Welding technology for nickel base alloy build-up welding of marine low-speed machine air valve sealing face

A technology of nickel-based alloy and welding process, which is applied in the field of surfacing nickel-based alloy welding process for the sealing surface of marine low-speed engine valves, which can solve the problems of harsh service environment of the gas valve, early failure of the sealing surface of the gas valve, and affecting the normal operation of the diesel engine, etc. , achieve excellent crack resistance and high temperature corrosion resistance, excellent corrosion resistance and oxidation performance, and reduce ship operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Firstly, select the power source for MIGMAW: the power source used for MIGMAW is an inverter welding power supply, the dynamic characteristics of the power supply are adjusted through inductance, and the secondary welding parameter settings include advance gas feeding time, slow wire feeding, thermal Arc starting current, thermal starting current duration, crater current drop time, crater current duration, crater current value, wire burnback, delayed air supply time, spot welding time, the welding process can be controlled in real time. Main technical parameters of the power supply: input voltage + / -15% (50-60Hz): 3x400 V, maximum input current: 28.2 A, power / 100%: 19.3 kVA, maximum power: 24.2 kVA, no-load power consumption: 40 VA, Current range: 15-400 A, wire feed speed: 0.5-30 m / min, wire diameter: 0.6-2.4 mm, maximum gas pressure: 0.5 MPa (5.0 bar).

