Method for reducing 3-MCPD ester and/or glycidyl ester in oil

A technology for glycidyl esters and oils, which is applied in the field of reducing 3-MCPD esters and/or glycidyl esters in oils, and can solve the problems of reduced oil yield and low oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

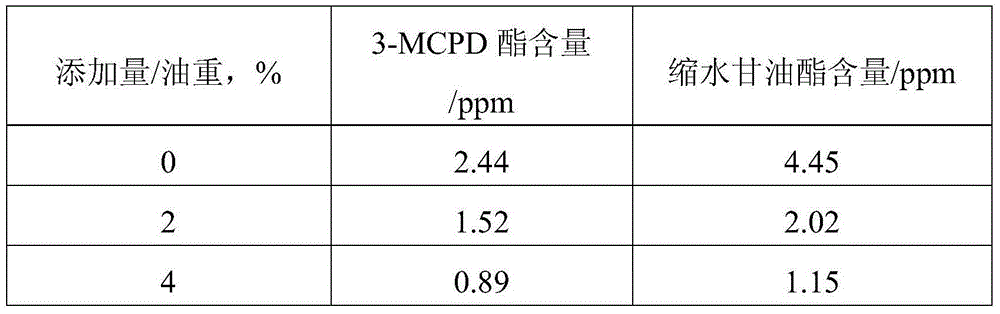

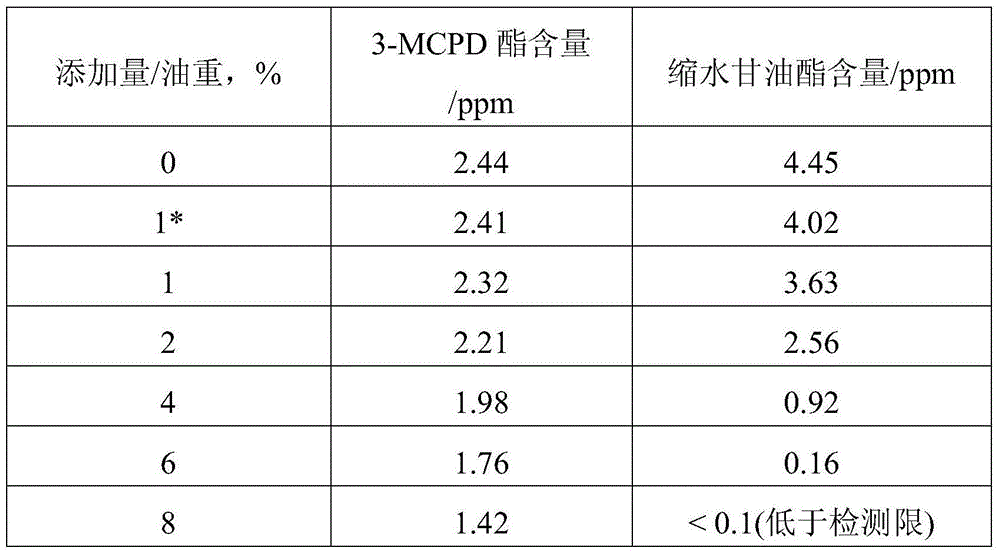

[0178] 3-MCPD ester and glycidyl ester in embodiment 1, common refined oil

[0179] 1. Degumming: Take 1000g of refined palm oil, add citric acid solution (50wt%) of 0.5% oil weight, stir at 80°C for 30 minutes, centrifuge at 4500rpm for 10 minutes, collect the oil phase, and obtain degummed oil;

[0180] 2. Alkali refining: Add NaOH solution (concentration 15%) to the degummed oil, until the excess alkali is 20%, that is, a total of 53.04g solution is added; after stirring at 80°C for 30 minutes, wash the oil phase with hot water with 20% oil weight To neutrality, centrifuge at 4500rpm for 15 minutes each time; then vacuum dry (90°C) for 10 minutes to obtain desoaped oil;

[0181] 3. Decolorization: Add Taiko Supreme1B (Taiko PGEO and SBE Gold) with 1wt% oil weight to the desoaped oil at 105°C, keep vacuum (25mbr) and stir for 30 minutes, and suction filter while it is hot (50°C) to obtain decolorized oil;

[0182] 4. Deodorization: Use nitrogen gas as the deodorization medi...

Embodiment 2

[0184] Embodiment 2, the effect of adding rosemary extract on 3-MCPD ester and glycidyl ester in deodorization section

[0185] According to the method in Example 1, the decolorized oil was prepared.

[0186] Add 6% rosemary extract of oily weight (purchased from Kalsec company) to the decolorized oil while stirring, then feed nitrogen as a deodorizing medium, and keep it for 1 hour at a vacuum of 10-20mbar at 240°C. ℃ to break the vacuum, and stop nitrogen, and collect refined palm oil 2.

[0187] After testing, the 3-MCPD ester content in the obtained refined palm oil 2 was 0.43ppm, and the glycidyl ester content was 0.33ppm.

Embodiment 3

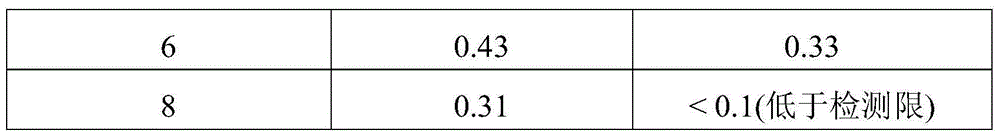

[0188] Embodiment 3, the effect of adding natural α-tocopherol on 3-MCPD ester and glycidyl ester in the deodorization section

[0189] According to the method in Example 1, the decolorized oil was prepared.

[0190] Add 6% natural alpha-tocopherol (purchased from DSM) to the decolorized oil while stirring, then feed nitrogen as a deodorizing medium, and keep it for 1 hour at a vacuum of 10-20mbar at 240°C , the vacuum was broken at 50° C., and the nitrogen flow was stopped, and refined palm oil 3 was collected.

[0191] After testing, the 3-MCPD ester content in the obtained refined palm oil 3 was 1.76ppm, and the glycidyl ester content was 0.16ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com