Patents

Literature

37results about How to "Reduce arc voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding process

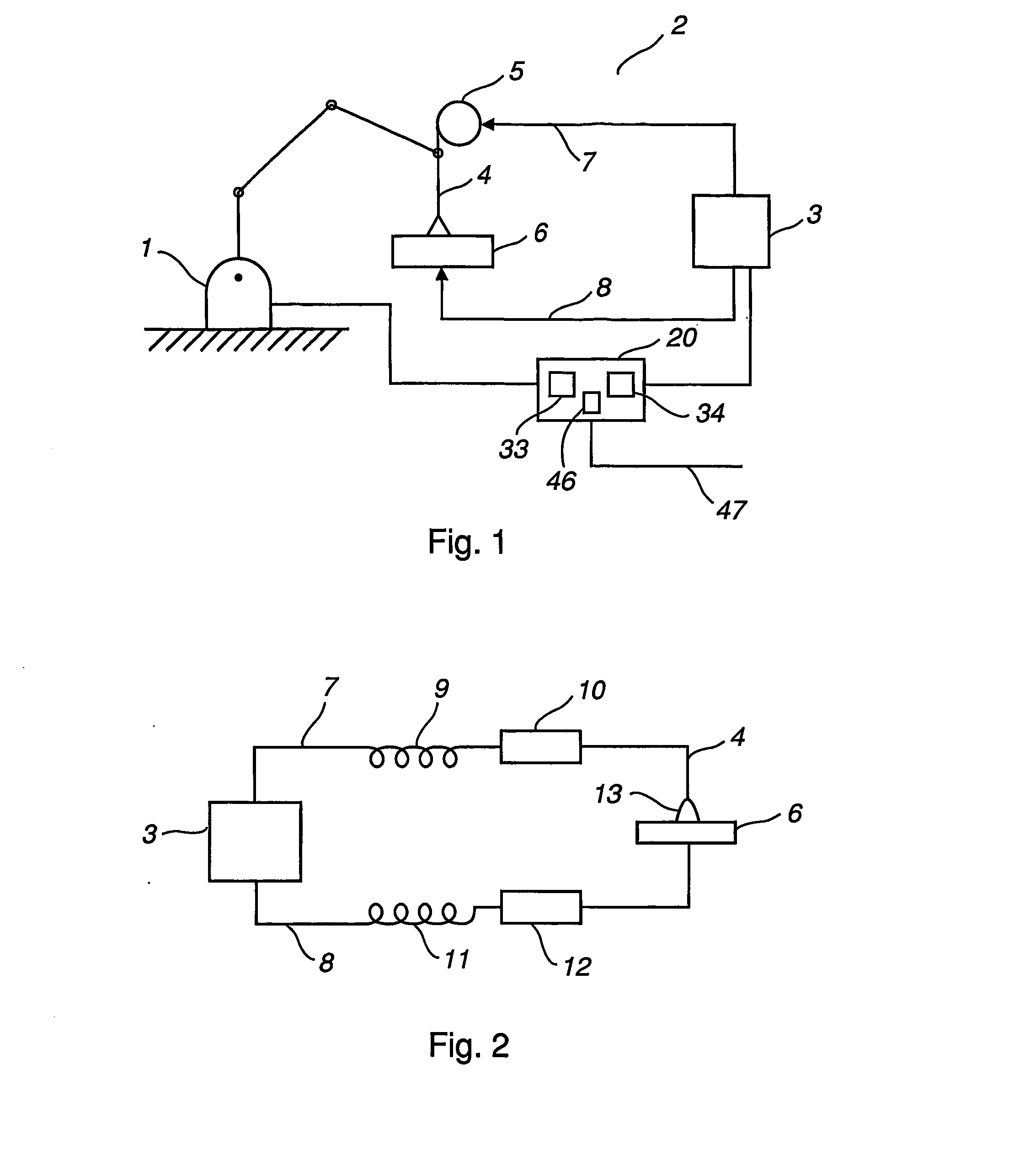

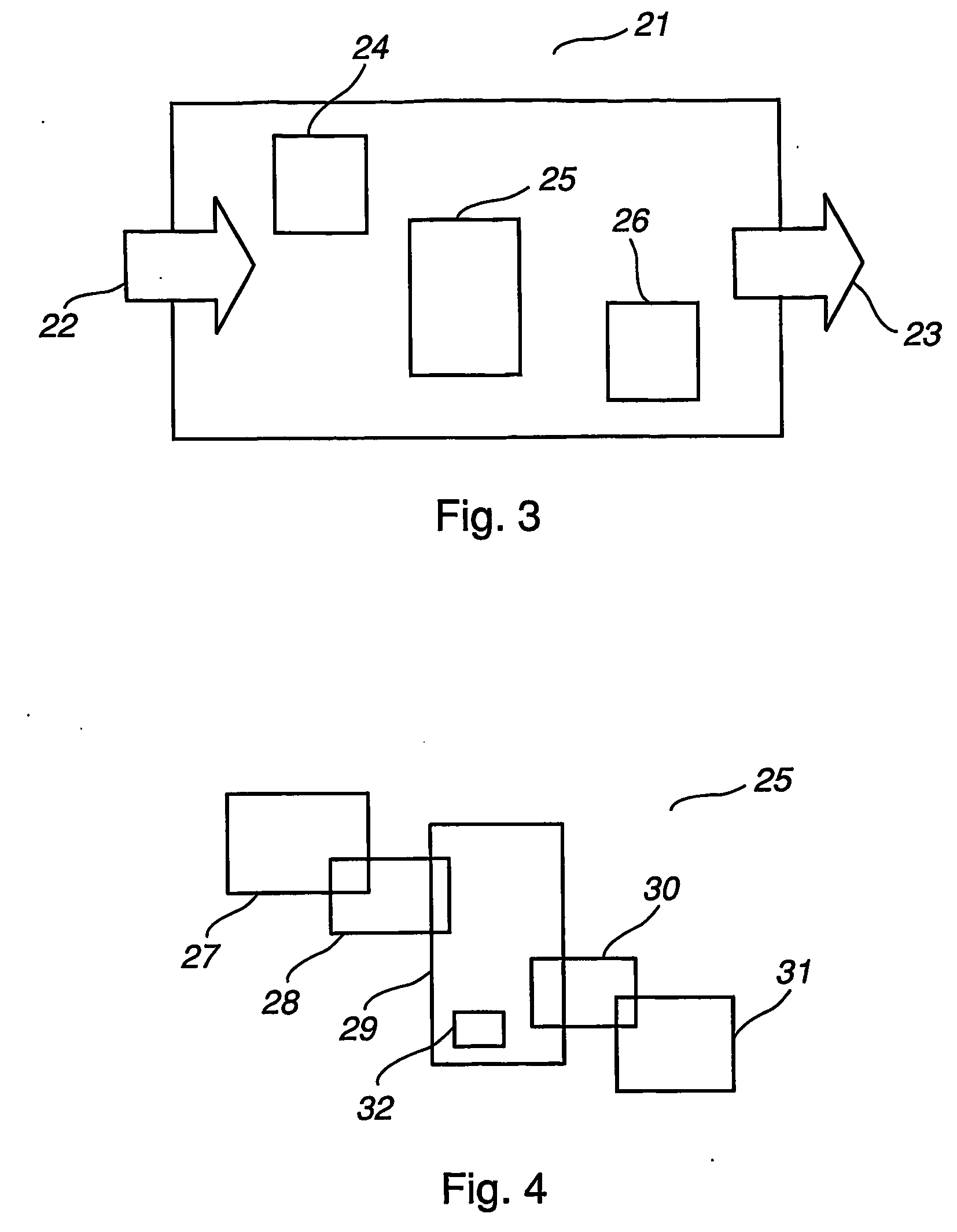

InactiveUS20070181548A1Increase arc voltageReduce arc voltageArc welding apparatusControl systemComputer memory

An arc welding system including an electric circuit including a power source, a welding torch with a consumable welding wire, a workpiece and a control system including a computer, memory and elements for tuning the arc welding system.

Owner:ABB (SCHWEIZ) AG

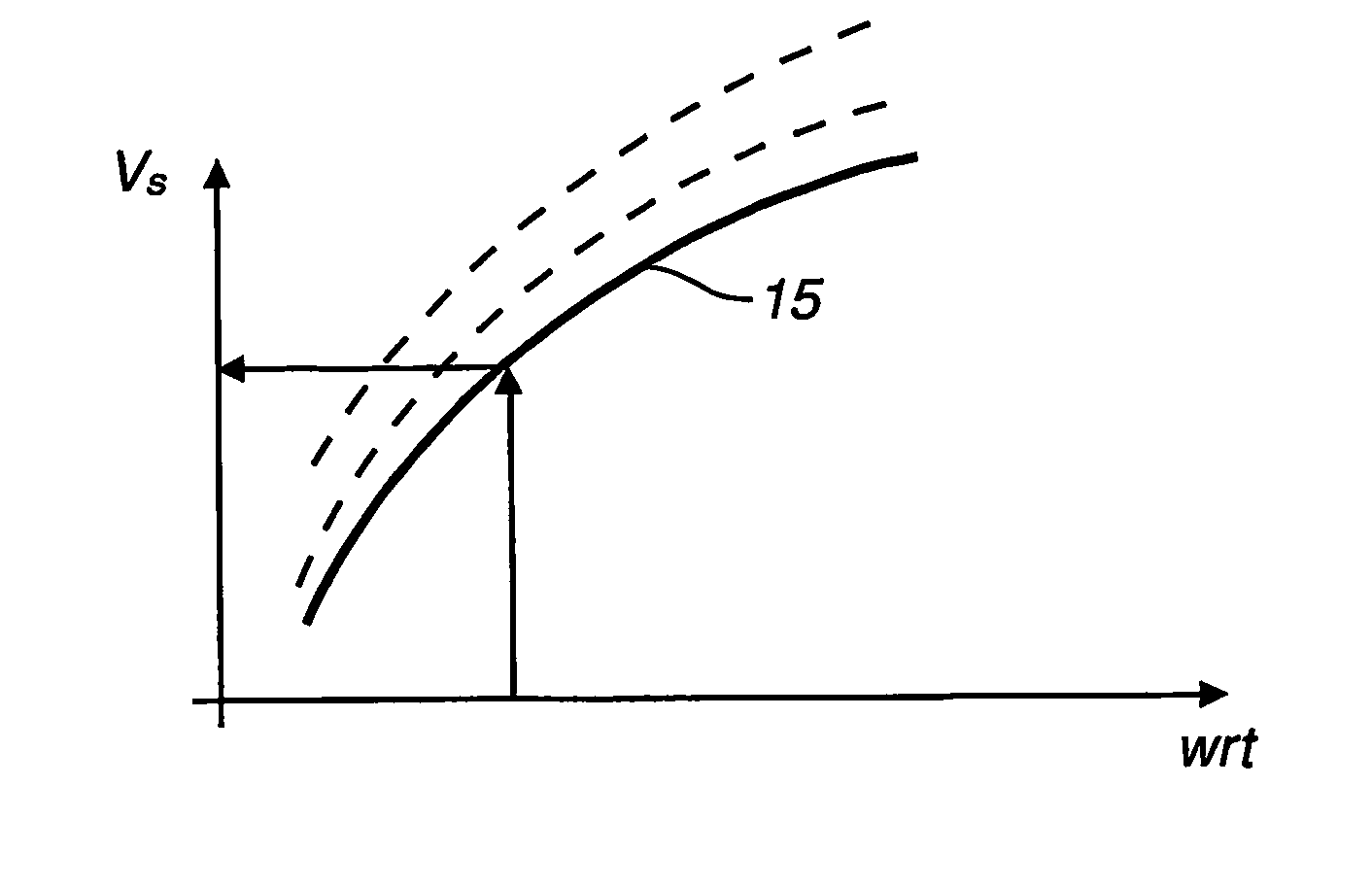

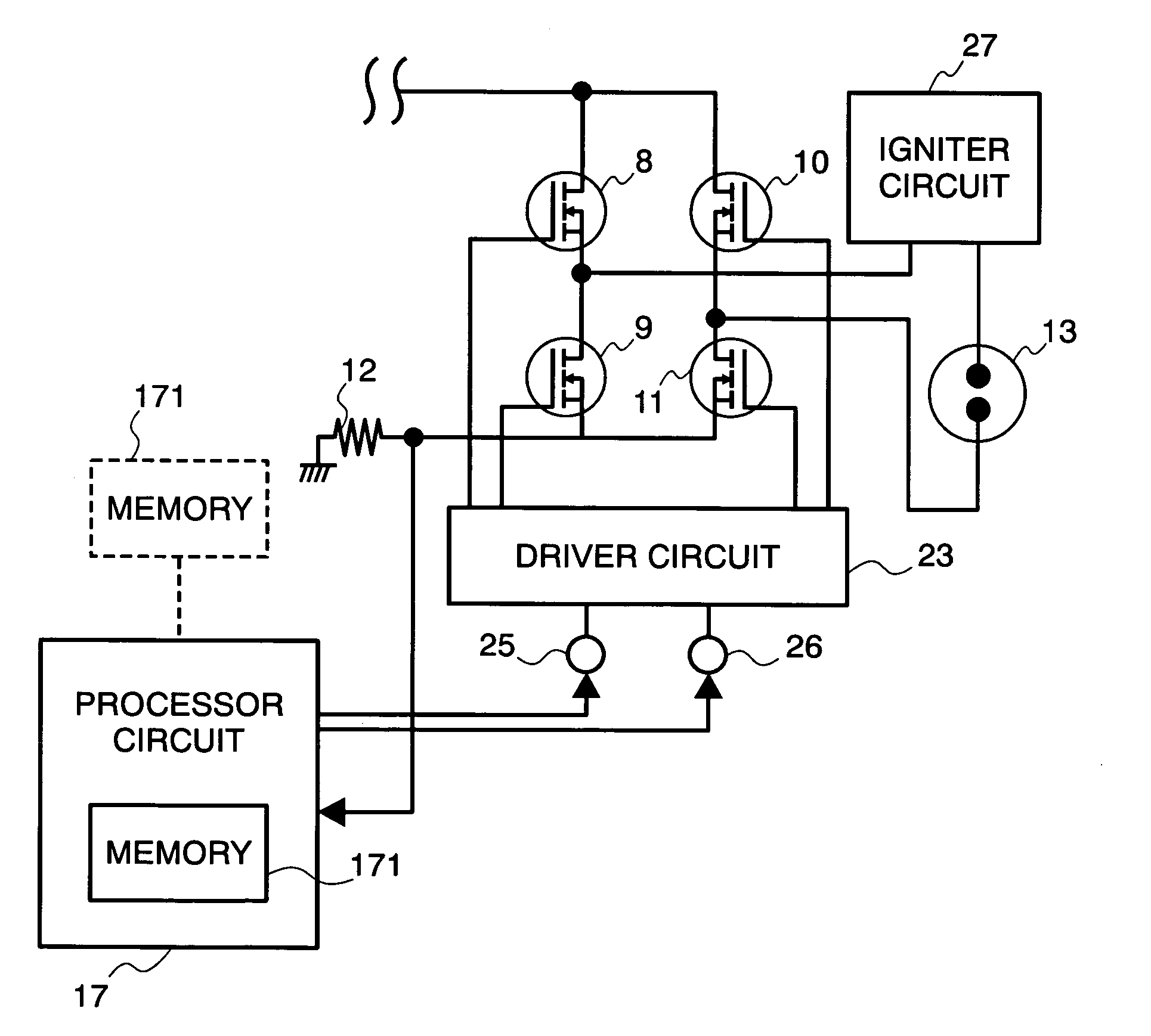

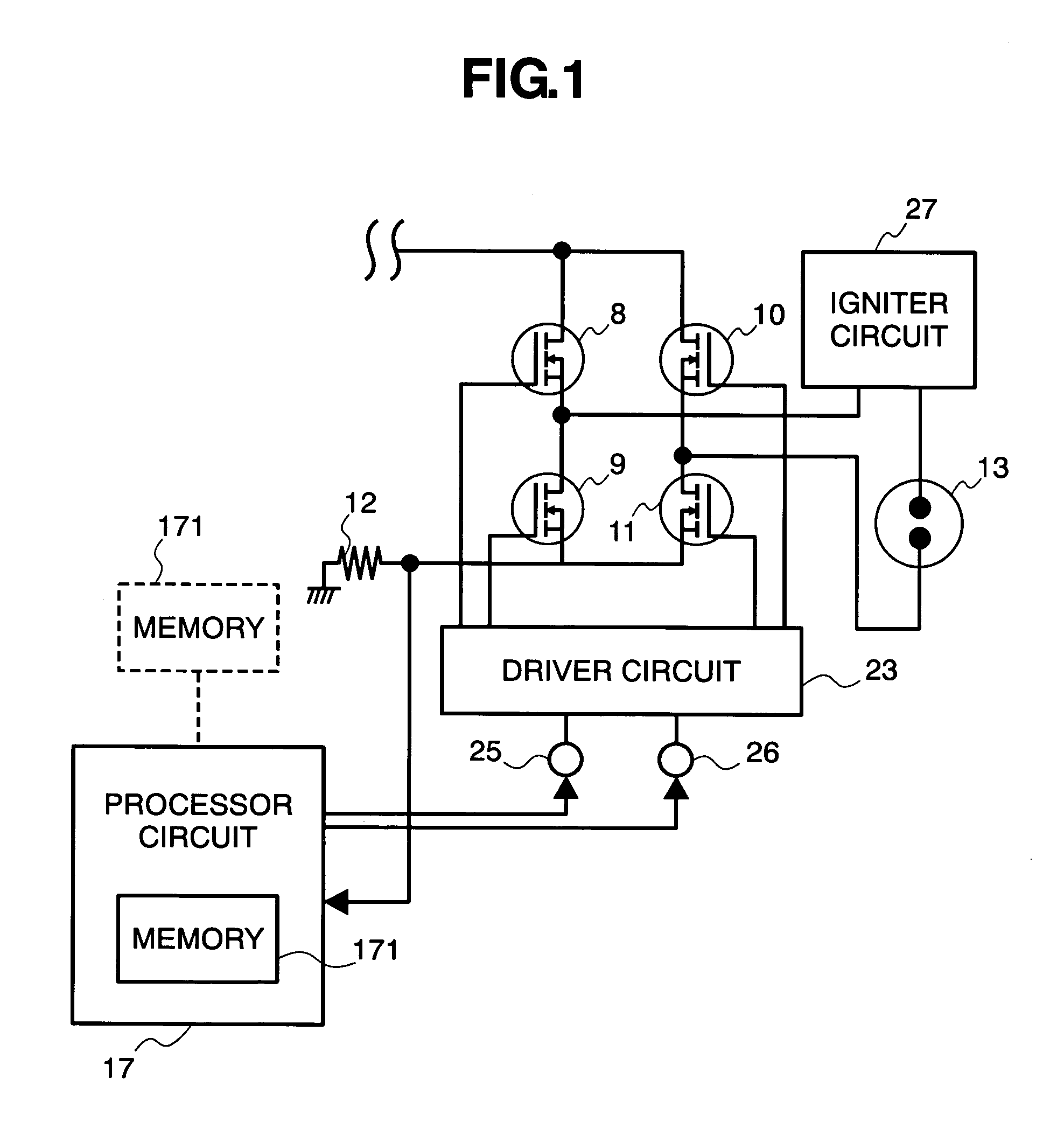

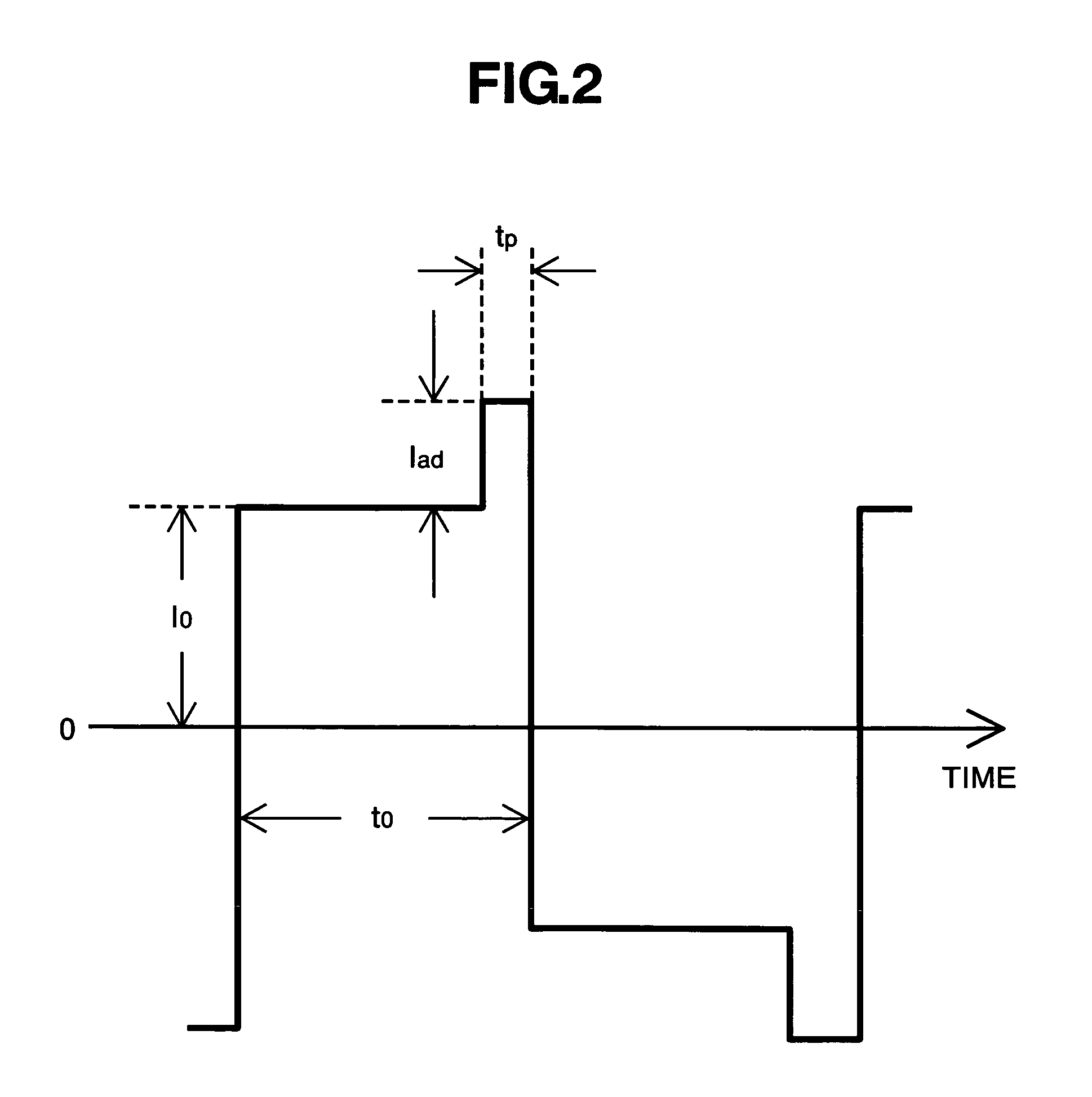

Lamp operation controller and controlling method of lamp operation

ActiveUS20060012316A1Reduce volatilityReduce arc voltageElectrical apparatusElectric light circuit arrangementDriver circuitEffect light

