Method for reducing content of trichloropropanol in grease and ester thereof

A technology of oil and content, applied in the direction of oil/fat refining, fat production, etc., to achieve the effect of simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

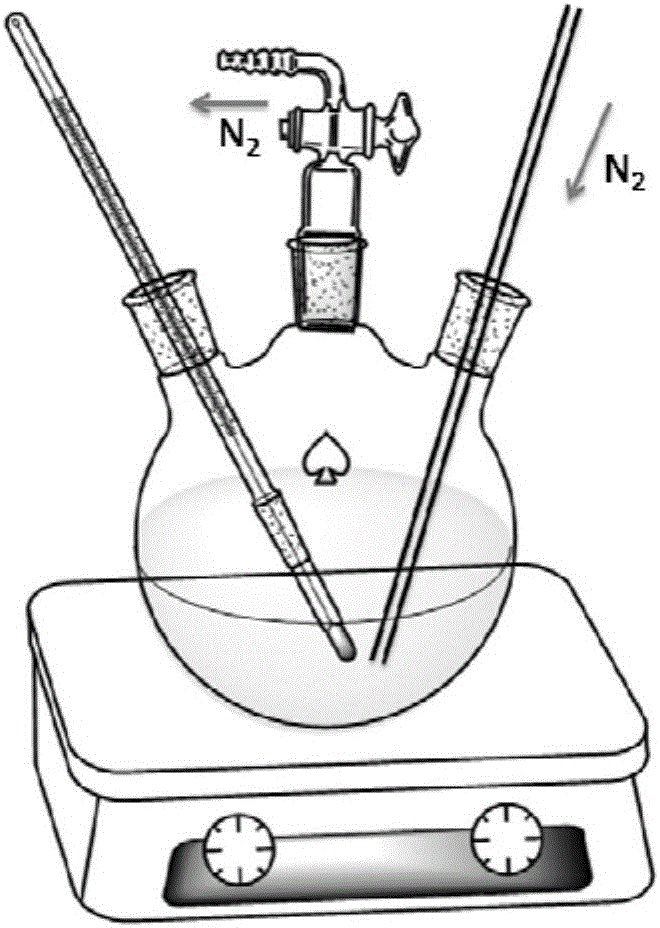

Method used

Image

Examples

preparation example Construction

[0108] The preparation method of potassium ascorbate, potassium erythorbate is as follows:

[0109] Mix ascorbic acid or erythorbic acid with potassium bicarbonate molar ratio 1:1.2 and add it into a three-necked flat-bottomed flask, then add a certain amount of water according to the mass concentration of potassium bicarbonate of 20%, react at 55°C for 1 hour under nitrogen, and add no Precipitate with water and ethanol to obtain two phases, take the lower layer of the target product phase and continue to rinse with absolute ethanol twice, and rotary evaporate to obtain a brownish-yellow solid, which is potassium ascorbate and potassium erythorbate.

[0110] The preparation method of potassium ascorbyl palmitate is as follows:

[0111] First add ascorbyl palmitate to 20 times of absolute ethanol and heat up to 50°C to dissolve, then add potassium bicarbonate and a small amount of water according to the molar ratio of ascorbyl palmitate and potassium bicarbonate at 1:2. Keep ...

