Patents

Literature

58 results about "3-MCPD" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3-MCPD (3-monochloropropane-1,2-diol or 3-chloropropane-1,2-diol) is an organic chemical compound which is the most common member of chemical food contaminants known as chloropropanols. It is suspected to be carcinogenic in humans.

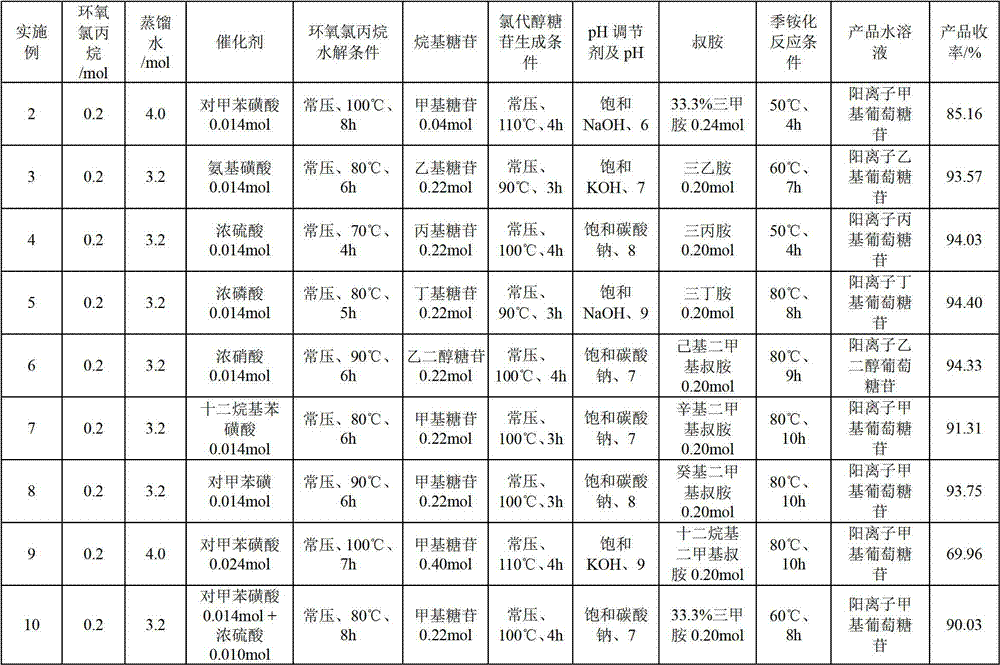

Method of preparing CAPG for drilling fluid

InactiveCN102786561AThe process operation is simple and environmentally friendlyShort operating timeSugar derivativesDrilling compositionEpoxyGlycoside

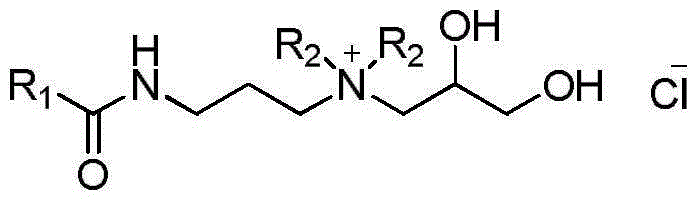

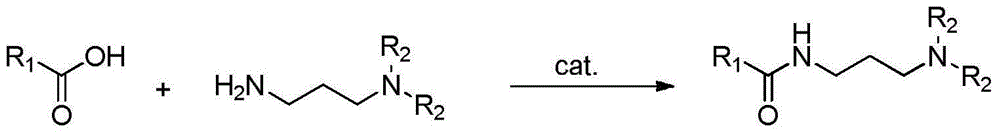

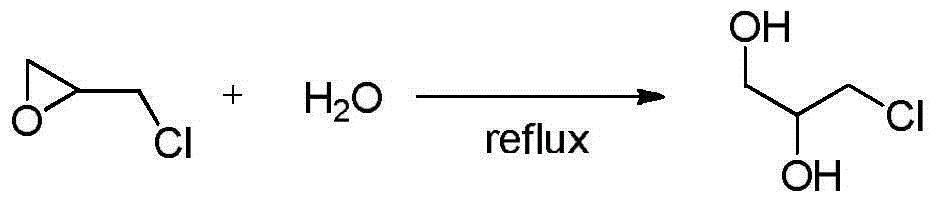

The invention discloses a method of preparing CAPG (Cationic alkyl polyglucoside) for a drilling fluid, and belongs to the technical field of chemical drilling fluid treating agents in oilfields. The method comprises the following steps: (1), reacting the materials of epoxy chloropropane, water and a catalyst at the molar ratio of 1:(12-20):(0.02-0.12) at the temperature of 60-100 DEG C for 3-8 h, so as to obtain a 3-chlorine-1, 2-propylene glycol aqueous solution; (2), reacting alkyl polyglucoside and the 3-chlorine-1, 2-propylene glycol aqueous solution at the molar ratio of 1: (0.5-5) at the temperature of 80-110 DEG C for 0.5-4.0 h, so as to obtain a chlorohydrin polyglucoside aqueous solution; and (3) neutralizing the chlorohydrin polyglucoside aqueous solution with a neutralizer to an extent that the pH value is 6-9, then adding tertiary amine, and finally reacting tertiary amine and chlorohydrin polyglucoside for 3 to 10 h at the temperature of 40-80 DEG C and a normal pressure so as to obtain a CAPG aqueous solution, wherein the molar ratio of the tertiary amine to the chlorohydrin polyglucoside is 1: (0.2-1.2). According to the method, the CAPG has an excellent shale inhibition performance, and through the CAPG aqueous solution with the concentration of 1%, the primary recovery rate of the shale is 95.55 percent, while the secondary recovery rate is 94.70 percent, and the relative recovery rate is up to 99.11 percent at the temperature of below 120 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cationic viscoelastic surfactant and preparation and application thereof

InactiveCN105080424AExcellent high temperature resistance and shear resistanceGood suspension effectOrganic compound preparationTransportation and packagingFracturing fluid3-MCPD

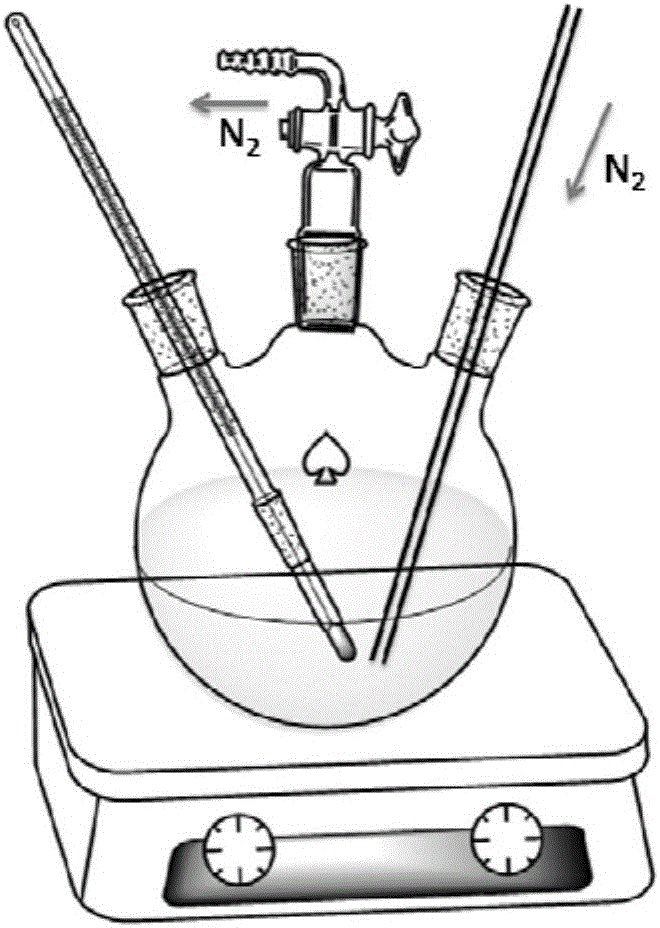

The invention discloses a cationic viscoelastic surfactant and preparation and application thereof. The preparation method of the cationic viscoelastic surfactant comprises the following steps: firstly, mixing long-chain fatty acid with dimethylaminopropylamine according to a certain proportion, adding a catalyst solution to obtain a required amide product intermediate A by a series of reaction; allowing reflux condensation reaction of epoxy chloropropane and water at a certain proportion to be carried out in oil bath of 100 DEG C to obtain colourless and transparent 3-chloro-1,2-propylene glycol aqueous solution, namely an intermediate B; heating the intermediate A in oil bath for melting, and dropwise adding an aqueous solution B to obtain the required viscoelastic surfactant by a series of reaction; the surfactant can be mixed with a potassium chloride solution according to a certain proportion to obtain clean fracturing fluid which is low in cost and excellent in performance, besides, the clean fracturing fluid has excellent high-temperature resistance, shearing resistance, and excellent solid-carrying performance, is automatic and thorough in gel breaking, causes little damage to the reservoir stratum and has the characteristic of wide application range.

