A kind of preparation method of zwitterionic alkyl glucoside for drilling fluid

An alkyl glycoside, zwitterion technology, applied in the preparation of sugar derivatives, drilling compositions, chemical instruments and methods, etc., to achieve the effects of mild reaction conditions, excellent temperature resistance, and short operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Use sodium hydroxide to adjust the pH value of the 50% cationic methyl glycoside aqueous solution to 8; add 50% cationic methyl glycoside aqueous solution 72.16g , 4.50 g of formaldehyde aqueous solution and 5.15 g of sodium bisulfite were reacted for 2 hours under normal pressure at a temperature of 80 ° C to obtain a reddish-brown zwitterionic methyl glucoside aqueous solution; the zwitterionic methyl glucoside aqueous solution was distilled and dehydrated under reduced pressure to obtain a viscous Zwitterionic methyl glycoside product.

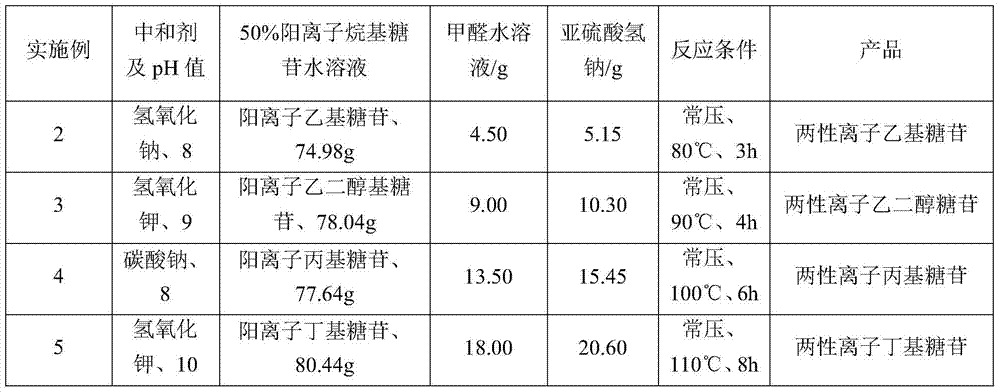

[0016] Embodiment 2~5 steps are identical with embodiment 1, and concrete reaction substance and reaction condition are as shown in table 1:

[0017] Table 1 Amounts of reacting substances and reaction conditions

[0018]

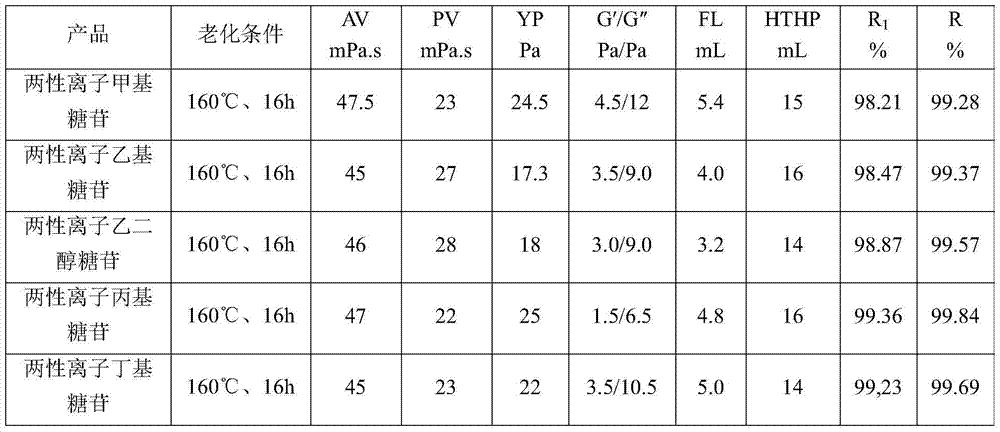

[0019] The properties of the zwitterionic alkyl glycoside products prepared in Examples 1 to 5 in drilling fluid are shown in Table 2:

[0020] Table 2 Comparison of drilling fluid performance indicators of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com