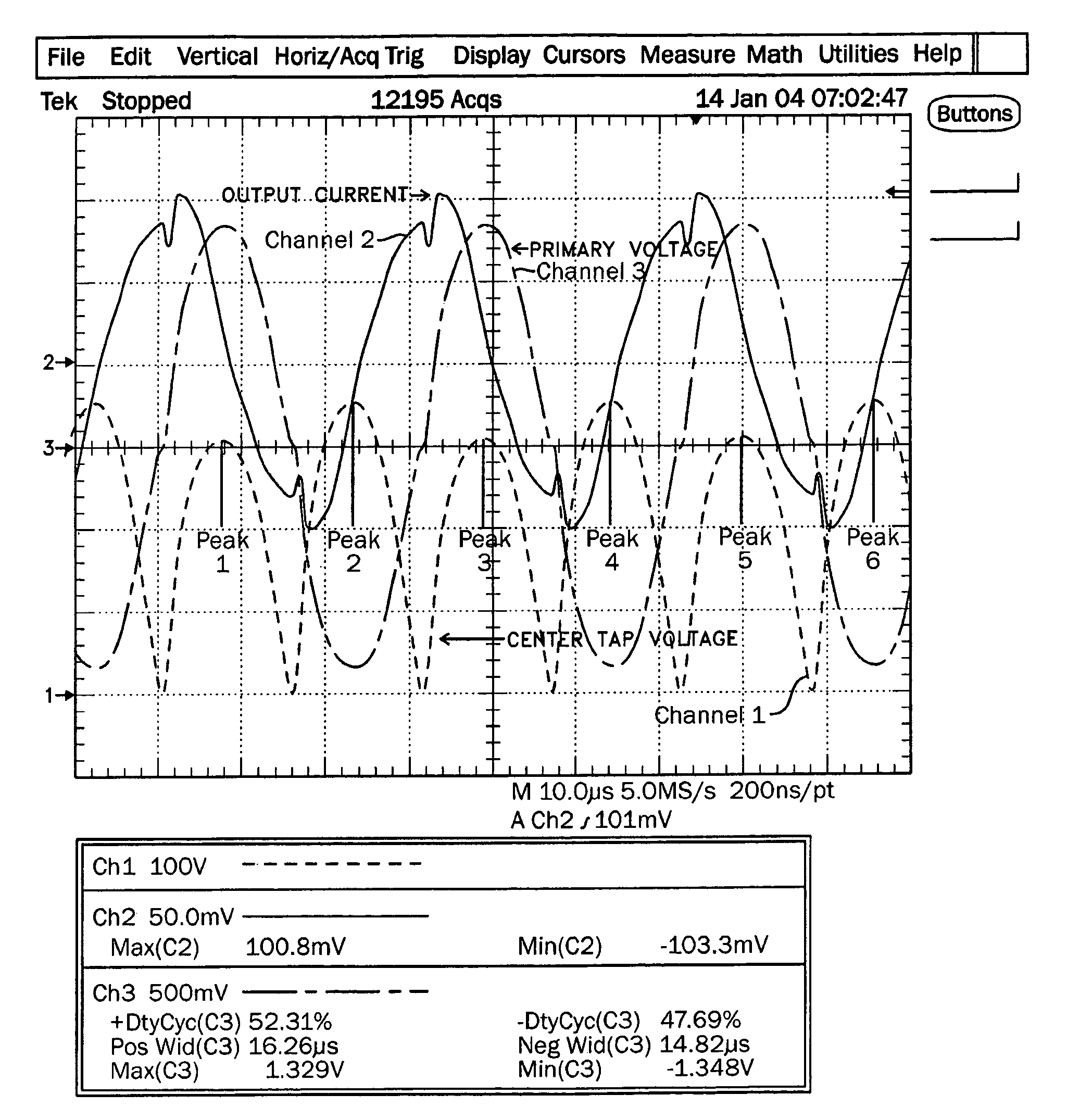

In a lamp operation controller and a method thereof, for obtaining a stable light emission, simply and certainly, without necessity of detection of a parameter accompanying discharge, the lamp operation controller, for operating a discharge lamp having a pair of electrodes, which are disposed at both ends of a light emission tube to have a predetermined distance therebetween, converts electric power of an electric power source 1, through an inverter, into alternating voltage and alternating current, changing the polarity thereof continuously and alternately, so as to produce operating current, and apply that across the pair of the electrodes of the discharge lamp, thereby letting the lamp to emit a light. A driver circuit provides a pulse at a trailing edge of the lamp current or the lamp voltage to be supplied when the discharge lamp emits the light, and also determine amplitude of the pulse, in accordance with fluctuation on the lamp voltage (VL) with respect to lighting time of the discharge lamp, which is measured in advance.

Owner:MAXELL HLDG LTD

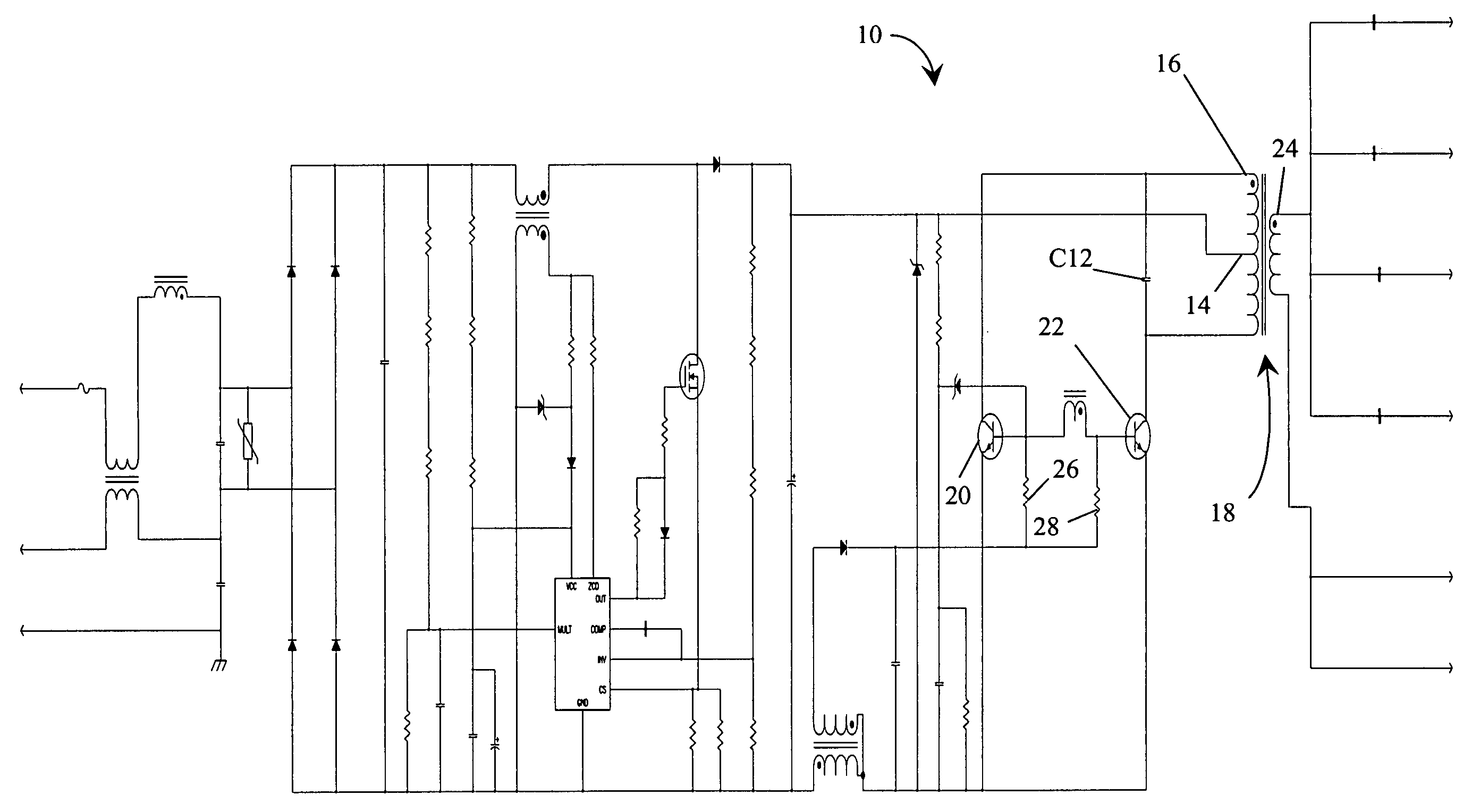

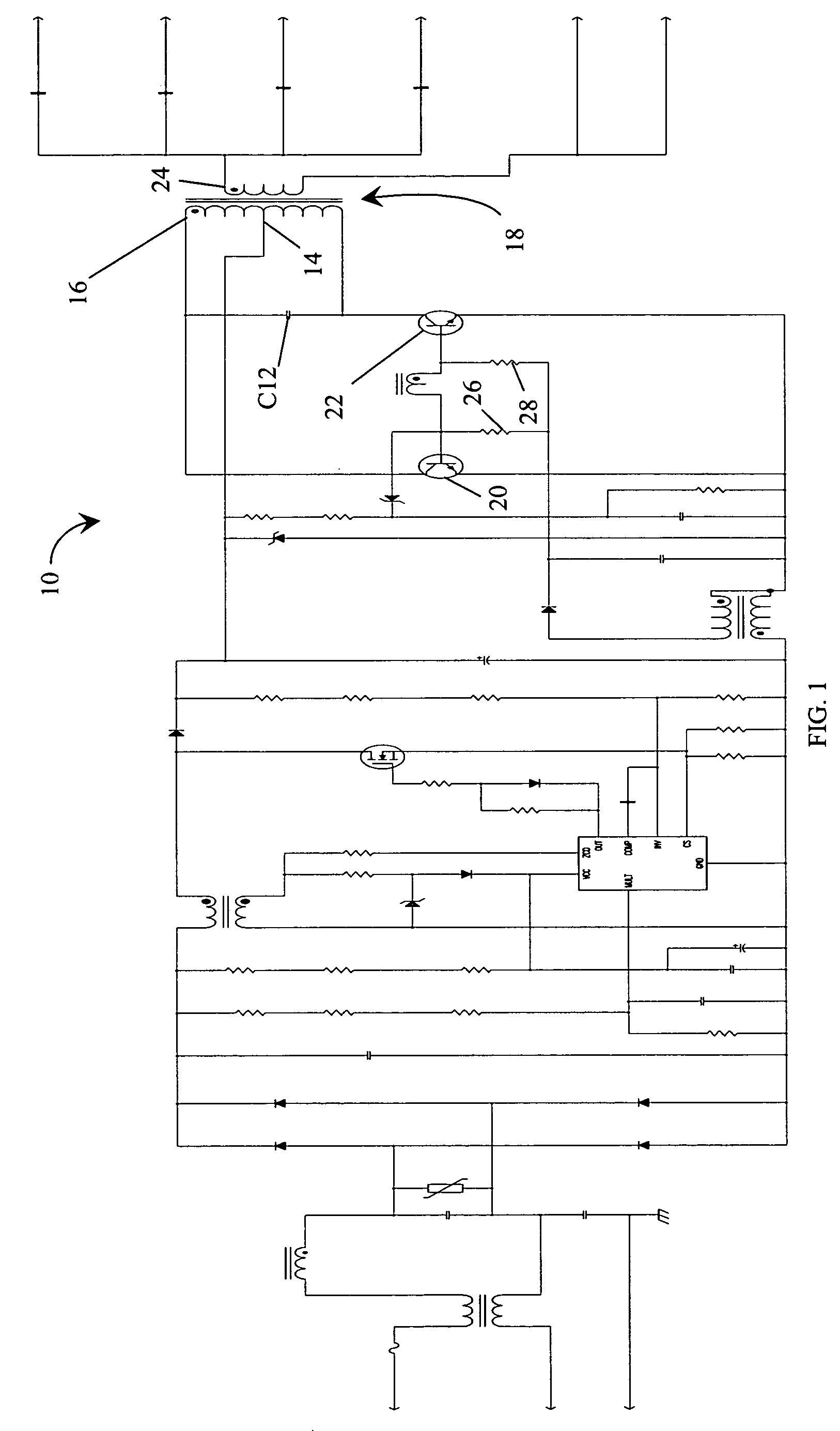

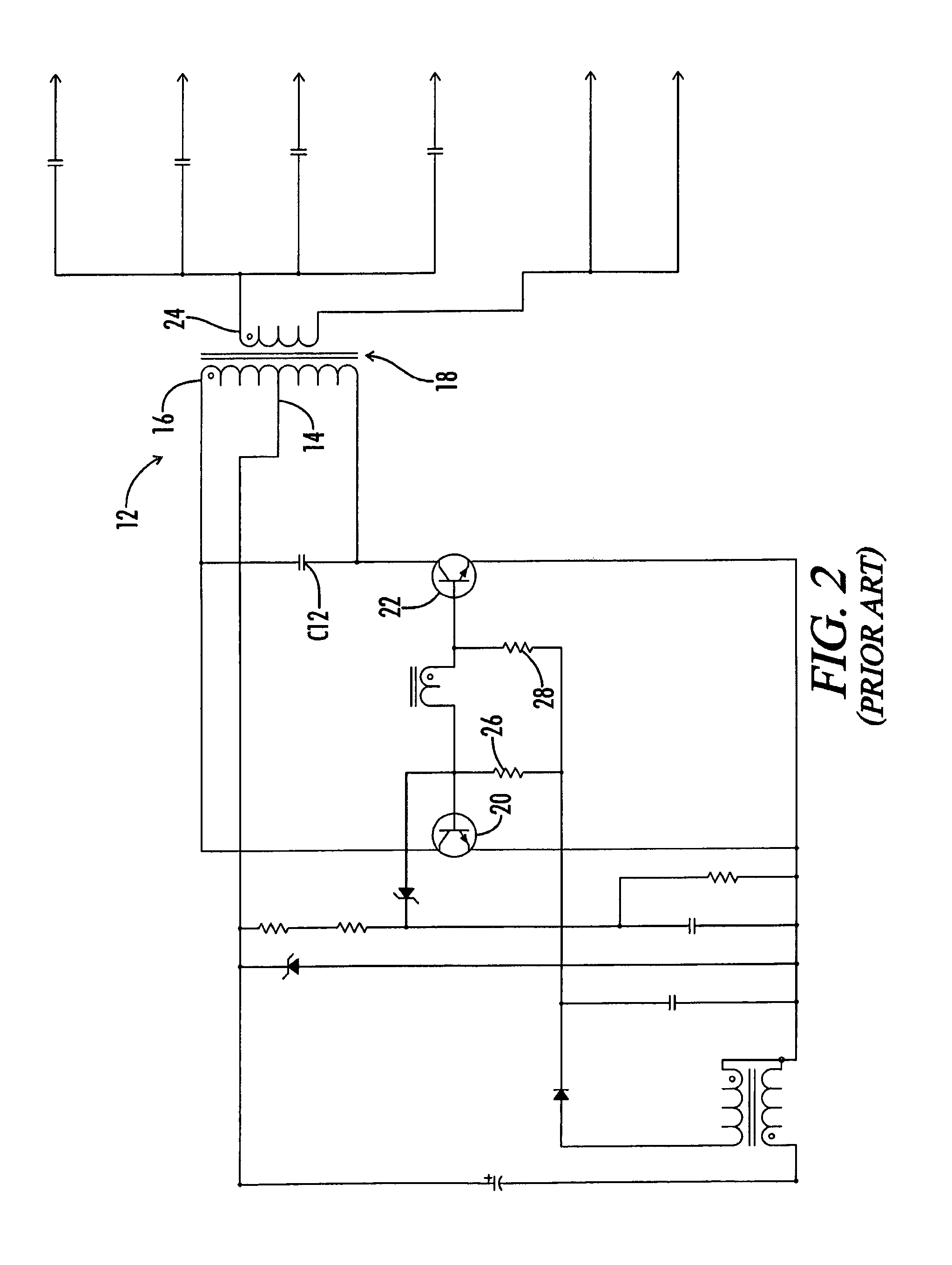

Method for controlling striations in a lamp powered by an electronic ballast

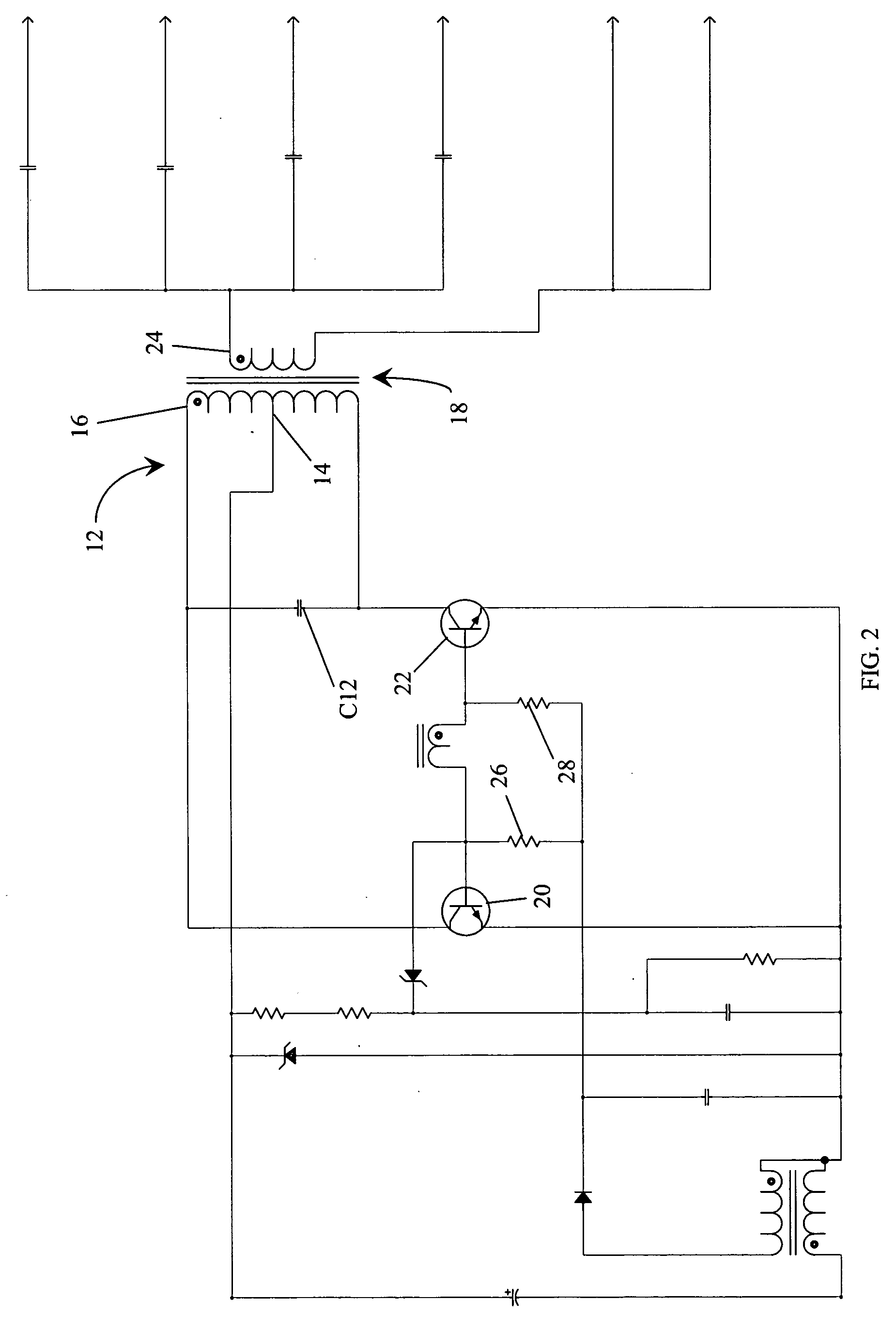

InactiveUS20050168171A1Reduce arc voltageIncrease probabilityElectrical apparatusElectric light circuit arrangementOutput transformerEngineering

