Coated ammunition and methods of making

a technology of coating and ammunition, applied in the field of coating ammunition, can solve the problems of affecting the quality of coating ammunition, and presenting a problem in terms of being observable from a long distance,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

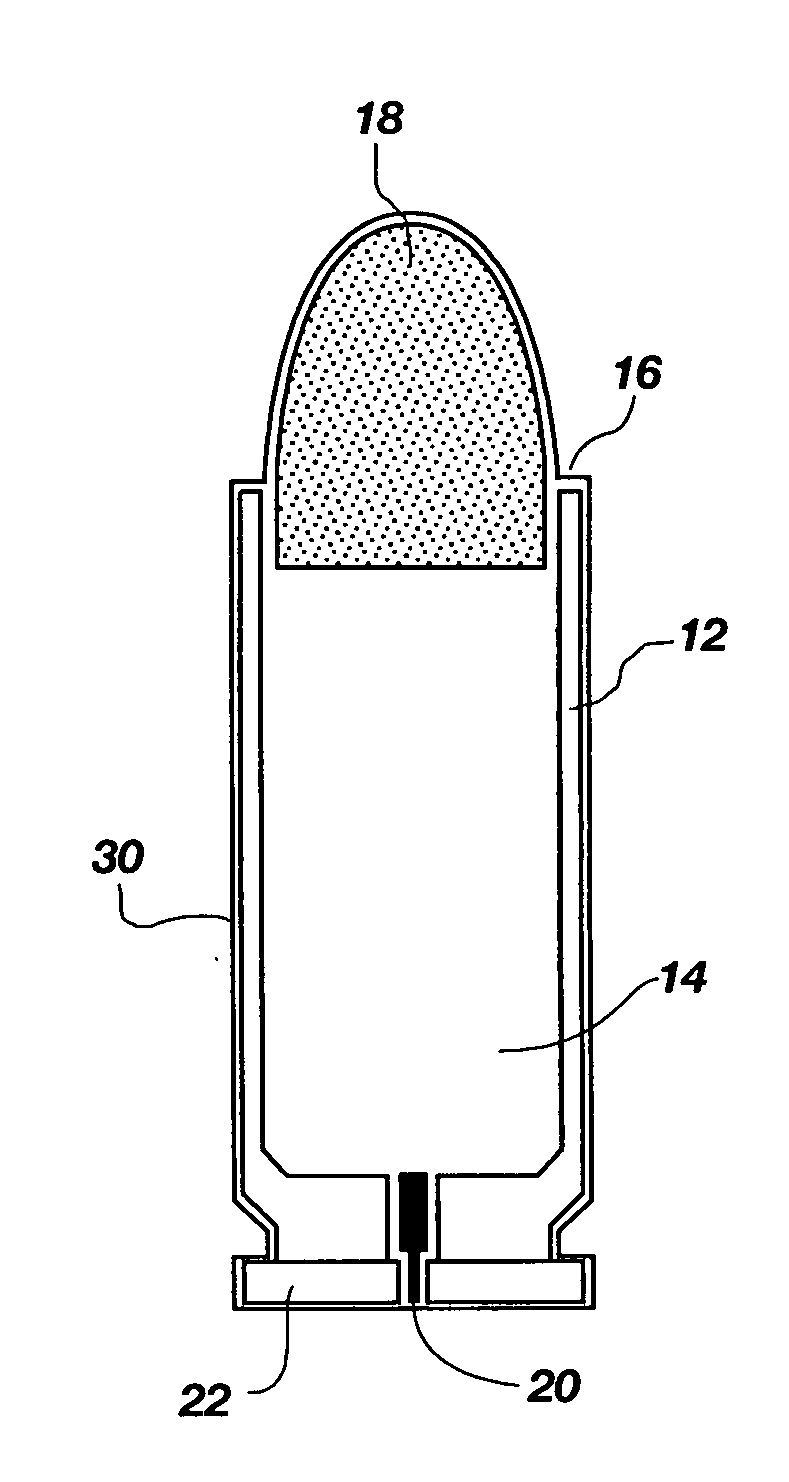

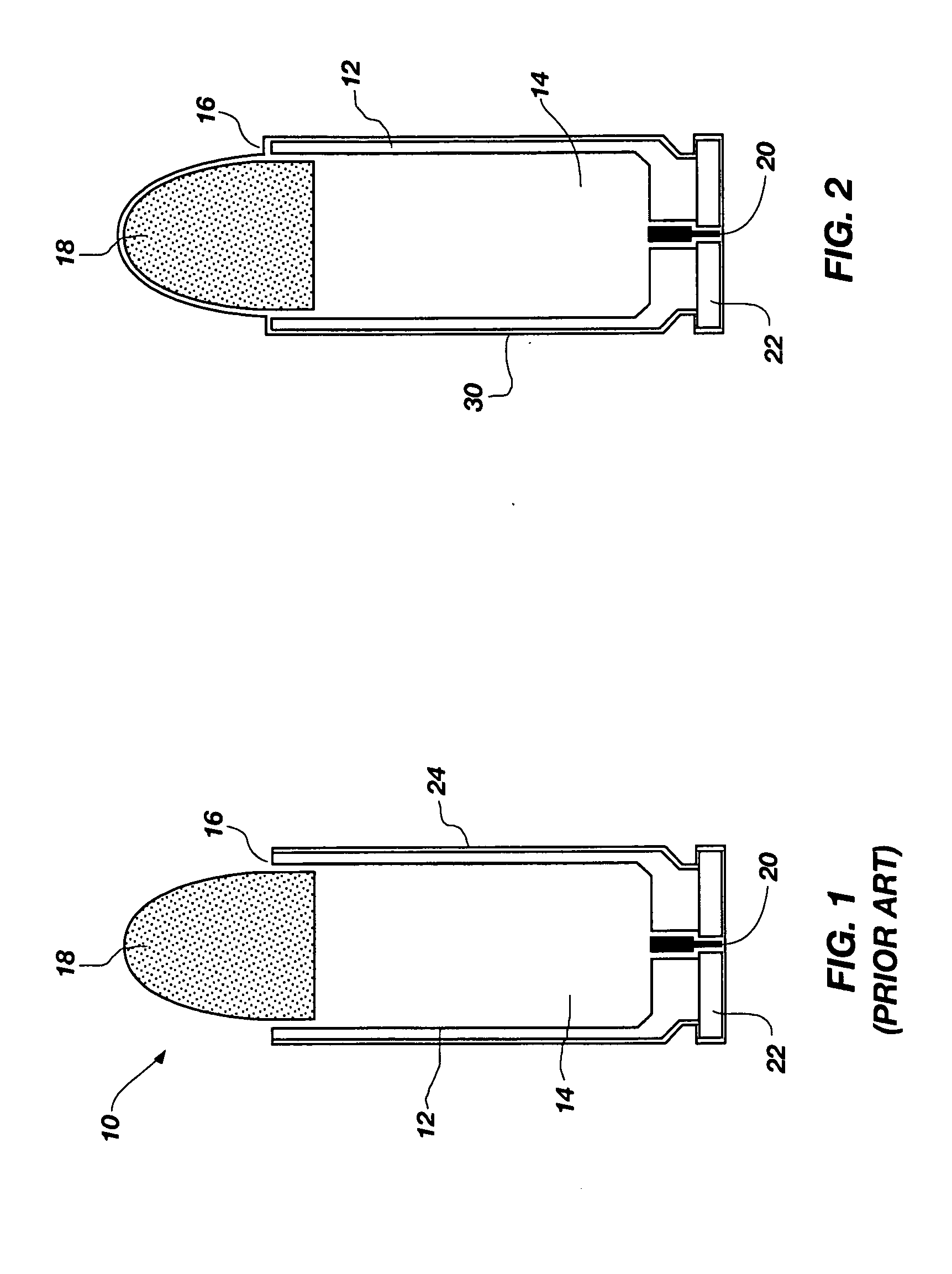

[0017]FIG. 1 illustrates a typical unit of ammunition, or bullet 10. As used herein, the term “ammunition” is meant to refer to any manner, form, design or configuration of a member that can be fired from a weapon, and which comprises at least a casing, propellant, a projectile and primer. Others terms that may be used herein that are considered synonymous with “ammunition” include “cartridge,”“shell,”“bullet,”“projectile” and “round.”

[0018]While the present invention can be adapted to use in the formation of any type of ammunition, the invention is described and illustrated herein by way of a small caliber ammunition cartridge.

[0019]A typical bullet 10, as depicted in FIG. 1, comprises a casing 12 which houses a propellant 14. The casing 12 has an open end 16 in which is positioned a projectile 18. A fuse or primer 20 is positioned through the closed end 22 of the casing 12 and is in contact with the propellant 14.

[0020]In prior art ammunition coating systems, the casing 12 is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com