Low-voltage transparent electrothermal film

An electric heating film and low voltage technology, applied in the field of transparent electric heating film and its preparation, can solve the problems of burning electric heating film, poor heating uniformity, lower resistance, etc., to increase heating uniformity, ensure heating uniformity, and improve heating The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

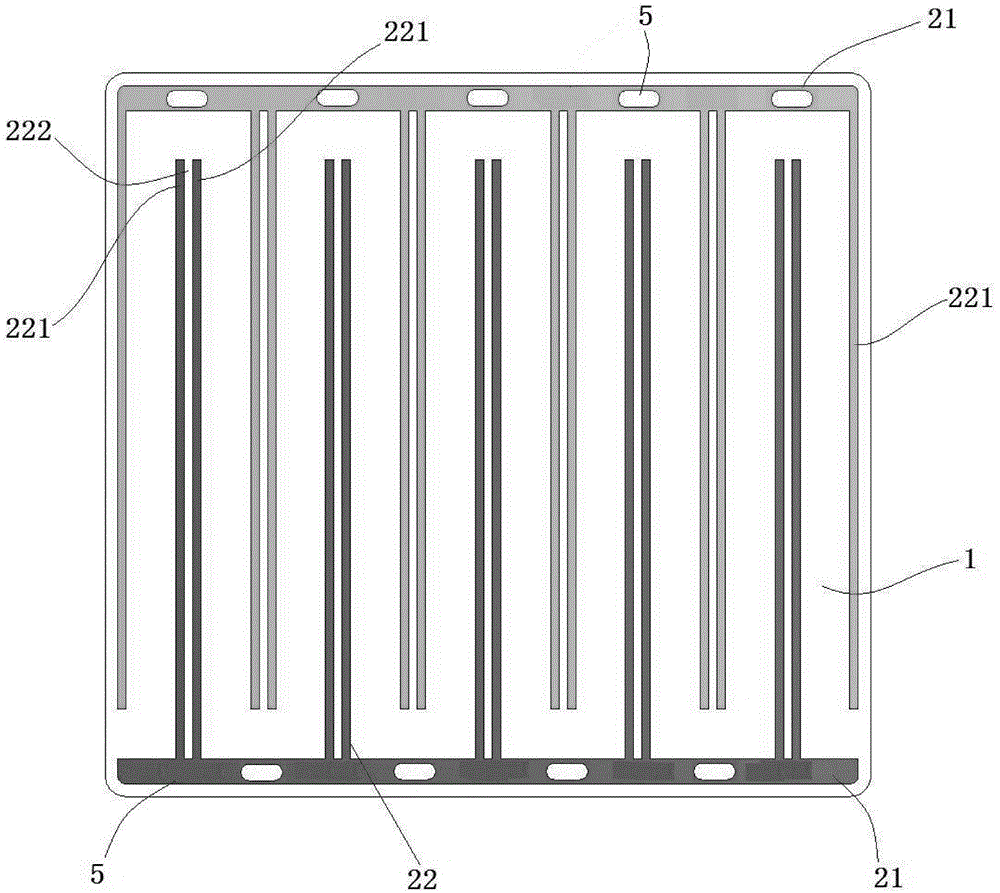

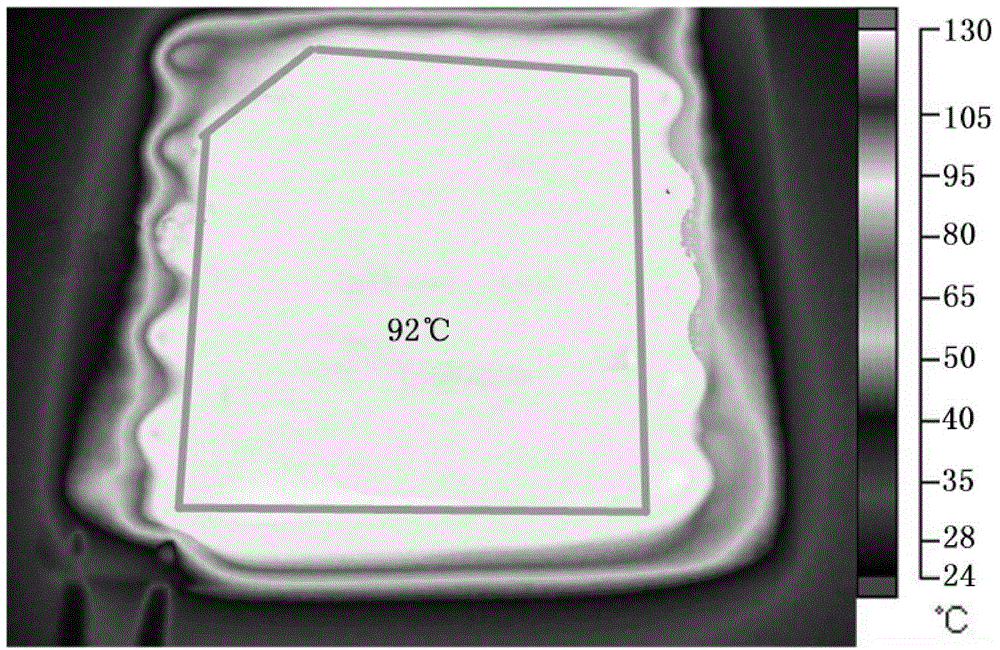

[0107] see figure 2 , 3 As shown, single-layer graphene is used as a low-voltage transparent electrothermal film for heating components, and the electrodes are printed with silver paste.