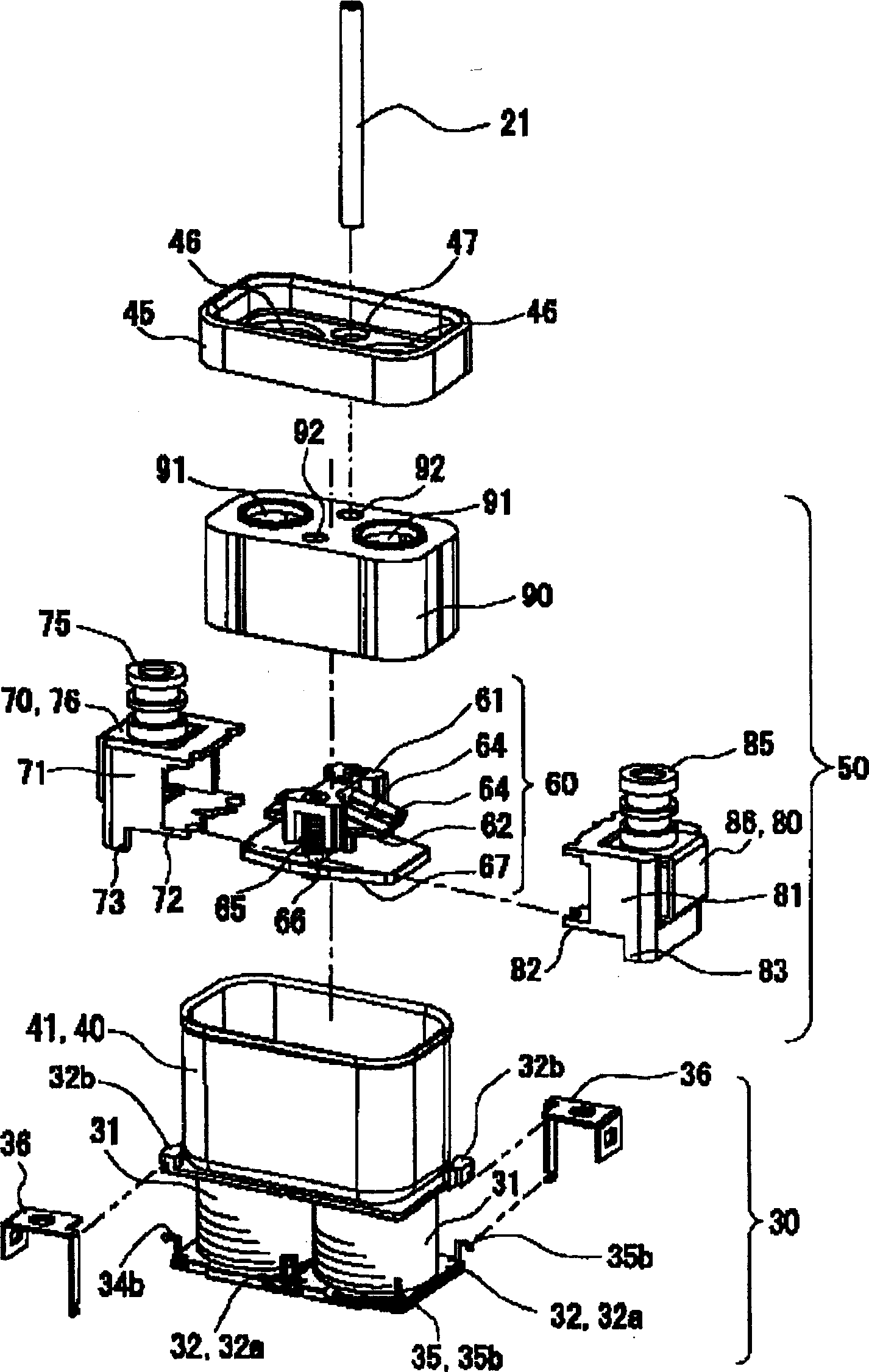

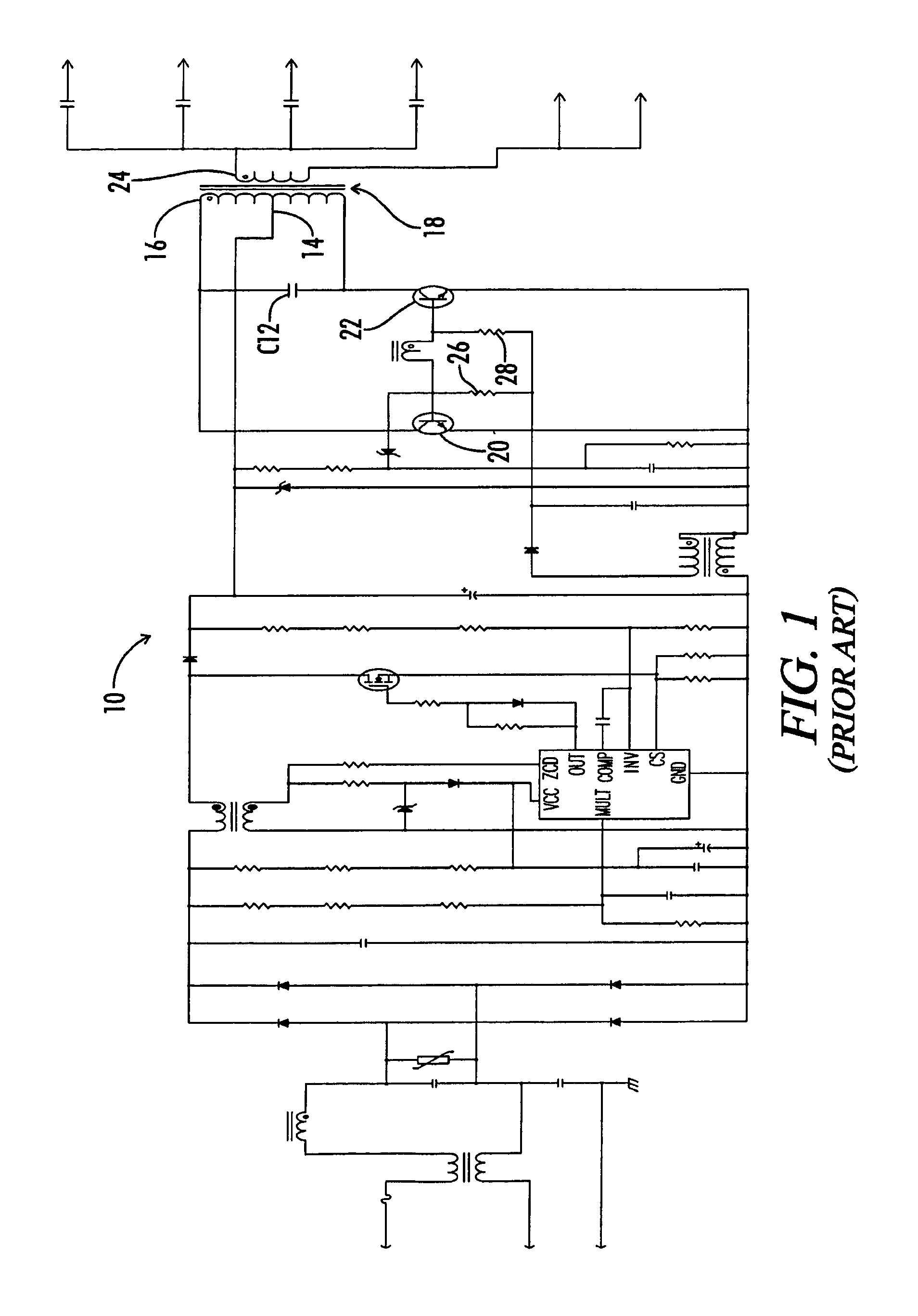

A method for controlling striations in a lamp powered by an electronic ballast includes the steps of generating an asymmetric lamp current using an unbalanced circuit component in the electronic ballast and supplying that current to the lamp. The unbalanced circuit component may be an unbalanced output transformer or an unbalanced DC choke. The output transformer is unbalanced by offsetting the number of turns on each side of the tap on the primary winding of the transformer. In a similar manner, the DC choke is unbalanced by offsetting the number of turns in each winding of the choke.

Owner:UNIVERSAL LIGHTING TECHNOLOGIES

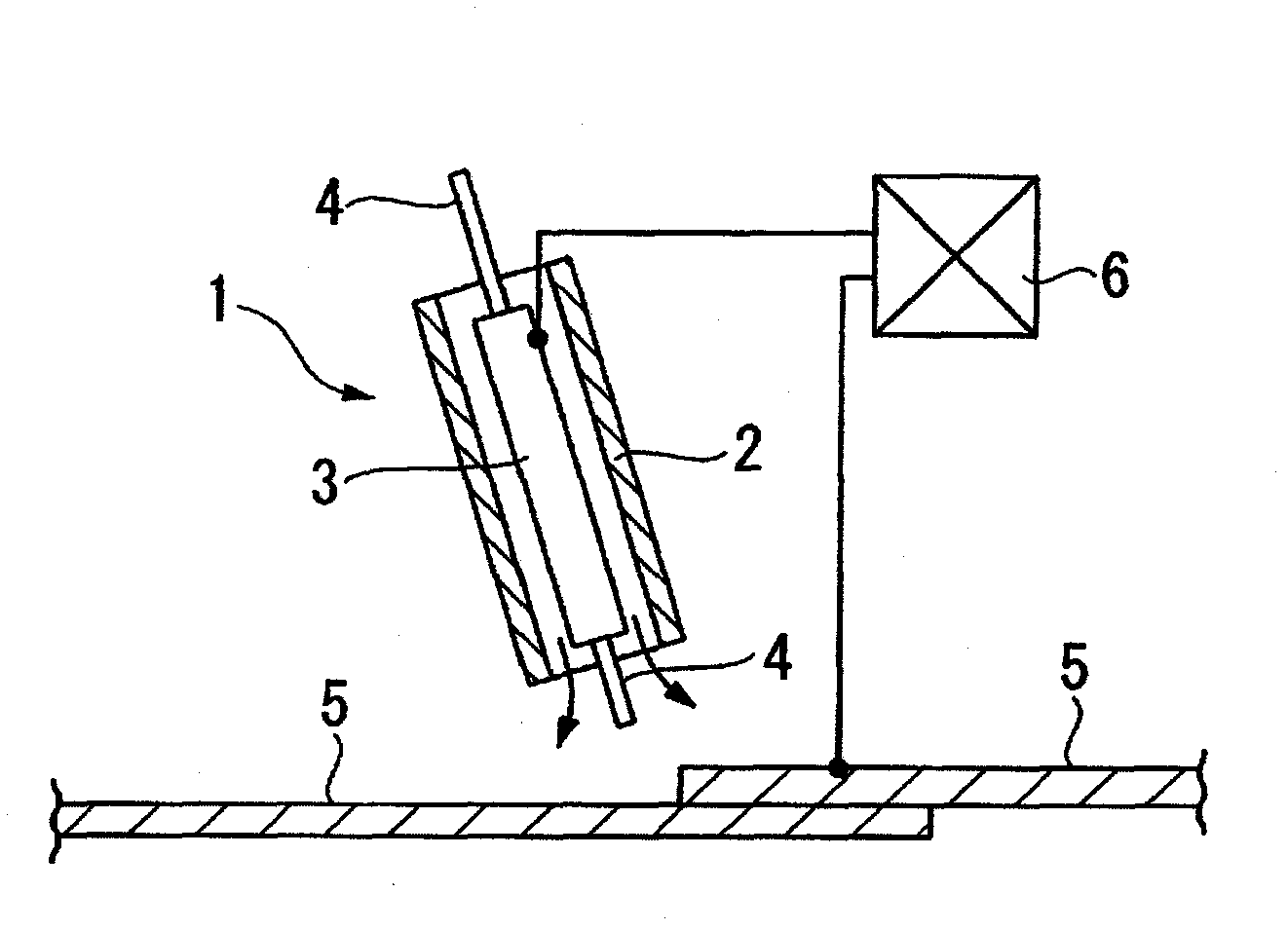

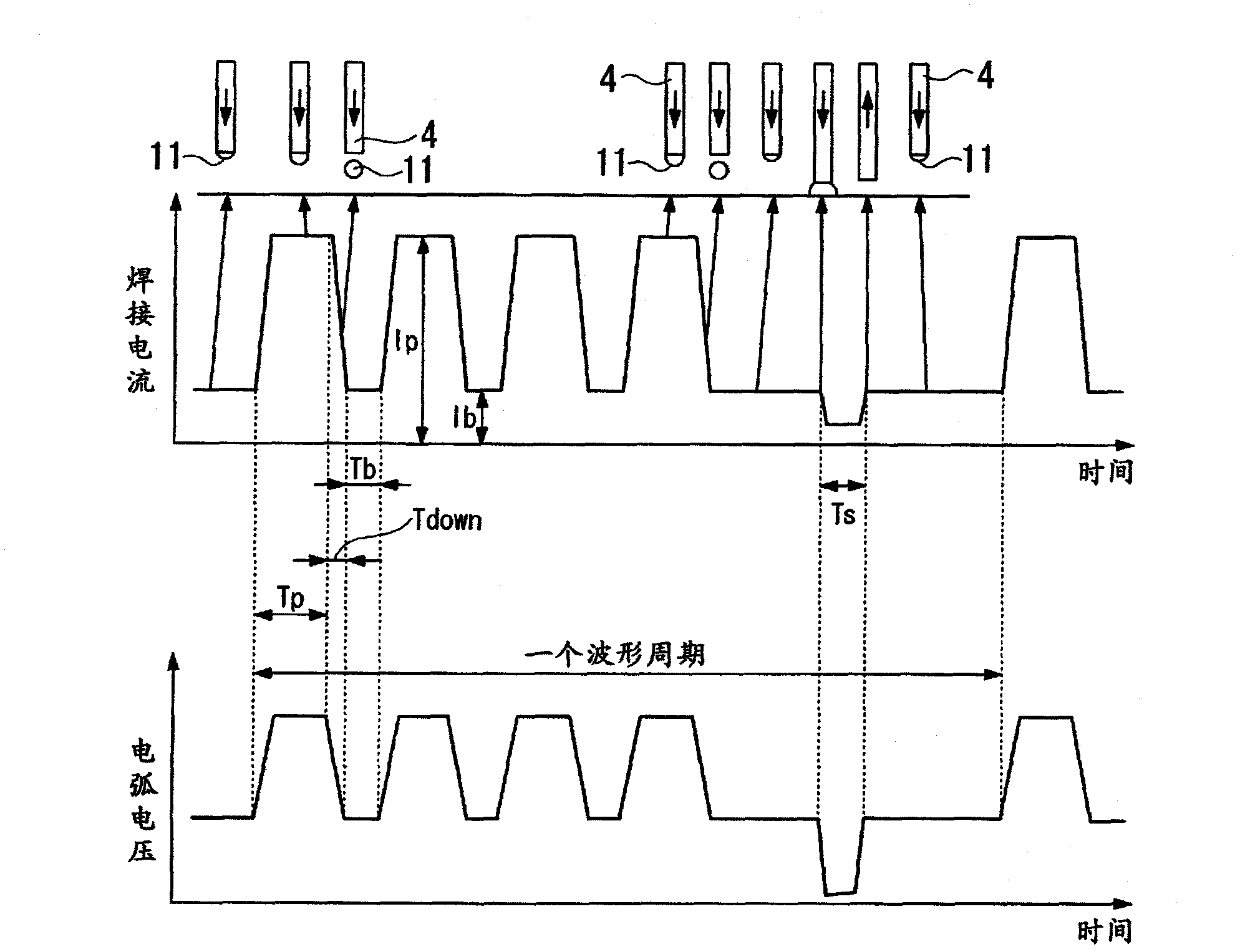

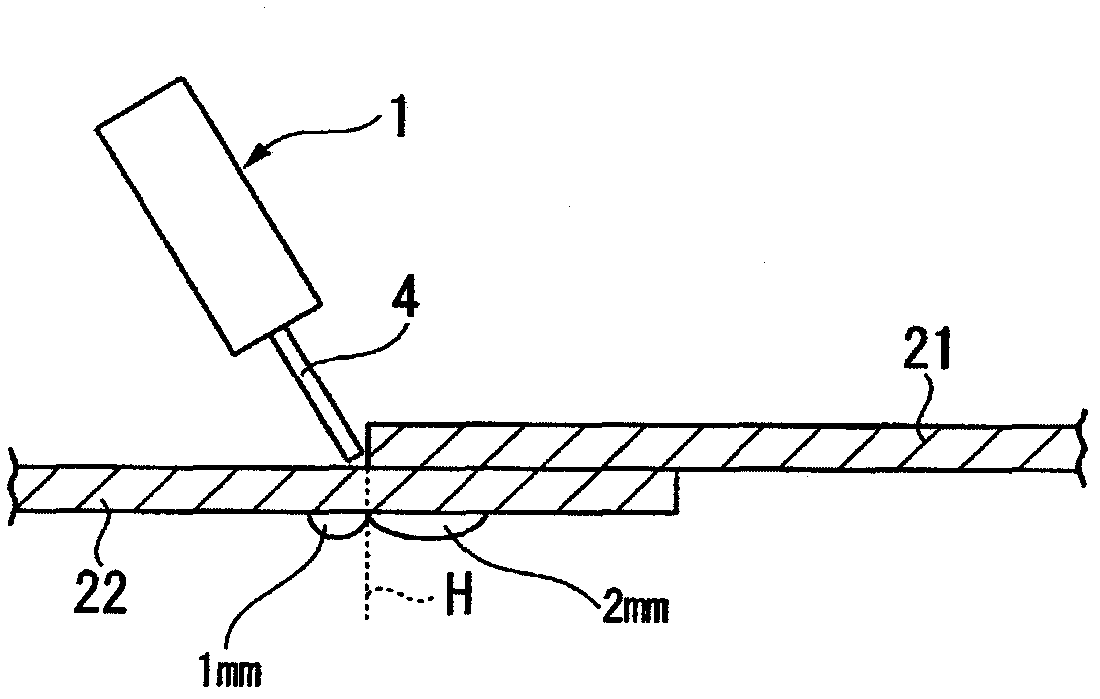

Method for gas-shielded arc brazing of steel sheet

InactiveCN102149502AImprove instabilityAvoid excessive concentrationArc welding apparatusWelding/cutting media/materialsShielding gasMixed gas

A method for gas-shielded arc brazing of a steel sheet; wherein a solid wire containing copper, as a main component, and aluminum is used in arc brazing of a steel sheet; and the method including periodically carrying out pulse droplet transfer and short circuit droplet transfer in arc brazing using, as a shielding gas, a mixed gas consisting of 0.03 to 0.3% by volume of oxygen gas and the remainder which is argon.

Owner:NIPPON SANSO CORP

Method for preparing difficult-to-harden potassium titanate with low hygroscopicity and high bulk density

InactiveCN102070188ALower firing temperatureHigh bulk densityTitanium compoundsPolymer sciencePotassium

The invention discloses a method for preparing difficult-to-harden potassium titanate with low hygroscopicity and high bulk density. The method is mainly characterized in that: a titanium source is compounded with a potassium source under calcination condition by auxiliary agents and the like, so that the surface condition and structure of the product potassium titanate are improved, and the product potassium titanate is difficult to harden, has the low hygroscopicity, the high bulk density, high flowability and high dispersibility and is particularly suitable for producing flux cored wires.

