Precise CRDM part casting forming method

A technology of precision casting and molding method, applied in casting molding equipment, molds, mold components, etc., can solve problems such as restricting the development of nuclear power industry, large consumption, threatening national defense security, etc., and achieve considerable economic and social benefits, parts The effect of high yield and meeting technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present invention is the precision casting molding method of CRDM part-claw and connecting rod, and it comprises the following steps:

[0030] 1). According to the design shape of the CRDM hook and connecting rod, the matching ceramic mold shell is manufactured by investment molding.

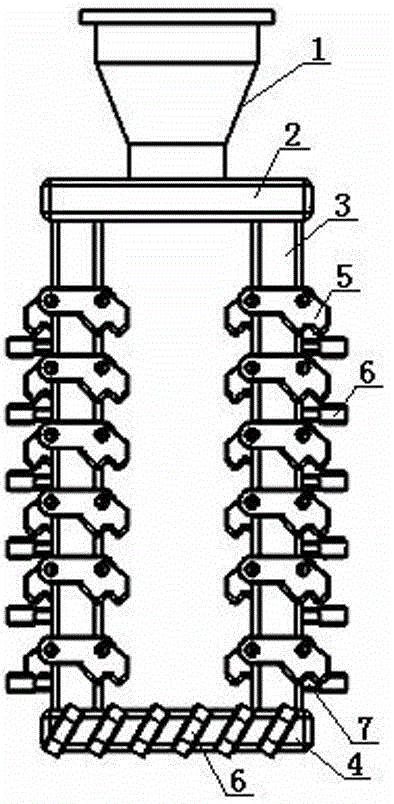

[0031] Specifically, the ceramic formwork of the present invention is molded on a ceramic pouring system, which includes a sprue cup, a top runner, two straight runners (ie vertical runners) and a bottom runner , all runners are hollow structures.

[0032] Wherein, the sprue cup is formed on the top of the top runner, preferably in the center of the top surface of the top runner. The top runner is a hollow elongated structure, and its outline size should be able to cover the upper end faces of the two sprues without affecting the spatial arrangement of the two sprues.

[0033] Two sprues are arranged at both ends of the top runner, each sprue is a hollow structure, and the hollow of...

Embodiment 2

[0045] The present invention is the precision casting molding method of CRDM part-claw, and it comprises the following steps:

[0046] 1). According to the design shape of the CRDM hook, the matching ceramic mold shell is manufactured by investment molding.

[0047] Specifically, the ceramic formwork of the present invention is molded on a ceramic gating system, which includes a sprue cup, a top runner and two sprues, all of which are hollow.

[0048] Wherein, the sprue cup is formed on the top of the top runner, preferably in the center of the top surface of the top runner. The top runner is a hollow elongated structure, and its outline size should be able to cover the upper end faces of the two sprues without affecting the spatial arrangement of the two sprues.

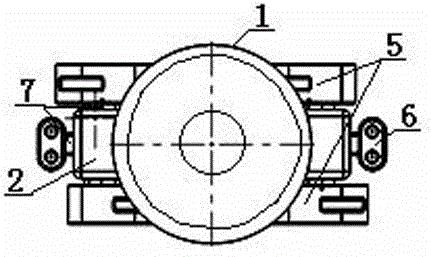

[0049] Two sprues are arranged at both ends of the top runner, each sprue is a hollow structure, and the hollow of the sprue communicates with the hollow of the top runner. On each sprue, there are multiple claw f...

Embodiment 3

[0060] The present invention is the precision casting molding method of CRDM part-connecting rod, comprises the following steps:

[0061] 1). According to the design shape of the CRDM connecting rod, the matching ceramic mold shell is manufactured by investment molding.

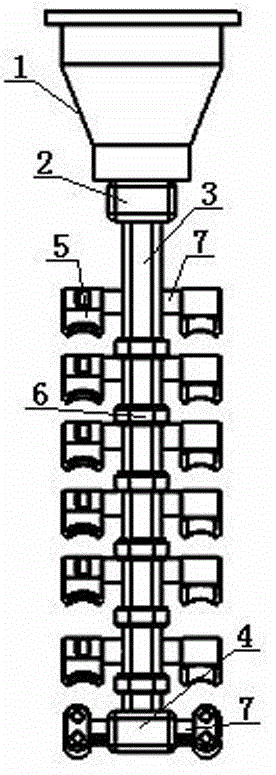

[0062] Specifically, the ceramic formwork of the present invention is molded on a ceramic gating system, and the gating system includes a sprue cup and a sprue, and the sprue is a hollow structure.

[0063] Wherein, the sprue cup is formed on the top of the sprue, and the two are axially arranged and formed.

[0064] The hollow of the sprue communicates with the hollow of the sprue cup. A plurality of connecting rod formworks are arranged radially on the sprue, and these connecting rod formworks are preferably arranged in a grouped rectangular array, so that the formworks can be arranged neatly, efficiently and compactly, each of the aforementioned formworks It cannot be directly installed on the sprue, oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com