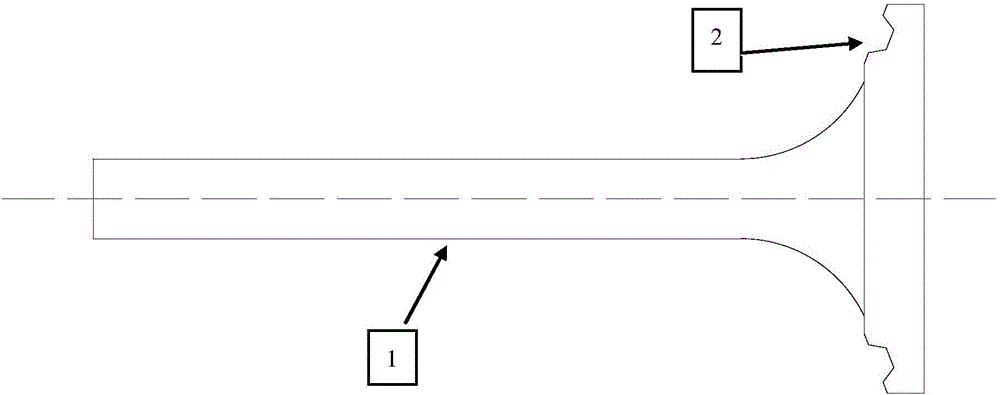

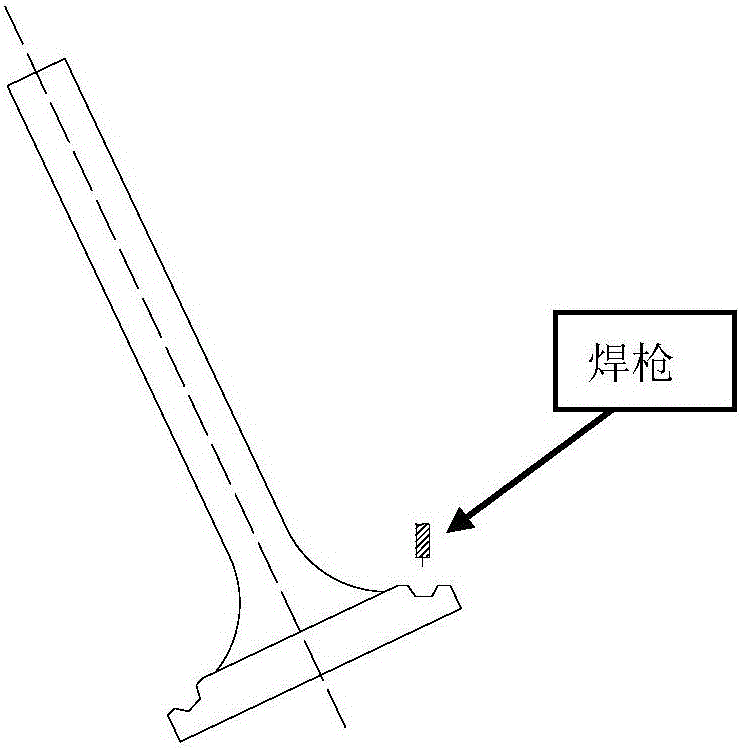

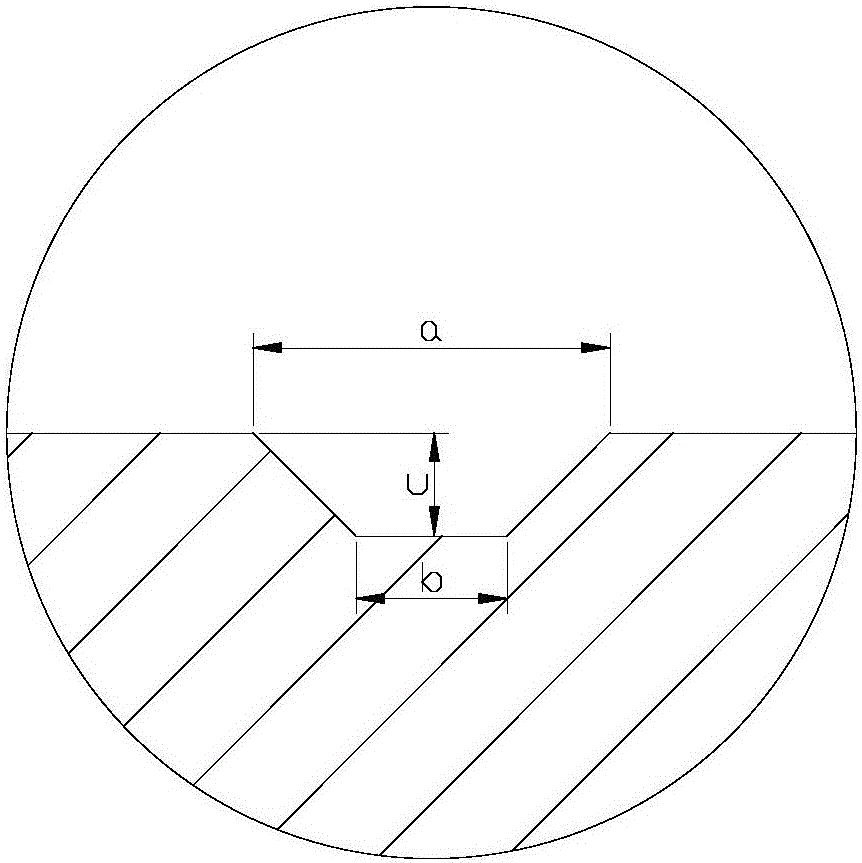

[0033] Next prepare the diesel engine valve blank 1 of SNCrW material, and process the sealing surface position, ma...

Embodiment 2

[0043] Firstly, select the power source for MIGMAW: the power source used for MIGMAW is an inverter welding power supply, the dynamic characteristics of the power supply are adjusted through inductance, and the secondary welding parameter settings include advance gas feeding time, slow wire feeding, thermal Arc starting current, thermal starting current duration, crater current drop time, crater current duration, crater current value, wire burnback, delayed air supply time, spot welding time, the welding process can be controlled in real time. Main technical parameters of the power supply: input voltage + / -15% (50-60Hz): 3x400 V, maximum input current: 28.2 A, power / 100%: 19.3 kVA, maximum power: 24.2 kVA, no-load power consumption: 40 VA, Current range: 15-400 A, wire feed speed: 0.5-30 m / min, wire diameter: 0.6-2.4 mm, maximum gas pressure: 0.5 MPa (5.0 bar).

[0044] Next prepare the diesel engine valve blank 1 of SNCrW material, and process the sealing surface position, ma...

Embodiment 3

[0054] Firstly, select the power source for MIGMAW: the power source used for MIGMAW is an inverter welding power supply, the dynamic characteristics of the power supply are adjusted through inductance, and the secondary welding parameter settings include advance gas feeding time, slow wire feeding, thermal arc starting current, thermal starting current duration, crater current drop time, crater current duration, crater current value, welding wire burnback, delayed air supply time, spot welding time), and the welding process can be controlled in real time. Main technical parameters of the power supply: input voltage + / -15% (50-60Hz): 3x400 V, maximum input current: 28.2 A, power / 100%: 19.3 kVA, maximum power: 24.2 kVA, no-load power consumption: 40 VA, Current range: 15-400 A, wire feed speed: 0.5-30 m / min, wire diameter: 0.6-2.4 mm, maximum gas pressure: 0.5 MPa (5.0 bar).

[0055] Next prepare the diesel engine valve blank 1 of SNCrW material, and process the sealing surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com