Owner:SOUTHWEST PETROLEUM UNIV

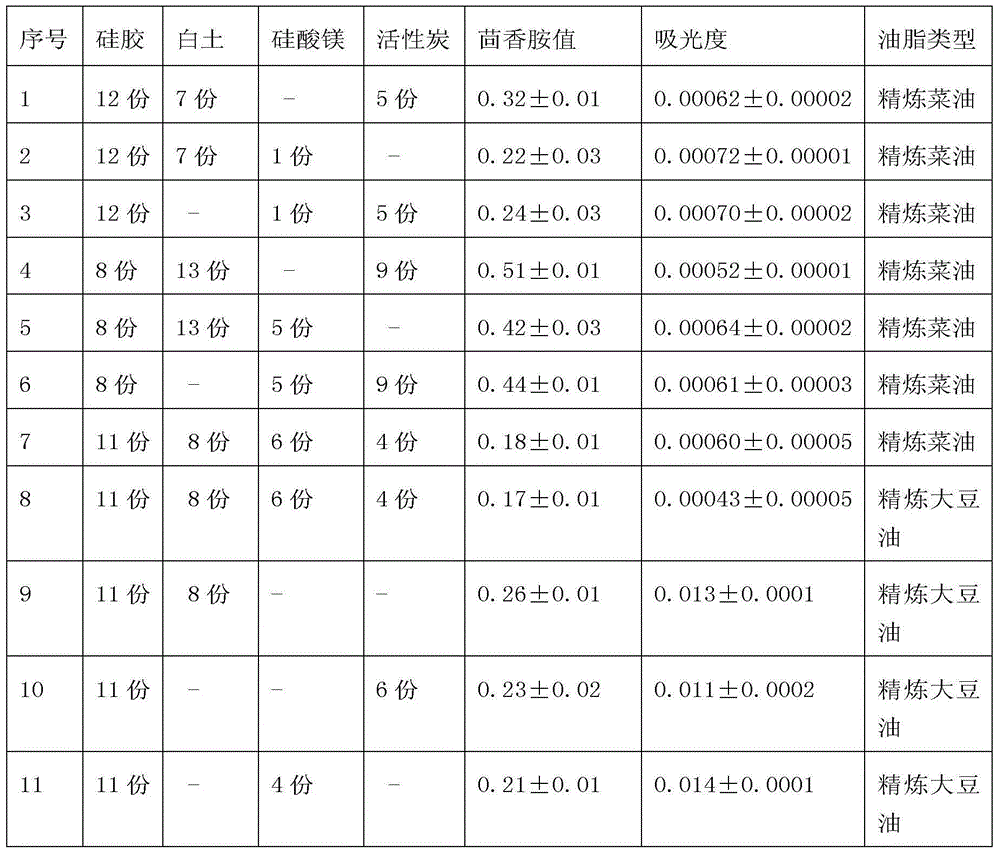

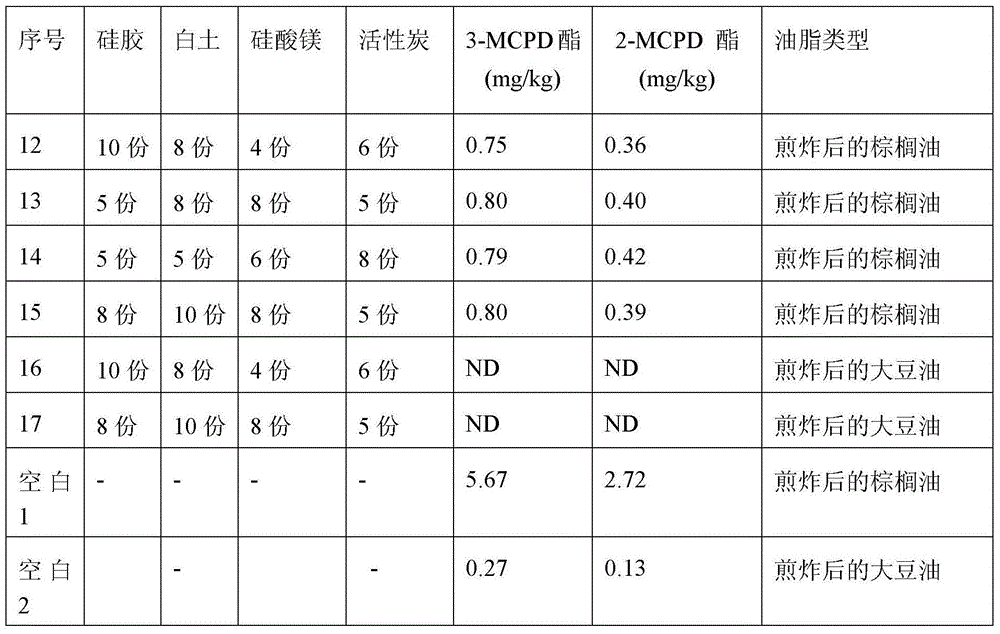

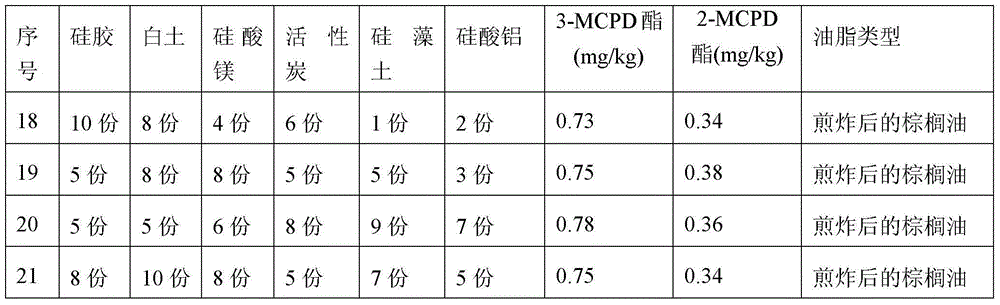

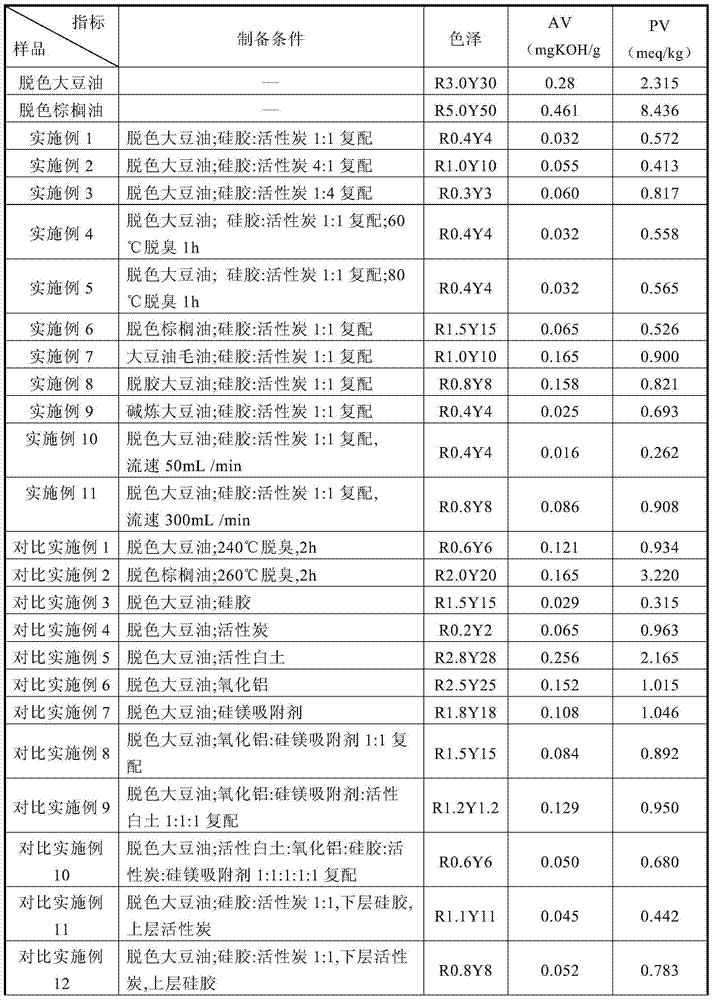

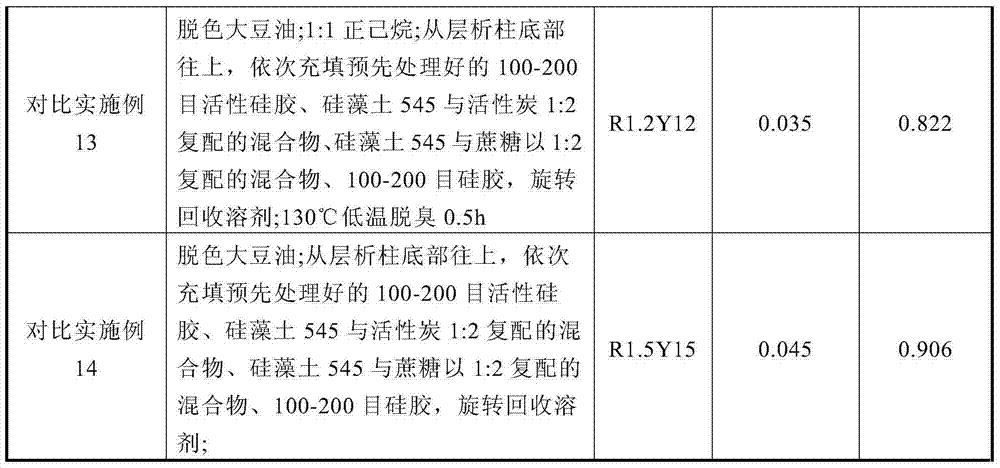

Mixed adsorbent, grease and preparation method thereof

ActiveCN103908946AImprove qualityHigh medicinal safetyOther chemical processesFatty-oils/fats refiningM-AnisidineActivated carbon

The invention provides a mixed adsorbent, comprising one or more of a silica gel, carclazyte, silicate and activated carbon. The mixed adsorbent can be used for preparing the grease with an extremely low anisidine value and absorbance value. The invention also provides a method for removing chloropropanol ester substances from the grease. The method comprises a step of contacting to-be-treated grease with the above mixed adsorbent. The content of 3-MCPD ester in the obtained grease product is below 0.8 ppm; and the content of 2-MCPD ester is below 0.5 ppm.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

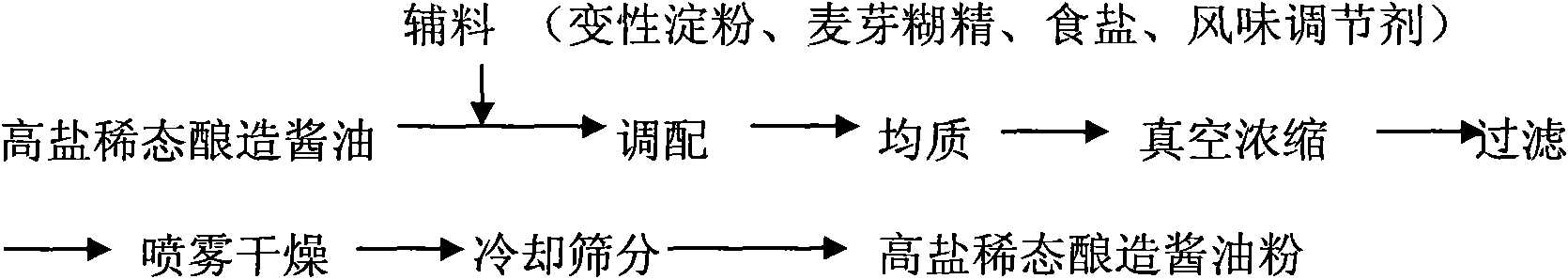

High-salt liquid-state brewing soy sauce powder and preparation method thereof

The invention discloses a high-salt liquid-state brewing soy sauce powder and a preparation method thereof. The high-salt liquid-state brewing soy sauce powder is prepared by the following materials in percentage by weight: 68%-85% of high-salt liquid-state brewing soy sauce, 1%-6% of modified starch, 2%-9% of maltodextrin, 2%-8% of salt and 0.2%-25% of flavor regulator through procedures, i.e. blending, homogeneity, vacuum concentration, filtering, spray drying, cooling, sieving, and the like. The high-salt liquid-state brewing soy sauce powder has the advantages of unique lobster sauce taste, enriched fermented flavor without burnt smell, uniform granularity, powder body granule diameter between 60 micrometers and 90 micrometers, compact and smooth surface, good flowability, superior humidity resistance and good instant property, is clear when being recovered to a liquid state, contains no 3-MCPD and preservative and has a quality guarantee period more than two years. Compared with liquid soy sauce, the high-salt liquid-state brewing soy sauce powder has very low water content and greatly reduces the transportation and storage costs.

Owner:GUANGDONG PRB BIO TECH CO LTD

Method for reducing trans fatty acids

ActiveCN104711118AChange the traditional processing methodLower operating temperatureFatty-oils/fats refiningPerformance index3-MCPD

The invention provides a method for reducing trans fatty acids, 3-chloro-1,2-propylene glycol and esters of 3-chloro-1,2-propylene glycol, and / or glycidol and glycidol esters and a grease refining method; the methods include the step of carrying out column chromatography of decolorized grease and the step of optionally carrying out deodorization in the temperature range of 60-150 DEG C after column chromatography. The methods reduce the production energy consumption, satisfy product indexes, meet and even are more superior to edible performance indexes of grease prepared by a conventional processing method, besides, can avoid formation of a series of side products brought by high temperature deodorization, and improve the edible grease quality and edible safety.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