Owner:JIANGNAN UNIV

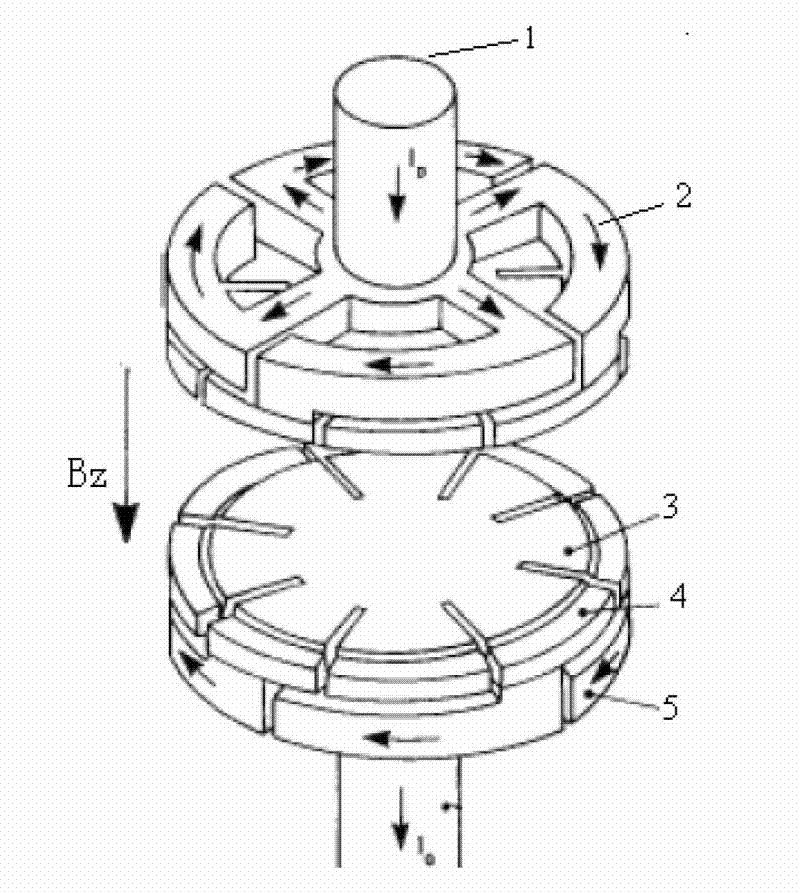

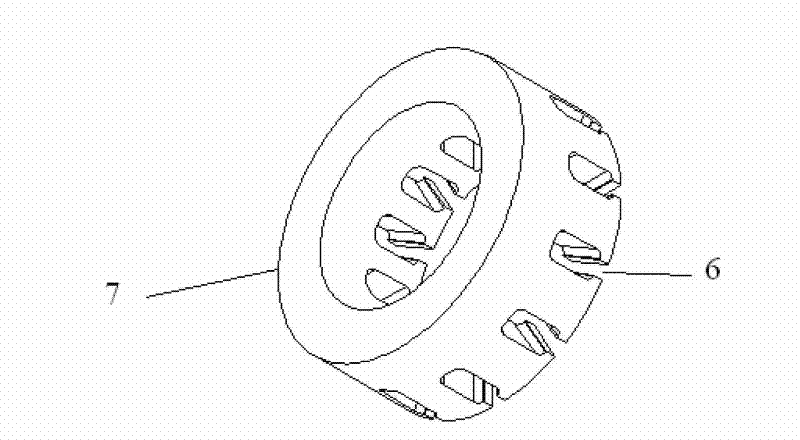

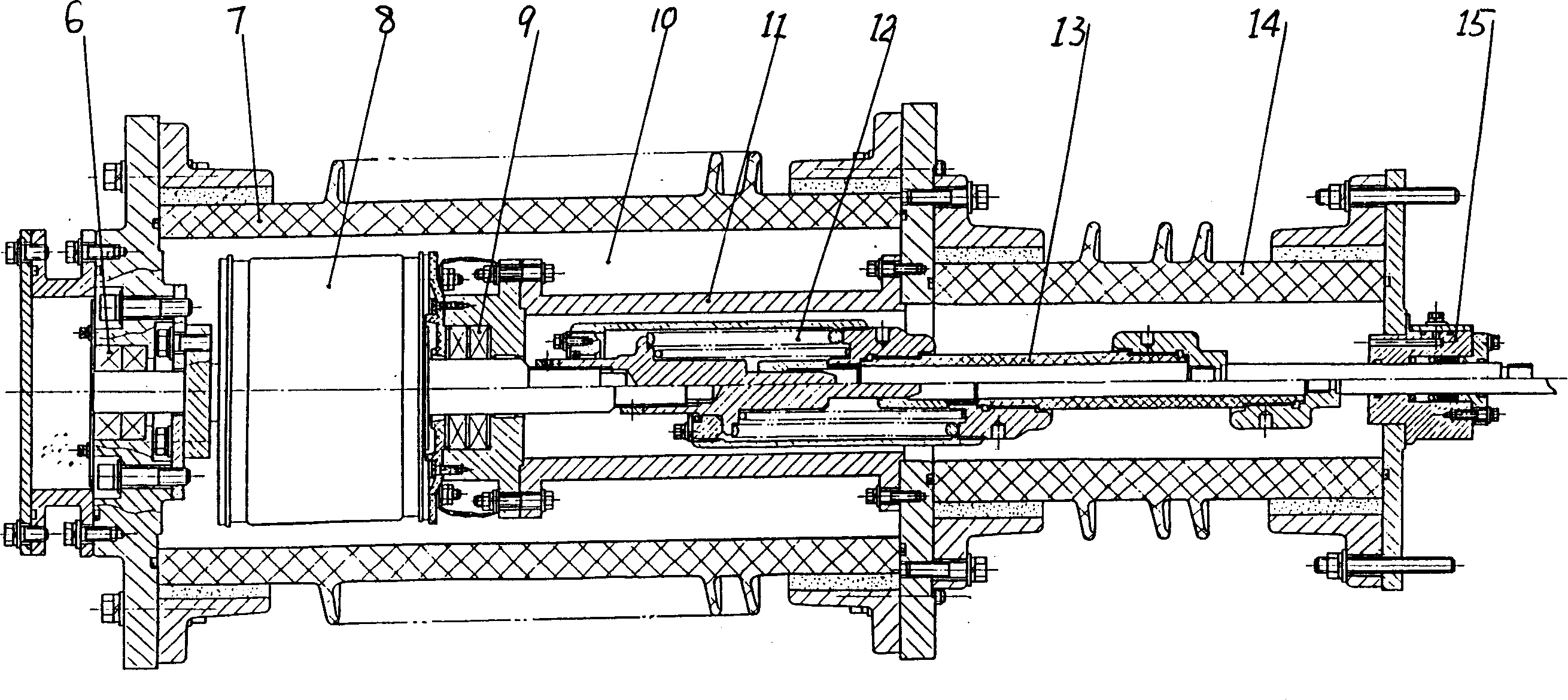

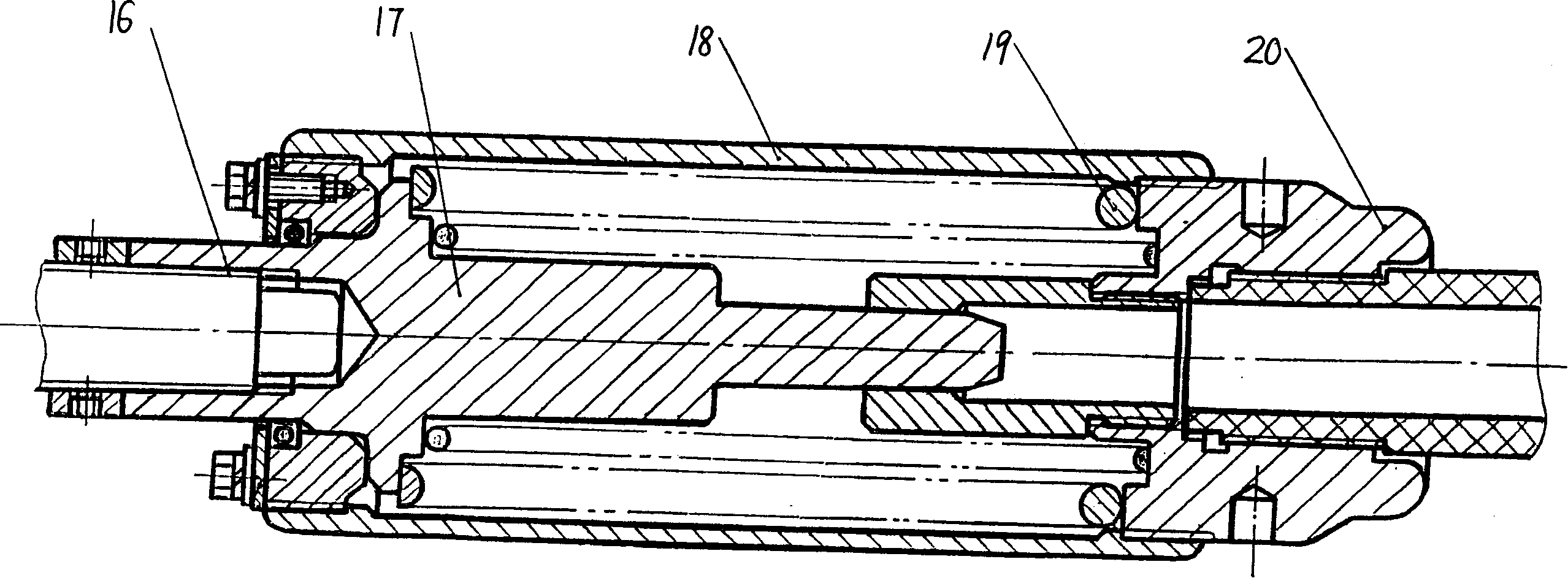

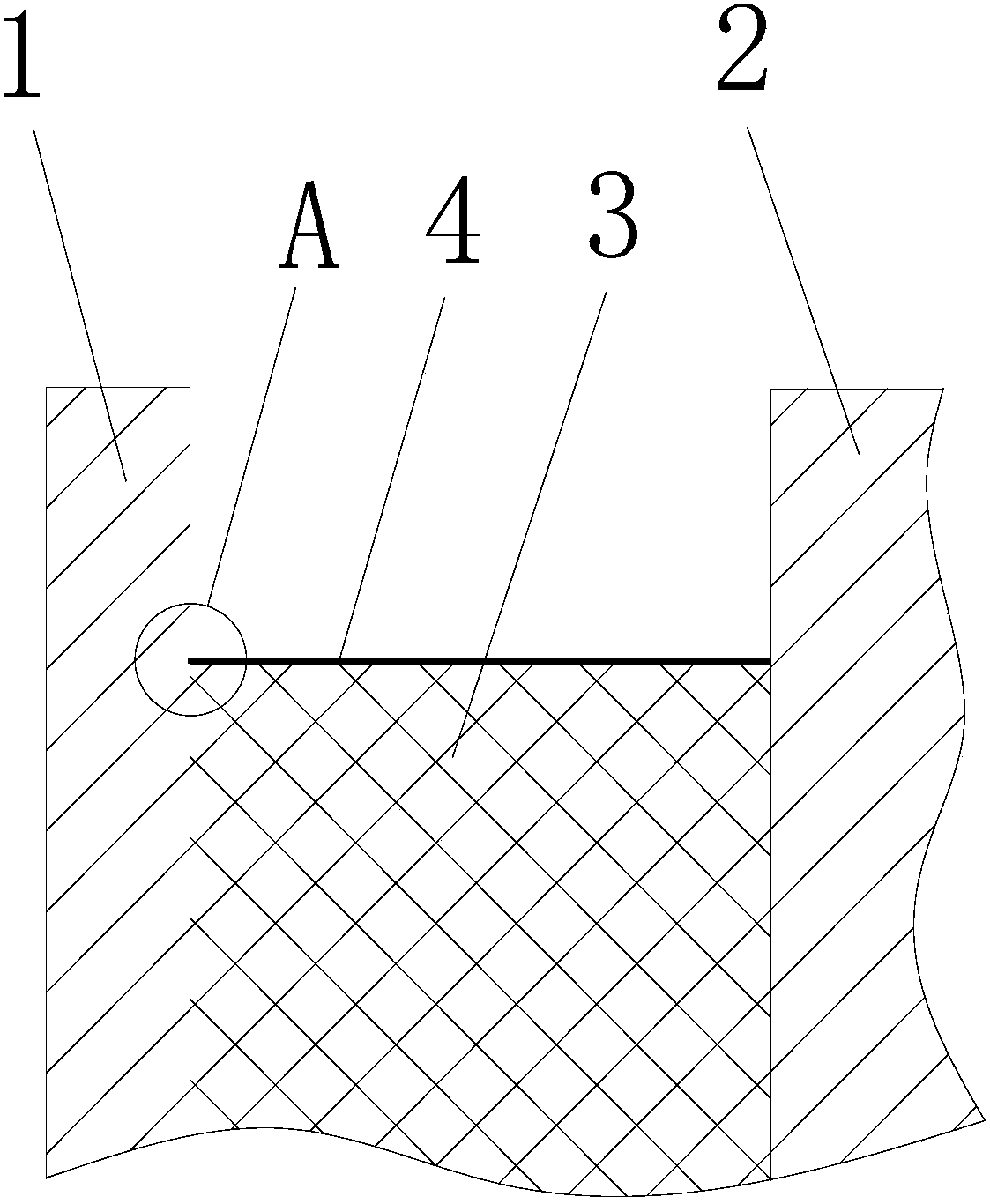

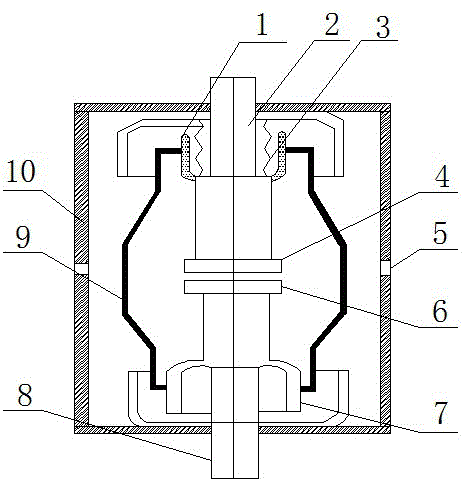

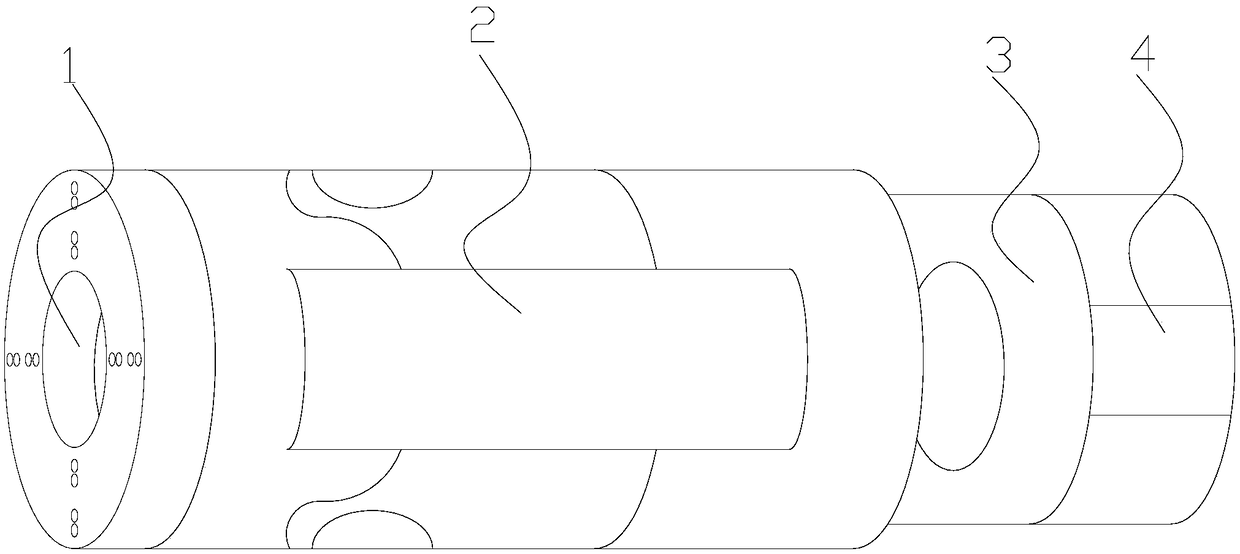

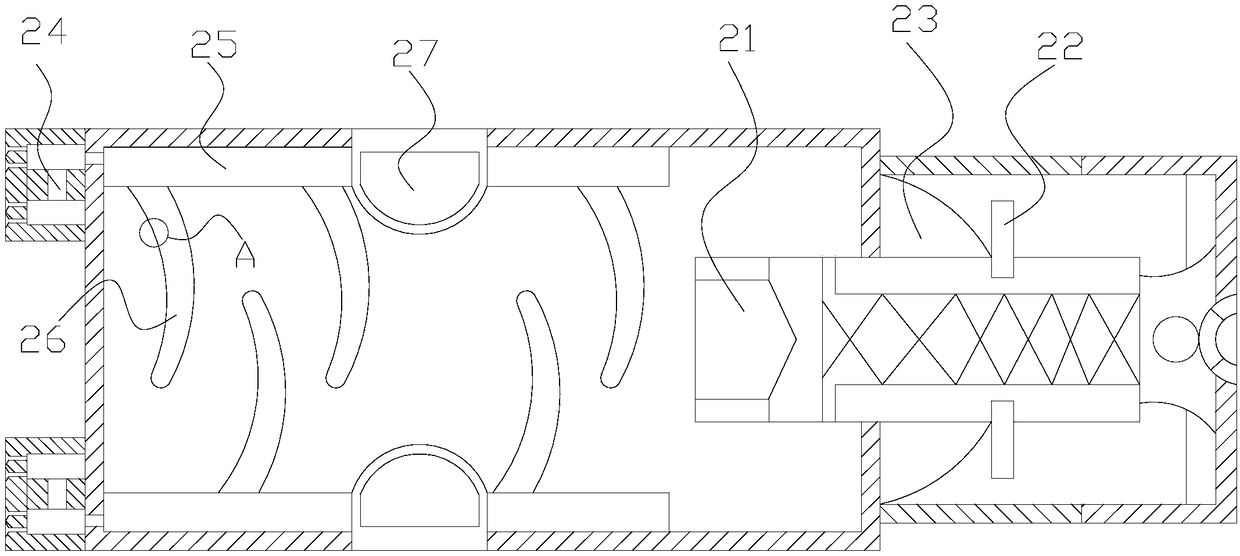

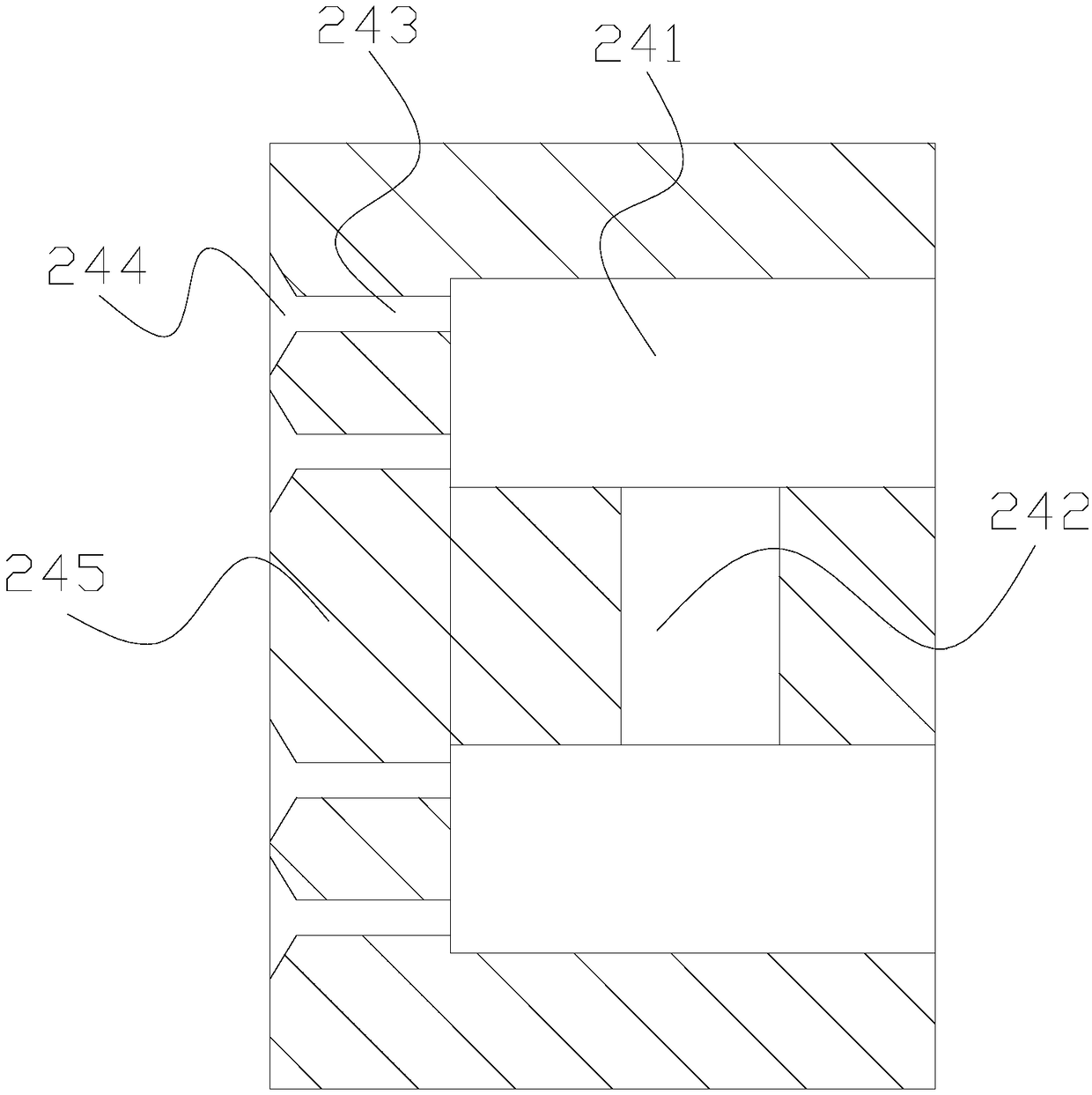

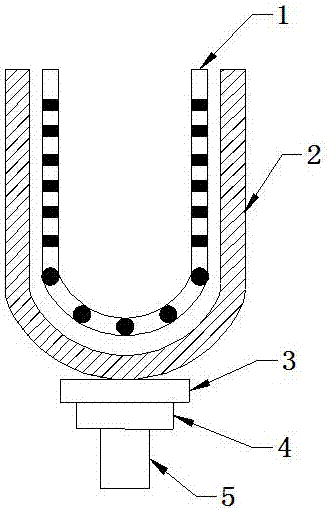

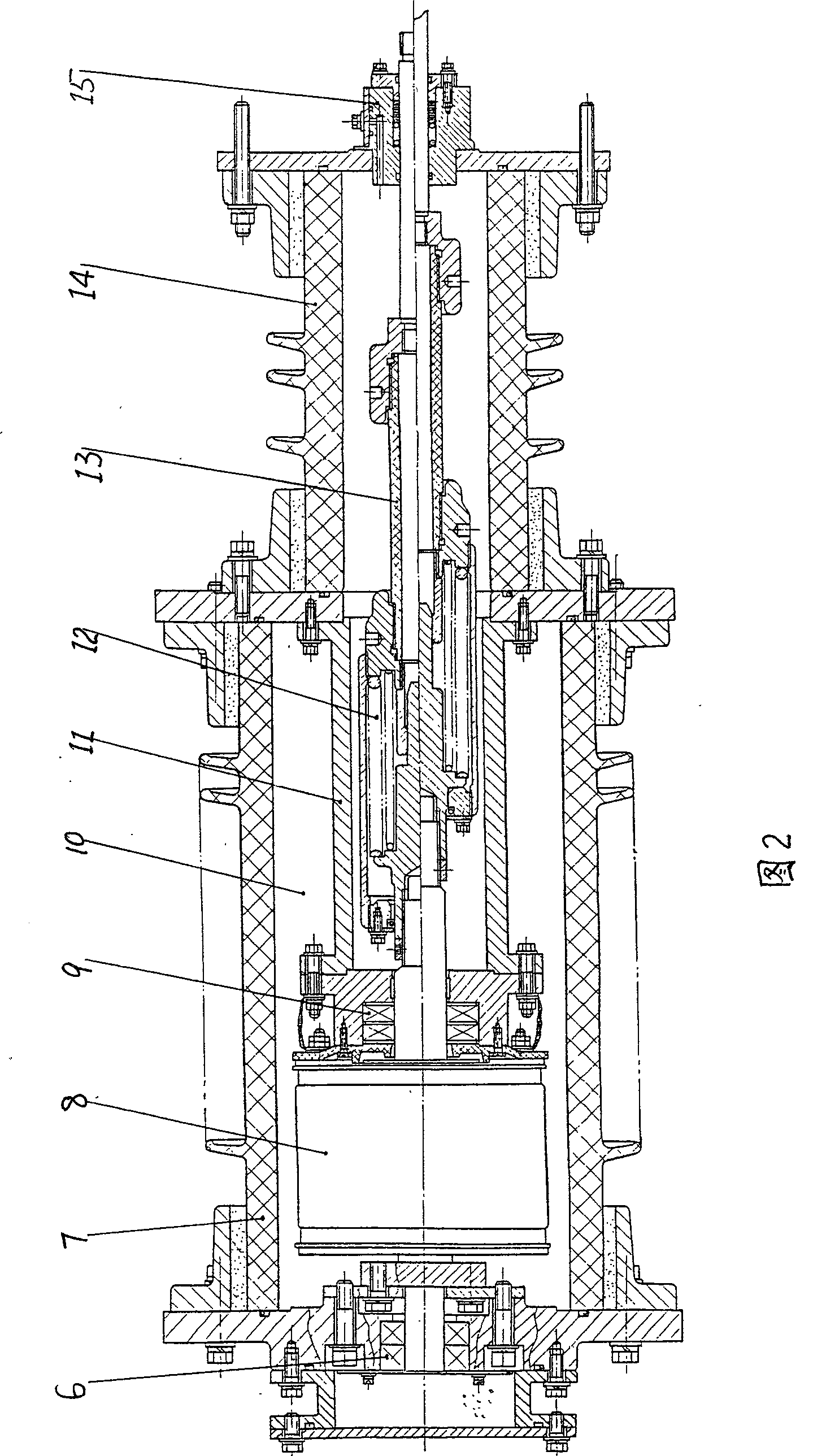

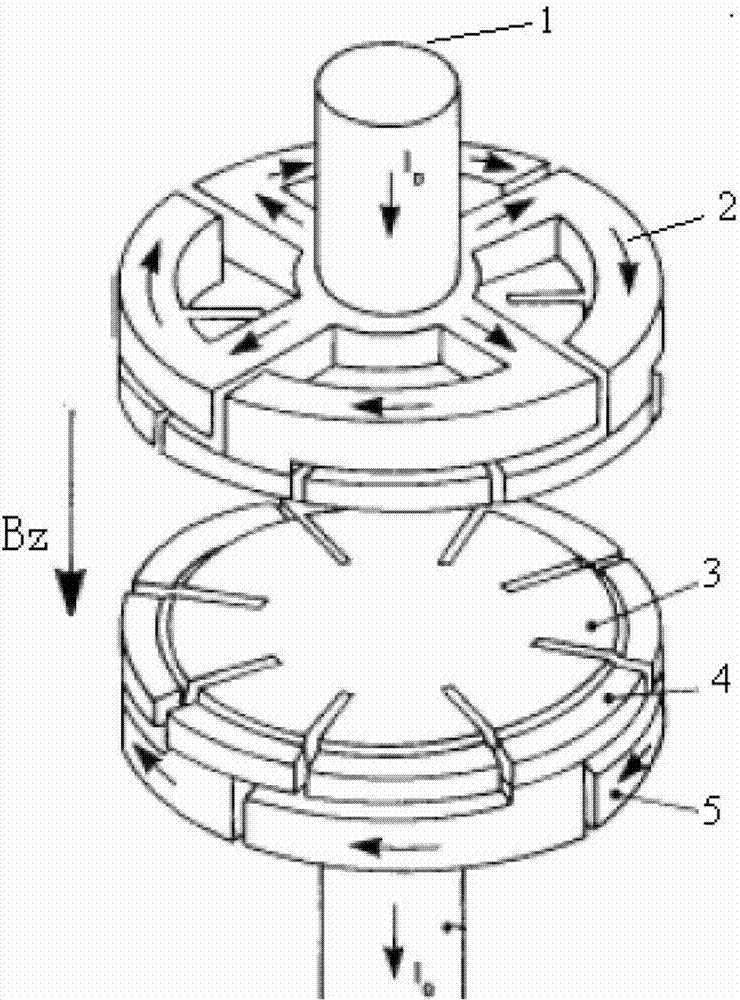

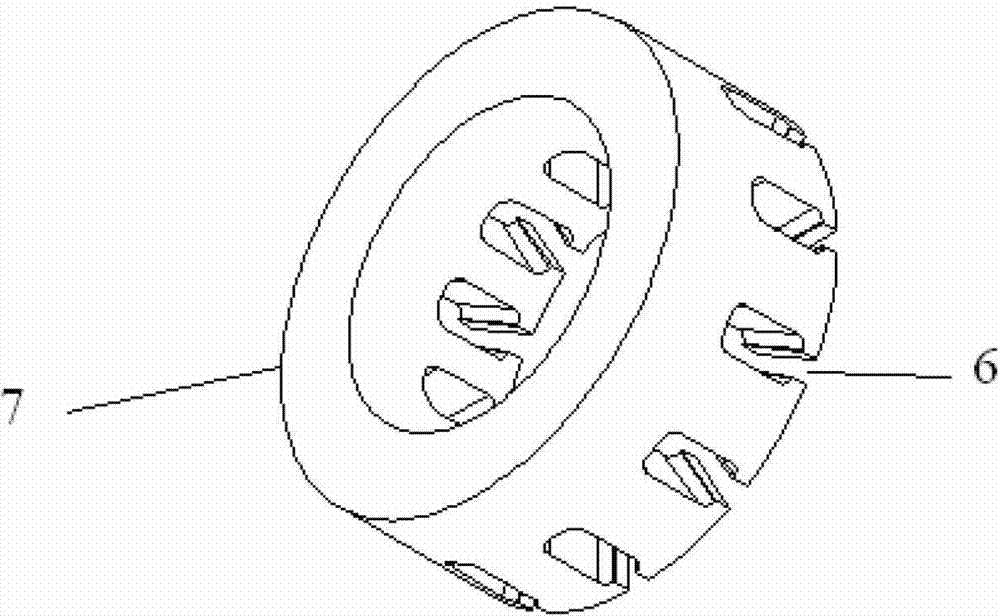

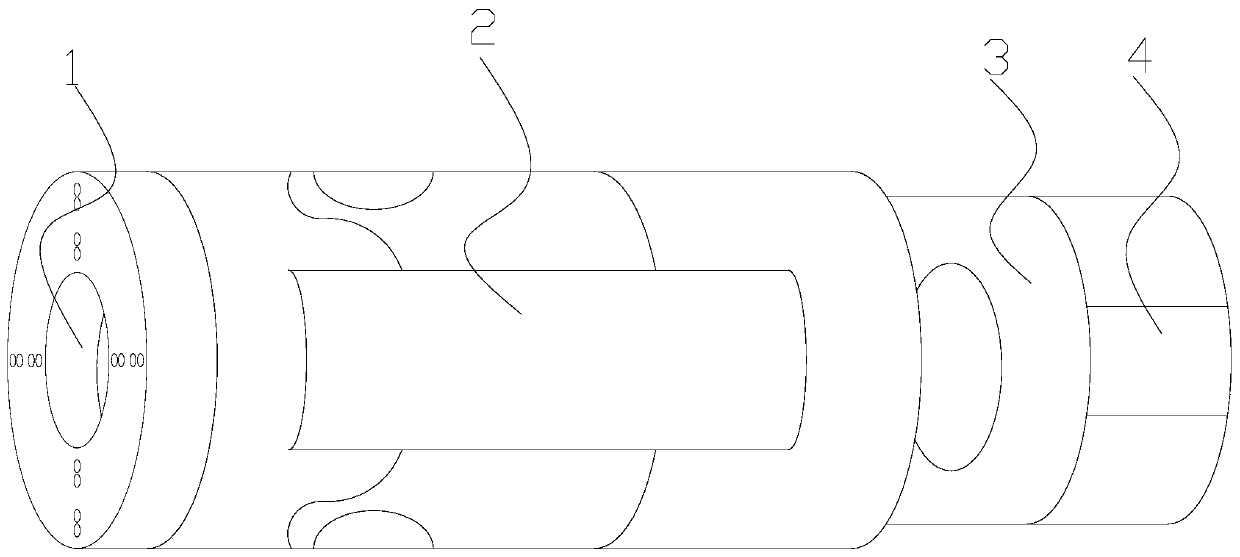

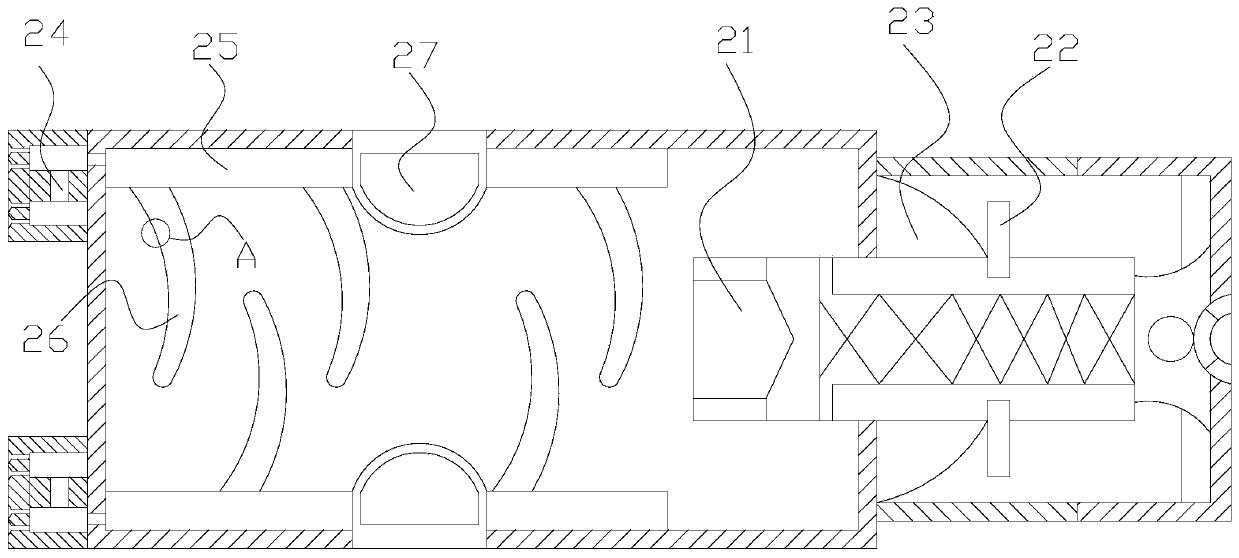

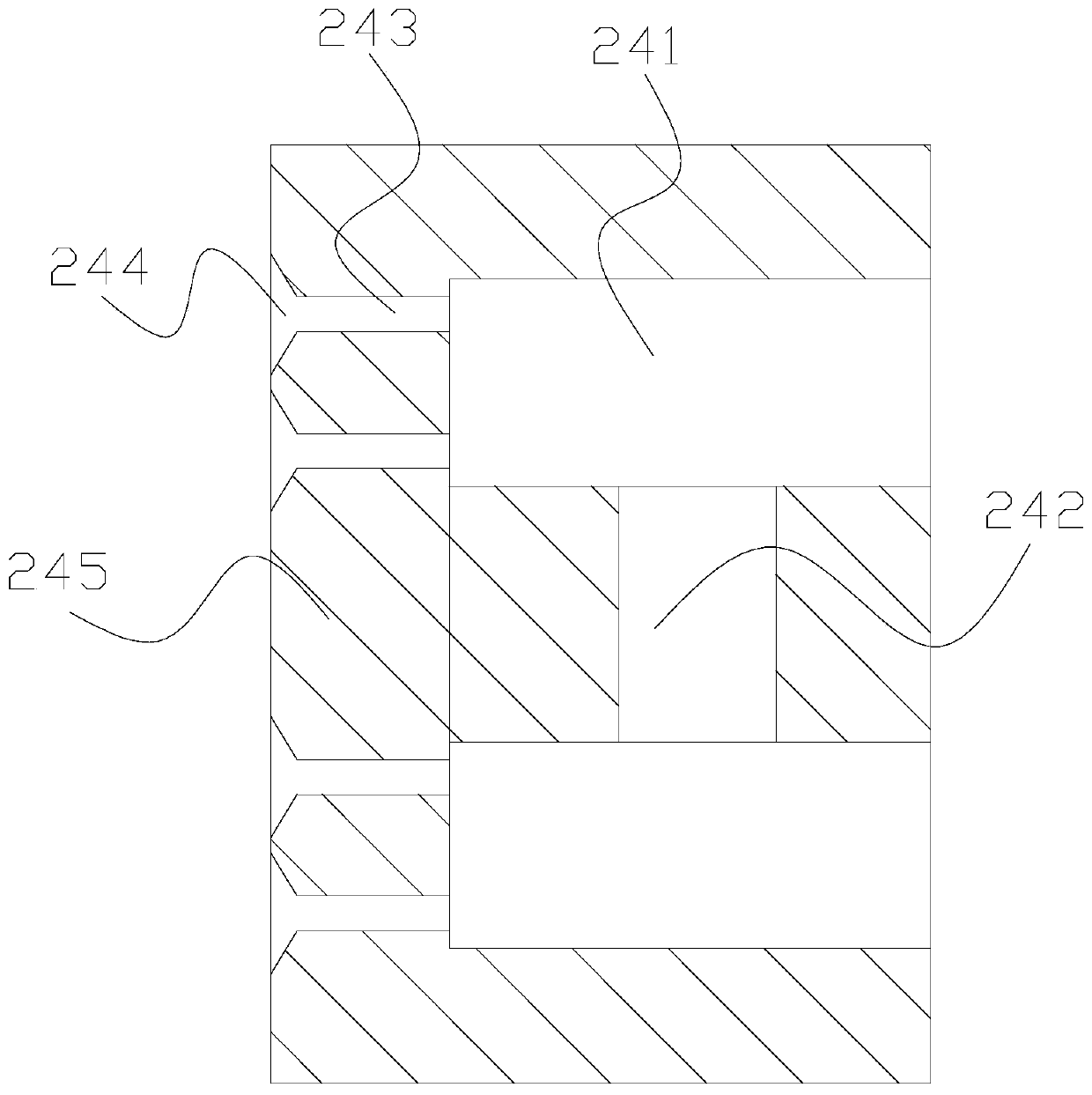

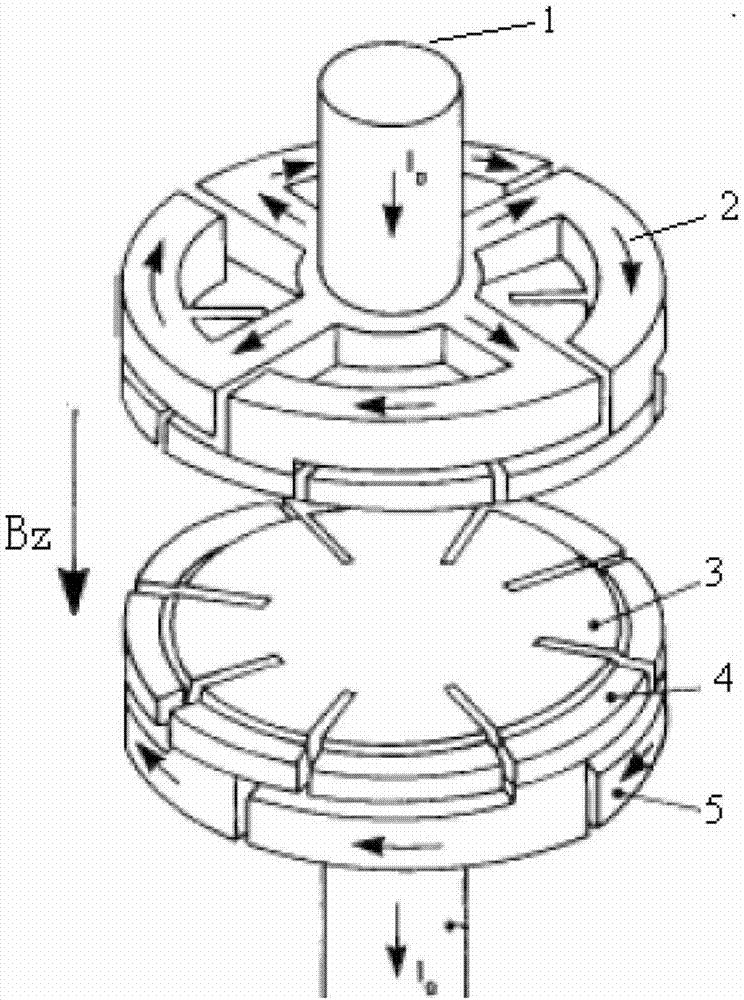

Disc-type overlapping gyromagnetic longitudinal blowing vacuum arc extinguish chamber

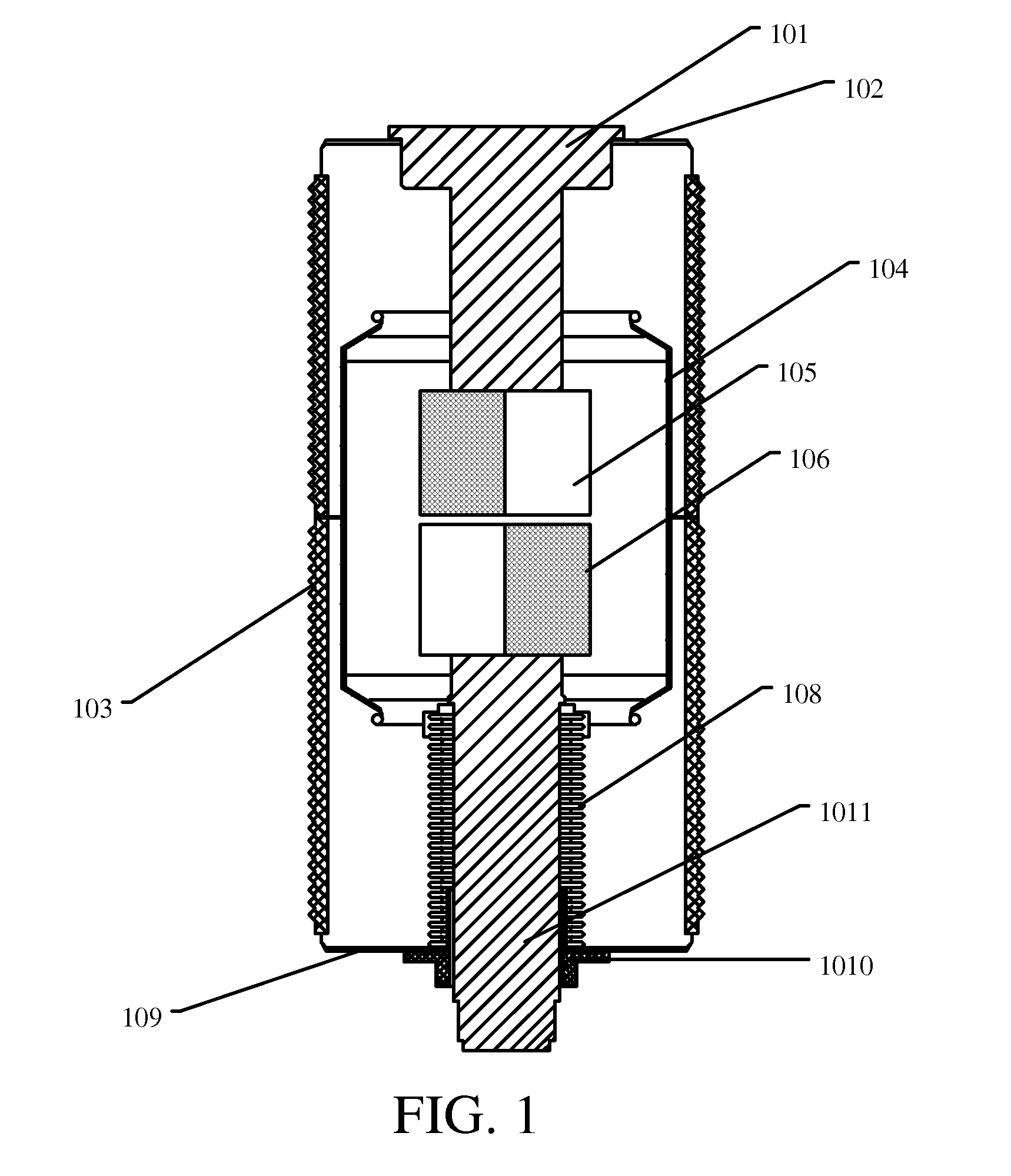

ActiveCN102522259AHigh strengthShorten burn timeHigh-tension/heavy-dress switchesAir-break switchesEngineeringConductor Coil

The invention belongs to a vacuum circuit breaker field and especially relates to a disc-type overlapping gyromagnetic longitudinal blowing vacuum arc extinguish chamber. The vacuum arc extinguish chamber comprises: a conducting rod (1), a contact cup (5), an iron core (7) and an electrode (4) which is connected to the contact cup (5). The contact cup (5) is fixedly matched with the conducting rod (1). The iron core (7) is placed in the contact cup (5). The contact cup (5) is provided with a plurality of circulation side slots with equal