Heat treatment method for cast aluminum alloy gearbox

A technology of casting aluminum alloy and heat treatment method, which is applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as plasticity decline, strength not reaching an ideal high value, internal stress removal and aging strengthening cannot achieve ideal results at the same time, etc. , to achieve the effect of low quenching water temperature, large aging strengthening effect, and improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

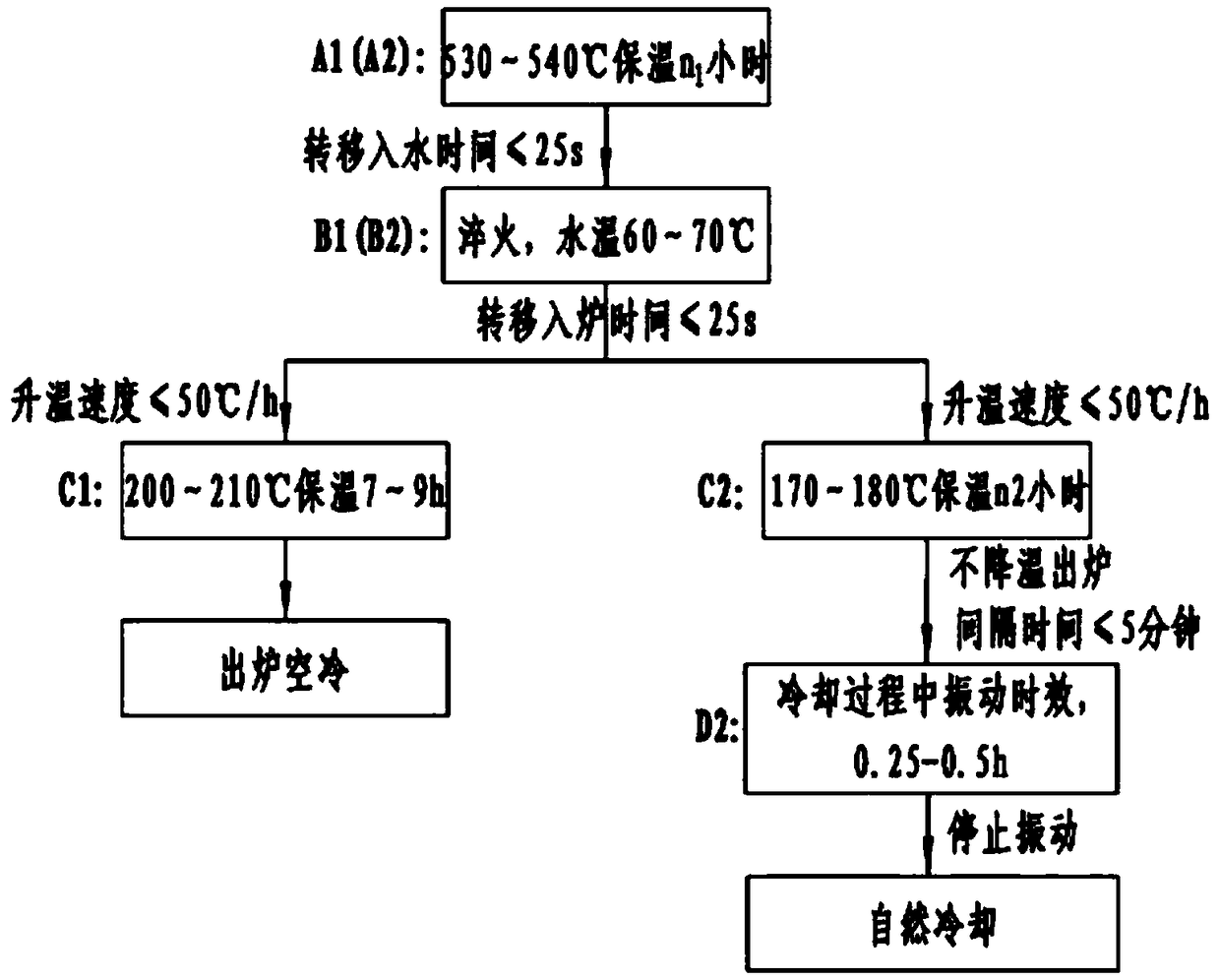

[0028] as attached figure 1 Shown, a kind of heat treatment method of casting aluminum alloy gearbox, comprises the following steps:

[0029] A1: The cast aluminum alloy gearbox is firstly subjected to solution treatment, the solution treatment temperature is 535°C, and the holding time is n 1 hours, where n 1 It is equal to dividing the maximum wall thickness of the gearbox by 25 mm and then adding 1. In this embodiment, the maximum wall thickness of the gearbox is 65 mm. Dividing by 25 mm equals 2.6, and the heat preservation is 3.6 hours;

[0030] B1: Immediately put the gear box into the water after the solution treatment, the transfer time is not longer than 25s, and the quenching temperature is 65°C;

[0031] C1: Immediately after quenching, transfer it into the furnace for aging treatment. The aging temperature is 205°C. The temperature rise rate in the furnace for aging treatment is not greater than 50°C. After holding time for 8 hours, it is out of the furnace and a...

Embodiment 2

[0035] as attached figure 1 Shown, a kind of heat treatment method of casting aluminum alloy gearbox, comprises the following steps:

[0036] A2: The cast aluminum alloy gearbox is subjected to solution treatment first, the solution treatment temperature is 538°C, and the holding time is n 1 hours, where n 1 Equal to the maximum wall thickness of the gearbox divided by 25 mm and then add 1. In this embodiment, the maximum wall thickness of the gearbox is 65 mm, divided by 25 mm equals 2.6, then the heat preservation is 3.6 hours;

[0037] B2: Immediately put the gearbox into water after the solution treatment, the transfer time is not longer than 25s, and the quenching temperature is 62°C;

[0038] C2: Immediately after quenching, it is transferred into the furnace for aging treatment. The aging temperature is 175°C. The existing aging treatment temperature is the incomplete aging temperature or the complete aging temperature. The temperature of the present invention is betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com