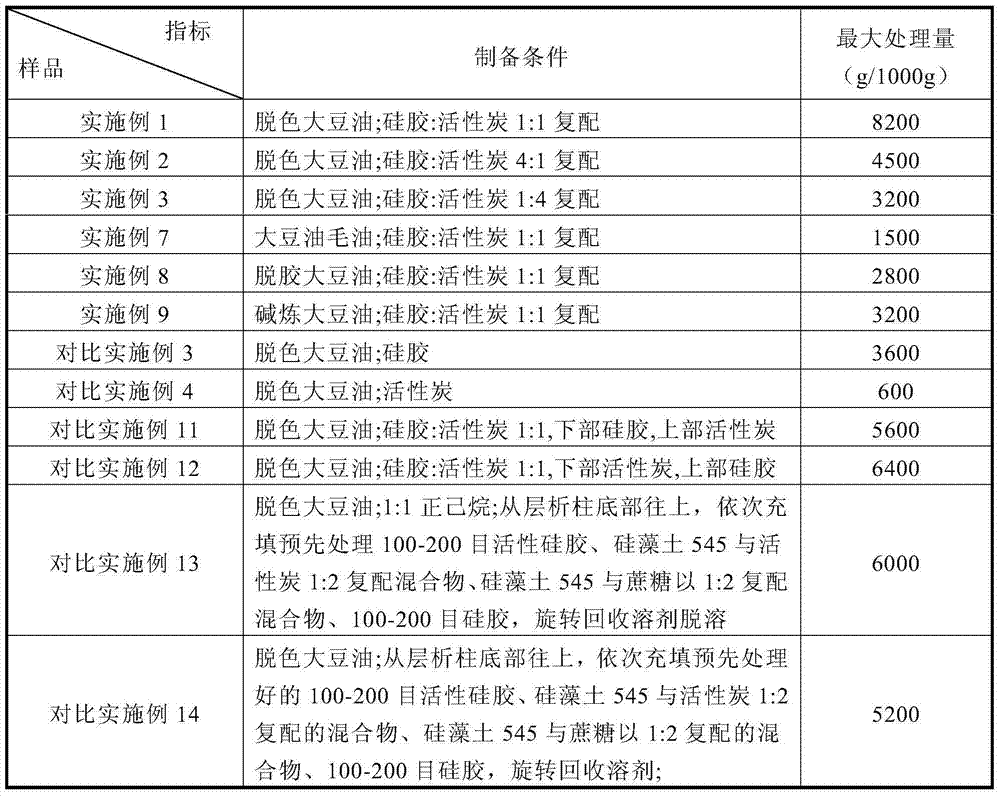

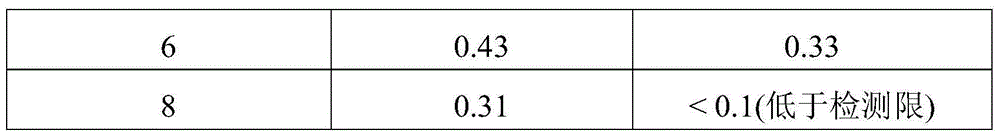

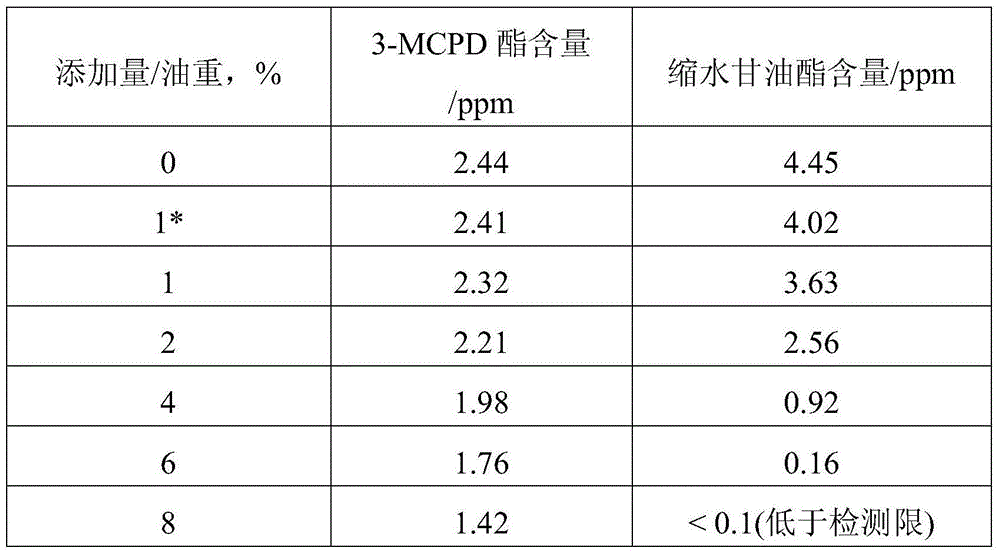

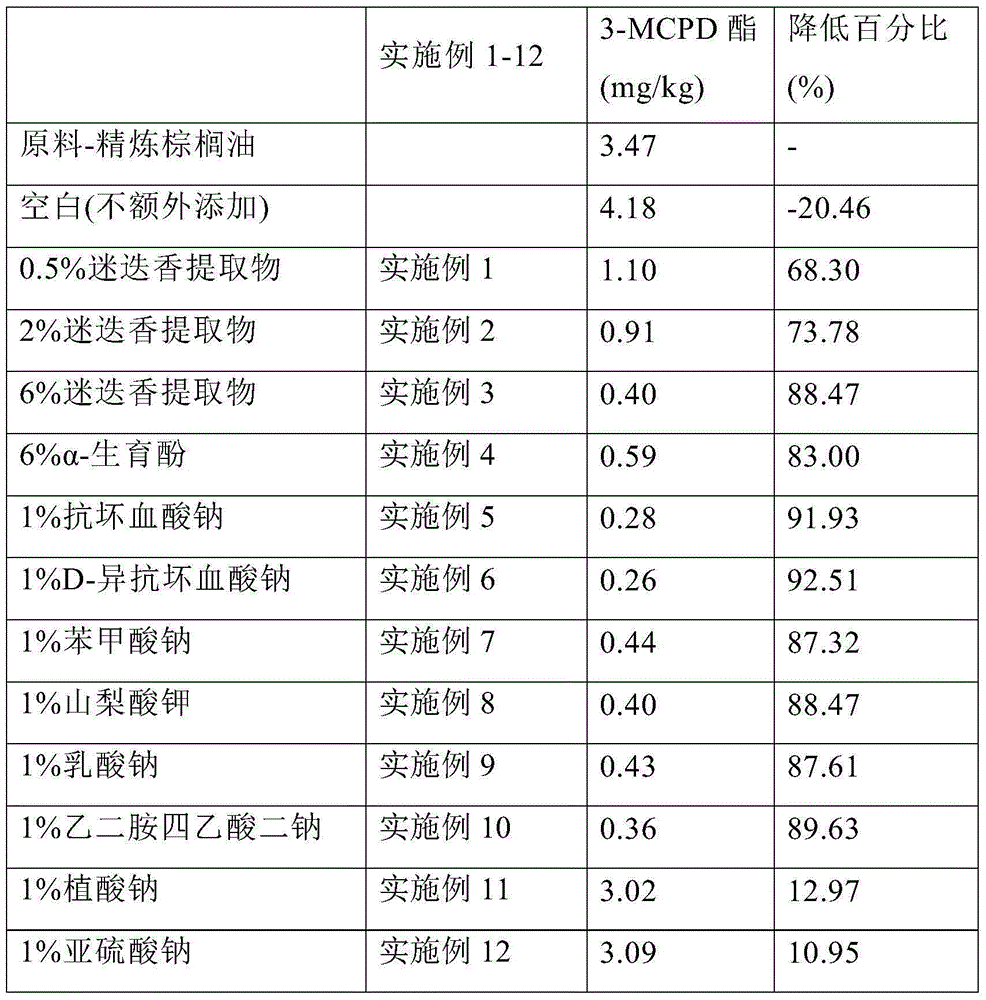

Method for reducing 3-MCPD ester and/or glycidyl ester in oil

The invention provides a method for reducing 3-MCPD ester and / or glycidyl ester in oil, an oil processing method, oil with a low 3-MCPD ester and / or glycidyl ester content, oil for deodorization treatment, application of an antioxidant to preparing oil with a low 3-MCPD ester and / or glycidyl ester content, and an oil composition. The oil processing method provided by the invention comprises the following steps: adding one or more antioxidants into oil after the oil is decolorized or before the oil is deodorized, and then performing deodorization. Through the adoption of the methods provided by the invention, the oil with a low 3-MCPD ester and / or glycidyl ester content and the corresponding oil composition can be obtained.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

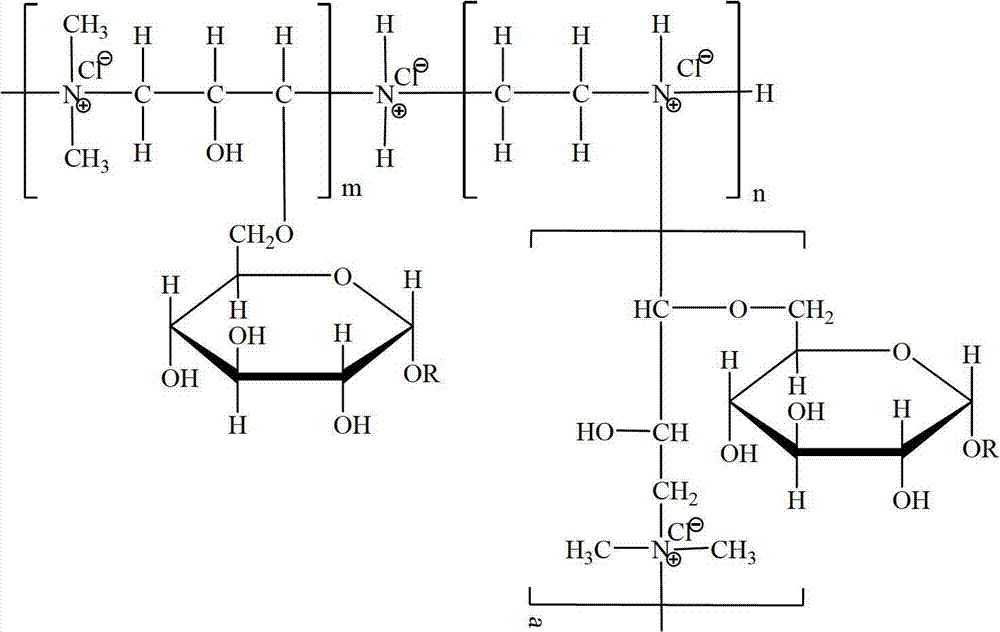

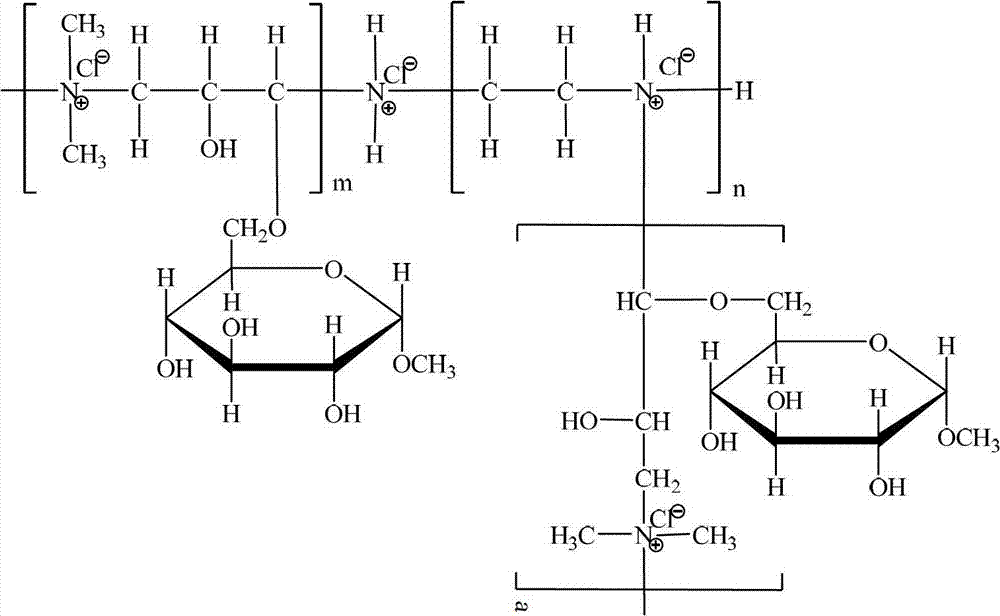

Drilling fluid inhibitor and preparation method thereof

ActiveCN102766444AEnhanced inhibitory effectInhibition dispersionDrilling compositionPolyamide3-MCPD

The invention relates to drilling fluid inhibitor and a preparation method thereof and belongs to the technical field of treating agents for oilfield chemical drilling fluids. The preparation method includes the steps of firstly, allowing epichlorohydrin, water and catalyst to react at 60-100 DEG C for 3-8 hours according to a mole ratio of 1:(12-20):(0.02-0.12) so as to obtain 3-chloro-1, 2-propanediol solution; secondly, allowing alkyl glycoside and the 3-chloro-1, 2-propanediol to react at 80-110 DEG C for 0.5-4.0 hours according to a mole ratio of 1:(0.5-5) so as to obtain chlorohydrin glucoside solution; thirdly, adjusting pH of the chlorohydrin glucoside solution to 6-9, adding 33.3% dimethylamine solution according to a mole ratio of the chlorohydrin glucoside to the dimethylamine, 1:(0.2-2.2); and fourthly, adding crosslinking agent accounting for 2%-5% of the dimethylamine in effective content; and allowing for polymerization at 40-80 DEG C for 1-5 hours before concentration, drying and crushing to obtain the finished alkyl glucoside polyamide. Water is used as solvent in reaction. The preparation process is simple and environment-friendly, and the drilling fluid inhibitor is high in shale inhibition performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

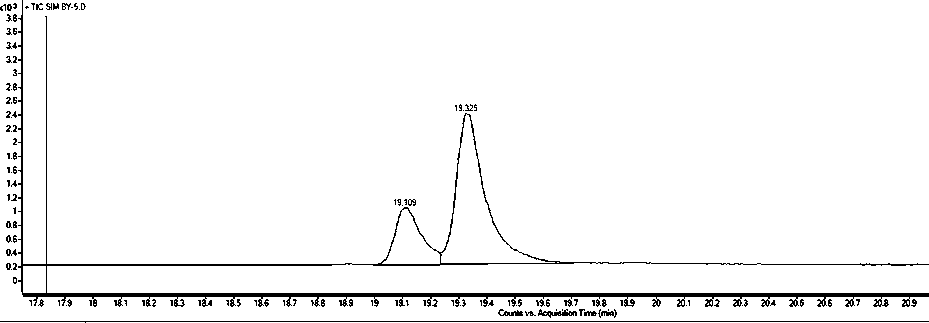

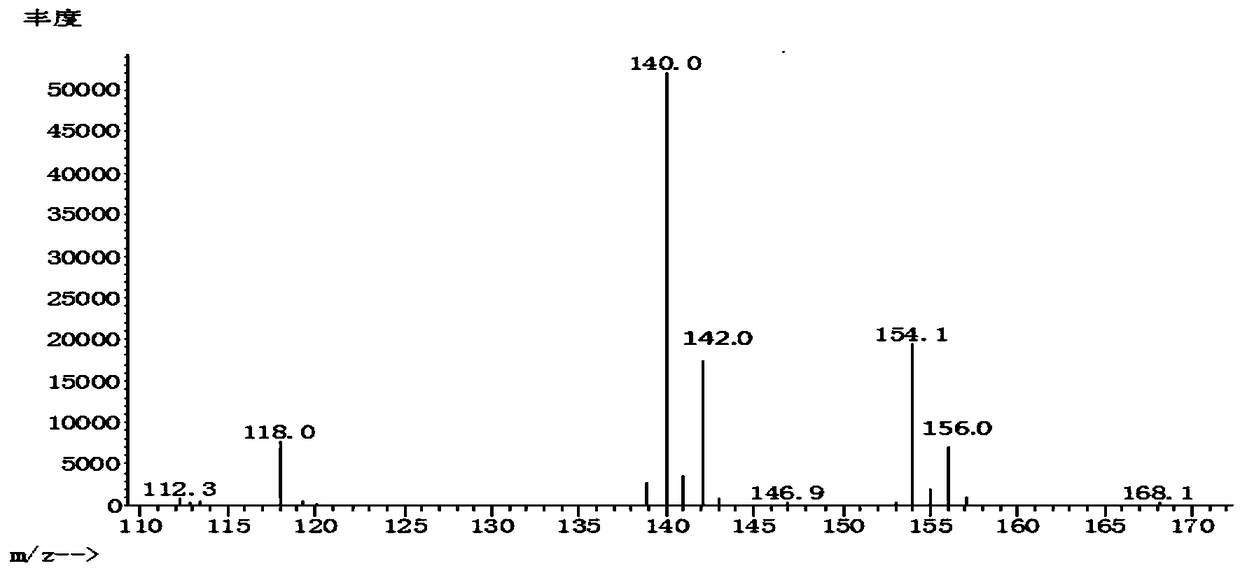

Method for detecting content of 3-monochloropropanol-1, 2-diol ester in edible oil

The invention relates to a method for detecting content of 3-monochloropropanol-1, 2-diol (3-MCPD) ester in edible oil. The method comprises the following steps: preprocessing a sample, carrying out acid-catalytic ester exchange, salting out, extracting, purifying, carrying out derivatization and detecting. According to the method, the internal labeling of stable isotopes is adopted, and the acid-catalytic ester exchanging is combined with the derivatization of heptafluorobutyrylimidazole to indirectly quantitatively analyze 3-MCPD ester by utilizing a single four-level lever GC-MS, so that the preprocessing time is shortened, the analysis efficiency is improved, the consumption amount of an organic solvent is greatly reduced, the environmental pollution is avoided, meanwhile, the analysis cost is also reduced, after the derivatization of heptafluorobutyrylimidazole, the information of a sample mass spectrum fragment is rich, and a gas chromatograph-mass spectrometer is hardly polluted.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Reduction of mcpd-compounds in refined plant oil for food

InactiveUS20150166930A1Controlling the degree of interesterificationEfficient removalFatty oils/acids recovery from wasteOrganic compound preparationVegetable oilCarbon chain

The present invention provides a process for lowering the amount of esters of 2- and 3-MCPD in refined triglyceride oil, wherein said oil prior to entering the process has been treated with one or more refining steps and wherein said oil comprises triglycerides of fatty acids having a carbon chain length of C12-C24 in an amount of at least 50% of the total triglyceride content, the process comprising the steps of: blending the oil with a base and heat treating the oil while passing steam through the oil at reduced pressure, keeping the degree of interesterification in the product from the process below 60%.