intervals. The iron core (7) is provided with the winding slots (6) with the equal intervals. More than two groups of the coaxial coil windings (8) are stacked into the winding slots (6) and the coaxial coil windings are staggered with a certain angle theta successively. According to the invention, through a strong force of a rotating magnetic field and simultaneously under an effect of a vertical magnetic field, an arc voltage can be reduced; arc columns are impelled to be uniformly distributed on an anode surface; arc energy release can be accelerated; a breaking capacity of the vacuum circuit breaker can be increased.

Owner:SHENYANG POLYTECHNIC UNIV

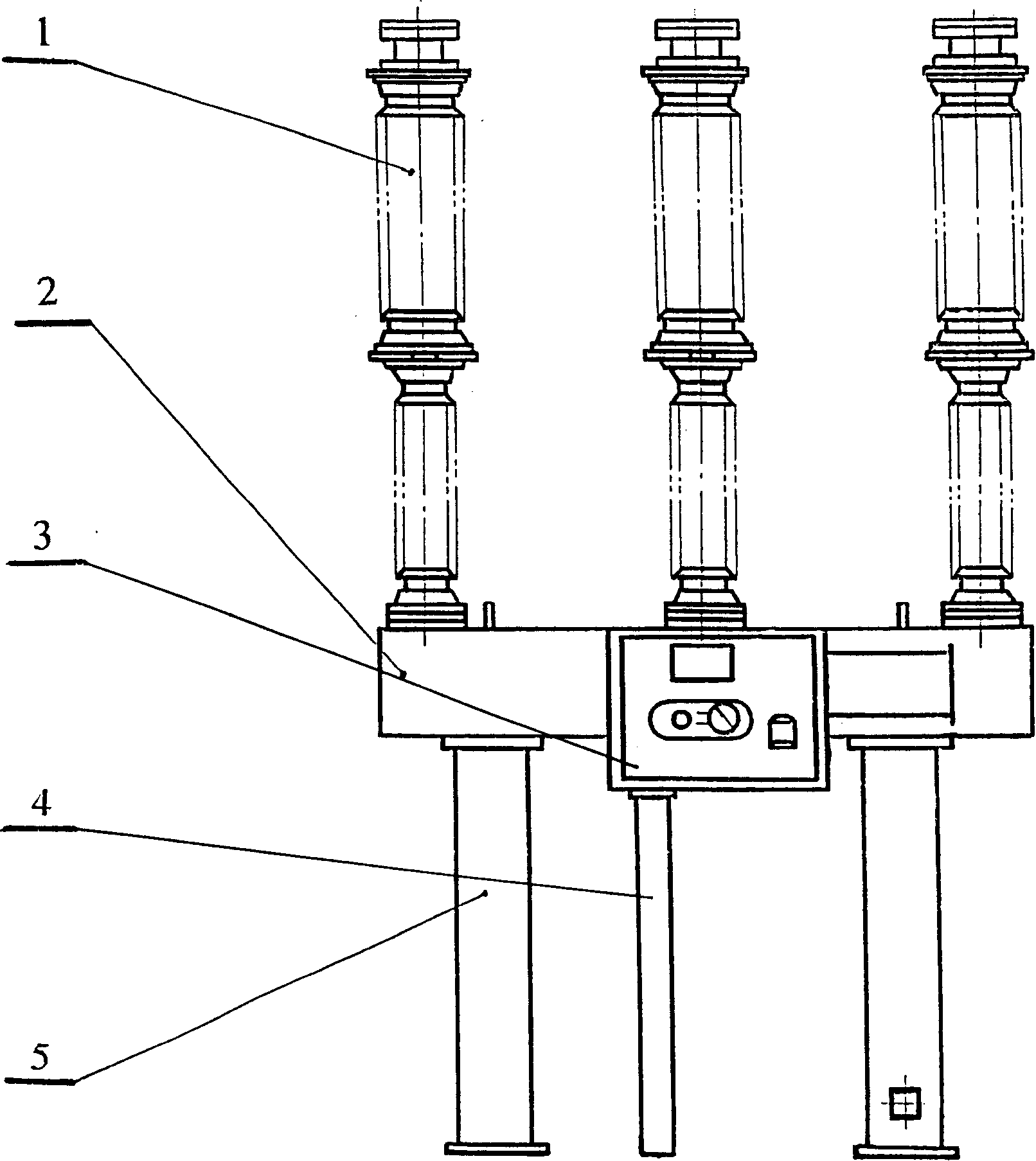

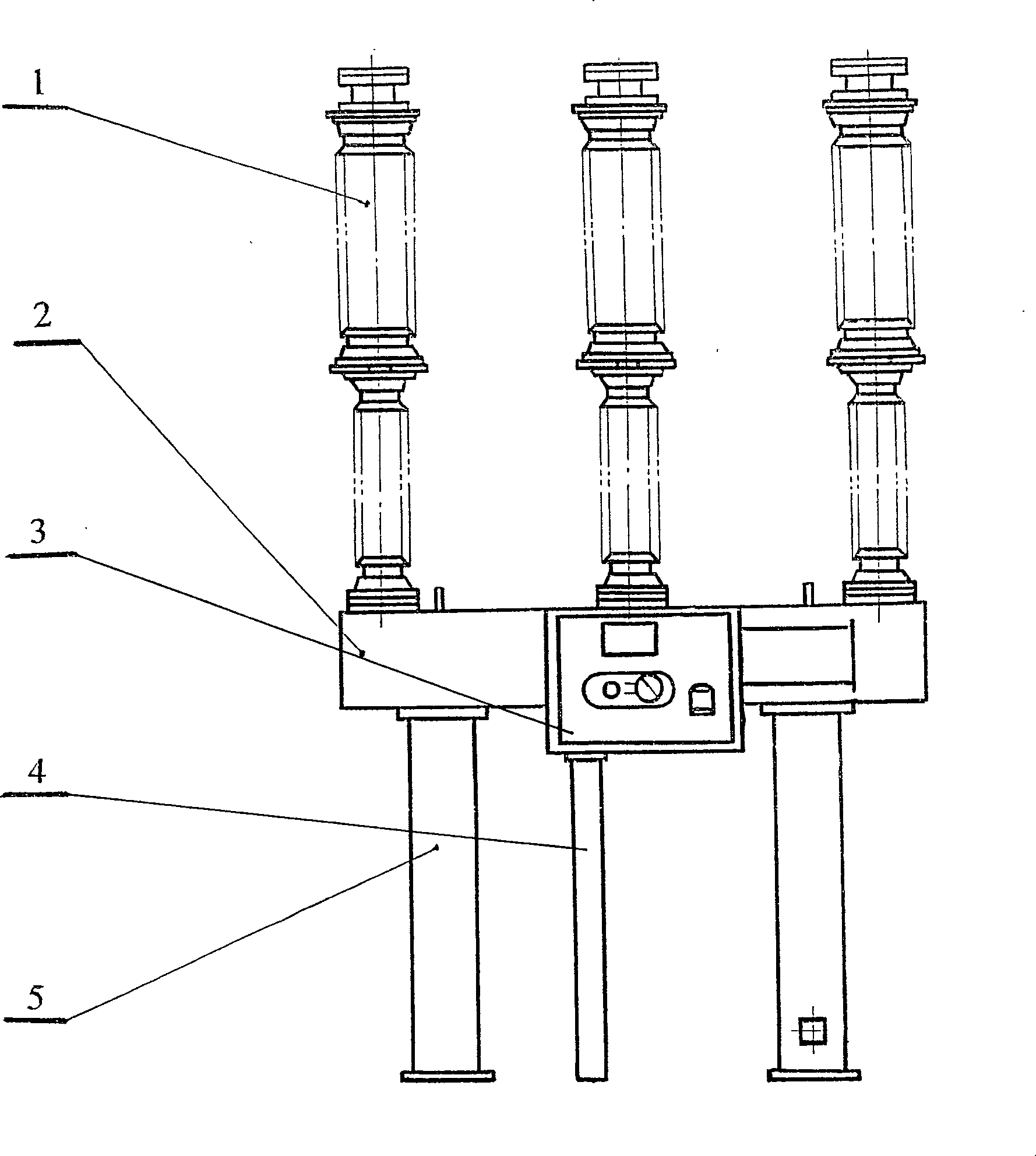

High-pressure vacuum circuit breaker

InactiveCN1848337ANo flashoverWon't break downHigh-tension/heavy-dress switchesAir-break switchesEngineeringThree-phase

The present invention relates to a high-voltage vacuum circuit-breaker. It is composed of upper wiring flange, lower wiring flange, arc extinguishing unit, frame, supporting frame and control box. The frame is fixedly mounted on the supporting frame, the three-phase arc extinguishing unit is fixedly mounted on the frame, all the movable components of said arc extinguishing unit are mechanically connected on the spring mechanism in the control box, the arc extinguishing unit is characterized by that in its arc extinguishing chamber a vacuum tube is mounted, and its movable contact and static contact are mounted in the vacuum tube.

