A kind of method for preparing lidocaine by continuous reaction

A technology of lidocaine and dimethylaniline, which is applied in the field of continuous reaction to prepare lidocaine, can solve the problems of excessive residue, cumbersome process operation, high price, etc., achieve reduced sewage discharge, environmentally friendly process, and improve use efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

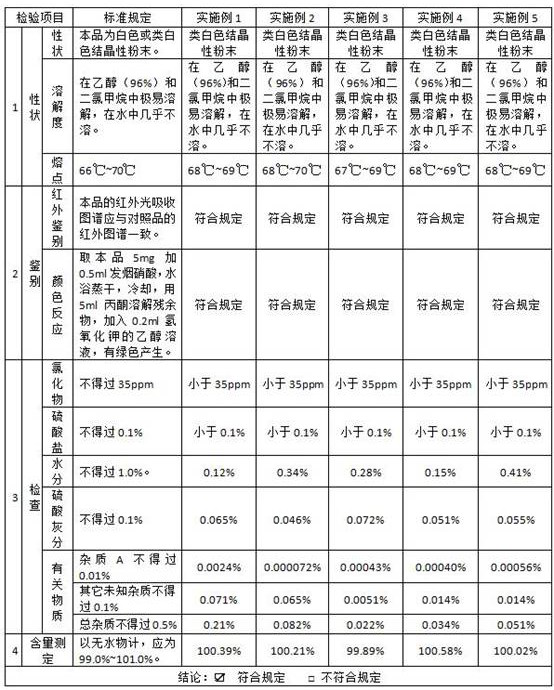

Examples

Embodiment 1

[0033] Put 300kg of 2,6-dimethylaniline and 1500kg of ethyl acetate into the reaction kettle, stir; add 307kg of chloroacetyl chloride dropwise, rise to 70-75°C after the dropwise addition, absorb the hydrogen chloride gas produced by deionized water as Dilute hydrochloric acid, apply mechanically to the acid adjustment in the next step; stir the reaction for 1 hour until the reaction is complete, cool down to 50°C, add 520kg of sodium carbonate, 15kg of potassium iodide, and 2400 kg of water, dropwise add 430kg of diethylamine, after the addition is completed, heat up to 70°C until the reaction Complete, cool down to normal temperature; stand still, separate liquid, adjust pH to 3.0-4.0 with dilute hydrochloric acid absorbed by the tail gas before adding the ethyl acetate layer, extract, stand still, separate liquid; recover ethyl acetate from the organic layer; add activated carbon to decolorize and filter the water layer, The filtrate was adjusted to pH=8.0-9.0 with sodium h...

Embodiment 2

[0035] Put 100kg of 2,6-dimethylaniline and 500kg of toluene into the reaction kettle and stir; add 102.5kg of chloroacetyl chloride dropwise, and the addition is completed in about 2 hours; Absorb the hydrogen chloride gas produced as dilute hydrochloric acid, apply mechanically to the next step to adjust the acid; stir for 1 hour until the reaction is complete, add 175 kg of sodium carbonate, 5 kg of potassium iodide, and 800 kg of water, continue stirring for 0.5 hours until uniformly mixed; add 145 kg of diethylamine , add in about 0.5-1 hour; heat preservation reaction for 6-9 hours until the reaction is complete, cool down to room temperature; stand still for 0.5-1 hour; separate liquid, add the dilute hydrochloric acid absorbed by the tail gas before adding the toluene layer to adjust the pH to 2.0-4.5, stir and extract , stand still for 30 minutes, and separate liquids; the organic layer recovers the solvent toluene; the water layer is added with activated carbon to sti...

Embodiment 3

[0037] Put 300kg of 2,6-dimethylaniline and 1500kg of ethyl acetate into the reaction kettle, stir; start to add 307kg of chloroacetyl chloride dropwise, and the dropwise addition is completed; raise the internal temperature to 70-75°C, and absorb the resulting Hydrogen chloride gas is used as dilute hydrochloric acid, which is applied to the acid adjustment in the next step; stir the reaction for 1 hour until the reaction is complete, cool down to 40-60 ° C, add 515 kg of potassium carbonate, 9 kg of potassium iodide, 2400 kg of water, add 362 kg of diethylamine, and heat up 65 -75°C until the reaction is complete, cool down to room temperature; stand still, separate liquids, add dilute hydrochloric acid absorbed by the tail gas before adding the ethyl acetate layer, adjust the pH to 3.0-3.5, extract, stand still, separate liquids; recover ethyl acetate from the organic layer; water layer Add activated carbon for decolorization and filtration, adjust the pH of the filtrate to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com