Owner:AAK

Harmless treatment method of epoxidized wastewater

ActiveCN106630083ARealize harmless treatmentSimple processWater contaminantsWater/sewage treatmentAlkaline waterHydrogen

A harmless treatment method of epoxidized wastewater comprises: a) mixing epoxidized wastewater from epichlorohydrin synthesized by epoxidizing 3-chloropropene and hydrogen perioxide, and alkaline water solution in a wastewater treatment reactor, so that 3-chloro-1,2-propanediol therein is converted into glycerol; b) optionally, neutralizing the reaction mixture of the step a). By using the method of the invention, it is possible to conveniently convert toxic and harmful epoxidized wastewater, produced in the synthesis of epichlorohydrin from epoxidizing of 3-chloropropene and hydrogen perioxide, into nontoxic and harmless wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reversibly crosslinked cellulose ethers and process for the production thereof by selective oxidation of vicinal OH groups

Reversibly crosslinked, water-soluble cellulose ethers having at least two different ether components is disclosed. At least one ether component is an alkyl, hydroxyalkyl or carboxymethyl group and at least one is an alkyl group having an aldehyde function which forms hydrolyzable hemiacetals with free OH groups of the cellulose ether. The cellulose ethers are obtainable by selective oxidation of cellulose ethers containing alkyl groups having vicinal OH groups (glycol cleavage). Preferably, water-soluble cellulose ethers are co-etherified simultaneously or subsequently with 2,3-epoxypropanol (glycidol) or 3-chloro-1,2-propanediol and the 2,3-dihydroxypropyl ether groups converted entirely or partly into 2-oxoethyl ether groups by oxidation. Suitable oxidants include periodate, periodic acid or lead tetraacetate. After washing and drying, cellulose ethers reversibly crosslinked via hemiacetals can be dispersed in water or aqueous solutions, going into solution homogeneously with a time delay. No low molecular weight dialdehydes or other problematical crosslinking reagents are liberated on dissolution.

Owner:SE TYLOSE

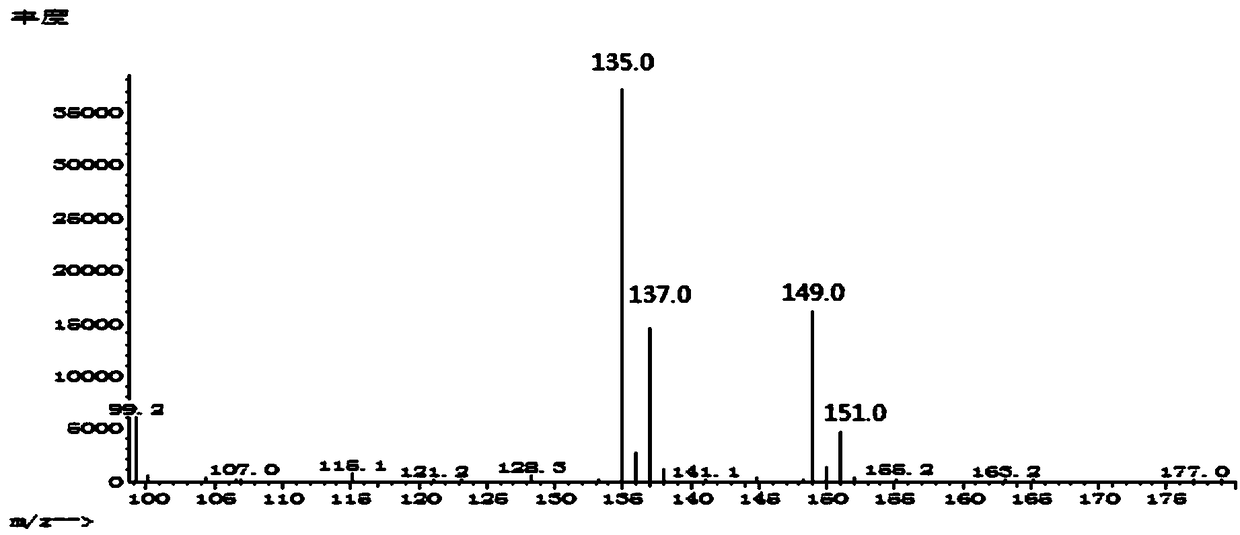

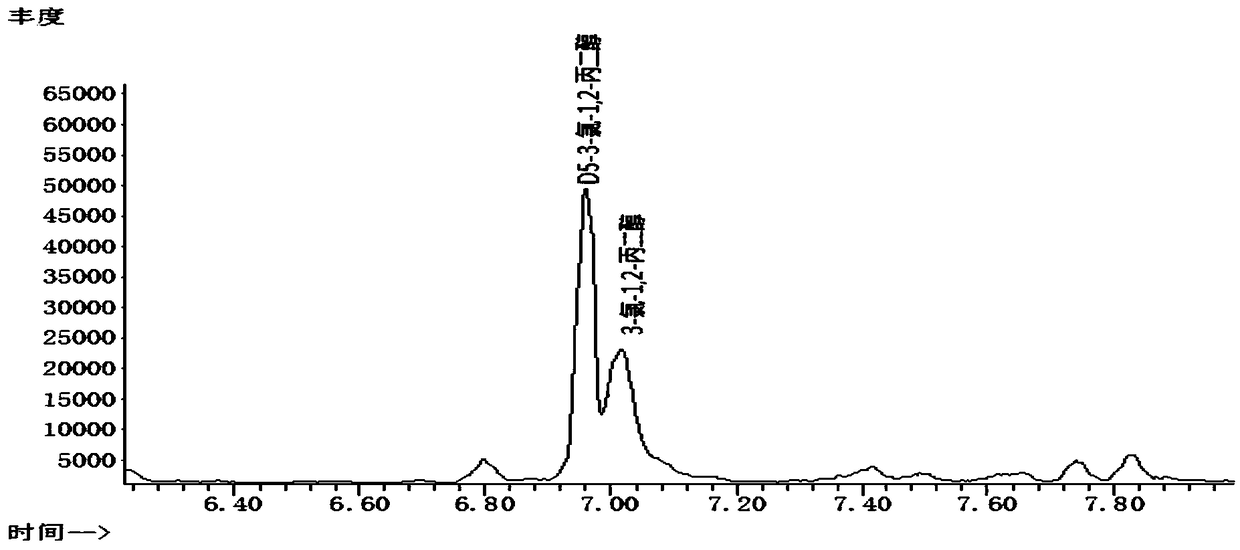

Method for detecting content of free and combined 3-chlorine-1, 2-propylene glycol in grease

The invention discloses a method for detecting content of free and combined 3-chlorine-1, 2-propylene glycol in grease, comprising the following steps: enriching polar components in grease, wherein the enriched polar components are divided into three groups to be treated, the first group is added with internal standard substance 3-MCPD-d5, the second group is added with the internal standard substance 3-MCPD-d5 after being subjected to acid catalysis alcoholysis, and the third group is subjected to acid catalysis alcoholysis after being treated by a sold-phase extraction column and is added with the internal standard substance 3-MCPD-d5; carrying out phenylboronic acid derivatization treatment on the three groups of mixtures after treatment so as to respectively obtain a derivative product; respectively carrying out GC-MS detection on the obtained derivation product; calculating the content of free and combined 3-MCPD in the grease. According to the invention, the contents of the 3-MCPD in the grease in different existence forms can be respectively detected so as to obtain the content data of free 3-MCPD, 3-MCPD monoester and 3-MCPD diester.

Owner:SHANGHAI RONGS HEALTH IND CO LTD

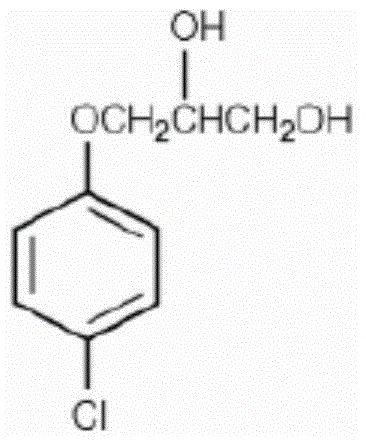

Synthetic method of chlorobenzene glyceryl ether

ActiveCN105016989AEmission reductionLow costEther separation/purificationEther preparation by ester reactions3-MCPDPhase-transfer catalyst

The invention relates to a synthetic method of chlorobenzene glyceryl ether. 3-chloro-1,2-propanediol and parachlorophenol are directly used as raw materials, high-corrosion chemical solvents are not introduced, a reaction is simple, the yield is high, and the yield can reach 95 percent or more under the optimal reaction condition. By adding a few phase transfer catalysts, the reaction can be promoted to be conducted quickly and effectively, and the reaction time can be shortened by at least two hours.

Owner:BEIJING SUNPU BIOCHEM TECH

Method for reducing content of trichloropropanol in grease and ester thereof

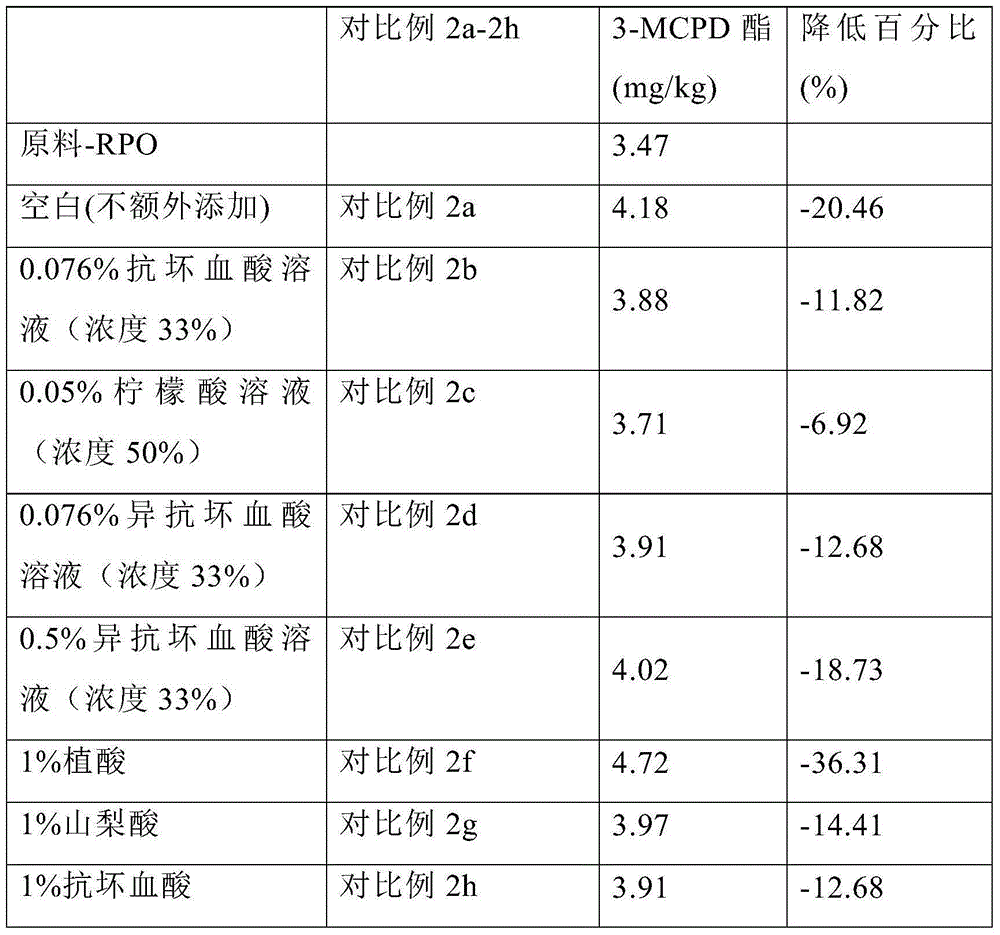

ActiveCN106281672ADoes not affect productivityDoes not affect the processFatty-oils/fats refiningOrganic acidAntioxidant

The invention relates to a method for reducing content of trichloropropanol in grease and ester thereof. The method comprises the steps of causing grease to contact with an antioxidant and / or an antioxidant derivative, wherein the system pressure during the contact is larger than or equal to 0.1 bar, and the antioxidant and / or the antioxidant derivative does not include an organic acid antioxidant. The invention also provides a method for preparing the grease by adopting the means, the grease prepared accordingly and application of the antioxidant and / or the antioxidant derivative to reduction of the content of 3-MCPD in the refined grease or ester thereof. The method has an obvious effect of reducing 3-MCPD ester, there is no requirement for the content of the 3-MCPD ester in the raw materials, the grease production or refining process is not affected, follow-up processing only needs to be performed, and the method is simple to operate and practical.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