Owner:瓦房店高压开关有限公司

Purifying device and purifying method

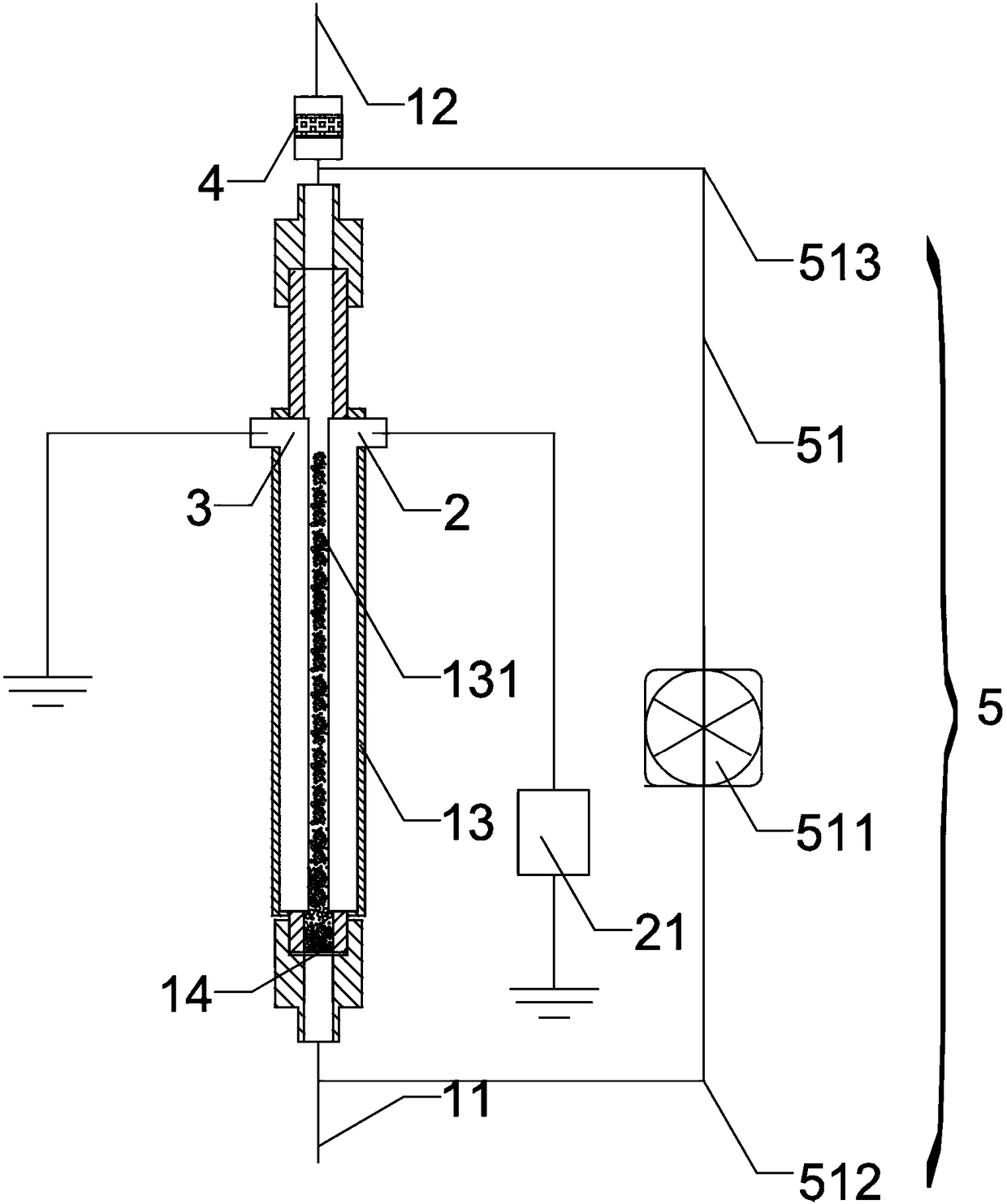

PendingCN109126402AImprove uniformityReduce energy consumptionGas treatmentDispersed particle separationLow voltageFluidized bed

The invention relates to the field of environment protection, and discloses a purifying device which comprises a fluidized bed. The fluidized bed comprises a hollow reaction pipe, a gas inlet and a gas outlet, wherein the gas inlet and the gas outlet are formed in the two ends of the reaction pipe. Biomass conductive carbon particles are arranged in the reaction pipe and can be in a fluidized state under the effect of gas flow. The purifying device further comprises a high-voltage electrode and a low-voltage electrode which are arranged on the two sides of the fluidized bed. Organic pollutantgas enters the reaction pipe, the potential difference is formed between the high-voltage electrode and the low-voltage electrode, the biomass conductive carbon particles in the fluidized state are broken down to form discharging, and the organic pollutant gas is degraded. By means of the purifying device, energy consumption can be reduced, and the organic pollutant gas degradation capacity can beimproved.

Owner:ZHEJIANG UNIV

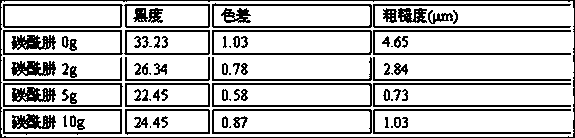

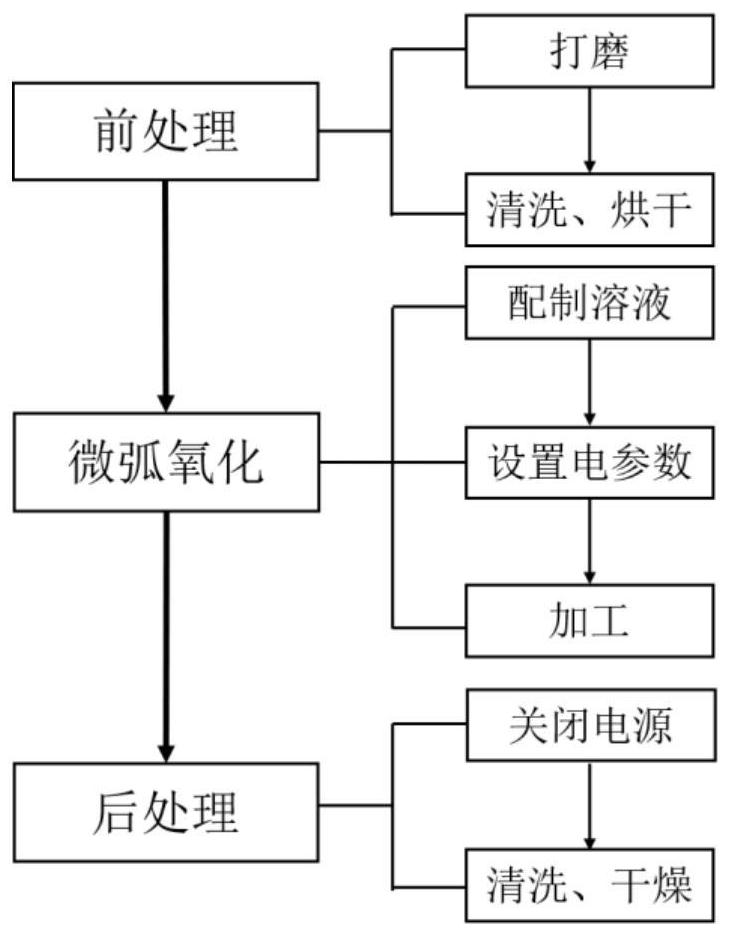

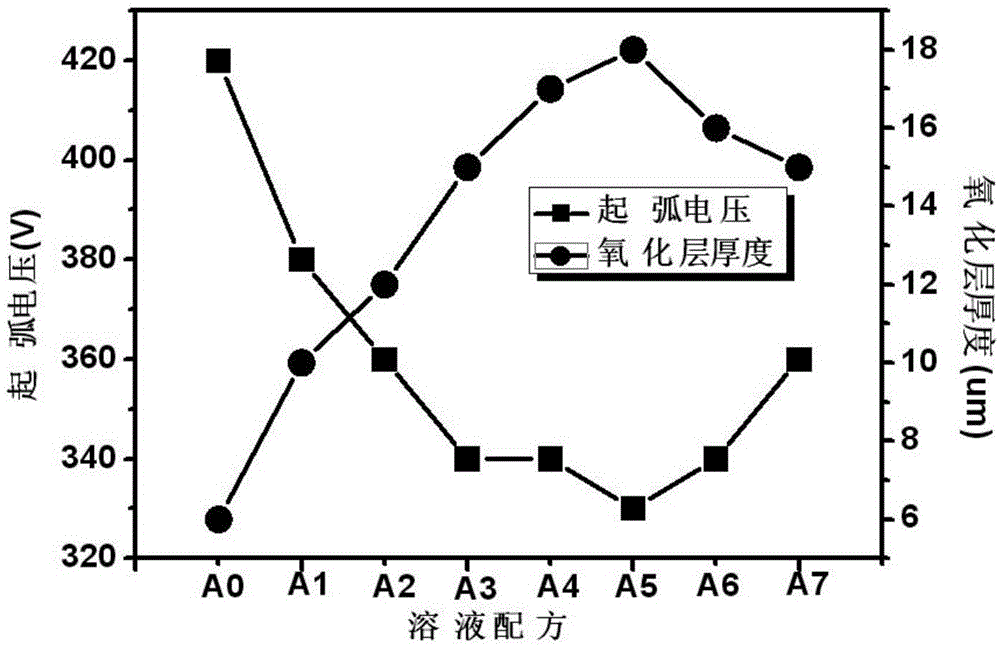

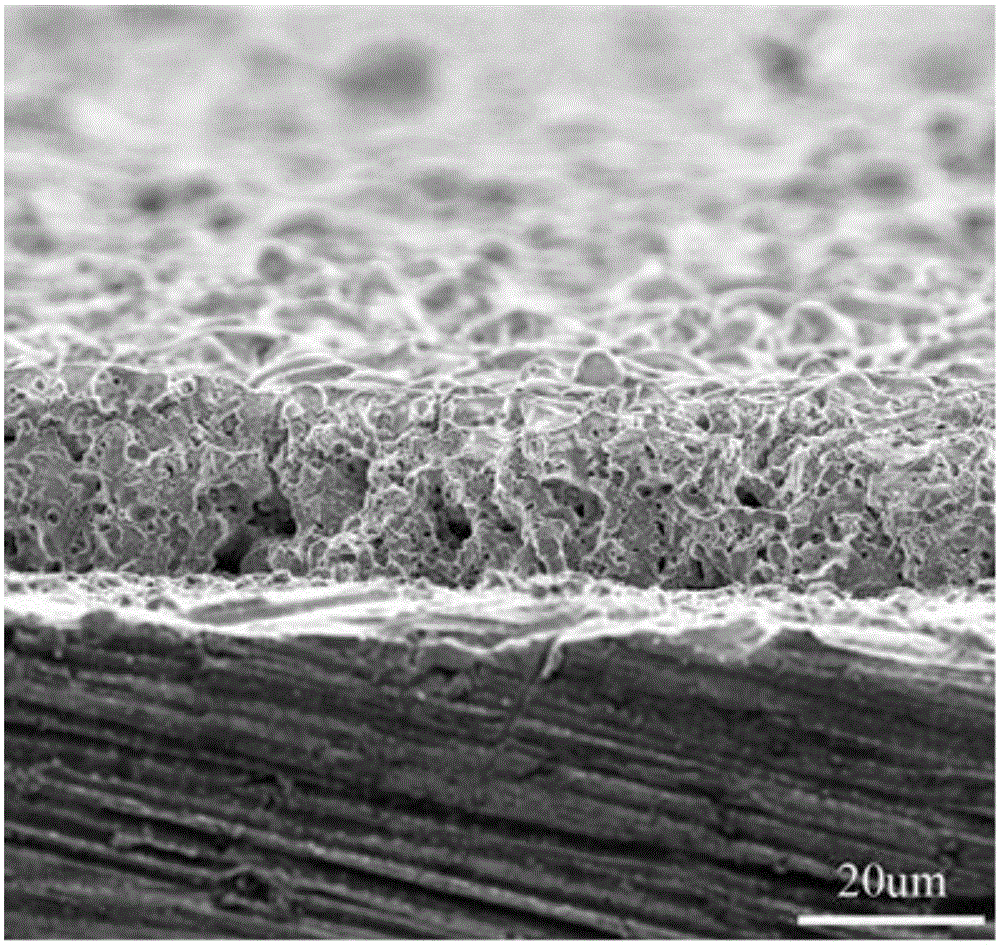

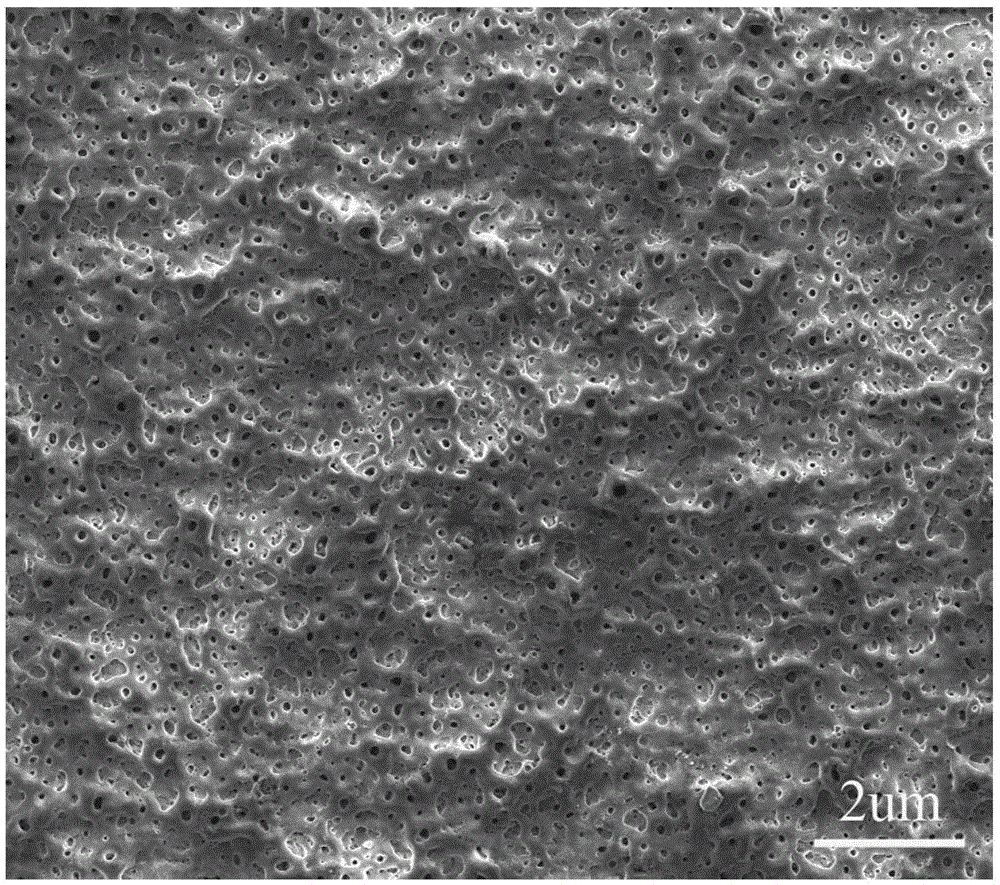

Magnesium alloy micro-arc oxidation black ceramic membrane and preparation method thereof

InactiveCN109440164AQuality improvementImprove corrosion resistanceSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a magnesium alloy micro-arc oxidation blackness ceramic membrane and a preparation method thereof. The preparation method comprises the steps: a magnesium alloy is polished through SiC abrasive paper, then subjected to deoiling washing, blow-dried through an electric air blower, and placed into a drier for standby application; and the magnesium alloy serves as an anode, a stainless steel sheet serves as a cathode, the pretreated magnesium alloy is soaked in an electrolyte, the magnesium alloy is subjected to micro-arc oxidation in a bipolar pulse constant current mode,then taken out to be washed through deionized water and dried, and then the black ceramic membrane is obtained. Under the condition that electric parameters are not changed, a membrane forming promoter, namely carbohydrazide is added into the electrolyte, the arcing voltage is lowered, the membrane layer quality is improved, thus the membrane layer corrosion resisting property is good, the black ceramic membrane has the small blackness value, even color and firmer membrane-based combination, and the advantages that the prepared membrane layer quality is high, the preparation efficiency is high, and unit energy consumption is low are achieved.

