Detection method for 3-MCPD ester in oil product

A product and oil testing technology, which is applied in the field of 3-chloropropanol ester detection, can solve the problems of further improvement of sensitivity, specificity and precision, decreased sperm activity, and weakened reproductive capacity of male animals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] This embodiment is used to illustrate the method for detecting 3-chloropropanol esters in oil products provided by the present invention

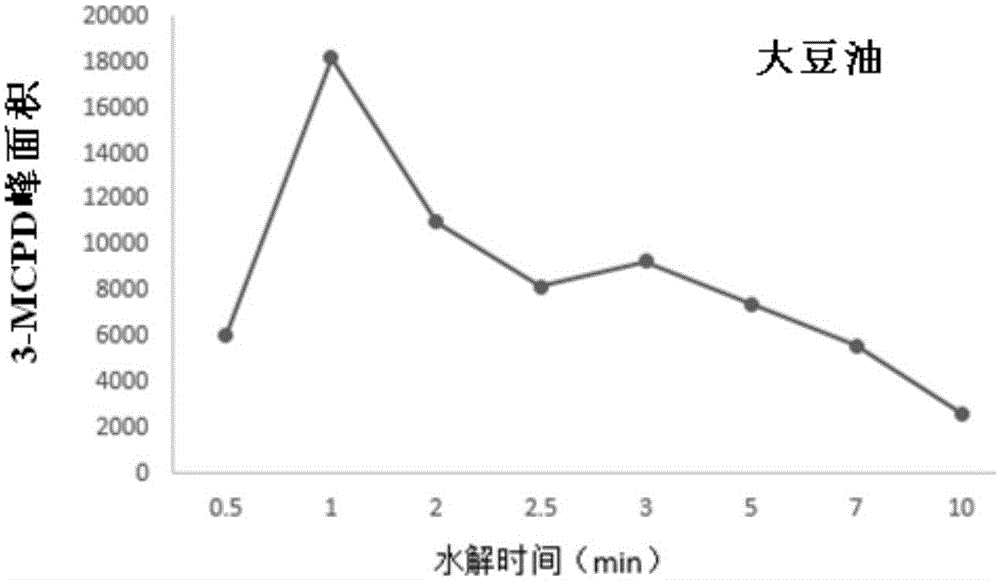

[0072] (1) Alkaline hydrolysis

[0073] Take 100 mg of soybean oil samples that do not contain 3-MCPD ester, and add 3-MCPD ester to prepare standard samples with concentrations of 50 μg / kg, 150 μg / kg, 300 μg / kg, 1500 μg / kg, and 12000 μg / kg, respectively. 6 repetitions, then add 0.0397mL deuterated isotope internal standard d 5 - 3-MCPD ester standard solution (126 μg / mL) and 100 μL of tBME, vortex to fully dissolve and mix. 200 μL of 25 g / L NaOH methanol solution (25 g NaOH dissolved in 1 L of methanol) was added thereto, vortexed for 1 min for hydrolysis, and a hydrolyzate was obtained.

[0074] (2) Acid neutralization

[0075] Add 600 µL of NaBr-H to the hydrolyzate from step (1) 2 SO 4 Mixed solution (3.5mL 25% H 2 SO 4 Dissolve in 100mL of 600g / L NaBr solution), vortex and mix well to carry out the neutralization reaction...

Embodiment 2

[0093] This embodiment is used to illustrate the method for detecting 3-chloropropanol esters in oil products provided by the present invention