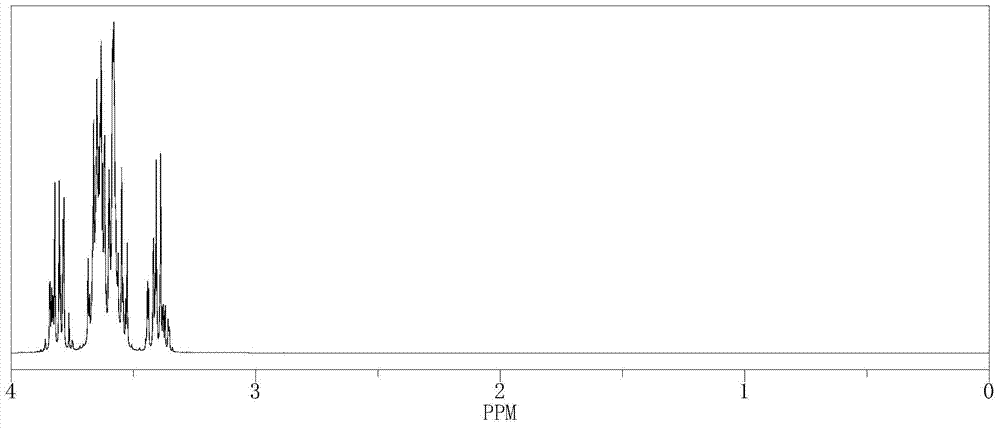

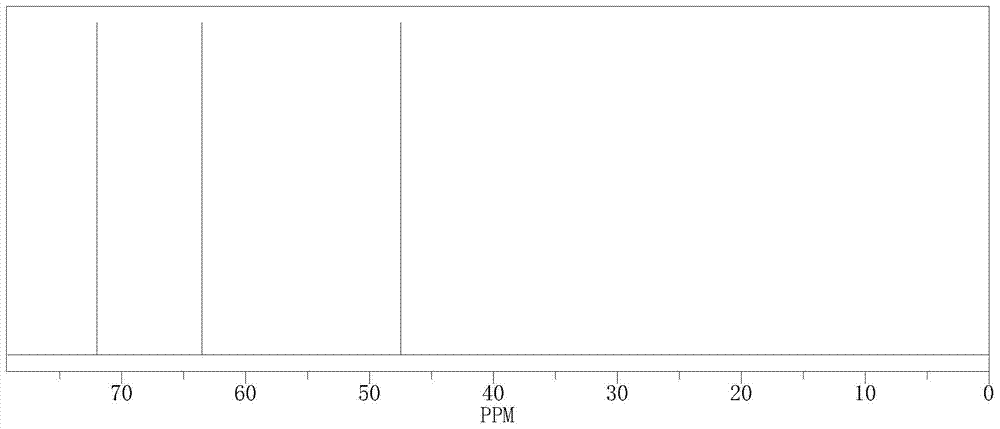

Production method of high-purity 3-chloro-1, 2-propanediol

InactiveCN101928202AThe hydrolysis reaction is stable and sufficientQuick responseOrganic compound preparationPreparation by hydrolysisChemistry3-MCPD

The invention discloses a production method of high-purity 3-chloro-1, 2-propanediol, which comprises the following steps: (1) taking sulfuric acid, benzenesulfonic acid and succinic acid, respectively dissolving the three in deionized water, and preparing into sulfuric acid solution, benzenesulfonic acid solution and succinic acid solution; (2) firstly mixing part of the sulfuric acid solution, part of the benzenesulfonic acid solution and part of epichlorohydrin, carrying out reaction for a period of time, raising temperature, further adding the remaining epichlorohydrin, sequentially adding the remaining benzenesulfonic acid solution and the sulfuric acid solution according to time periods, then adding the succinic acid solution once, raising the temperature, and continuously carrying out the reaction; (3) adding alkaline solution after completing hydrolysis reaction, and stirring for leading the reaction to be uniform; (4) carrying out dehydration on hydrolysate after adding the alkaline solution, adding the alkaline solution after finishing the dehydration, and raising the temperature under stirring condition; and (5) firstly heating materials under vacuum condition, then transferring the materials into a distillation system, and obtaining a product of 3-chloro-1, 2-propanediol by distillation when the vacuum degree is not less than 0.1MPa.

Owner:青岛中科荣达新材料有限公司

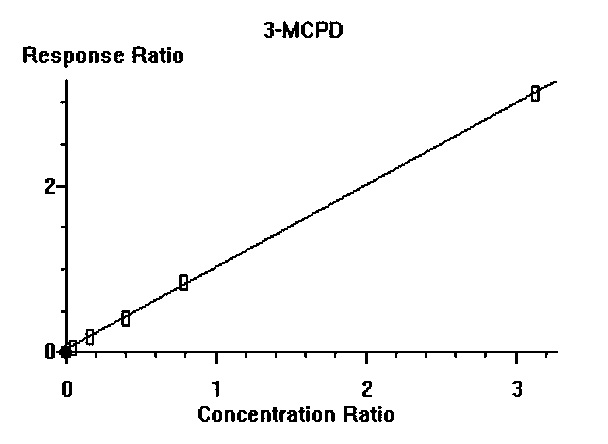

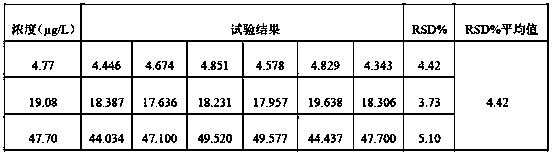

Method for testing 3-chlorine-1, 2-propylene glycol and aliphatic ester content of 3-chlorine-1, 2-propylene glycol

The invention discloses a method for testing 3-chlorine-1, 2-propylene glycol. The method comprises the steps: (1) oxidizing the 3-chlorine-1, 2-propylene glycol in a water solution into chloroacetaldehyde; (2) performing derivatization to subject the chloroacetaldehyde and a derivatization reagent to a reaction to produce substances with fluorescent effects; and (3) using a high performance liquid chromatograph-forming limit diagram (HPLC-FLD) method to perform testing, and obtaining content of 3-chlorine-1, 2-propylene glycol. Compared with an existing gas chromatography-mass spectrometer (GC-MS) method, the method is simple in operation, equipment investment is greatly reduced, an expensive deuterated master standard is not needed, the using cost is greatly reduced, and barriers are cleared for addition of testing indexes of 3-chlorine-1, 2-propylene glycol for relative products. 3-chlorine-1, 2-propylene glycol aliphatic ester is converted into 3-chlorine-1, 2-propylene glycol by ester exchange so that the aliphatic ester content of 3-chlorine-1, 2-propylene glycol is tested.

Owner:湖北莱菔子科技有限公司

Method for detecting content of fatty acid-chlorine-propylene glycol monoester and diester in food

The invention relates to a method for detecting content of a fatty acid in food, and particularly relates to a method for detecting the contents of a fatty acid 3-chlorine-1,2-propylene glycol monoester, a fatty acid 3-chlorine-1,2-propylene glycol diester, a fatty acid 2-chlorine-1,3-propylene glycol monoester and a fatty acid 2-chlorine-1,3-propylene glycol diester in food by a gas chromatograph-mass spectrometer. According to the method, an amino solid-phase extraction column is adopted, a normal hexane-ethyl acetate mixed solvent is utilized for implementing elution, a GC-MS approach of alkaline hydrolysis-phenylboronic acid derivatization is utilized for determination; the method comprises seven steps of: sample treatment, extraction separation, alkaline hydrolysis treatment, derivatization treatment, analysis by the gas chromatograph-mass spectrometer, preparation of a standard curve, and quantification; and the method only needs few types of solvents and is low in solvent consumption, easy to operate, high in sensitivity, strong in analysis capability, correct in quantitive analysis result, low in detection limit and short in analysis time.

Owner:FUJIAN CENT FOR DISEASE CONTROL & PREVENTION

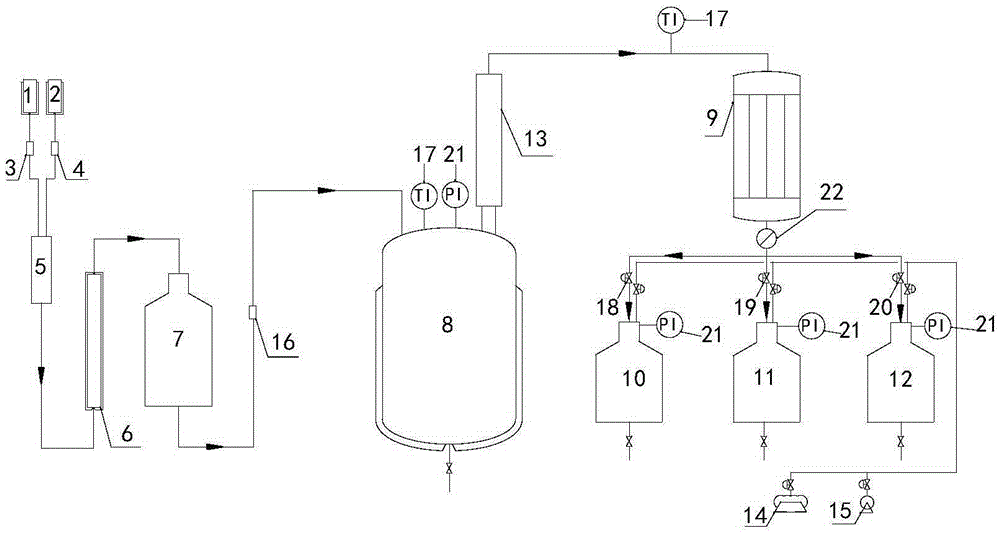

System and method for continuously synthesizing high-purity 3-chloro-1,2-propylene glycol

InactiveCN105237338AReduce labor intensityLarge production tonnageOrganic compound preparationPreparation by hydrolysisSoftened waterDistillation

The invention discloses a system and a method for continuously synthesizing high-purity 3-chloro-1,2-propylene glycol. The system includes, in a successively connection manner through pipelines, an overhead tank, a static mixer, a tubular reactor, a hydrolysate intermediate tank, a distillation kettle, a distillation column and a condenser. An output pipeline on the condenser is respectively connected to a first receiving pot, a second receiving pot and a finish product receiving pot. The receiving pots are connected to a hydraulic jet vacuum pump and a Roots-oil ring vacuum machine set at the same time. The method includes the steps of pre-heating epoxy chloropropane and softened water, mixing the epoxy chloropropane and the softened water in the static mixer according to ratio, feeding the mixture into the tubular reactor, controlling the vacuum degree and temperature of the reaction liquid in the distillation kettle to produce different fractions, and finally producing the fraction at specified vacuum degree and temperature as a finish product.

Owner:TAISHAN MEDICAL UNIV

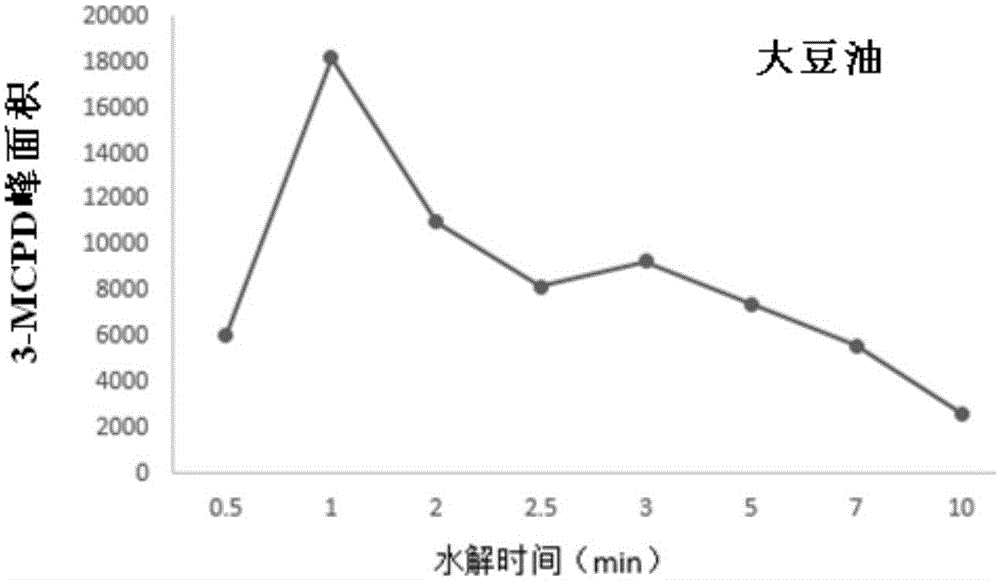

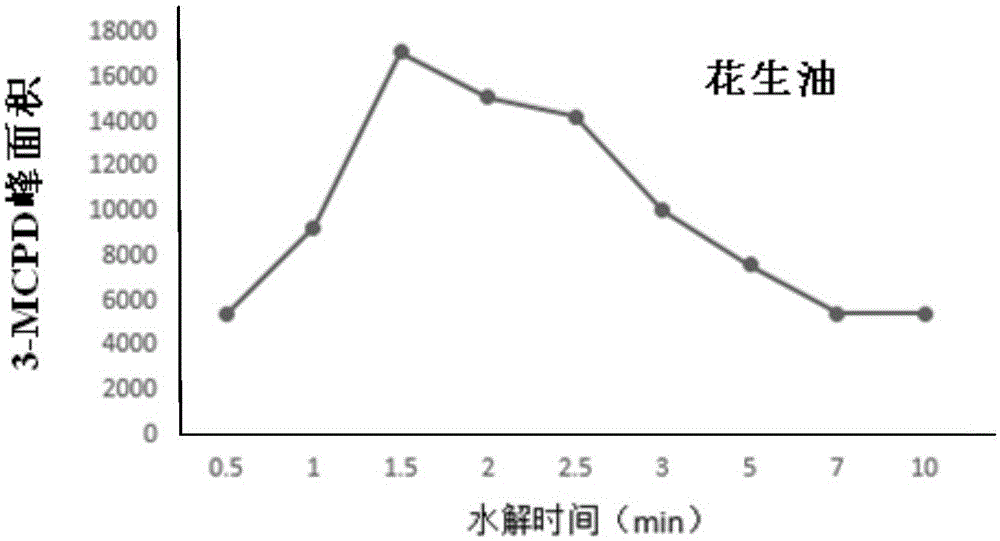

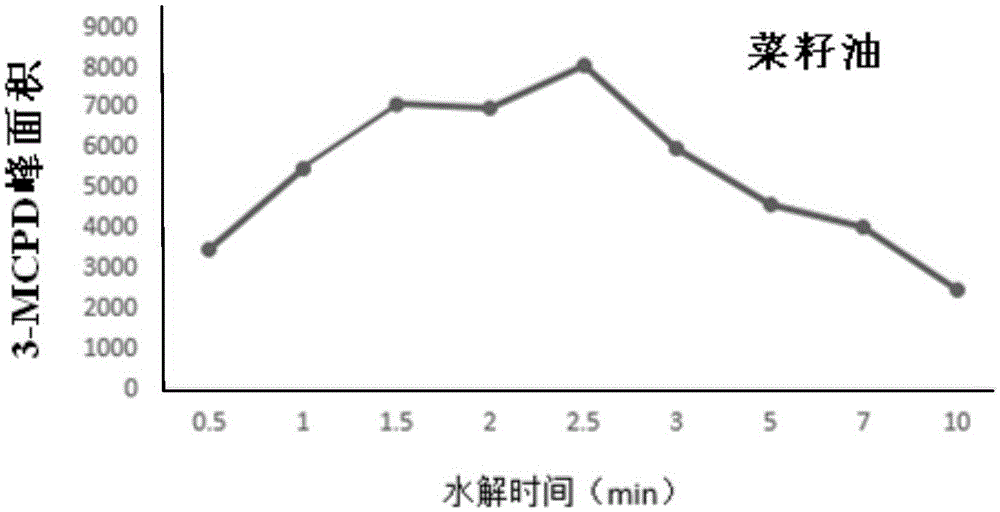

Detection method for 3-MCPD ester in oil product

ActiveCN106338552AHigh sensitivityImprove featuresComponent separationGas chromatography–mass spectrometrySodium iodide