Owner:DONGGUAN UNIV OF TECH

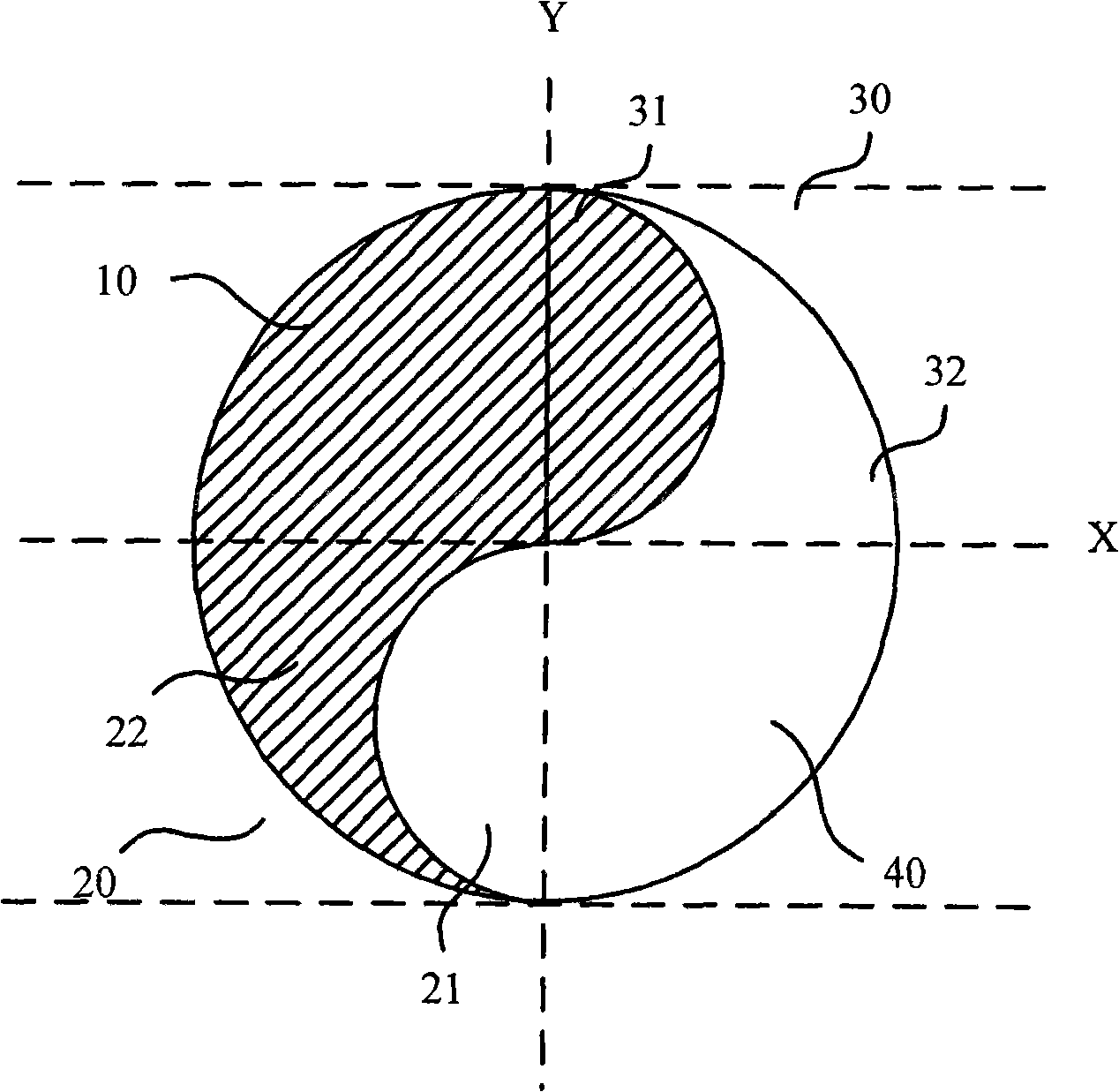

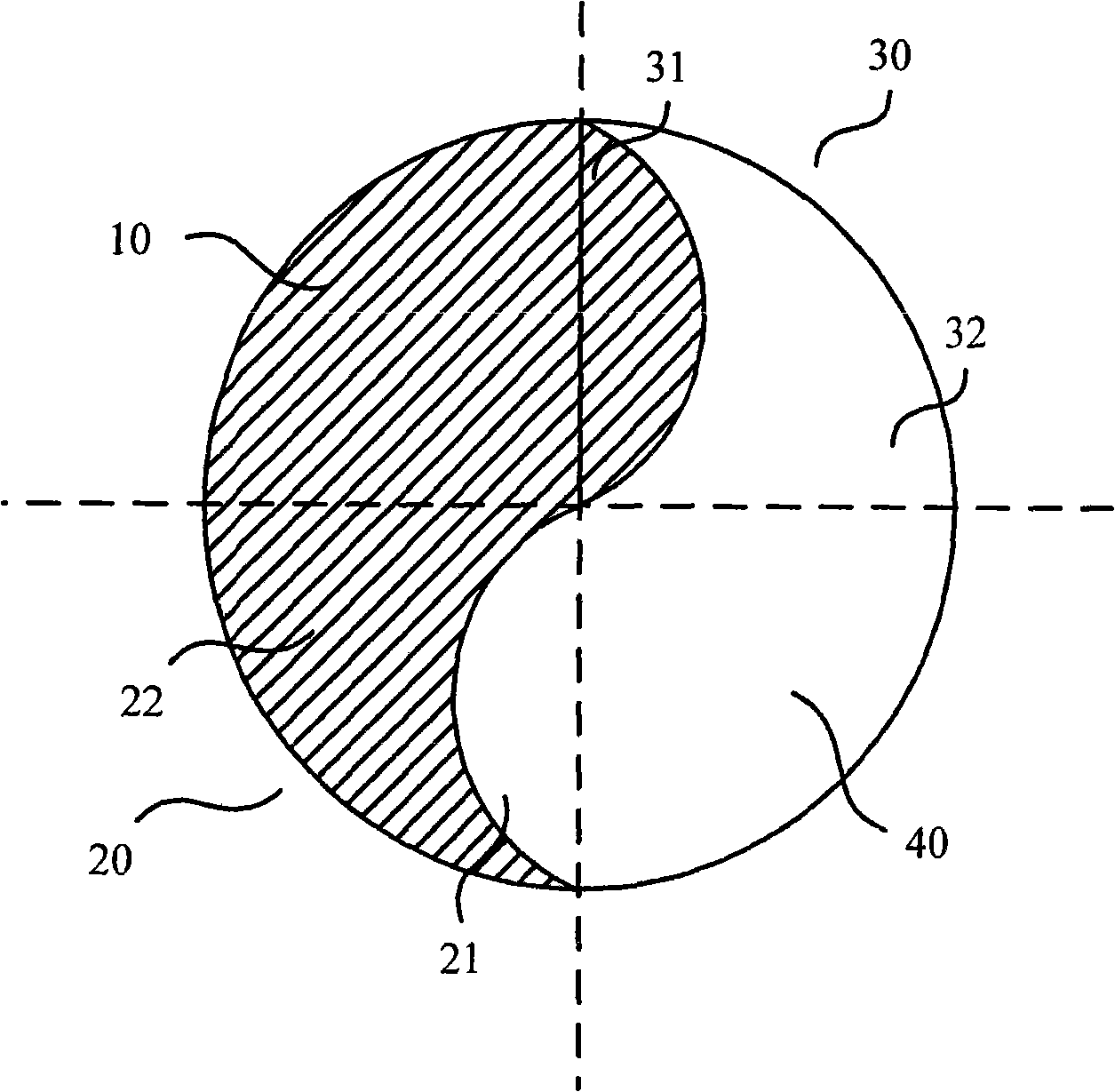

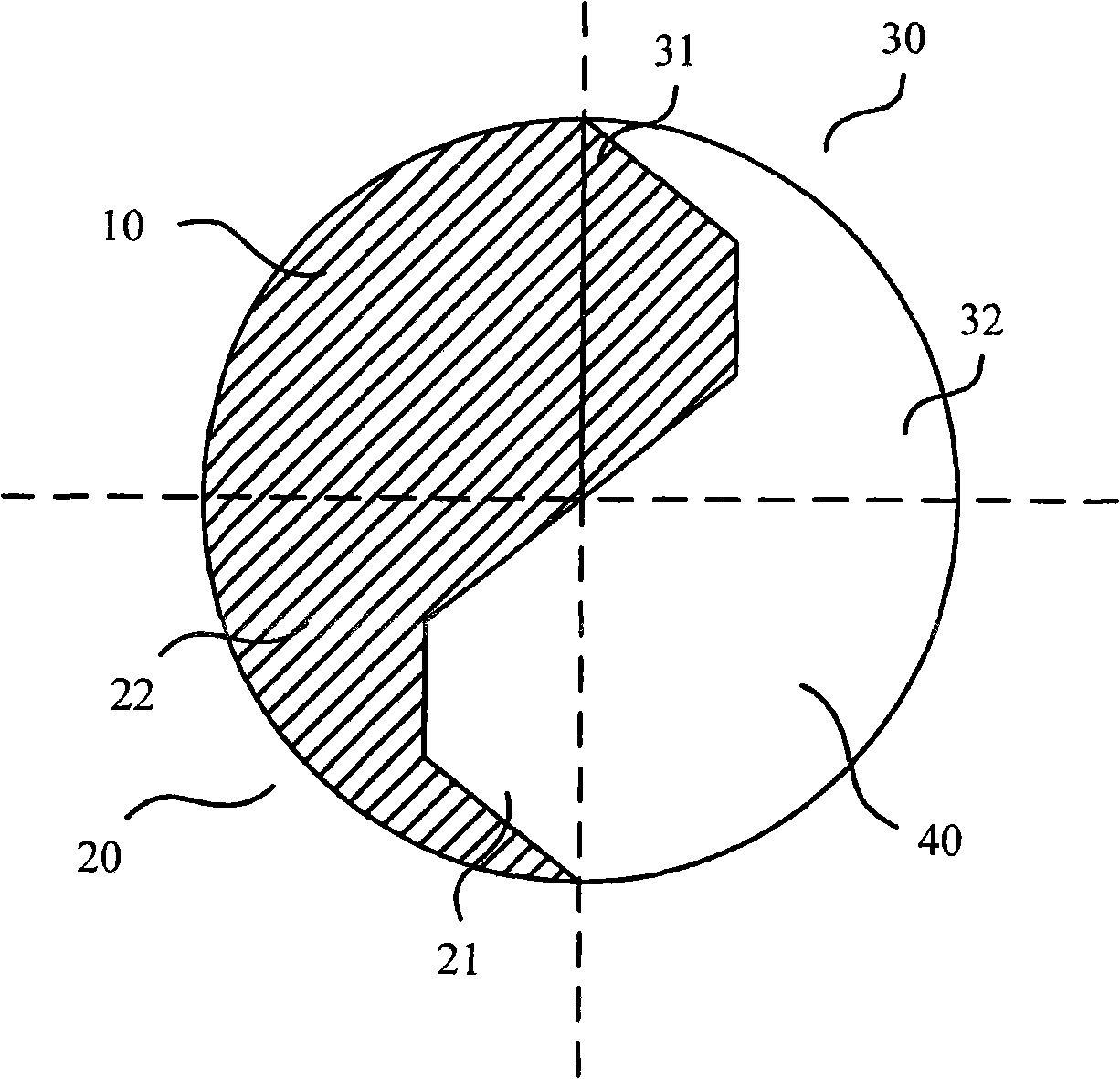

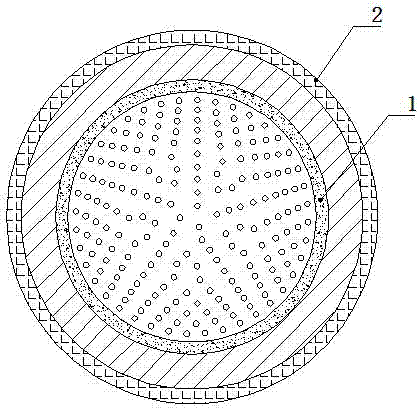

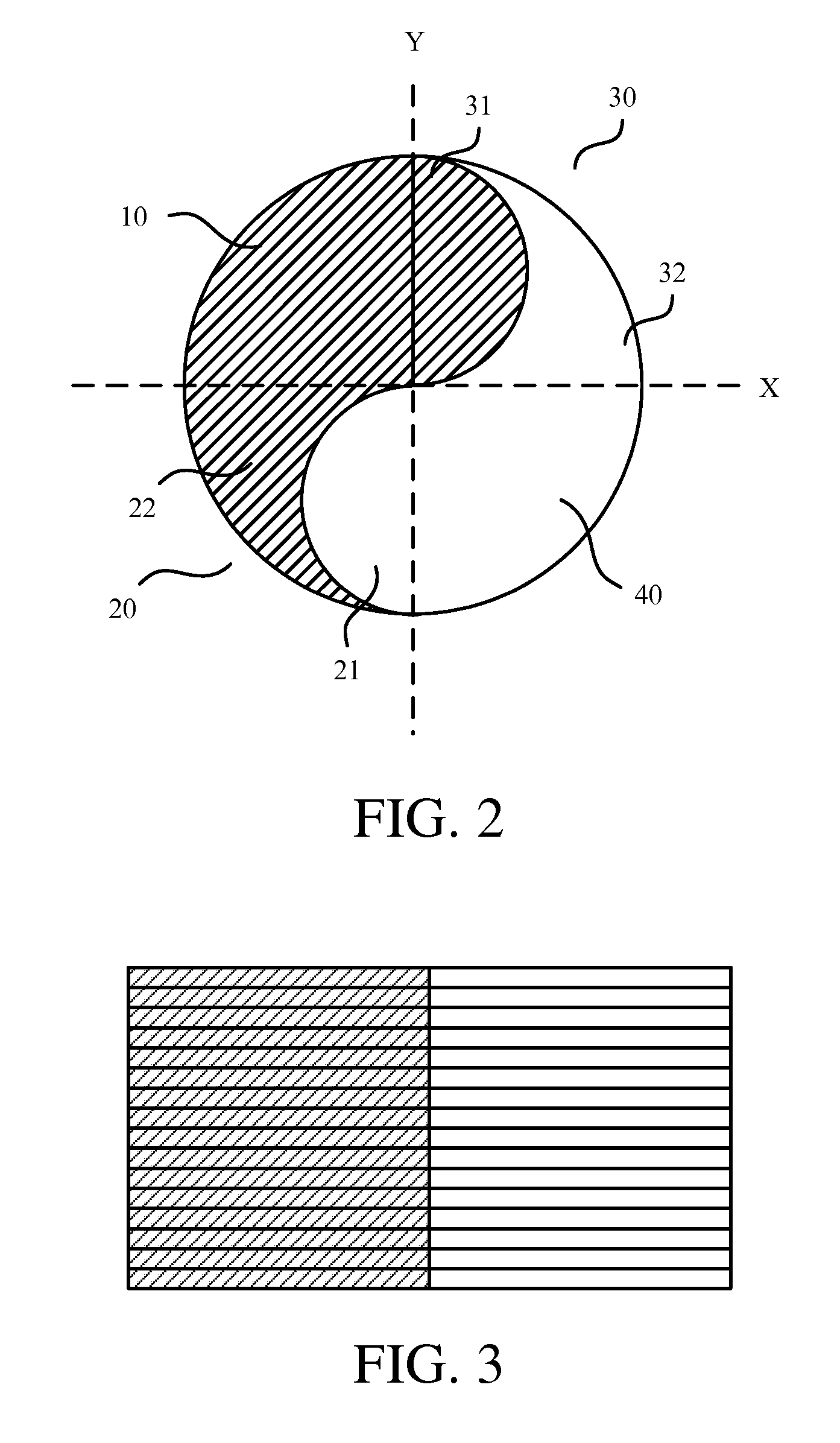

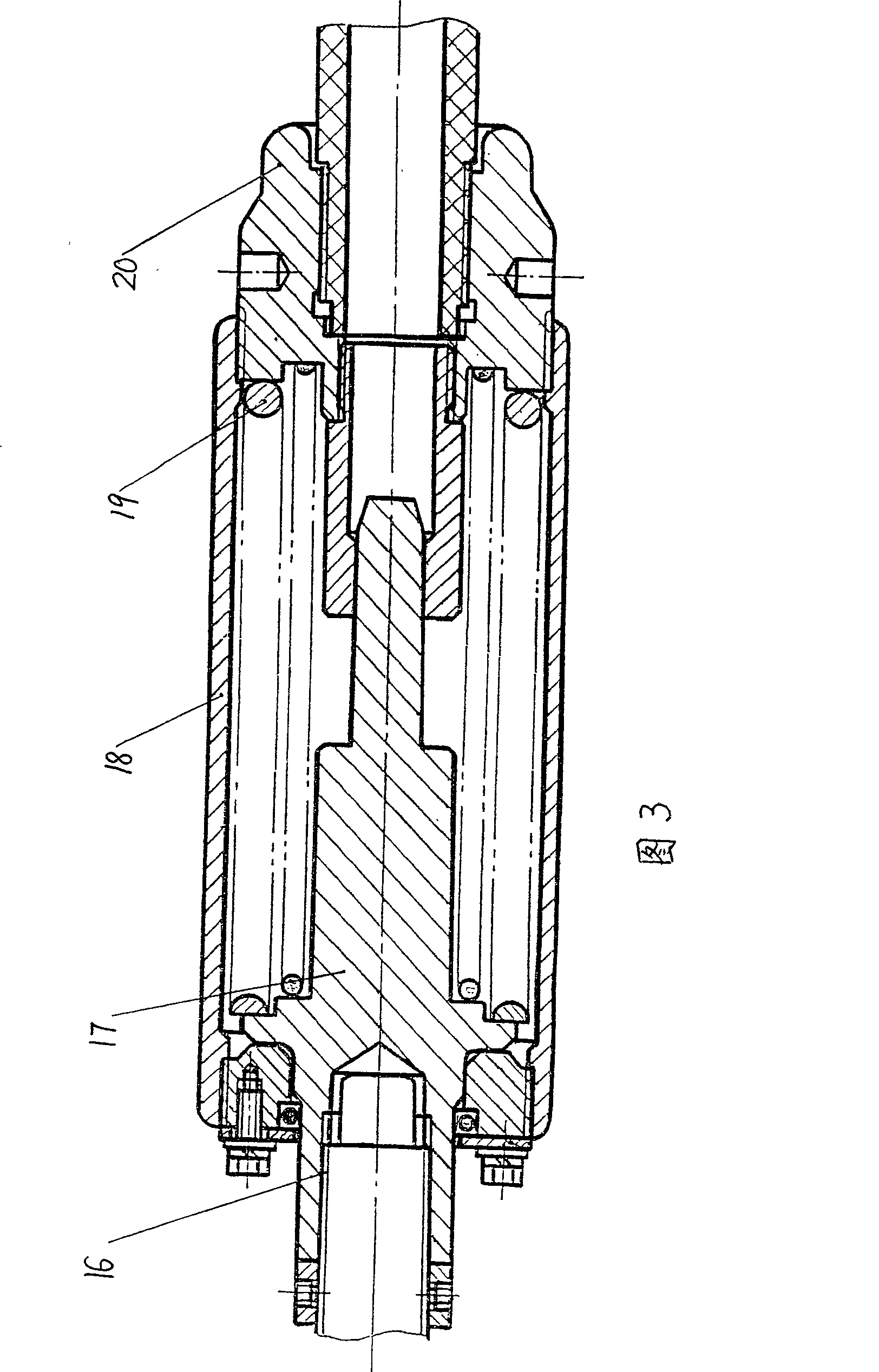

Vacuum switch contact

InactiveCN101359555AReduce the likelihood of reignitionEffective arc extinguishingContact surface shape/structureHigh-tension/heavy-dress switchesBit lineHigh pressure

The invention relates to a vacuum switch contact, comprising an electric conduction assembly and a magnetic conduction assembly which extend along the same direction and are in abuttal joint with each other, making up the main body of the contact; wherein, the cross section of the magnetic conduction assembly is divided into a first section and a second section by a bit line of the magnetic conduction assembly, and the area of the first section is larger than that of the second section. Since one end of the vacuum switch contact is big and the other end is small, the magnetic field generated by the magnetic conduction assembly can flow into the main body of another contact because of the small space between the main bodies of the two contacts, thus providing a longitudinal magnetic field which can extinguish arc. The vacuum switch contact can reduce restrike possibility at the time of voltage disjunction, reduce arc voltage, and realize arc extinguishing and satisfy the requirement of high voltage disjunction.

Owner:韩玉杰

Aluminum-lithium alloy micro-arc oxidation method and electrolyte adopted by same

The invention relates to the technical field of aluminum-lithium alloy surface treatment, and discloses an aluminum-lithium alloy micro-arc oxidation method and an electrolyte adopted by the same. Thealuminum-lithium alloy micro-arc oxidation method comprises three steps of pretreatment, micro-arc oxidation and aftertreatment. The adopted electrolyte comprises solute and a solvent, and comprisesthe following components including 10-20 g / L of sodium silicate, 6-10 g / L of strong base, 3-5 g / L of sodium tungstate and 0.5-1 g / L of an additive, and deionized water is used as the solvent. According to the aluminum-lithium alloy micro-arc oxidation method and the electrolyte, the content of the alkaline solute is increased, micro-arc oxidation is promoted to quickly form a film, and the time required by processing is shortened. The solution is good in stability, high in repeated utilization rate and low in cost of used raw materials, a film layer with a certain thickness and corrosion resistance can be prepared within a short time, after 600-hour complete soaking corrosion, the surface film layer is still complete, and an alloy matrix is kept intact; and an electrochemical test shows that the corrosion current density can be reduced by nearly two orders of magnitudes.