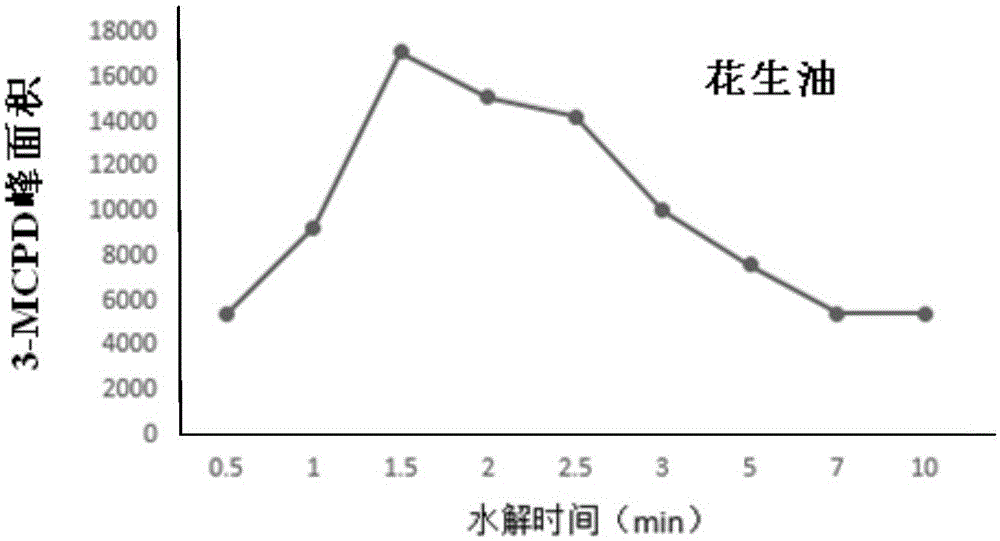

[0094] (1) Alkaline hydrolysis

[0095] Take 100 mg of olive oil samples that do not contain 3-MCPD esters, and add 3-MCPD esters to prepare standard samples with concentrations of 50 μg / kg, 150 μg / kg, 300 μg / kg, 1500 μg / kg, and 12000 μg / kg, each sample 6 repetitions, then add 0.0397mL deuterated isotope internal standard d 5 - 3-MCPD ester standard solution (126 μg / mL) and 80 μL of tBME, vortex to fully dissolve and mix. 180 μL of 28 g / L NaOH methanol solution (28 g NaOH dissolved in 1 L of methanol) was added thereto, vortexed for 1.5 min for hydrolysis, and a hydrolyzed product was obtained.

[0096] (2) Acid neutralization

[0097] Add 650 μL of NaBr-H to the hydrolyzate from step (1) 2 SO 4 Mixed solution (3.5mL 25% H 2 SO 4 Dissolve in 100mL of 600g / L NaBr solution), vortex and mix well to carry out the neutralization re...

Embodiment 3

[0105] This embodiment is used to illustrate the method for detecting 3-chloropropanol esters in oil products provided by the present invention

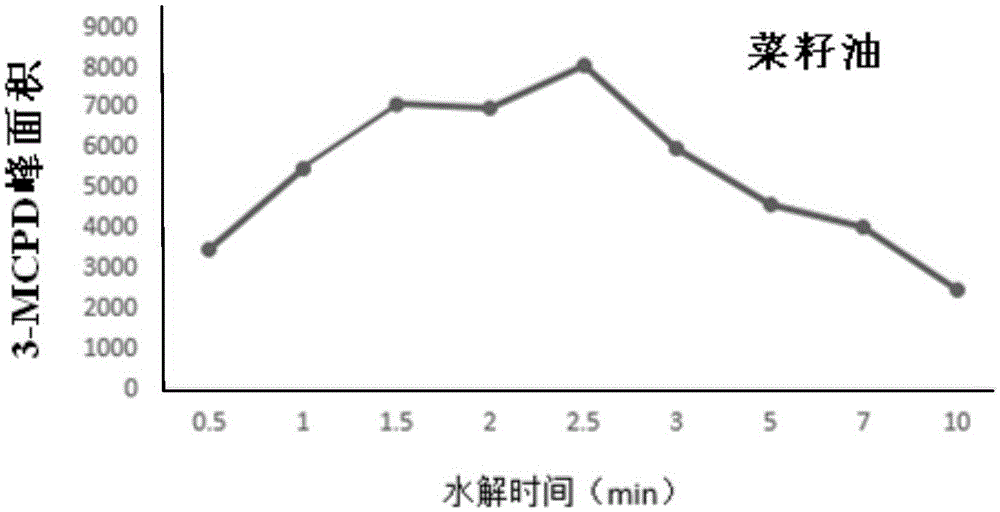

[0106] (1) Alkaline hydrolysis

[0107] Take 100 mg of sesame oil samples that do not contain 3-MCPD esters, and add 3-MCPD esters to prepare standard samples with concentrations of 50 μg / kg, 150 μg / kg, 300 μg / kg, 1500 μg / kg, and 12000 μg / kg, respectively, each sample 6 Repeat, then add 0.0397mL deuterated isotope internal standard d 5 - 3-MCPD ester standard solution (126 μg / mL) and 120 μL of tBME, vortex to fully dissolve and mix. 220 μL of 23 g / L NaOH methanol solution (23 g NaOH dissolved in 1 L of methanol) was added thereto, vortexed for 2.5 min for hydrolysis, and a hydrolyzed product was obtained.

[0108] (2) Acid neutralization

[0109] Add 550 µL of NaBr-H to the hydrolyzate from step (1) 2 SO 4 Mixed solution (3.5mL 25% H 2 SO 4 Dissolve in 100mL of 600g / L NaBr solution), vortex and mix well to carry out the neutra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com