Relating to the detection field of 3-MCPD ester, the invention discloses a detection method for 3-MCPD ester in an oil product. The method includes: (1) contacting a to-be-detected oil product with a methanol solution of sodium hydroxide to perform hydrolysis so as to obtain a hydrolysis product; (2) contacting the hydrolysis product with a mixed solution containing sulfuric acid and sodium halide to perform neutralization so as to obtain a neutralization product, wherein the sodium halide is sodium bromide and / or sodium iodide; (3) using an organic solvent to extract the neutralization product, and subjecting the obtained extracted solution and phenylboronic acid to contact reaction; and (4) conducting gas chromatography-mass spectrometry on the reaction product obtained by reaction in step (3). According to the technical scheme, the methanol solution of sodium hydroxide is employed to conduct alkaline hydrolysis on the to-be-detected sample, the mixed solution of sodium bromide and sulfuric acid is employed to conduct neutralization treatment on the alkaline hydrolysis product, thus effectively improving the sensitivity, specificity and precision of subsequent detection.

Owner:COFCO GROUP +1

Sample pretreatment method for detection of free and bonded 3-chlorine-1,2-propylene glycol in grease

The invention discloses a sample pretreatment method for detection of free and bonded 3-chlorine-1,2-propylene glycol in grease. The method comprises the steps of weighing proper amount of grease, adding a polar solvent at certain volume, taking out a solvent phase after the solution is layered, rotatably evaporating the solvent under a vacuum condition, dissolving the residue with tetrahydrofuran, and respectively conducting the following operations: (1) further processing of detection of free 3-chlorine-1,2-propylene glycol, and (2) further processing of detection of bonded 3-chlorine-1,2-propylene glycol. According to the invention, a sample for detecting the free and bonded 3-chlorine-1,2-propylene glycol in the grease can be pre-treated by using the simple method.

Owner:SHANGHAI RONGS HEALTH IND CO LTD

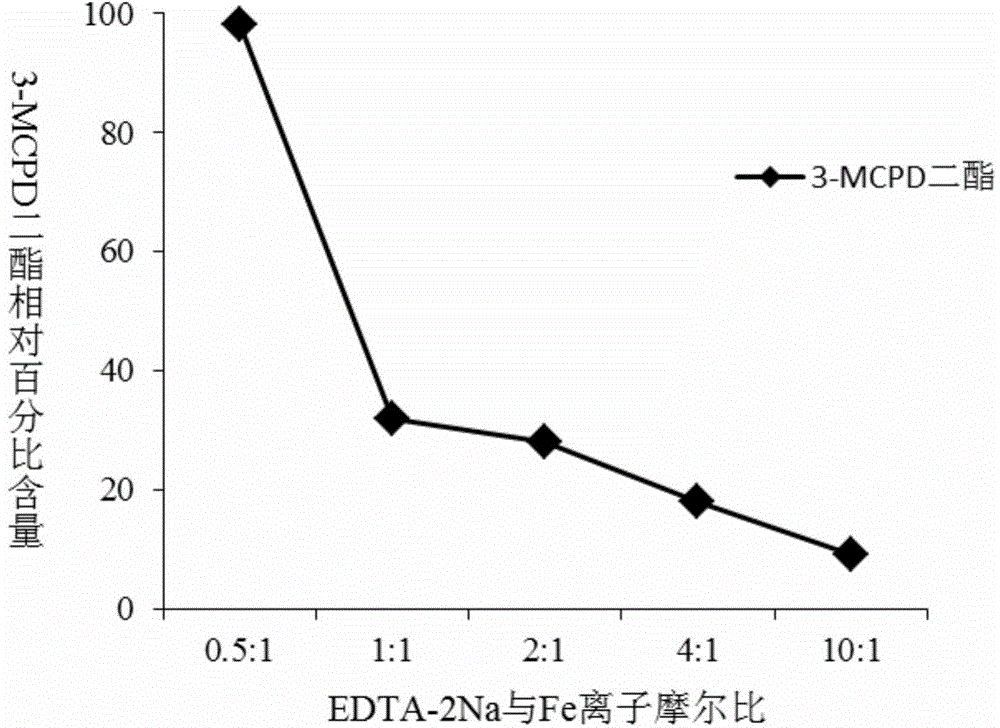

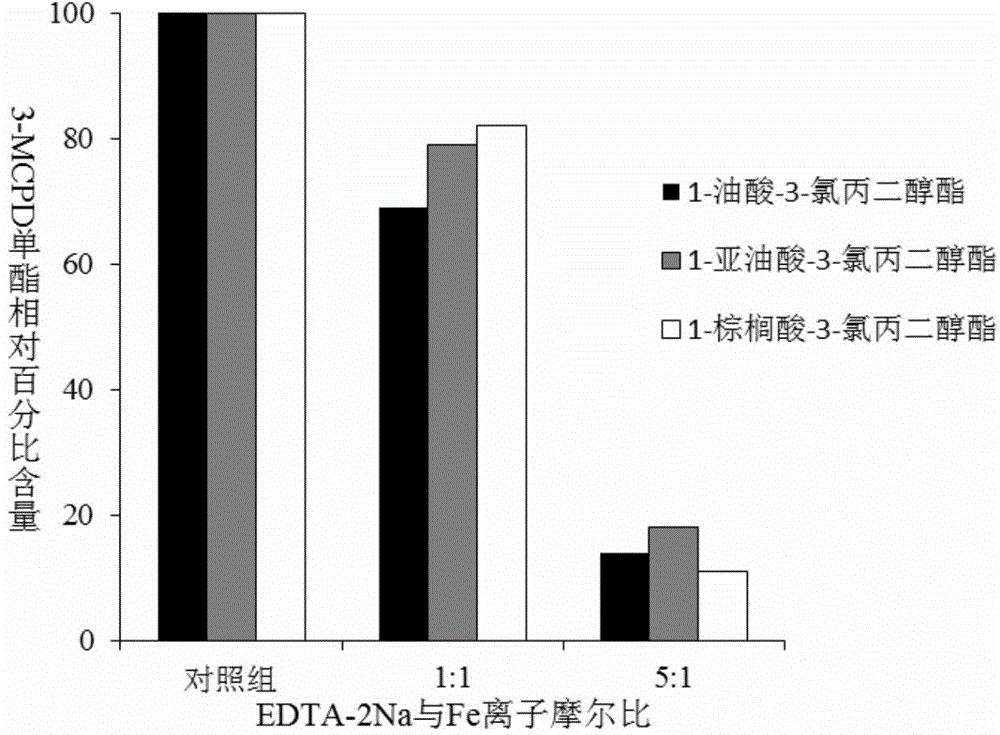

Method for reducing 3-chlorine-1,2-propylene glycol ester during grease processing

The invention provides a method for reducing 3-chlorine-1,2-propylene glycol ester (called 3-MCPD ester for short) during grease processing. 3-MCPD ester is a harmful substance generated during the grease processing, the control over the content of the 3-MCPD ester in grease and a related food has great significance in maintaining food safety. The idea of the invention is derived from that an iron ion is discovered to have catalytic action on the formation of the 3-MCPD ester in study, and thus the content of the 3-MCPD ester contained in the grease can be controlled by reducing the content of the iron ion. According to the method provided by the invention, the measures of storing the grease by using a non-ferrous container and adding an antioxidant, an iron ion chelating agent and the like during grease storage or processing are adopted, and the measures can both be used for obviously reducing the content of the 3-MCPD ester contained in the grease.

Owner:SHANGHAI JIAO TONG UNIV

Deodorization method used for lowering content of 3-chlorine-1,2-propylene glycol in vegetable oil

ActiveCN103525550AReduce generationFatty-oils/fats refiningEdible oils/fatsVegetable oilLowering plants

The invention discloses a deodorization method used for lowering the content of 3-chlorine-1,2-propylene glycol in vegetable oil. The deodorization method comprises the following steps: with discolored vegetable oil as a raw material, and heating up the discolored vegetable oil to 110 DEG C-150 DEG C by a heat exchanger; feeding the heated vegetable oil to a material distributor of a molecular distiller and uniformly distributing, and setting the temperature of a heating surface of the molecular distiller to 170 DEG C-190 DEG C, wherein the temperature of a condensing surface of an internal condenser of the molecular distiller is 5 DEG C-20 DEG C, and vacuum degree is 0.1 Pa-5 Pa; enabling a light-phase odor component to flow into a light component collecting tank after condensing through the internal condenser, and quickly cooling heavy phase to 50 DEG C or lower by the heat exchanger to obtain deodorized vegetable oil with 3-chlorine-1,2-propylene glycol content smaller than 300 mg / kg. Compared with the prior art, the deodorization method disclosed by the invention has the advantages of lowering production amount of the 3-chlorine-1,2-propylene glycol in the deodorized vegetable oil and providing references for improving an existing vegetable oil refining process.

Owner:JIANGNAN UNIV +1

Method for preparing high-purity 3-chlorine-1,2-propylene glycol aliphatic ester

ActiveCN102093215AReduce processing costsEasy to operatePreparation from carboxylic acid halidesReference productGas phase

The invention relates to a method for preparing high-purity 3-chlorine-1,2-propylene glycol aliphatic ester. The method comprises the following steps: thoroughly mixing 3-chlorine-1,2-propylene glycol with fatty acid chloride solution and a catalyst, standing for 6-36 hours at room temperature, and then filtering, washing and drying reaction liquid; processing dried organic residues by using any one or more of gel permeation chromatography (GPC), solid-phase extraction (SPE), liquid chromatography and the like so as to prepare the high-purity 3-chlorine-1,2-propylene glycol aliphatic ester; and finally, detecting the purity of the 3-chlorine-1,2-propylene glycol aliphatic ester by using a gas chromatograph-mass spectrometer. In the invention, the preparation method is simple, process parameters are stable, the purity of the extracted 3-chlorine-1,2-propylene glycol aliphatic ester is high, and the 3-chlorine-1,2-propylene glycol aliphatic ester can be used as a standard reference product for detection and analysis and as a raw material for a toxicology evaluation test.

