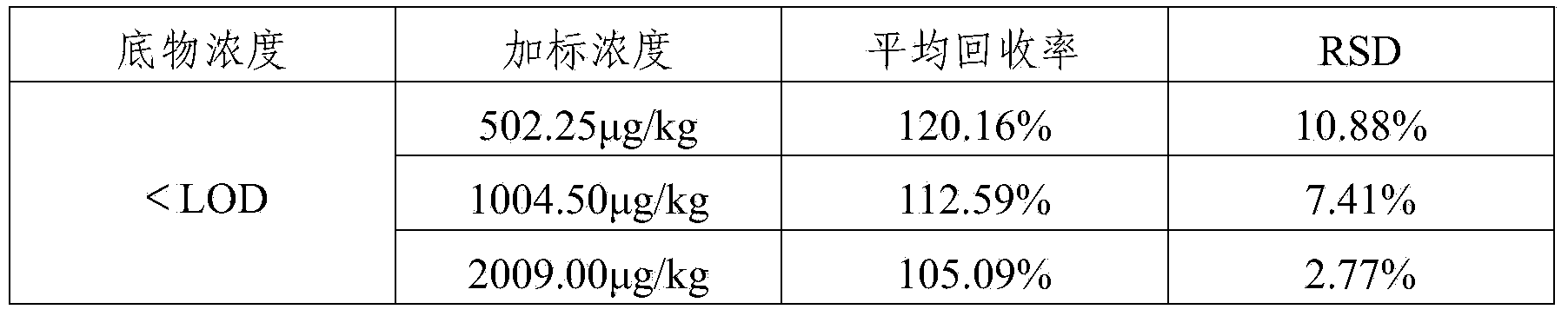

Examples

Embodiment 1

[0060] 1. Sample pretreatment

[0061] Weigh 0.100g of homogenized peanut oil into a centrifuge tube with a cover, heat slightly at 40°C to dissolve the fat completely, add 1mL THF solution of the sample, and add 80μL d 5 -3-Chloro-1,2-propanediol palmitic acid diester internal standard solution (4.675 μg / mL, calculated as free state), vortexed to mix.

[0062] 2. Acid catalyzed transesterification, salting out, extraction

[0063] Add 0.5mL of 0.1% sulfuric acid-methanol solution to the centrifuge tube, screw it tightly, and then place it at 40°C for 2 hours of constant temperature reaction. After the reaction is completed, add saturated sodium bicarbonate solution to neutralize and vortex, so that the pH after neutralization is 6.7. Add 2 mL of 20% (v / v) sodium sulfate aqueous solution to the centrifuge tube, and extract with 2 mL of n-heptane solution, discard the organic phase containing fatty acid methyl ester in the upper layer, and obtain the aqueous phase containing 3...

Embodiment 2

[0089] 1. Sample pretreatment

[0090] Weigh 0.150 g of homogenized perilla oil into a centrifuge tube with a cover, and heat slightly at 45°C to dissolve the fat completely. Add 1 mL of tetrahydrofuran solution to the sample, and add 80 μL d 5 -3-Chloro-1,2-propanediol palmitic acid diester internal standard solution (4.675 μg / mL, calculated as free state), vortexed to mix.

[0091] 2. Acid catalyzed transesterification, salting out, extraction

[0092] Add 0.5mL of 0.1 (v / v) sulfuric acid-methanol solution to the centrifuge tube, screw it tightly, and place it at 45°C for 1 hour of constant temperature reaction. After the reaction is over, add saturated sodium bicarbonate solution to neutralize and vortex, so that the pH after neutralization is 7.6. Add 2 mL of 20% (v / v) sodium sulfate aqueous solution to the centrifuge tube, and extract with 2 mL of n-heptane solution, discard the organic phase containing fatty acid methyl ester in the upper layer, and obtain the aqueous...

Embodiment 3

[0098] 1. Sample pretreatment

[0099] Weigh 0.200g of homogenized corn oil into a centrifuge tube with a cover, and heat slightly at 50°C to completely dissolve the fat. Add 1 mL of tetrahydrofuran solution to the sample, and add 80 μL d 5-3-Chloro-1,2-propanediol palmitic acid diester internal standard solution (4.675 μg / mL, calculated as free state), vortexed to mix.

[0100] 2. Acid catalyzed transesterification, salting out, extraction

[0101] Add 0.5 mL of 0.1 (v / v) sulfuric acid-methanol solution to the centrifuge tube, screw it tightly, and place it at 55°C for 30 min at a constant temperature for reaction. After the reaction is over, add saturated sodium bicarbonate solution to neutralize and vortex, so that the pH after neutralization is 8.0. Add 2 mL of 20% (v / v) sodium sulfate aqueous solution to the centrifuge tube, and extract with 2 mL of n-heptane solution, discard the organic phase containing fatty acid methyl ester in the upper layer, and obtain the aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com