Potassium titanate welding rod material and preparation method thereof

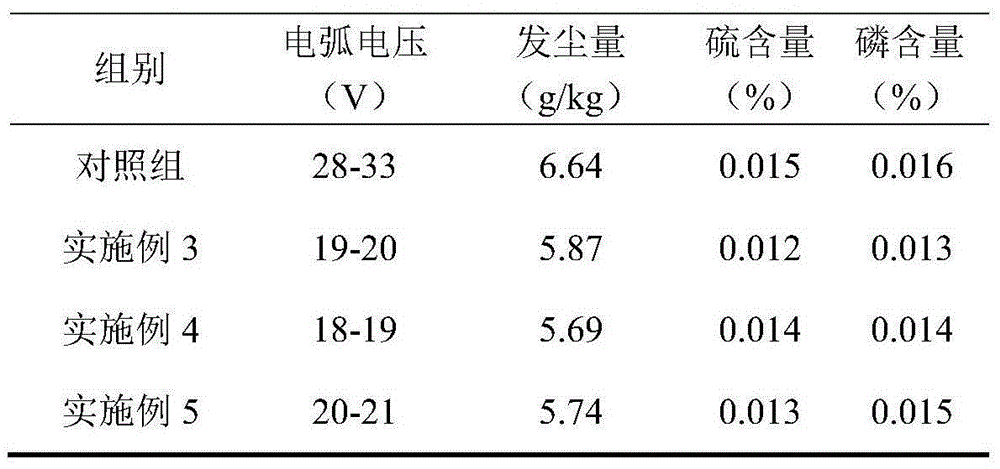

A technology of potassium titanate and welding rod, which is applied in the direction of welding/cutting medium/material, welding equipment, welding medium, etc., can solve the problems of small performance difference, high arc voltage, high content of sulfur and phosphorus, and achieve strong moisture absorption resistance, The effect of reducing the arc voltage and reducing the content of sulfur and phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Party:

[0025] 50 parts of potassium carbonate, 40 parts of titanium dioxide, 1 part of carbon nanotubes, 5 parts of diatomaceous earth,

[0026] 1 part of tungsten carbide, 2 parts of chromium carbide, 0.5 part of nano silicon dioxide.

[0027] Preparation:

[0028] (1) Mix potassium carbonate and titanium dioxide evenly, heat at 600° C., perform solid phase reaction for 10 hours, and cool to obtain the initial material;

[0029] (2) Take the above-mentioned initial material, mix it with carbon nanotubes, diatomaceous earth, tungsten carbide, chromium carbide and nano-silicon dioxide, heat at 800° C., and react for 10 hours to obtain an intermediate material;

[0030] (3) Slowly cool the above-mentioned intermediate material for 12 hours, dry and pulverize to obtain the final product.

Embodiment 2

[0032] Party:

[0033] 50 parts of potassium carbonate, 60 parts of titanium dioxide, 7 parts of carbon nanotubes, 15 parts of diatomaceous earth,

[0034] 9 parts of tungsten carbide, 8 parts of chromium carbide, and 1.5 parts of nano silicon dioxide.

[0035] Preparation:

[0036] (1) Mix potassium carbonate and titanium dioxide evenly, heat at 1200° C., perform solid phase reaction for 20 hours, and cool to obtain the initial material;

[0037] (2) Take the above-mentioned initial material, mix it with carbon nanotubes, diatomaceous earth, tungsten carbide, chromium carbide and nano-silicon dioxide, heat at 1000° C., and react for 20 hours to obtain an intermediate material;

[0038] (3) Slowly cool the above-mentioned intermediate material for 36 hours, dry and pulverize to obtain the final product.

Embodiment 3

[0040] Party:

[0041] 50 parts of potassium carbonate, 50 parts of titanium dioxide, 4 parts of carbon nanotubes, 10 parts of diatomaceous earth,

[0042] 5 parts of tungsten carbide, 5 parts of chromium carbide, and 1 part of nano silicon dioxide.

[0043] Preparation:

[0044] (1) Mix potassium carbonate and titanium dioxide evenly, heat at 900° C., perform solid phase reaction for 15 hours, and cool to obtain the initial material;

[0045] (2) Take the above-mentioned primary material, mix it with carbon nanotubes, diatomaceous earth, tungsten carbide, chromium carbide and nano-silicon dioxide, heat at 900° C., and react for 15 hours to obtain an intermediate material;

[0046] (3) Slowly cool the above-mentioned intermediate material for 24 hours, dry and pulverize to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com