System and method for continuously synthesizing high-purity 3-chloro-1,2-propylene glycol

A high-purity, propylene glycol technology, applied in chemical instruments and methods, the preparation of organic compounds, the preparation of hydroxyl compounds, etc., can solve the problem that the molar ratio of deionized water to epichlorohydrin is too large, and the quality of different batches of products cannot be guaranteed. In order to avoid problems such as high reliability and increased operation time by distillation, the effects of low labor intensity, improved production environment and short reaction time are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

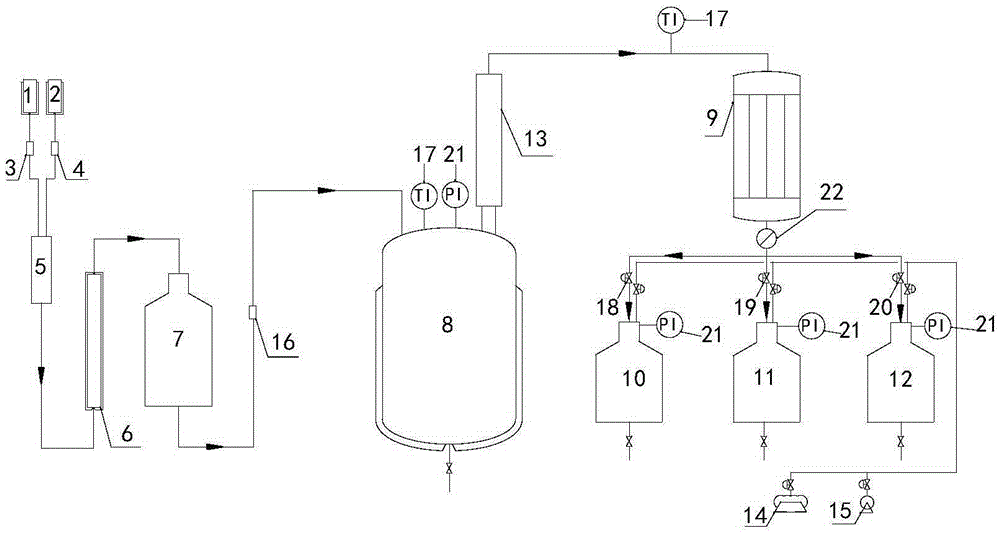

[0037] Such as figure 1 As shown, a system for continuously synthesizing high-purity 3-chloro-1,2-propanediol, the system includes a static mixer 5, a pipeline reactor 6, a hydrolyzate intermediate tank 7, a still 8, Distillation tower 13 and condenser 9, the first receiving tank 10, the second receiving tank 11 and the finished product receiving tank 12 are respectively connected on the outlet pipeline of described condenser 9;

[0038] The epichlorohydrin head tank 1 and the demineralized water head tank 2 are respectively connected with the input pipeline of the static mixer 5 through the epichlorohydrin metering pump 3 and the demineralized water metering pump 4;

[0039] A hydrolyzate feeding pump 16 is connected between the hydrolyzate intermediate tank 7 and the still 8;

[0040] The first receiving tank 10, the second receiving tank 11 and the finished product receiving tank 12 are simultaneously connected with a hydraulic jet vacuum pump 15 and a Roots-oil ring vacuu...

Embodiment 2

[0051] The system structure of this embodiment is the same as the system structure of Embodiment 1.

[0052] The method steps for the continuous synthesis of high-purity 3-chloro-1,2-propanediol are the same as in Example 1, except that:

[0053] In step (2), the speed of epichlorohydrin is 100kg / h, and the outlet pressure of demineralized water and epichlorohydrin is all adjusted to 2.3-2.4MPa respectively; In step (3), control pipeline reactor 6 top reaction temperature 79 -82° C.; in step (4), the rear fraction in the second receiving tank 11 is also added to the distillation still 8 .

[0054] The index of the prepared product: the product yield is 98.63%, and the purity (GC) is 99.74%.

Embodiment 3

[0056] The system structure of this embodiment is the same as the system structure of Embodiment 1.

[0057] The method steps for the continuous synthesis of high-purity 3-chloro-1,2-propanediol are the same as in Example 1, except that:

[0058] In step (2), the speed of epichlorohydrin is 105kg / h, and the outlet pressure of demineralized water and epichlorohydrin is all adjusted to 2.5-2.6MPa respectively; In step (3), control pipeline reactor 6 top reaction temperature 83 -86° C.; in step (4), the rear fraction in the second receiving tank 11 is also added to the distillation still 8 .

[0059] The index of the prepared product: the product yield is 98.93%, and the purity (GC) is 99.86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com