High-temperature and high-strength titanium alloy and processing method thereof

A processing method and titanium alloy technology, which is applied in the field of titanium alloy processing, can solve the problems of oxidation resistance and high temperature performance reduction, and achieve the effects of plasticity enhancement, precipitation promotion, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

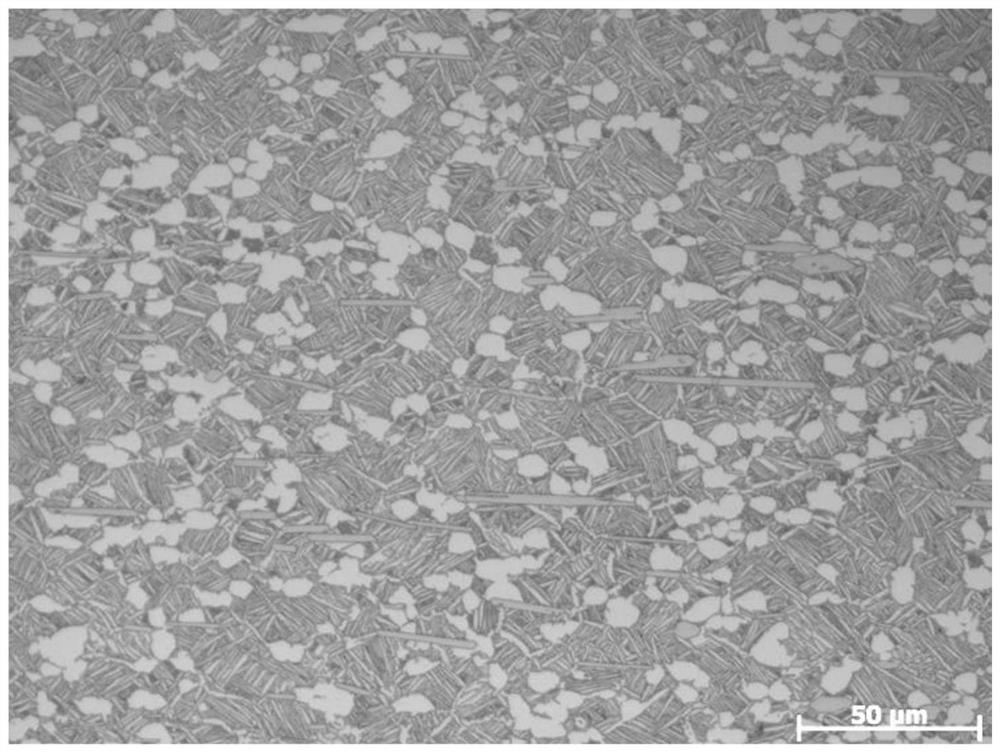

Embodiment 1

[0040] A TiB-reinforced titanium-based alloy ingot with a diameter of 380 mm was prepared by smelting method. The β transformation temperature of the alloy ingot was detected by metallographic method to be 1050 ° C. The chemical composition of the ingot is listed in Table 2.

[0041] Table 2 Example 1 TiB reinforced titanium-based alloy alloy composition (mass percentage, wt.%)

[0042]

[0043] Step 1): The alloy ingot is heated to 1200°C, kept warm for 24 hours, and then released from the furnace. The upsetting and elongation deformation is completed once on the hydraulic press. The forging ratio of each upsetting and elongation is 2. After forging, it is air cooled and completed. Homogenization of ingots. Then the ingot is heated to 1090°C, and the upsetting and elongation deformation is carried out for one fire, and one upsetting and one elongation are completed for each fire, and the forging ratio of upsetting and elongation is both 2. of blanks.

[0044] Step 2): He...

