Environmental-friendly zinc-aluminum damping alloy and preparation method thereof

A damping alloy, an environmentally friendly technology, applied in the field of alloys, can solve the problems of easy work hardening and high brittleness of damping materials, and achieve the effects of not easy work hardening, improved shock absorption and damping effect, strong metamorphism and refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

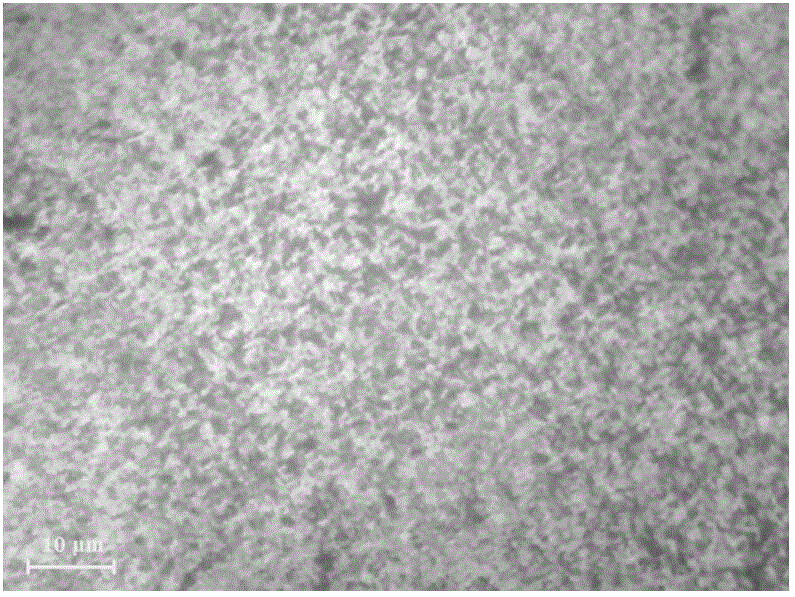

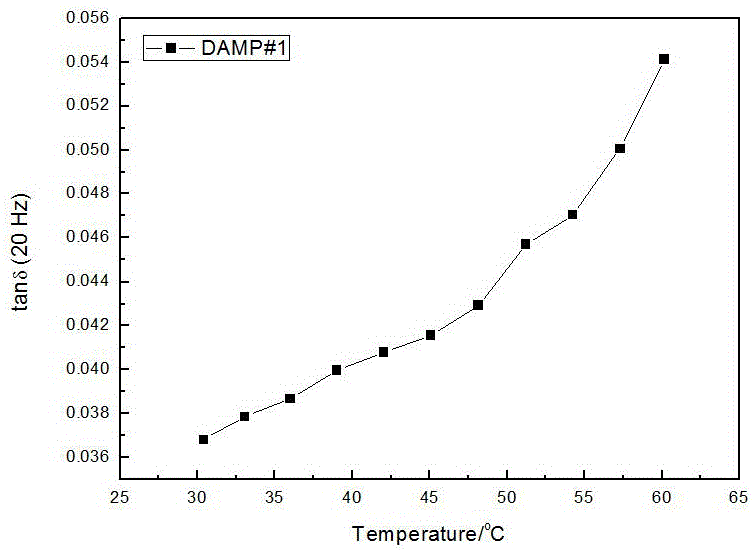

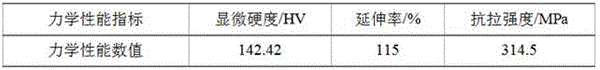

Image

Examples

Embodiment 1

[0018] A preparation method of environmentally friendly zinc-aluminum damping alloy ZADAMP#1, which contains the following components by weight percentage: 20% Al, 0.5% Ti-RE master alloy, 0.5% Cu, 0.4% Mg, the balance is Zn. The preparation process includes the following steps:

[0019] (1) Dry and preheat the crucible at 300°C for 30min, and add Al metal block and covering agent first, because the melting point of pure Al is 660.32°C, and the melting temperature is usually 50~150°C higher than the melting point, so set the melting furnace temperature It should be 700~800℃ and keep it for a period of time.

[0020] (2) After the aluminum block is completely melted, add titanium and rare-earth master alloy particles. After the metal block is melted, add the copper block and the magnesium block. After melting, add the zinc block, add the covering agent after adding the zinc block, and adjust the melting furnace temperature to Keep it at 600~650℃ for a period of time. When the Zn i...

Embodiment 2

[0030] A preparation method of environmentally friendly zinc-aluminum damping alloy ZADAMP#2, which contains the following components by weight percentage: 15% Al, 0.3% Ti-RE master alloy, 0.25% Cu, 0.34% Mg, and the balance is Zn . The preparation processes (1) to (6) are as shown in the steps in Example 1.

[0031] Step (7): Heat the prepared zinc-aluminum damping alloy as follows: heat preservation at 330°C for 36 hours, quench it in an ice-water mixture between 0 and 10°C to cool to room temperature, and then age at room temperature 3 day. After the room temperature aging treatment, the quenched alloy is further placed in a heat treatment furnace, held at 330°C for 0.5 to 1 hour, and then discharged from the furnace for hot rolling at 330°C. The temperature fluctuation during the rolling process cannot exceed 10°C, and then returned to the furnace Keep the temperature at 330°C for 5-10 minutes, and then roll it further, the alloy reduction rate is 25%. After that, the allo...

Embodiment 3

[0033] A preparation method of environmentally friendly zinc-aluminum damping alloy ZADAMP#3, which contains the following components by weight percentage: 27.5% Al, 0.01% Ti, 0.2% rare earth, and the balance is Zn. The preparation processes (1) to (6) are as shown in the steps in Example 1.

[0034] Step (7): Heat the prepared zinc-aluminum damping alloy as follows: heat preservation at 350°C for 48 hours, quench it in an ice-water mixture between 0 and 10°C to cool to room temperature, and then age at room temperature 3 day. After the room temperature aging treatment, the quenched alloy is further placed in a heat treatment furnace, held at 350°C for 0.5 to 1 hour, and then discharged from the furnace for hot rolling at 350°C. The temperature fluctuation during the rolling process should not exceed 10°C, and then returned to the furnace. Keep it at 350°C for 5-10 minutes, and then roll it further. The reduction rate of the alloy is 70%. After that, the alloy plate is placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com