Production method of TC16 alloy disc round wire for cold heading

A technology of TC16 and alloy plate, which is applied in the field of titanium alloy processing, can solve the problems of low production efficiency, poor consistency and stability of structure performance, and poor process performance of fastener cold heading process, etc., and achieve the effect of stable performance and fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

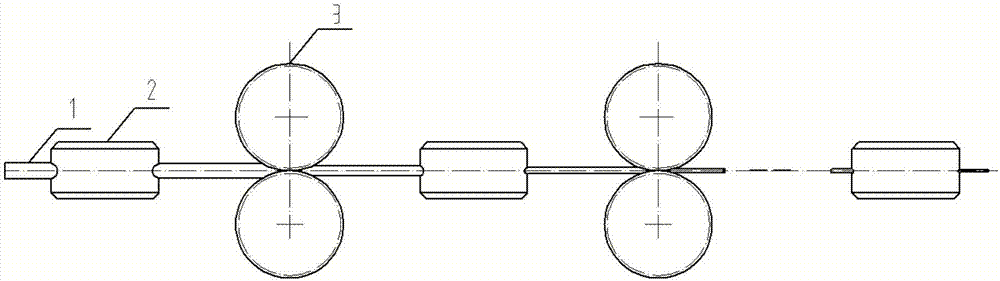

[0032] A kind of preparation method of TC16 alloy coil wire material for cold heading of the present invention, specifically comprises the following steps:

[0033] Step 1, blank processing:

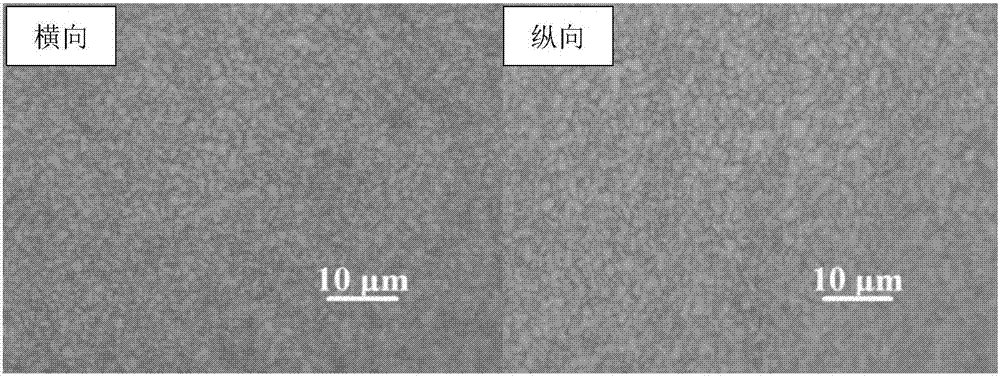

[0034] Place the TC16 titanium alloy forging billet with uniform longitudinal and transverse structures in a resistance furnace, heat it at 50°C to 100°C above the phase transition point, hold it for 60min to 150min, and then roll it over multiple passes with one heat to obtain a certain structure The intermediate blank in the state; the rolling pass is 8 to 16 passes, the deformation of each pass is 10% to 25%, and the cumulative deformation of one fire is 87% to 97%.

[0035] Step 2, cold tandem rolling billet preparation:

[0036] Annealing the intermediate slab obtained in step 1 after heating and drawing, and then peeling off the skin with a centerless car to obtain a continuous cold rolling slab with good processing performance and surface condition;

[0037] The heating temperat...

Embodiment 1

[0045] Step 1: Use Φ47.5mm TC16 titanium alloy precise forging rods with uniform horizontal and vertical structures, place them in a box-type resistance furnace, heat at 80°C to 100°C above the phase transition point, and keep the temperature in the furnace for 120min to 150min. The rolling passes are 14 to 16 passes, and the deformation amount of each pass is 15% to 25%, and rolled to a coil drawing blank with a specification of Φ9.3mm.

[0046] Step 2: Heat the round billet rolled in step 1 in a tubular furnace at a temperature of 80°C to 90°C below the transformation point, and draw it to Φ9.0mm in 2 passes. After drawing, anneal at 720°C to 780°C, cool in the furnace to 550°C and then air cool, and use a centerless car to peel the skin to Φ8.0mm after annealing.

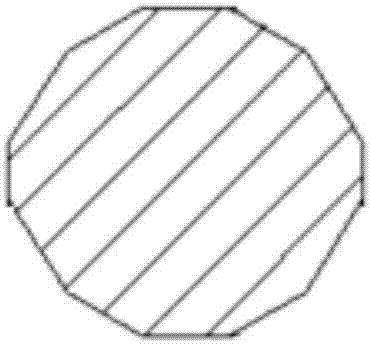

[0047] Step 3: Carry out continuous cold rolling of the Φ8.0mm billet obtained in step 2, match the mold according to the deformation amount of 10% to 15% in each pass, and roll it into a special-shaped wire with...

Embodiment 2

[0050] Step 1. Use a Φ30mm TC16 titanium alloy precision forged rod with uniform horizontal and vertical structures, place it in a box-type resistance furnace and heat it at 50°C to 65°C above the phase transition point. The holding time in the furnace is 60min to 90min, and the rolling pass 8 to 12 passes, each pass with a deformation of 10% to 25%, and rolled to a coiled drawing billet of Φ10.5mm.

[0051] Step 2, heat the coil obtained by rolling in step 1 in a tubular furnace, the heating temperature is 70°C to 80°C below the phase transition point, adopt 4 passes of hot drawing, and draw to Φ9.0mm, After drawing, anneal at 720°C to 780°C, cool in the furnace to 550°C and then air cool, and use a centerless car to peel the skin to Φ8.0mm after annealing.

[0052] Step 3: Carry out continuous cold rolling of the Φ8.0mm billet obtained in Step 2, match the mold according to the deformation amount of 8% to 11% in each pass, and roll it into a special-shaped wire with a 12-sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com