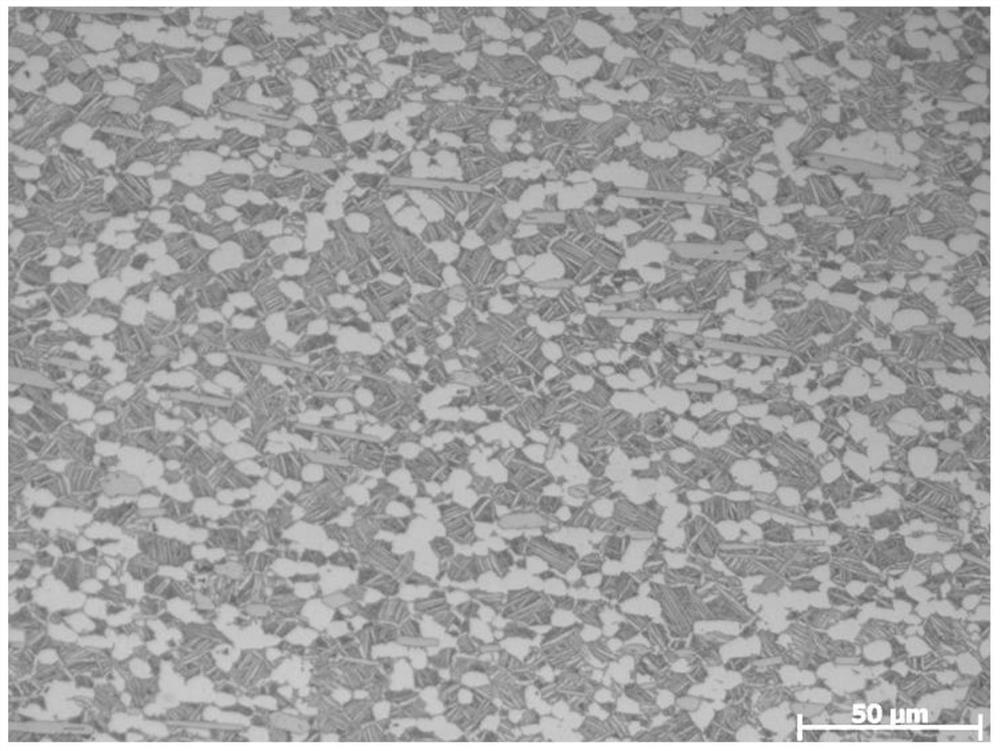

Embodiment 2

[0050] A TiB-reinforced titanium-based alloy ingot with a diameter of 380mm was prepared by smelting method. The β transformation temperature of the alloy ingot was detected by metallographic method to be 1035°C. The chemical composition of the ingot is listed in Table 4.

[0051] Table 4 Example 2 TiB reinforced titanium-based alloy alloy composition (mass percentage, wt.%)

[0052]

[0053] Step 1): The alloy ingot is heated to 1150°C, held for 20 hours, and then released from the furnace. The upsetting and elongation deformation is completed once on the hydraulic press. The forging ratio of each upsetting and elongation is 2.0. After forging, air cooling is completed. Homogenization of ingots. Then the ingot is heated to 1080°C, three upsetting and three drawing are completed in two fires, and the forging ratio of upsetting and drawing is both 1.8. After forging, it is air-cooled to obtain the billet after blanking.

[0054] Step 2): Heat the billet obtained in step 1) ...

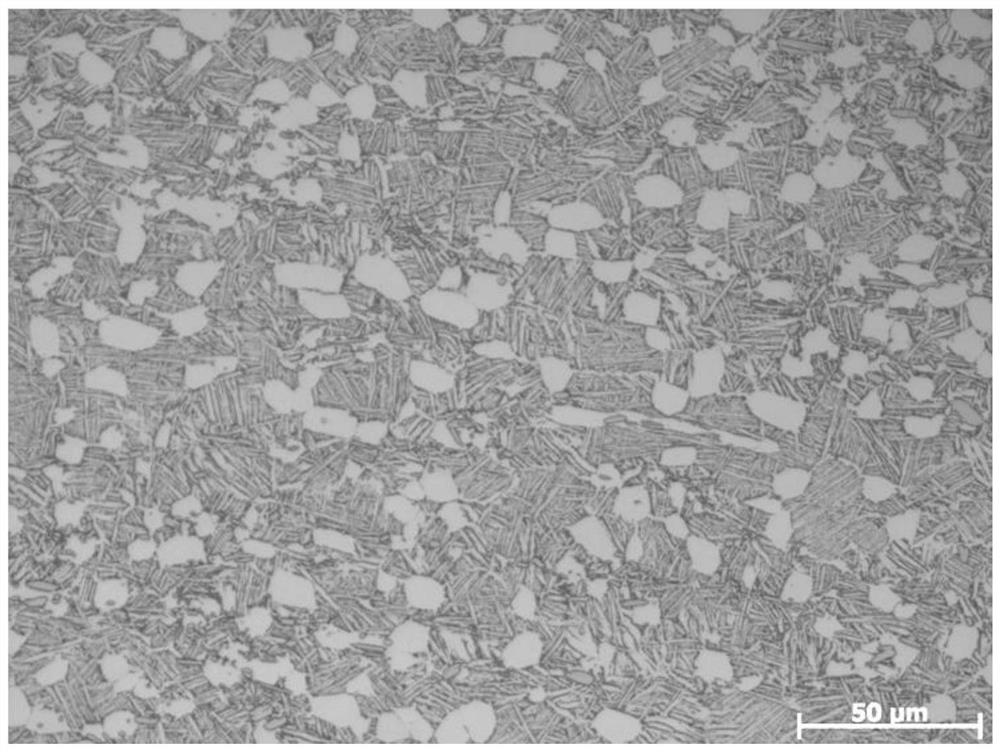

Embodiment 3

[0060] Step 1): A TiB-reinforced titanium-based alloy with a diameter of 300 mm was prepared by a hot-press sintering method, the sintering temperature was 1300° C., the pressure was 10 MPa, and the holding time was 3 hours. The β transformation temperature of the alloy ingot detected by metallographic method is 1040°C, and the chemical composition of the ingot is listed in Table 6.

[0061] Table 6 Example 3 TiB reinforced titanium-based alloy alloy composition (mass percentage, wt.%)

[0062]

[0063] Step 2): Heat the material to 1085°C successively, complete two upsetting and two drawing, the forging ratio of upsetting and drawing is both 2, and air-cool after forging.

[0064] Step 3): Heat the billet obtained in step 2) to 1015°C, carry out upsetting and elongating deformation on the hydraulic press for 2 fires, complete one upsetting and one elongation for each fire, and the forging ratio of each upsetting and elongation is uniform 2, air cooling after forging. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com