Owner:王力清

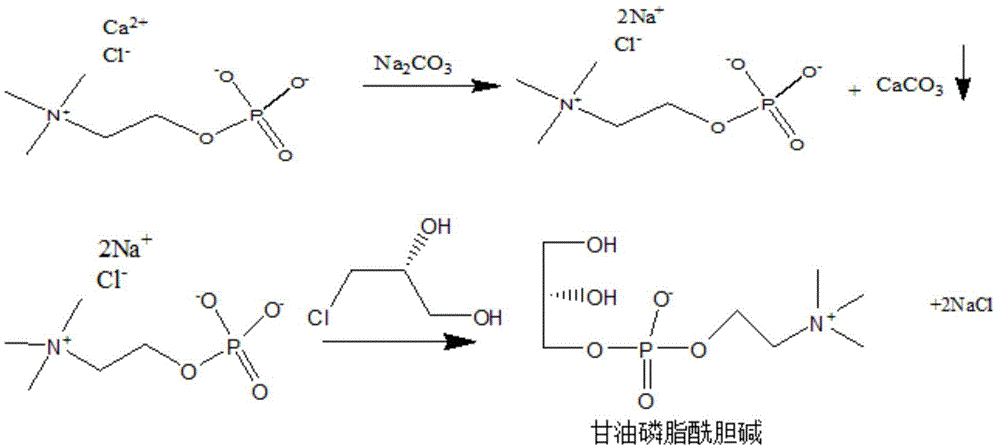

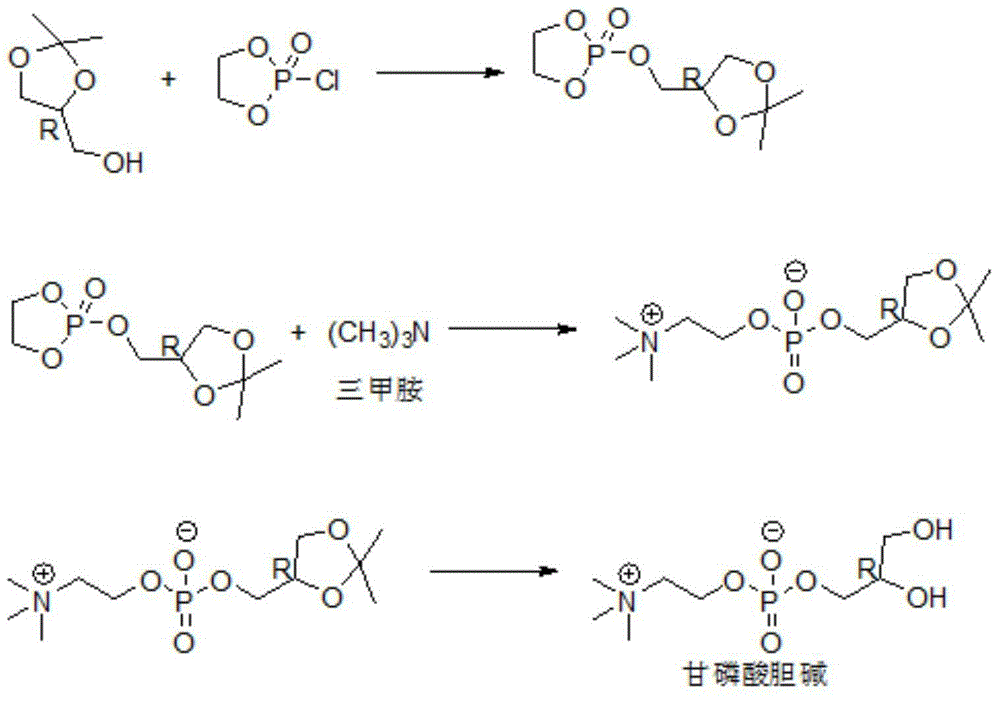

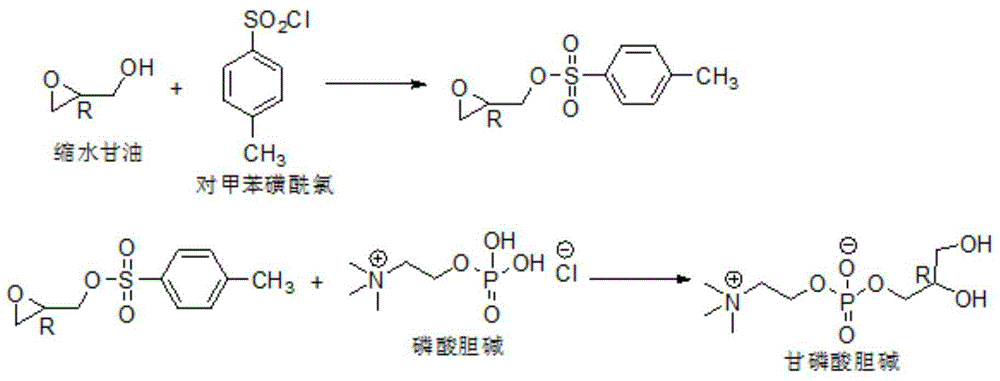

Preparation method for glycerophosphatidylcholine

ActiveCN104926862AReduce manufacturing costHigh synthesis ratePhosphorus organic compoundsAnhydrous ethanolReflux

The invention discloses a preparation method for glycerophosphatidylcholine. The preparation method comprises the steps: mixing a compound shown in the formula (I) with anhydrous sodium carbonate to prepare a mixture M1; putting the mixture M1 and (R)-(-)-3-chloro-1,2-propylene glycol in anhydrous ethanol for reflux to obtain a mixture M2; after diluting the mixture M2 by 5-10 times, flowing the mixture M2 through first ion exchange resin to obtain a mixture M3; after diluting the mixture M3 by 2-4 times, flowing the mixture M3 through second ion exchange resin to obtain a mixture M4; washing the mixture M4 by 70-90wt% ethanol to obtain a mixture M5; washing the mixture M5 by distilled water to obtain a mixture M6; after flowing the mixture M6 through third ion exchange resin, filtering the mixture M6 to obtain a filtrate so as to obtain the glycerophosphatidylcholine. The formula (I) is as shown in the description, wherein R is Ca2<+> or Mg2<+>. The effects of simple preparation method, high synthetic ratio and great reduction of production cost are achieved.

Owner:WUHU FOMAN BIOPHARMA CO LTD

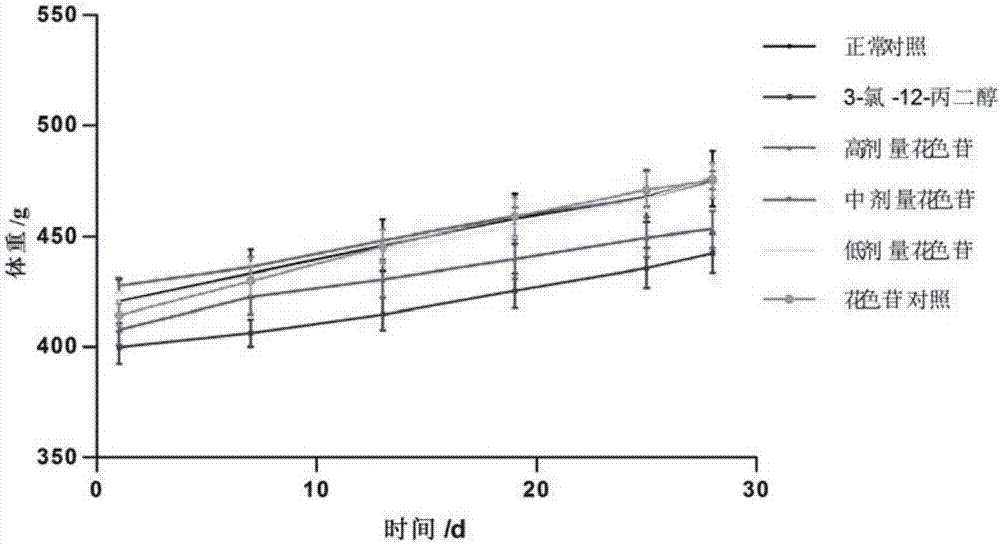

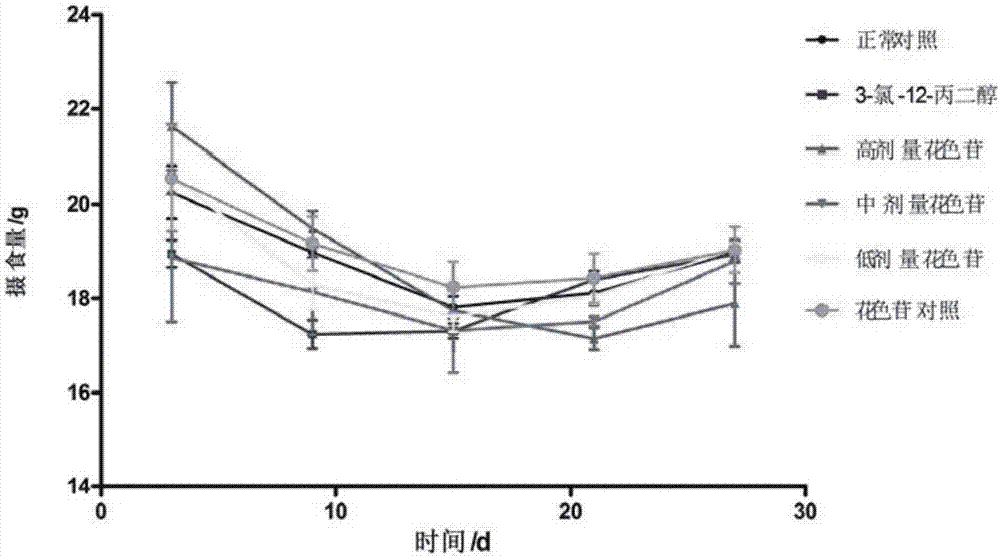

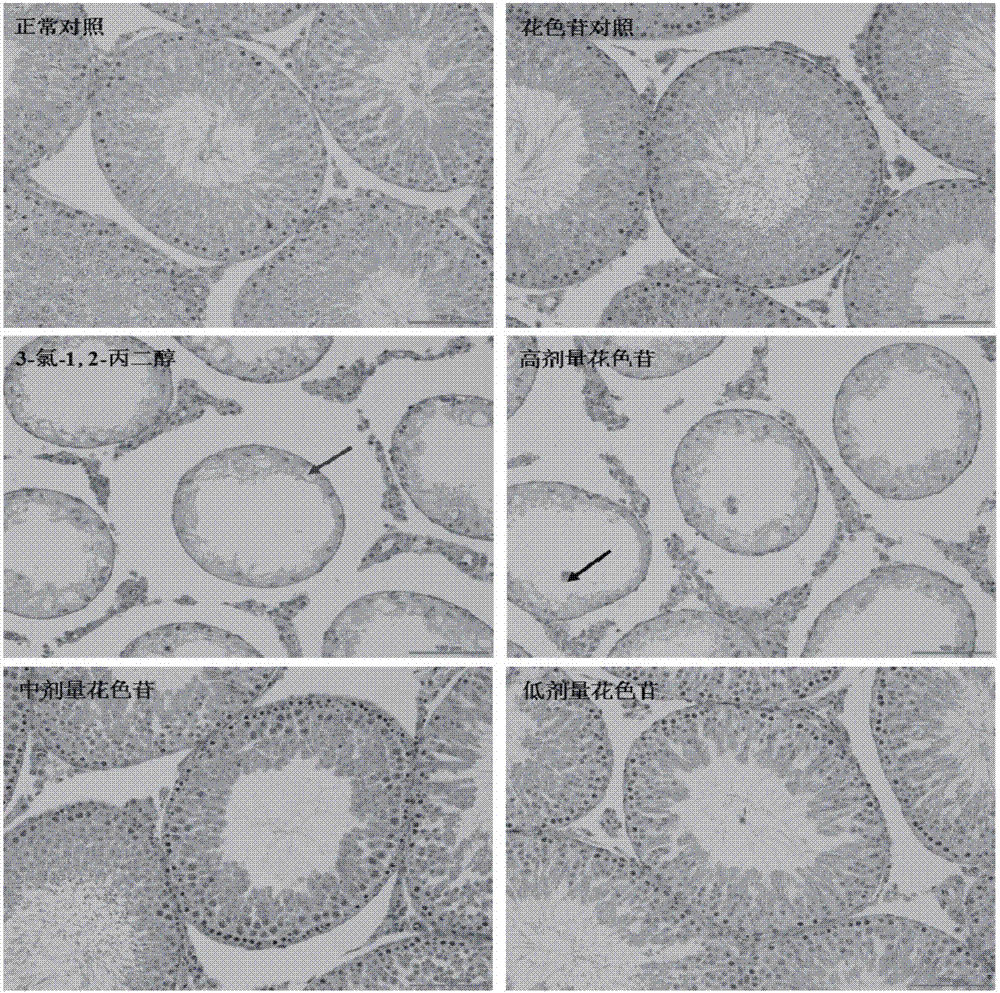

Applications of cyanidin-3-O-glucoside in preparation of medicines treating diseases caused by 3-chloropropane-1,2-diol

InactiveCN107485616AImprove growth retardationAntagonistic destructionOrganic active ingredientsAccessory food factorsDiseaseEpithelium

Applications of cyanidin-3-O-glucoside in preparation of medicines treating and / or preventing diseases caused by 3-chloropropane-1,2-diol are provided. The cyanidin-3-O-glucoside (C3G) can improve rat ingestion decrease and growth retardation which are caused by 3-MCPD poisoning, can effectively resist rat antioxidant system damage caused by 3-MCPD poisoning, and can activate and adjust BTB structural functions of sustentacular cells through inhibiting an MAPK signaling pathway, thus relieving seminiferous epithelium injuries caused by the 3-MCPD, maintaining stability of a spermatogenic microenvironment, regulating spermatogenic cell proliferation and differentiation, and improving dyszoospermia. In addition, the C3G can improve sperm activity through adjusting sperm energy metabolism related enzymes. The C3G can regulate rat sex hormone secretion disorders caused by 3-MCPD poisoning and can maintain normal levels of sex hormone in serum and androgen in testis inner environments. The applications provide theoretical foundations for 3-MCPD reproduction toxicity nutritional intervention utilizing anthocyanin.

