Method for reducing 3-chlorine-1,2-propylene glycol ester during grease processing

A technology of oil processing and propylene glycol ester, which is applied in the direction of fat oil/fat refining and fat production, and can solve the problems of decolorization and deodorization effects such as decline, increase, and incomplete degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

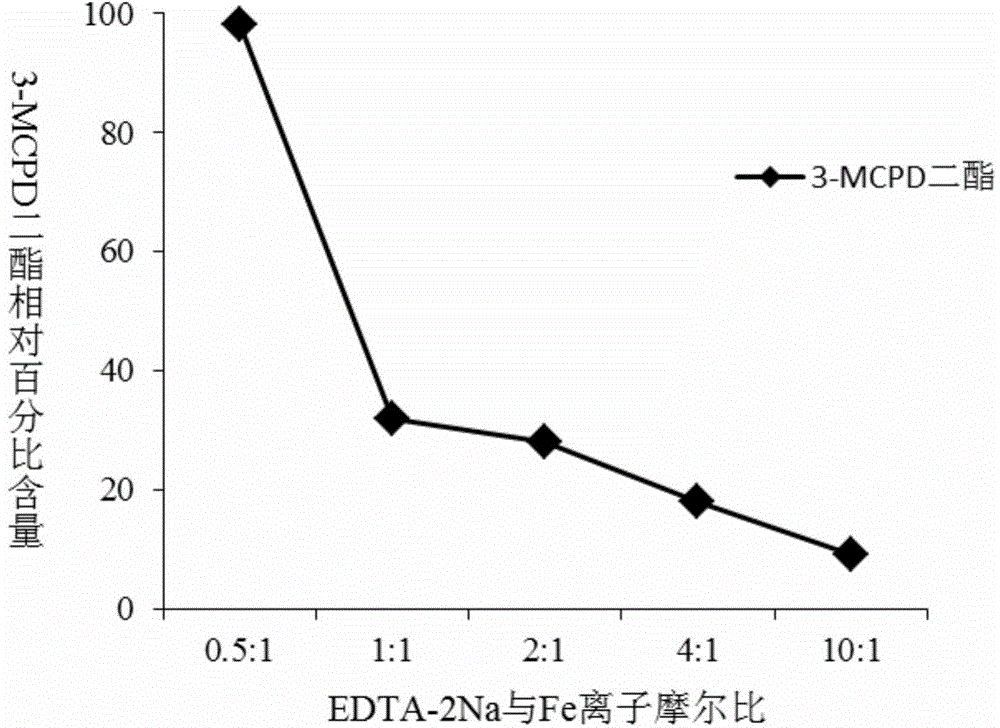

[0058] Add 2 mL of ferric chloride into 5 mL of glyceryl tristearate solution, the concentration of the solution is 0.5 mg / mL, and the solvent is n-hexadecane. After ultrasonic oscillation for 30 minutes, a series of different contents of EDTA-2Na (1.2, 2.3, 4.6, 9.2, 23.0 mg) were added, which, together with FeCl 3 The molar ratios are 0.5:1, 1:1, 2:1, 4:1, 10:1, respectively. The control group did not add such as EDTA-2Na. The reaction system was continuously stirred at 120° C. for 20 minutes, and then cooled to room temperature. The reaction solution was diluted with a 50-fold methanol:isopropanol=1:1 (v / v) solution, filtered and analyzed by UPLC-Q-TOF MS.

[0059] The content of the 3-MCPD diester that above-mentioned experiment generates is as follows figure 1 shown. The experimental results showed that with the increase of the ratio of EDTA-2Na and ferric chloride, the content of 3-MCPD ester formed in the reaction product decreased significantly. When EDTA-2Na and ...

Embodiment 2

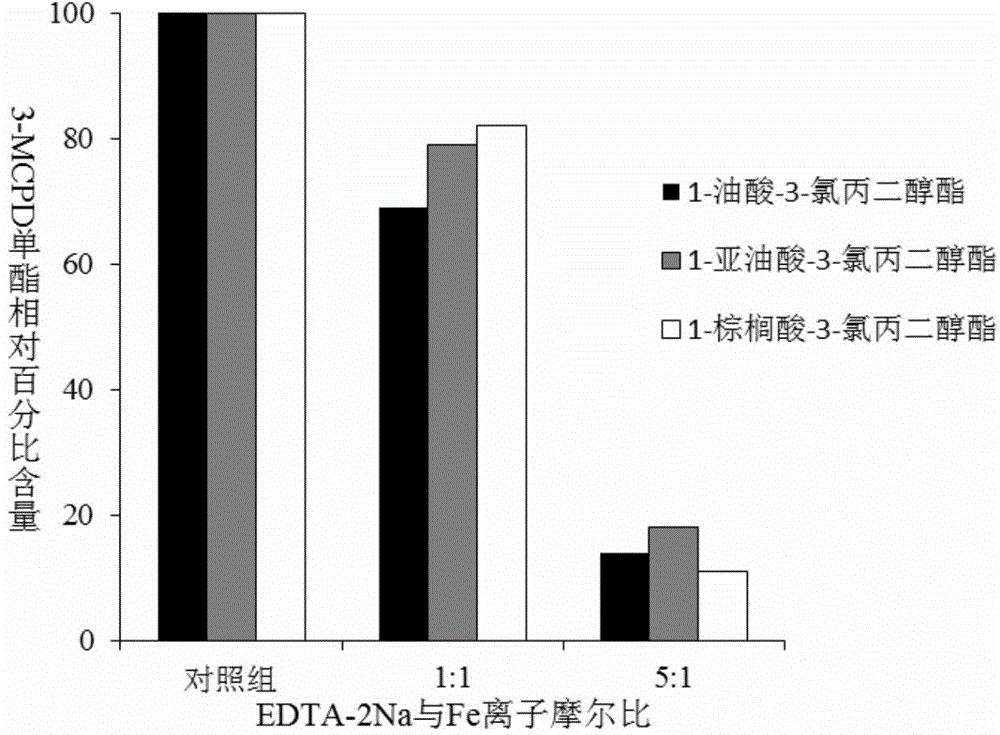

[0061] 400mg FeCl 3 Add to 80g refined palm oil, ultrasonic treatment for 5min, then add 0.938g and 4.655g EDTA-2Na respectively, the blank group does not add EDTA-2Na. Then under the protection of nitrogen, the pressure was maintained at 5 mbar with an oil pump, and the mixture was heated at 240° C. for 1 h. After the reaction was completed, the nitrogen gas was continuously fed. When the temperature was lower than 100°C, the pressure could return to normal atmospheric pressure. Take 10 μL of the sample and dilute it 100 times with isopropanol, filter it through a 0.2 μm GHP filter membrane, and detect the concentration of 3-MCPD ester (detection Method is identical with embodiment 1).

[0062] The content of the 3-MCPD ester that above-mentioned experiment generates is as follows figure 2 shown. With the increase of the ratio of EDTA-2Na and ferric chloride, the content of 3-MCPD ester in the reaction product decreased significantly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com