Method of preparing CAPG for drilling fluid

An alkyl glycoside and cation technology, which is applied in the preparation of sugar derivatives, drilling compositions, chemical instruments and methods, etc., can solve the problems of low final yield, harsh reaction conditions, long reaction time, etc. The effect of short time, mild reaction conditions and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

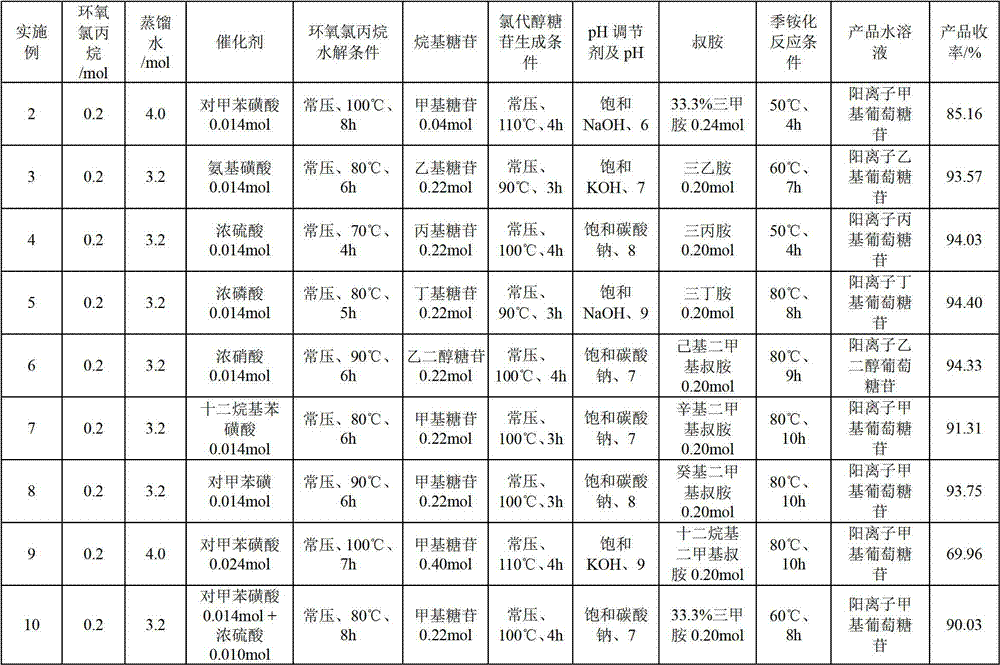

Examples

Embodiment 1

[0017] In a 500mL four-necked flask equipped with a thermometer, condenser, and stirrer, add 0.2mol of epichlorohydrin, 2.4mol of distilled water and 0.004mol of p-toluenesulfonic acid, and react for 3h at normal pressure at a temperature of 60°C to obtain a colorless Transparent aqueous solution of 3-chloro-1,2-propanediol; cool down to room temperature, add 0.40 mol of methyl glucoside, react at normal pressure, temperature 80°C for 0.5 h, and obtain a colorless transparent viscous liquid of chlorohydrin glycoside; Cool down to room temperature, neutralize with saturated sodium hydroxide aqueous solution to pH ≈ 7; then add 0.04 mol aqueous trimethylamine aqueous solution with a concentration of 33.3% to the bottom of the chlorohydrin glucoside aqueous solution through a self-made dripping device, and control the addition within 1 hour; At a temperature of 40°C, react for 3 hours to obtain a light yellow transparent liquid of cationic methyl glucoside, and the product yield a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com