Owner:JINAN UNIVERSITY

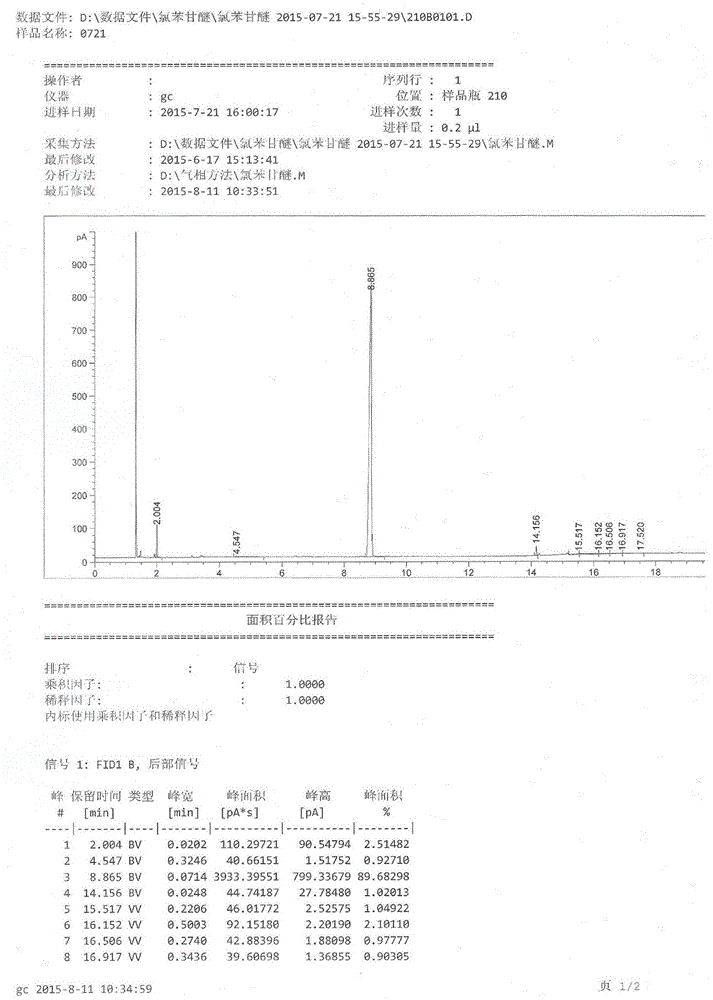

Detection method of content of 3-chlorine-1,2-propylene glycol in wine products

The invention discloses a detection method of the content of 3-chlorine-1,2-propylene glycol in wine products. The method comprises the following steps: adding internal standard into a sample, takingdiatomite as an adsorbent, carrying out solid-phase support liquid-liquid extraction, eluting by using a normal hexane-absolute ethyl ether solution (9+1), removing non-polar lipid components, eluting3-chlorine-1,2-propylene glycol by using absolute ethyl ether and taking the obtained solution as a sample solution; taking ethyl acetate as a solvent for preparing a 3-chlorine-1,2-propylene glycolstandard solution, taking heptafluorobutyrylimidazole as a derivatization reagent, setting analysis condition of a gas chromatograph-mass spectrometer, respectively feeding the sample by using a sample solution and a standard solution, calculating the content of 3-chlorine-1,2-propylene glycol in the sample solution by using an internal standard method according to testing results. The method is simple, is low in detection cost, rapid in speed, low in interference of detection process, high in result repeatability and high in accuracy, and is mainly used for detecting the content of 3-chlorine-1,2-propylene glycol in the wine products.

Owner:JING BRAND

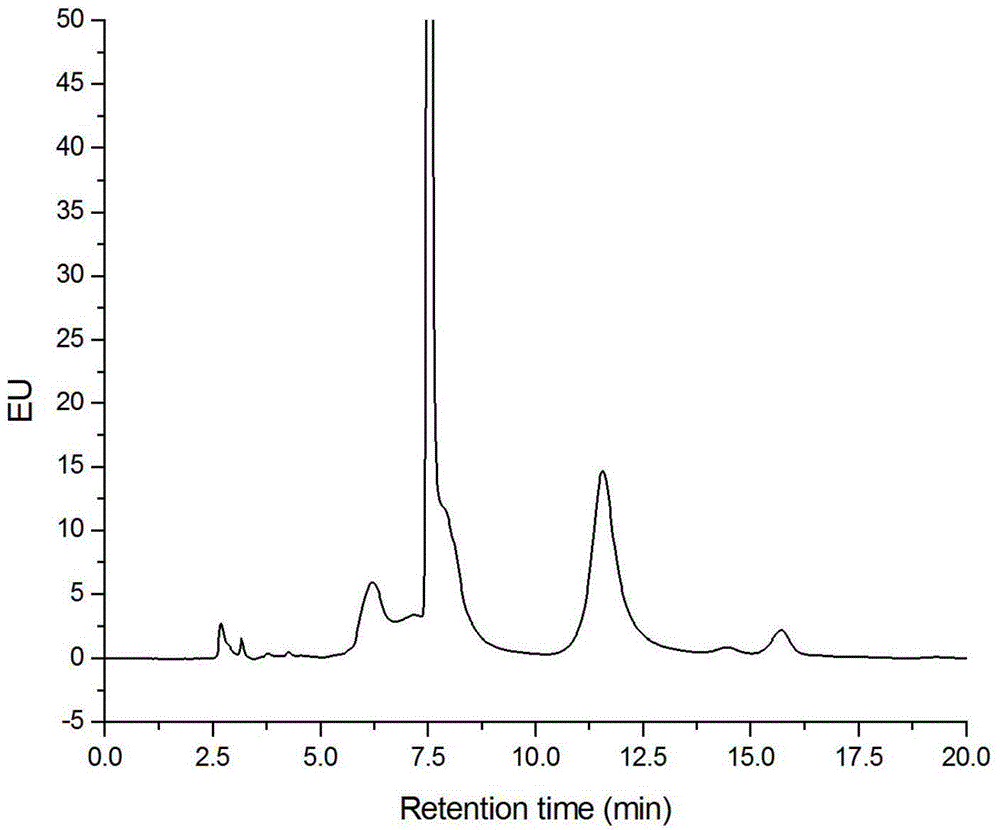

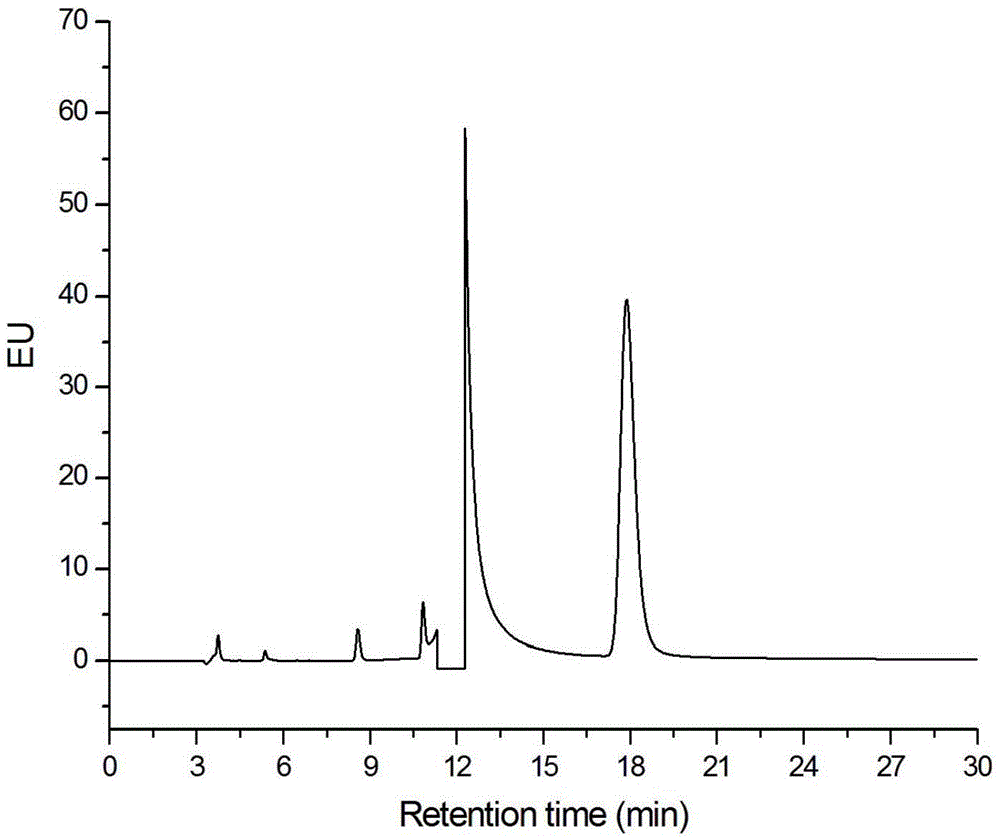

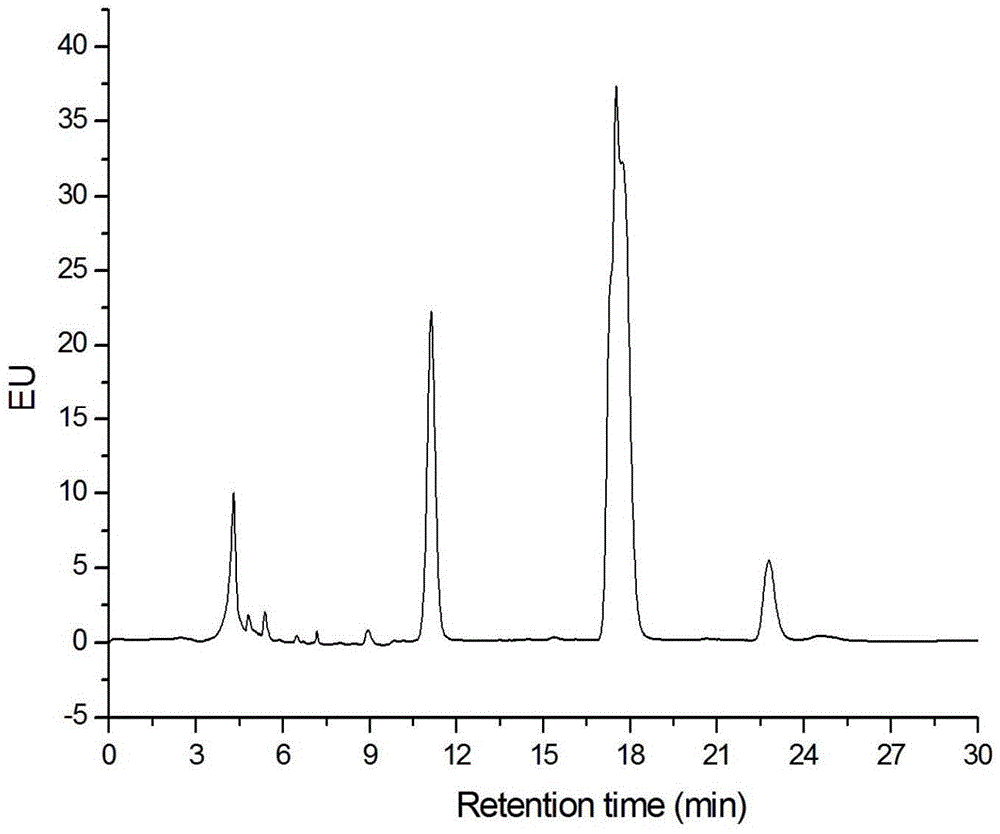

High performance liquid chromatography-fluorescence detection method for 3-chloro-1,2-propylene glycol

ActiveCN104597194AGood choiceHigh fluorescence efficiencyComponent separationFluorescenceReversed-Phase Liquid Chromatography

The invention discloses a high performance liquid chromatography-fluorescence detection method for 3-MCPD. The method comprises the following steps: (1) treating a 3-MCPD aqueous solution, and cracking the 3-MCPD into chloroacetaldehyde; (2) removing excessive periodate, and eliminating side reaction; (3) carrying out fluorescence derivation reaction, namely enabling the chloroacetaldehyde to react with a fluorescence derivation reagent so as to generate a target material with a fluorescence effect; and (4) performing HPLC-FLD measurement, namely separating the target material, and quantifying the 3-MCPD according to the chromatographic peak area, wherein the fluorescence derivation reagent refers to an o-amino binary N-heterocyclic compound. According to the method disclosed by the invention, a type of novel fluorescence derivation reagents with convenient and readily available materials, high selectivity, high fluorescence efficiency and high hydrophobicity can be used for high performance liquid chromatography-fluorescence detection of 3-MCPD, so that the target product has a good retention behavior in the reversed phase liquid chromatography, and the accuracy and sensitivity of the test method are improved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Oil compositions

Owner:CARGILL INC

Method for determining 3-chloro-1,2-propanediol in seasoning

InactiveCN109254088AReduce dosageThe pre-processing process is simpleComponent separationGas chromatography–mass spectrometry3-MCPD

The invention belongs to the field of analytical chemistry, and provides a method for determining 3-chloro-1,2-propanediol in a seasoning. The 3-MCPD in the seasoning is extracted by butanone, and reacts with butanone to generate a cyclic compound under the catalysis of toluenesulfonic acid for determination. The method comprises the following detection steps: preparation of the solution, preparation of the standard stock solution, preparation of the sample solution, qualitative analysis by gas chromatography-mass spectrometry, and quantitative determination. The method provided by the invention can be used for detecting liquid seasonings such as soy sauce, fish sauce and protein seasoning liquid, and 3-MCPD in solid seasonings such as chicken essence and seafood powder. The use of butanone as extraction solvent and derivatization reagent eliminates the need for concentration and solvent conversion processes, avoiding expensive derivatization reagents in traditional detection methods.The method has the advantages of simple pretreatment, low organic solvent dosage, environmental protection, mild derivatization conditions, high accuracy, low detection cost, easy promotion, and the like.

Owner:大连市食品检验所

Preparation method for (R)-3-chloro-1,2-propanediol

InactiveCN104844421AHigh yieldHigh purityOrganic compound preparationHydroxy compound separation/purification3-MCPDPropanediol

The invention discloses a preparation method for (R)-3-chloro-1,2-propanediol. The preparation method comprises the following steps: 1) subjecting (S)-3-chloro-1,2-epoxypropane and water to a ring-opening reaction in the presence of an acidic catalyst so as to obtain a ring-opening mixture; 2) subjecting alkali lye and the ring-opening mixture to a neutralization reaction so as to obtain a neutralization mixture; 3) removing water in the neutralization mixture and carrying out filtering so as to obtain a filtrate; and 4) fractionating the filtrate at a pressure of 30 to 35 pa and a temperature of 125 to 128 DEG C so as to prepare (R)-3-chloro-1,2-propanediol. The preparation method has excellent yield; and prepared (R)-3-chloro-1,2-propanediol has excellent total purity and low water content, and in particular, chiral purity of (R)-3-chloro-1,2-propanediol is as high as 99.5%.

Owner:WUHU FOMAN BIOPHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com