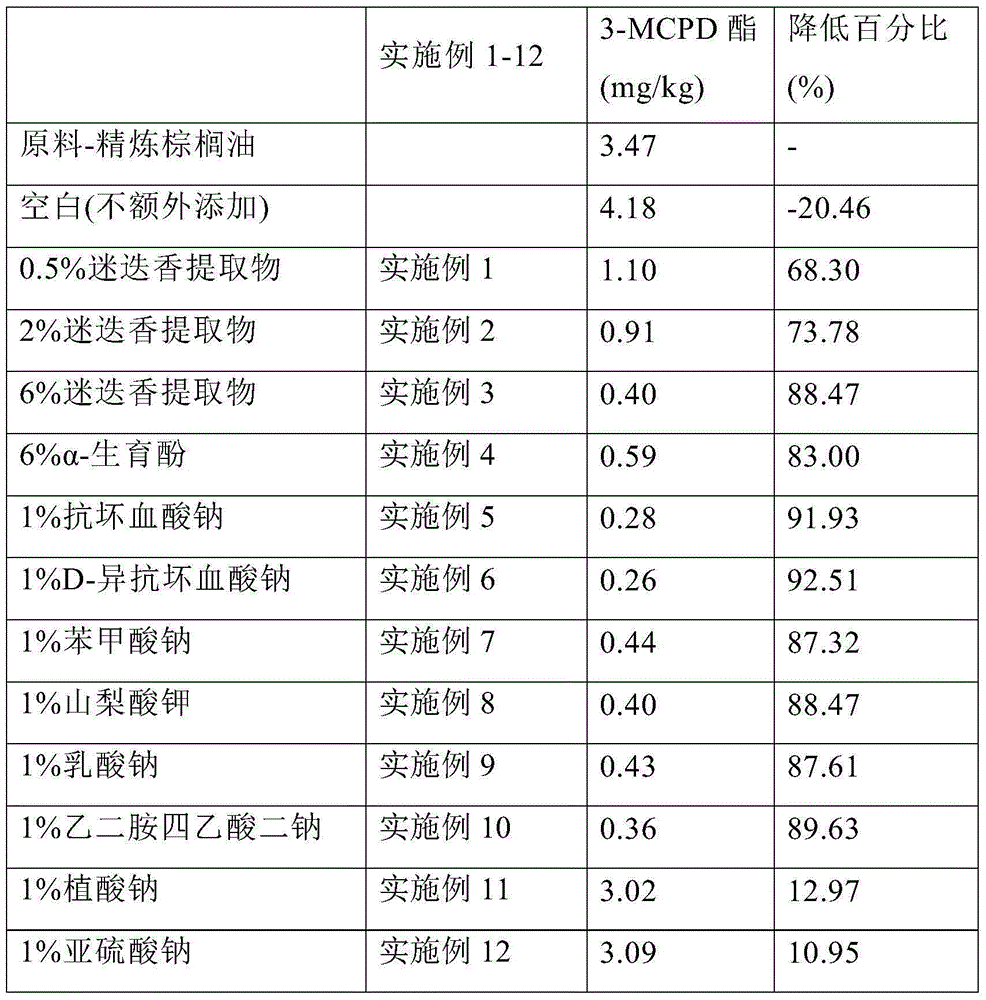

Embodiment 1-26

[0128] Refined palm oil (purchased from Kerry Special Oils (Shanghai) Co., Ltd.) 2 Stirring and heating to 200°C for 120 minutes and a pressure of 1 bar. After the reaction of the system is finished, the refined palm oil with reduced 3-MCPD ester content is obtained.

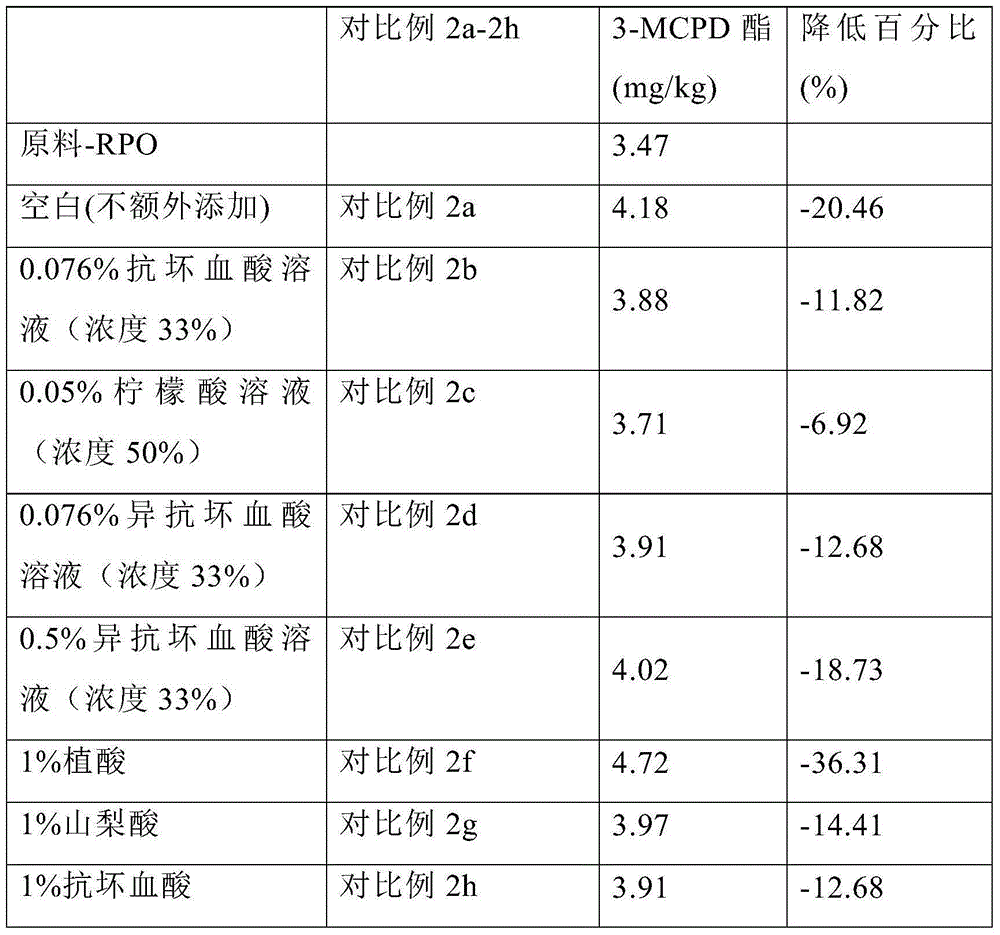

[0129]

[0130]

[0131]

[0132] Conclusion: Adding a certain amount of antioxidants such as rosemary extract and α-tocopherol can significantly reduce the content of 3-MCPD ester in RPO; adding a certain amount of antioxidant derivatives such as ascorbate, ascorbyl palmitate, potassium salt of TBHQ and Its fatty acid ester, phytate and its fatty acid ester all can reduce the 3-MCPD ester in the RPO of initial high 3-MCPD ester content, especially the good reduction rate of effect can reach more than 90%; Similarly, antioxidant Mixtures of derivatives also reduced 3-MCPD esters in RPOs initially high in 3-MCPD esters; antioxidant derivatives also reduced 3-MCPD esters in RPOs low in 3-MCPD esters.

Embodiment 27-32

[0134] With refined palm oil (purchased from Kerry Special Oils (Shanghai) Co., Ltd.) as raw material, add 1% potassium ascorbyl palmitate by oil weight, pass N 2 Stir and heat to a certain temperature and react for 120 minutes with a pressure of 1 bar. After the reaction of the system is finished, RPO with reduced 3-MCPD ester content is obtained.

[0135]

[0136] Conclusion: The reduction degree of 3-MCPD ester is different under different temperature. It can be seen from the above data that with the increase of temperature, the reduction degree of 3-MCPD ester first increases and then decreases, and there is an optimal temperature point in the middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com