[0108] The preparation process is as follows:

[0109]1. Transfer a layer of graphene on PET (transparent substrate) with a thickness of 125 μm. The graphene has been doped and the square resistance is 250Ω / □;

[0110] 2. Use screen printing equipment to print the silver paste electrode pattern on the transferred graphene, the shape of the pattern is as follows: figure 2 As shown, 1--transparent conductive layer, 2--electrode, 21--bus bar, 22-inner electrode, 221-single electrode, 5-the first opening, the inner electrode spacing is 6mm, the length is 108mm, a total of 11 Strips, a total of 10 intervals are produced, and the thickness of the silver paste is 25 μm;

[0111] 3. Bake the printed electrode pattern in an oven to solidify the silver paste. The baking temperature is 130°C for ...

Embodiment 2

[0121] In order to further ensure that the difference between the highest voltage and the lowest voltage at different positions of the bus bar does not exceed 10%, this embodiment adjusts the width of the bus bar and the number of bifurcated electrodes as internal electrodes on the basis of the first embodiment. Specifically: the distance between the internal electrodes is 6 mm, the length is 108 mm, there are 15 bars in total, and 14 intervals are generated in total, and the width of the bus bar is 8 mm.

[0122] After testing, the difference between the highest voltage and the lowest voltage at different positions of the bus bar is 0.5%.

Embodiment 3

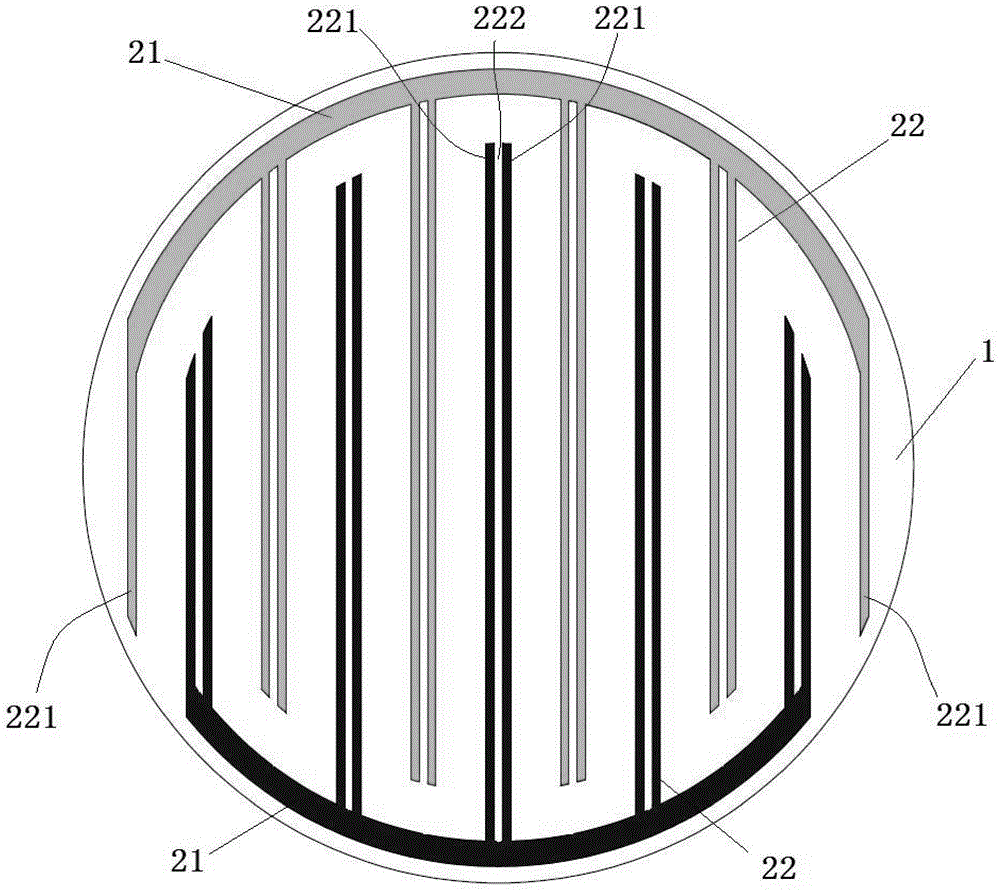

[0124] see Figure 6 As shown, the double-layer graphene is used as a low-voltage transparent electrothermal film for heating components, and the preparation process is as follows:

[0125] 1. Lay the copper foil with grown graphene (graphene has been doped, the square resistance is 120Ω / □) and the PET with a maximum thickness of 125 μm through UV glue, and the thickness of the copper foil is 25 μm;

[0126] 2. Curing the UV glue, the wavelength is 365nm, and the energy is 1000mJ / cm 2 ;

[0127] 3. Use screen printing equipment to print a peelable mask on the laminated copper foil, the pattern shape is as follows Figure 4 As shown, the internal electrode spacing is 3mm, the length is 108mm, and there are 11 electrodes in total, resulting in 10 intervals in total;

[0128] 4. Bake the printed electrode pattern in an oven to cure the peelable glue. The baking temperature is 135°C for 40 minutes;

[0129] 5. Cut out bifurcated electrodes by one-time forming with cutting die....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com