High-salt liquid-state brewing soy sauce powder and preparation method thereof

A technology for brewing soy sauce, high-salt dilute state, applied in the field of condiments, can solve the problems of Japanese-style soy sauce powder easy to have a burnt taste, poor flavor, carcinogens, poor instant solubility, etc., and achieves excellent moisture absorption resistance and flowability The effect of good sex, strong fermented flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

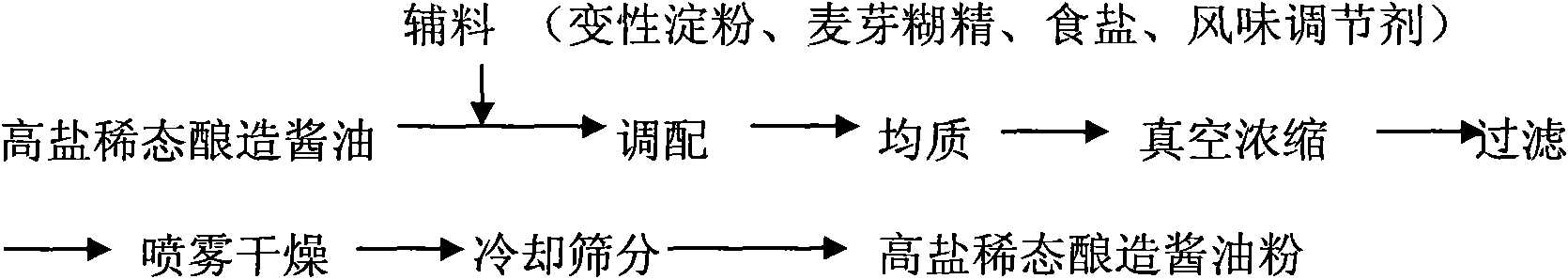

[0037] Preparation of high-salt dilute brewed soy sauce powder, such as figure 1 Shown:

[0038] (1) Preparation: Mix and dissolve the following ingredients according to mass percentage: 80% high-salt dilute brewed soy sauce, 4% modified starch, 6% maltodextrin, 6% salt, 1% yeast extract, and 0.05% I+G and Monosodium Glutamate 2.95%;

[0039] (2) Homogenization: Homogenize once at 40MPa the feed liquid prepared in step (1);

[0040] (3) Vacuum concentration: After the homogenized feed liquid is concentrated in vacuum at 60°C for 12 minutes, stop the concentration when the solid content of the feed liquid reaches at least 60g / 100ml;

[0041] (4) Filtration: filter the concentrated feed liquid through a 200-mesh filter cloth to remove impurities in the middle;

[0042] (5) Spray drying: put the sieved material liquid into the spray dryer, use the centrifugal atomizer on the top of the spray tower to atomize the sieved material liquid, and the atomized liquid droplets and the ...

Embodiment 2

[0046] Preparation of high-salt dilute brewed soy sauce powder, such as figure 1 Shown:

[0047] (1) Preparation: Mix and dissolve the following ingredients according to mass percentage: 85% high-salt dilute brewed soy sauce, 1% modified starch, 9% maltodextrin, 2% salt, 2% yeast extract, 0.5% I+G and sodium glutamate 0.5%;

[0048] (2) Homogenization: Homogenize the feed liquid prepared in step (1) once at 30MPa;

[0049] (3) Vacuum concentration: After the homogenized feed liquid is concentrated in vacuum at 58°C for 13 minutes, stop the concentration when the solid content of the feed liquid reaches at least 60g / 100ml;

[0050] (4) Filtration: filter the concentrated feed liquid through a 150-mesh filter cloth to remove impurities in the middle;

[0051] (5) Spray drying: put the sieved material liquid into the spray dryer, use the centrifugal atomizer on the top of the spray tower to atomize the sieved material liquid, and the atomized liquid droplets and the hot air di...

Embodiment 3

[0055] Preparation of high-salt dilute brewed soy sauce powder, such as figure 1 Shown:

[0056] (1) Blending: Mix and dissolve the following ingredients according to mass percentage: 77% high-salt dilute brewed soy sauce, 4% modified starch, 6% maltodextrin, 6% salt, 1% yeast extract, 1% lactic acid, white Granulated sugar 2%, I+G 0.05% and sodium glutamate 2.95%;

[0057] (2) Homogenization: Homogenize once at 40MPa the feed liquid prepared in step (1);

[0058] (3) Vacuum concentration: After the homogenized feed liquid is concentrated in vacuum at 60°C for 10 minutes, stop the concentration when the solid content of the feed liquid reaches at least 60g / 100ml;

[0059] (4) Filtration: filter the concentrated feed liquid through a 200-mesh filter cloth to remove impurities in the middle;

[0060] (5) Spray drying: put the sieved material liquid into the spray dryer, use the centrifugal atomizer on the top of the spray tower to atomize the sieved material liquid, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com