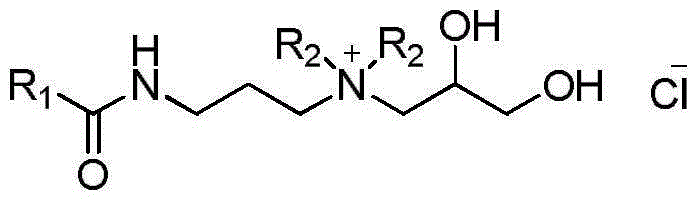

Cationic viscoelastic surfactant and preparation and application thereof

A surfactant and cationic technology, applied in the field of reservoir fracturing fluid, can solve the problems of poor temperature resistance of fracturing fluid, temperature resistance of only 95°C, and limited popularization and application, and achieve excellent sand suspension performance, Reservoir damage is small and the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

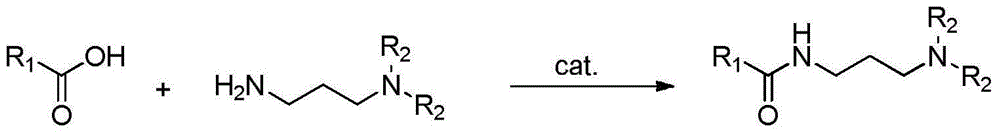

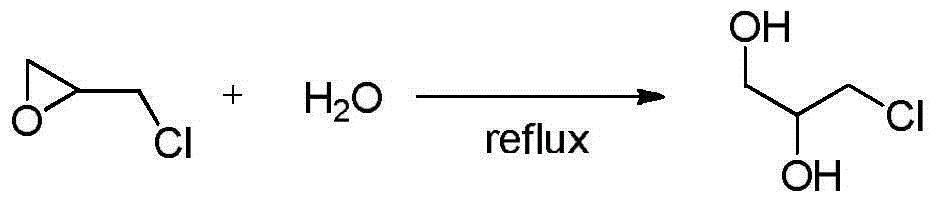

[0029] Embodiment 1: Long-chain fatty acid and dimethylaminopropylamine or diethylaminopropylamine are determined according to the ratio of n (long-chain fatty acid): n (dimethylaminopropylamine or diethylaminopropylamine)=1:1.1, Add 0.2mol of fatty acid into a 250mL three-necked flask, pass argon gas for 10 minutes to drive away oxygen, then add 0.22mol of dimethylaminopropylamine (diethylaminopropylamine), dropwise add 5wt% catalyst solution dissolved in an appropriate amount of water, dropwise After completion, the temperature was raised to 130-150°C, protected by argon, refluxed for 7-12 hours, cooled, and unreacted amine and water were distilled off under reduced pressure to obtain intermediate A of the desired amide product. The catalyst includes one or more mixtures of phosphoric acid, hypophosphorous acid, boron trifluoride, potassium acetate, sodium acetate, ammonium acetate, lithium acetate, sodium hydroxide, potassium hydroxide, lithium hydroxide, sodium ethoxide, po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com