Novel multi-child viscoelastic surfactant and its preparation method and application

A technology of surfactant and viscoelasticity, applied in the field of novel multi-sub viscoelastic surfactant and its preparation, can solve the problems of poor temperature resistance, high cost, poor sand suspension performance, etc., and achieves less raw material consumption and cost Low, low reservoir damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

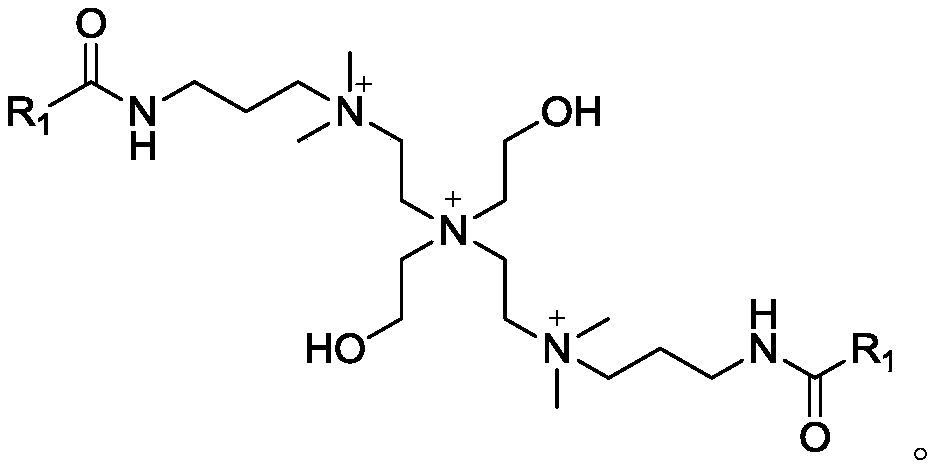

Image

Examples

Embodiment 1

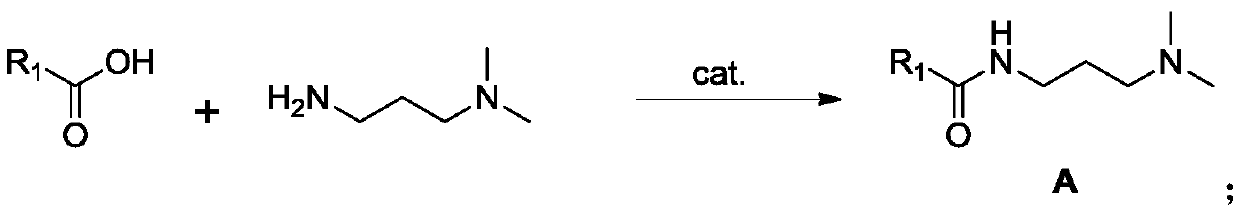

[0027] A preparation method of a novel multi-child viscoelastic surfactant, comprising the following steps:

[0028] (1) Add 0.2mol of behenic acid into a 250mL three-necked flask, pass argon gas for 10min to remove oxygen, then add 0.22mol of dimethylaminopropylamine, then dropwise add a solution with a water-soluble hypophosphorous acid content of 5wt%, dropwise After completion, the temperature was raised to 150-170°C, protected by argon, refluxed for 12 hours, cooled, and unreacted amine and water were distilled off under reduced pressure to obtain the desired amide product intermediate A;

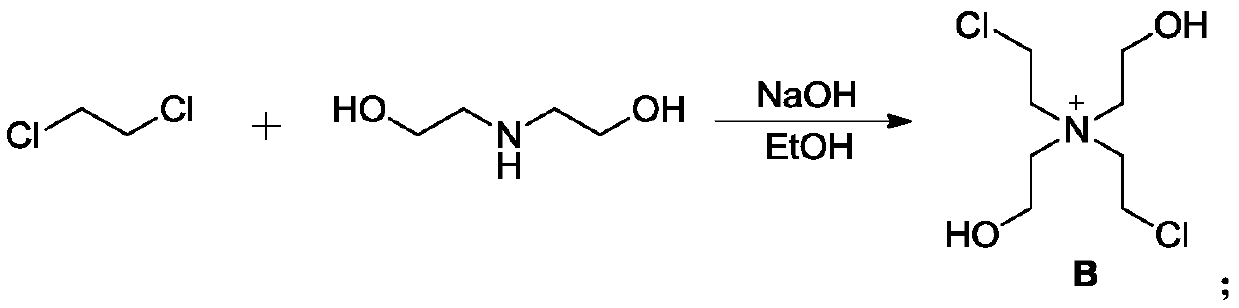

[0029] (2) Add 0.1mol of dichloroethane, 0.2mol of diethanolamine, appropriate amount of NaOH and 100mL of ethanol into a 250mL round bottom flask, condense and reflux in an oil bath at 80°C for 24 hours, cool to room temperature to remove the solvent, and obtain intermediate B;

[0030] (3) Add 0.2mol of amide product intermediate A and 0.1mol of intermediate B to a 500mL round bottom...

Embodiment 2

[0032] A preparation method of a novel multi-child viscoelastic surfactant, comprising the following steps:

[0033] (1) Add 0.2mol of behenic acid into a 250mL three-necked flask, pass argon gas for 10min to remove oxygen, then add 0.24mol of dimethylaminopropylamine, then add dropwise the solution of 3wt% hypophosphorous acid dissolved in water, dropwise After completion, the temperature was raised to 150 ° C, protected by argon, refluxed for 7 hours, cooled, and unreacted amine and water were removed by vacuum distillation to obtain the desired amide product intermediate A;

[0034] (2) Add 0.1mol of dichloroethane, 0.25mol of diethanolamine, appropriate amount of NaOH and 100mL of ethanol into a 250mL round bottom flask, condense and reflux in an oil bath at 90°C for 20 hours, cool to room temperature to remove the solvent, and obtain intermediate B;

[0035] (3) Add 0.2 mol of amide product intermediate A and 0.1 mol of intermediate B to a 500mL round bottom flask and mix...

Embodiment 3

[0037] A preparation method of a novel multi-child viscoelastic surfactant, comprising the following steps:

[0038] (1) Add 0.2mol stearic acid into a 250mL three-necked flask, vent argon for 10min to remove oxygen, then add 0.26mol dimethylaminopropylamine, then add dropwise a solution of 5wt% sodium acetate dissolved in water, dropwise After completion, the temperature was raised to 164 ° C, protected by argon, refluxed for 8 hours, cooled, and unreacted amine and water were removed by vacuum distillation to obtain the desired amide product intermediate A;

[0039] (2) Add 0.1mol of dichloroethane, 0.3mol of diethanolamine, appropriate amount of NaOH and 100mL of ethanol into a 250mL round bottom flask, condense and reflux in an oil bath at 86°C for 24 hours, cool to room temperature to remove the solvent, and obtain intermediate B;

[0040] (3) Add 0.2 mol of amide product intermediate A and 0.1 mol of intermediate B to a 500mL round bottom flask and mix, add ethanol as a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com