Owner:SHANGHAI JIAO TONG UNIV

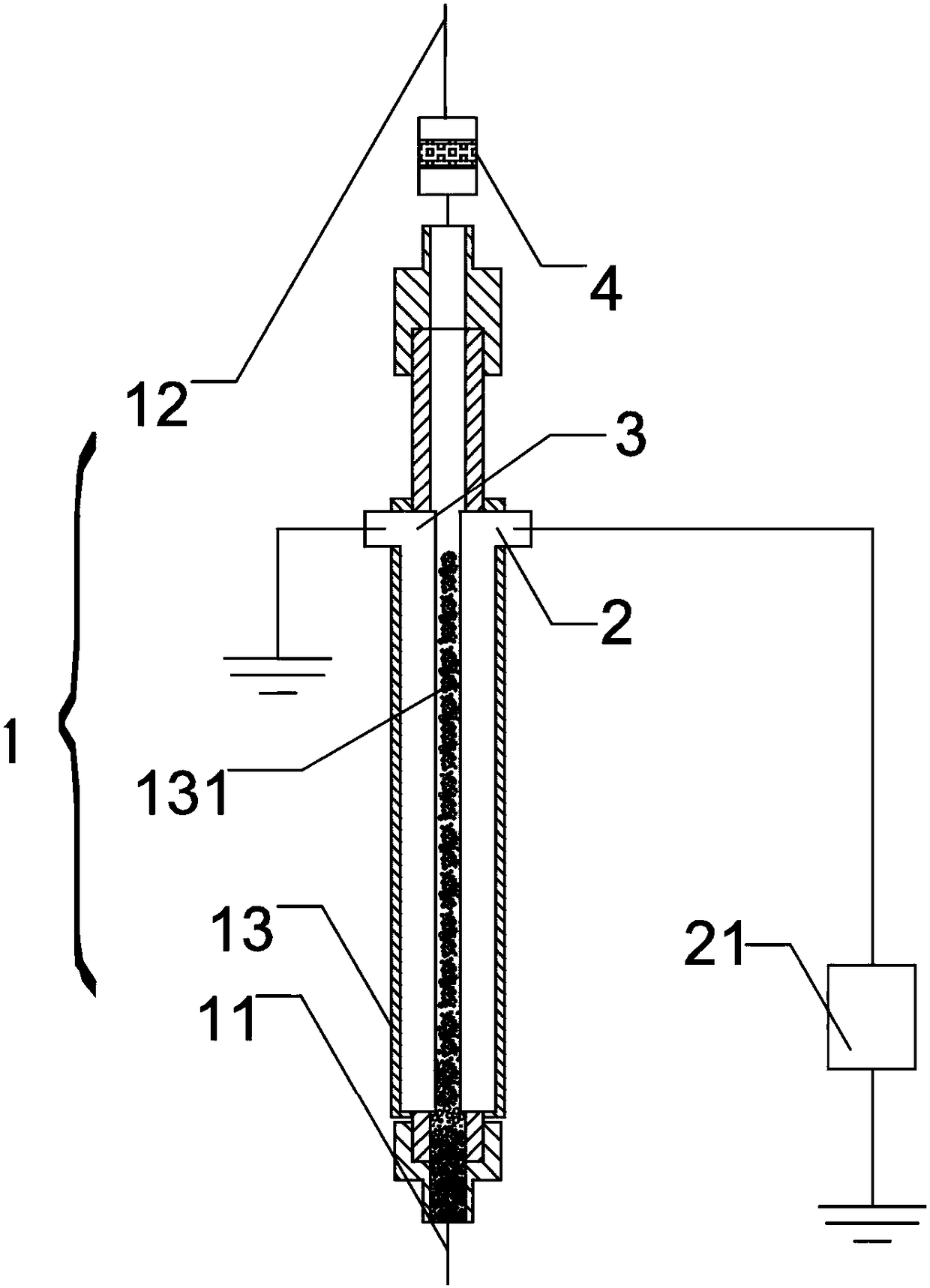

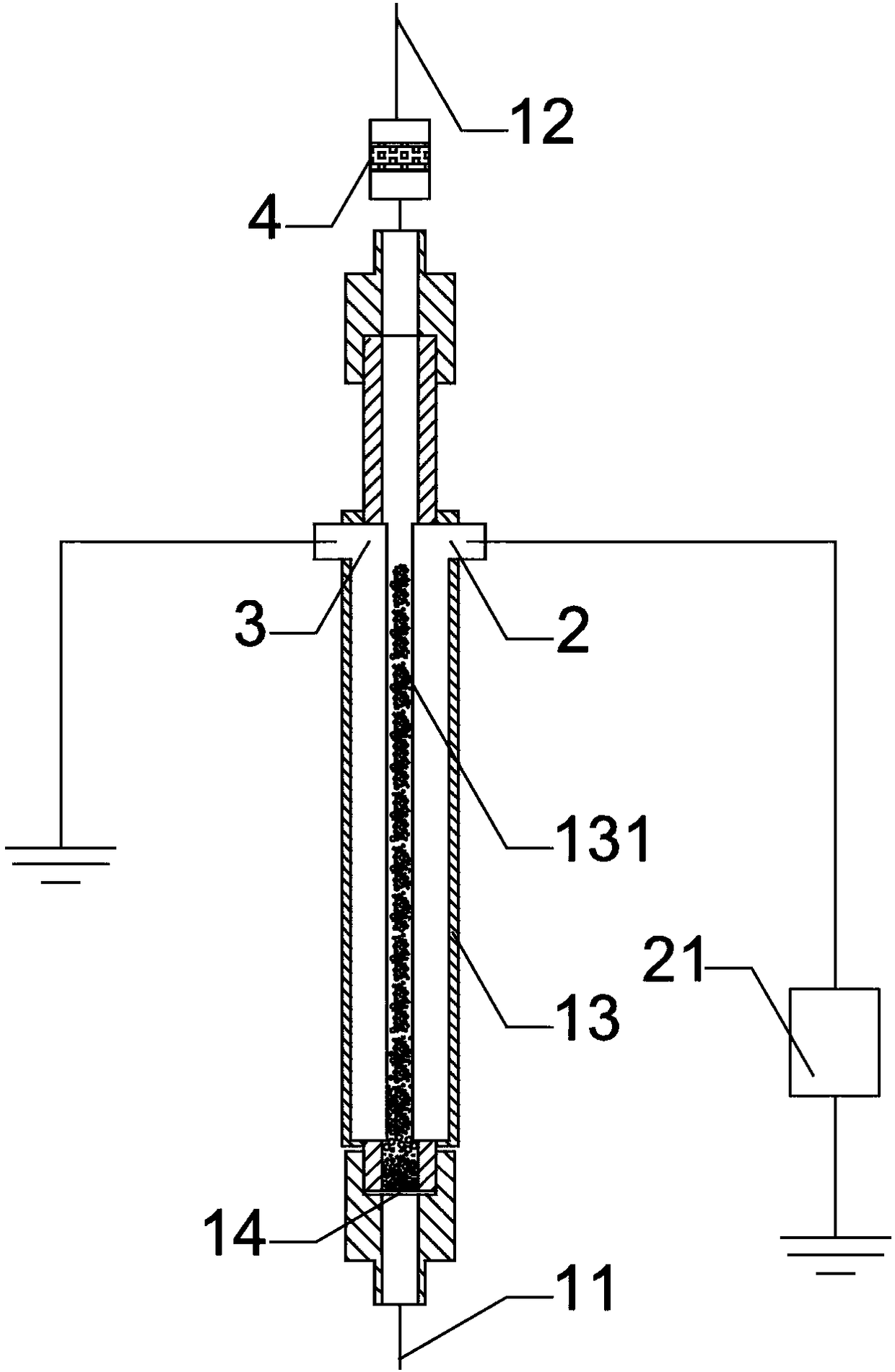

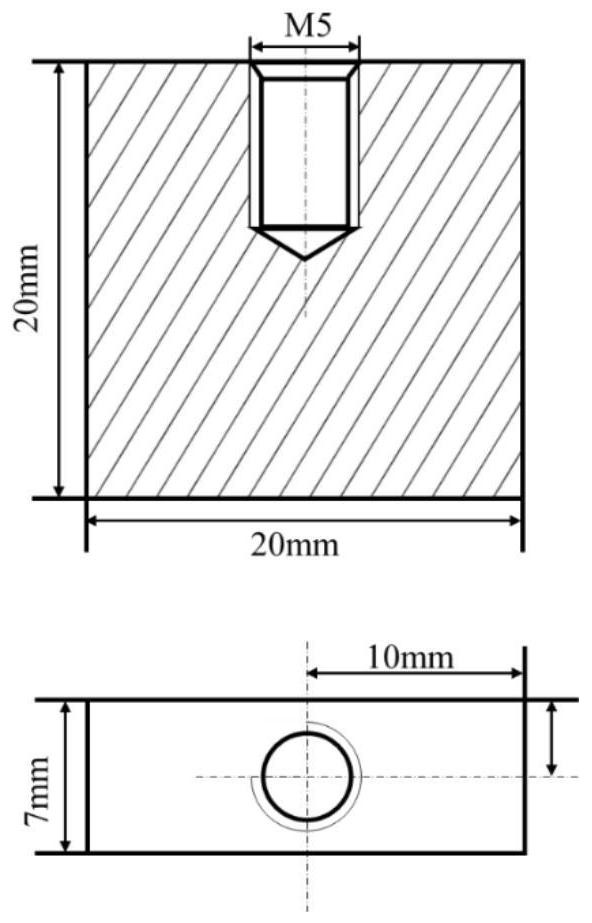

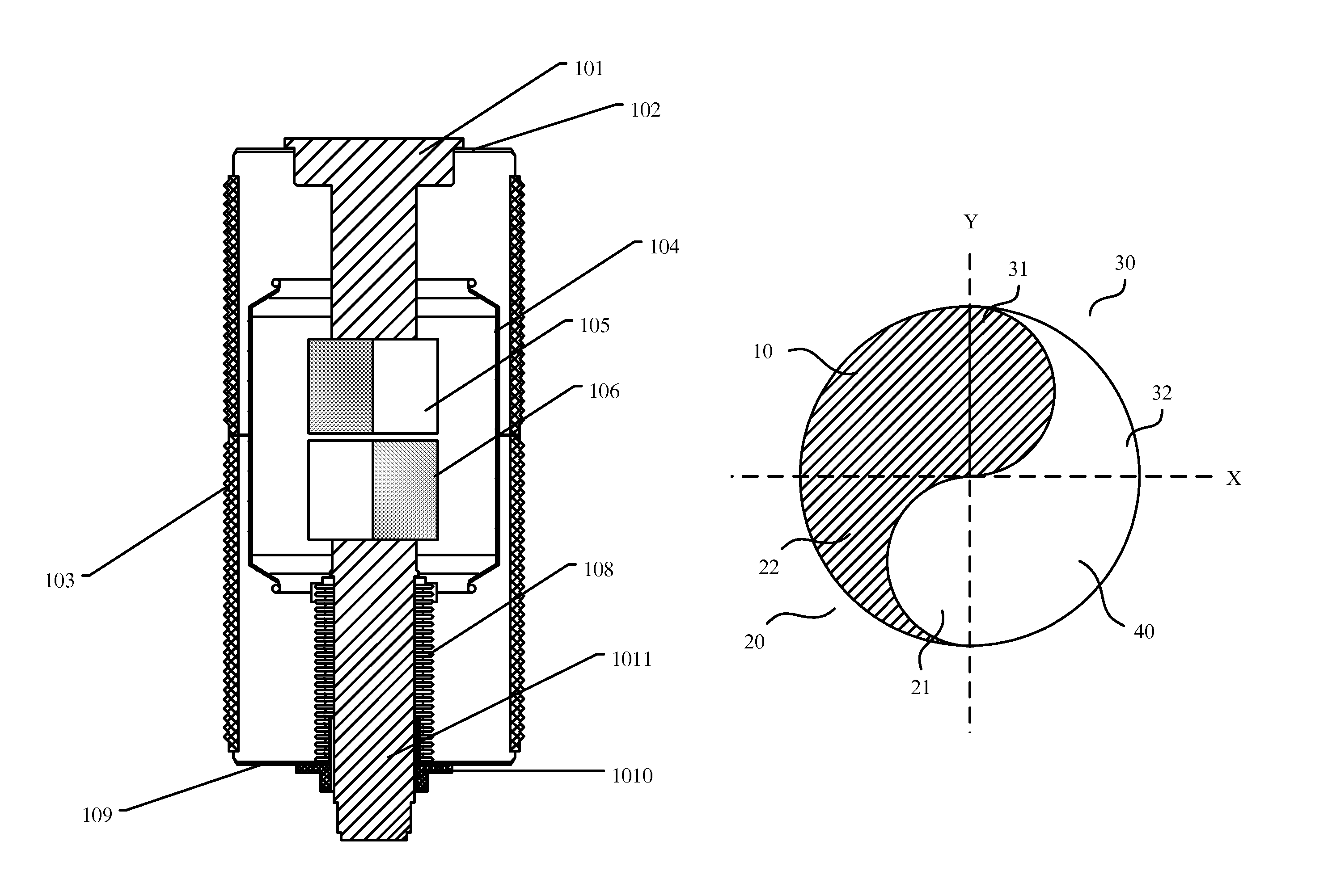

Non-triggering-type electrode capable of reducing arcing energy of vacuum electric arc thruster

PendingCN108194295AReduce arc voltageSave energyMachines/enginesUsing plasmaConductive materialsApplication areas

The invention provides a non-triggering-type electrode capable of reducing arcing energy of a vacuum electric arc thruster. According to the non-triggering-type electrode, the problems that an existing vacuum electric arc thruster needs large energy, and a power source is complex in structure and large in size and weight are solved. The non-triggering-type electrode comprises an anode and a cathode. The anode is cylindrical, and the cathode is in a drum shape and is coaxially arranged outside the anode in a sleeving mode; a drum-shaped insulating medium is further arranged between the cathodeand the anode, and the cathode and the anode both make contact with the insulating medium; and the exposed surface of the insulating medium is coated with a layer of conductive material. A non-triggering-type discharge is adopted, the flashover electric arc generating probability is increased, and the energy required for arcing of the vacuum electric arc thruster is reduced to a great extent; thestructure of a power source is simplified, and the size of weight of the power source are decreased; and the application field of the vacuum electric arc thruster is expanded, and thus the vacuum electric arc thruster has higher application value.

Owner:XIAN AEROSPACE PROPULSION INST

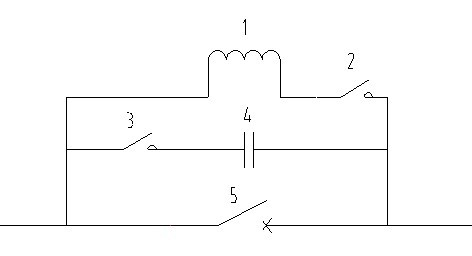

Self-powered type direct-current quick circuit breaker

InactiveCN102420084AExtended service lifeRealize passive operationCircuit-breaking switch detailsElectrical polarityArc energy

The invention discloses a self-powered type direct-current quick circuit breaker which comprises a circuit breaker switch main body, a first transient connecting device, a second transient connecting device, an arc voltage suppressing device and an energy absorbing device, wherein a series branch circuit consisting of the arc voltage suppressing device and the first transient connecting device is connected at two ends of the circuit breaker switch main body in parallel and is used for generating a suppression voltage of which the polarity is opposite to that of the arc voltage; and a series branch circuit consisting of the energy absorbing device and the second transient connecting device is connected at two ends of the circuit breaker switch main body in parallel and is used for absorbing arc energy generated by the circuit breaker switch main body in the switching in / off process. According to the self-power type direct-current quick circuit breaker, the switching on / off passive operation of the circuit breaker switch main body can be realized; meanwhile, the roles in reducing the arc energy and extinguishing the arc can be played; the electromagnetic pollution is avoided; and the service life of the circuit breaker can be prolonged.

Owner:XUJI GRP +1

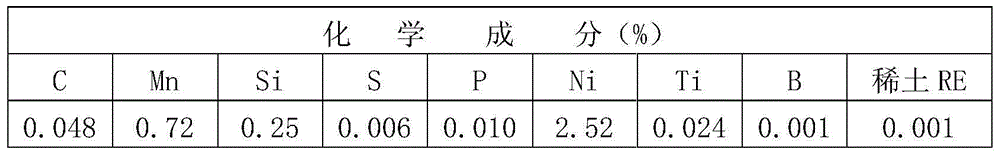

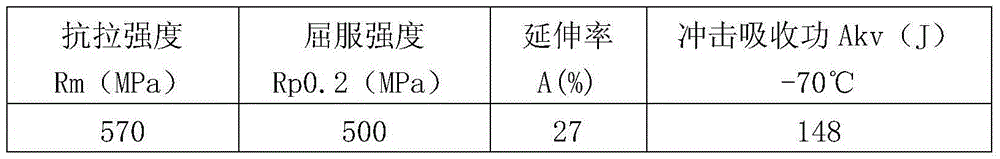

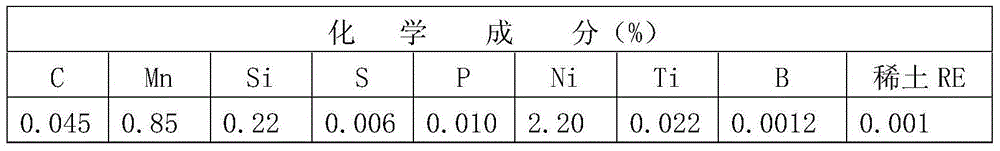

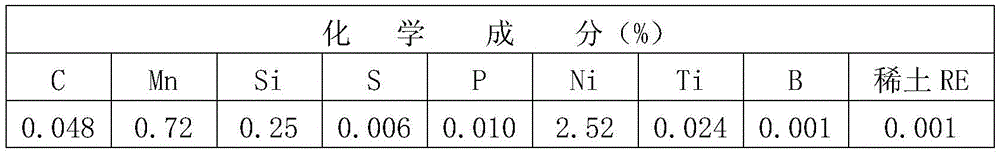

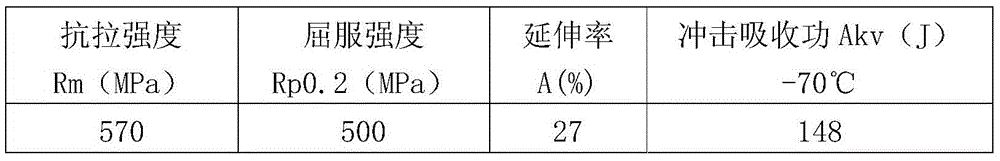

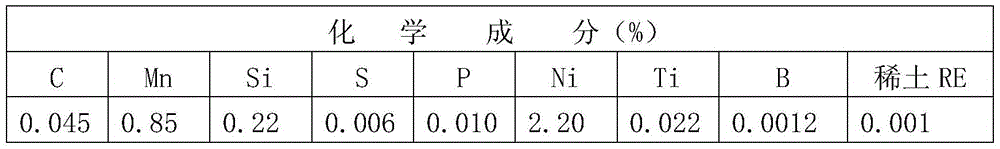

-70 degrees centigrade low-temperature steel welding bar

ActiveCN104551455AReduce segregationDecreased low temperature toughnessWelding/cutting media/materialsSoldering mediaSlagMolten bath

The invention discloses a -70 degrees centigrade low-temperature steel welding bar. The -70 degrees centigrade low-temperature steel welding bar comprises a welding core and a coating, the coating of the welding bar is composed of 44-54% of marble, 15-24% of fluorite, 3-6% of barium carbonate, 2-5% of quartz, 2-5% of dehydration potassium titanate, 0.5-1.5% of borax, 1-3% of manganese metal, 3-6% of atomized ferrosilicon, 1-3% of rare earth ferrosilicon, 3-6% of ferrotitanium, 0.5-1.0% of silicon calcium alloy, 6.0-8.0% of nickel powder and 0.2-1.0% of Teflon. The -70 degrees centigrade low-temperature steel welding bar is featured with low nickel content, less splashing, good molten bath fluidity, uniform slag cover, soft electric arc sound, beautiful weld joint appearance, easiness in sediment separation and good welding technique, the content of diffusible hydrogen in the weld joint metal is within 5ml / 100 g (mercury process), and this meets the standard super-low-hydrogen welding bar requirement.

Owner:JIANGSU JIUZHOU NEW MATERIAL TECH CO LTD

Vacuum switch with vacuum arc-extinguishing chamber

InactiveCN105590785AReduce wearExtended maintenance cycleHigh-tension/heavy-dress switchesAir-break switchesCombustionControl power

The invention discloses a vacuum switch with a vacuum arc-extinguishing chamber. The vacuum switch comprises insulating housings which are internally provided with an intermediate shielding cover. Furthermore the intermediate shielding cover is internally provided with a corrugated pipe protecting cover. The corrugated pipe protecting cover is internally provided with a corrugated pipe. Furthermore the corrugated pipe is internally provided with a dynamic conductive rod. One end of the dynamic conductive rod is provided with a moving contact, and furthermore one side of the moving contact is provided with a static contact. One end of the static contact is connected with a static conductive rod. A static grading shield is arranged outside the static contact. The insulating housings are connected with each other through an intermediate sealing ring. According to the vacuum switch with the vacuum arc-extinguishing chamber, arc is extinguished in a sealed container, thereby realizing no leakage of arc and hot gases; small clearance between 1mm and 40mm is realized between the static contact and the moving contact; and furthermore the vacuum switch with the vacuum arc-extinguishing chamber has advantages of short arc combustion time, low arc voltage, low arc energy, low contact wearing, large number of allowed on-and-off times, small inertia of the dynamic conductive rod, high suitability for high-frequency operation, small size of the operating mechanism, small size of the vacuum switch, small weight and low control power.

Owner:钟斐琴

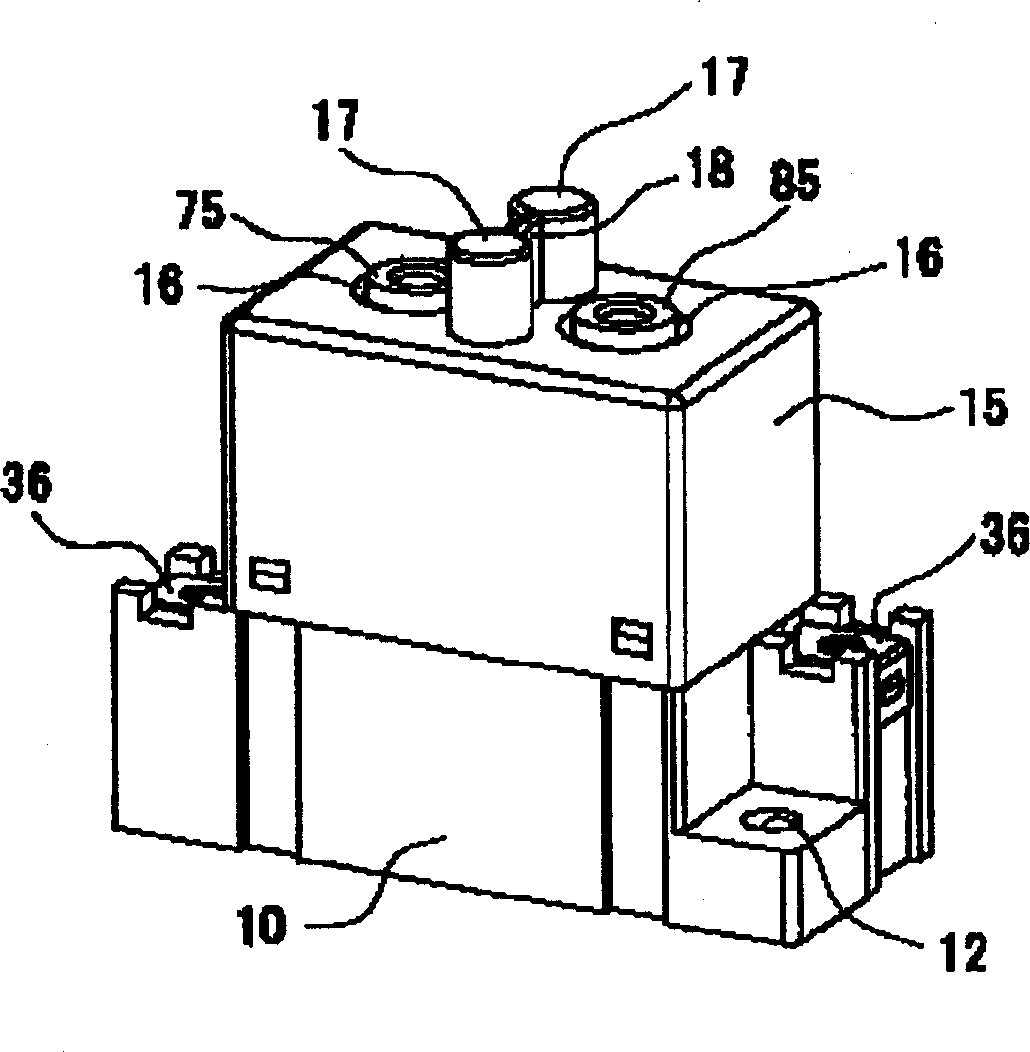

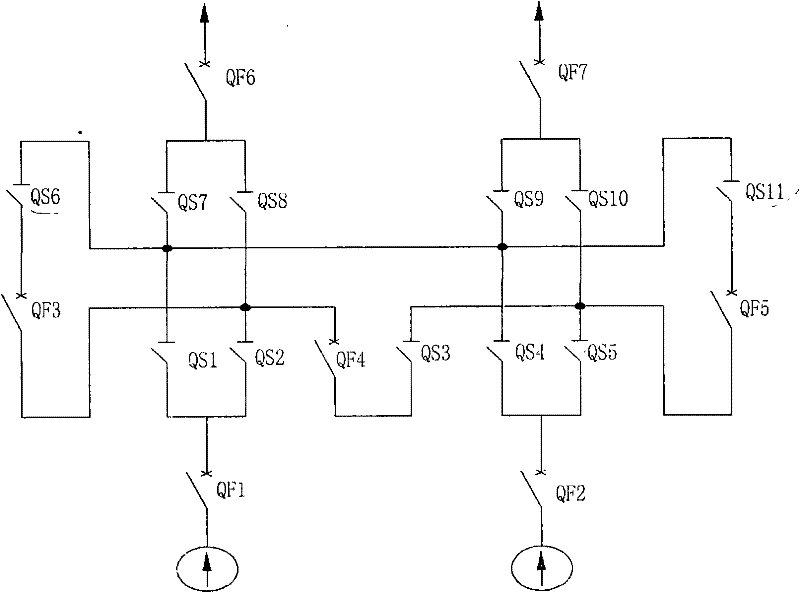

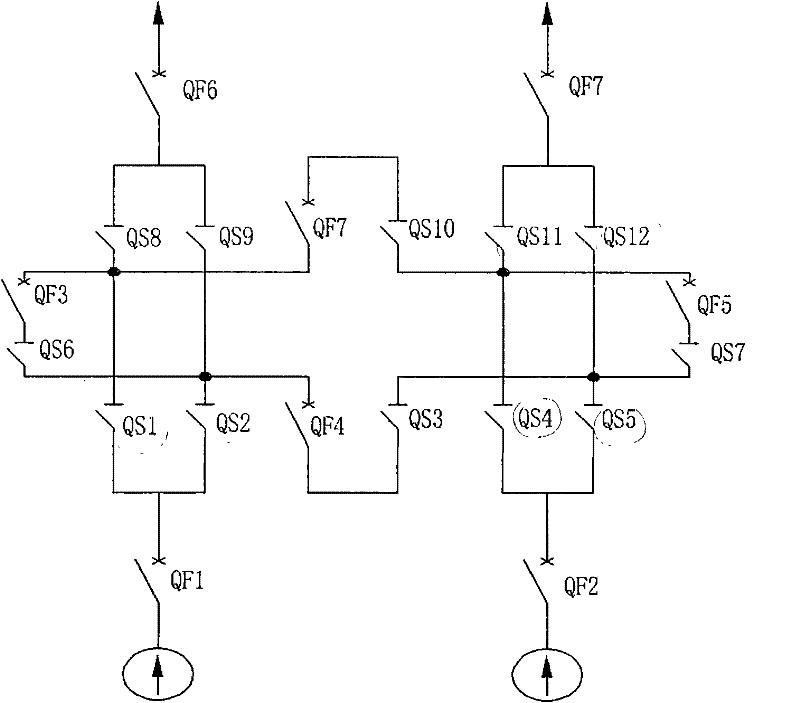

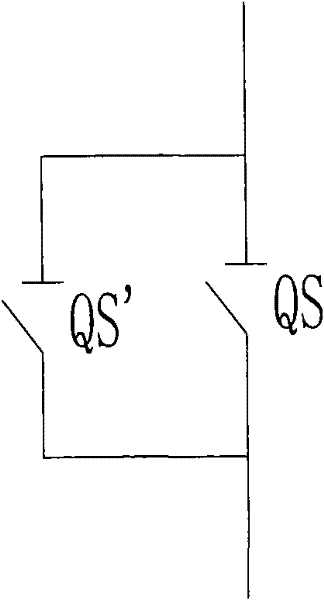

Synthetic equivalence test circuit for circuit breaker testing

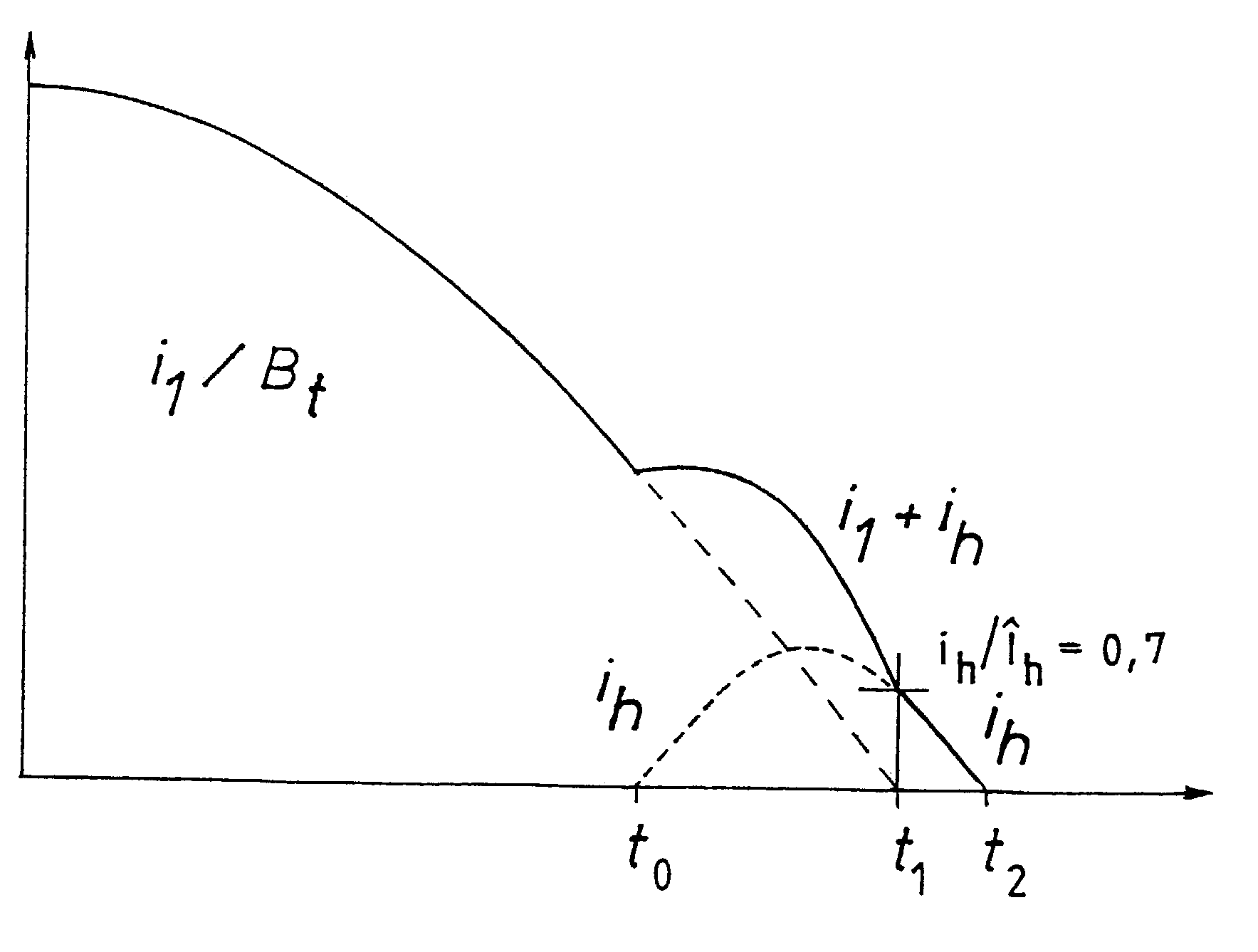

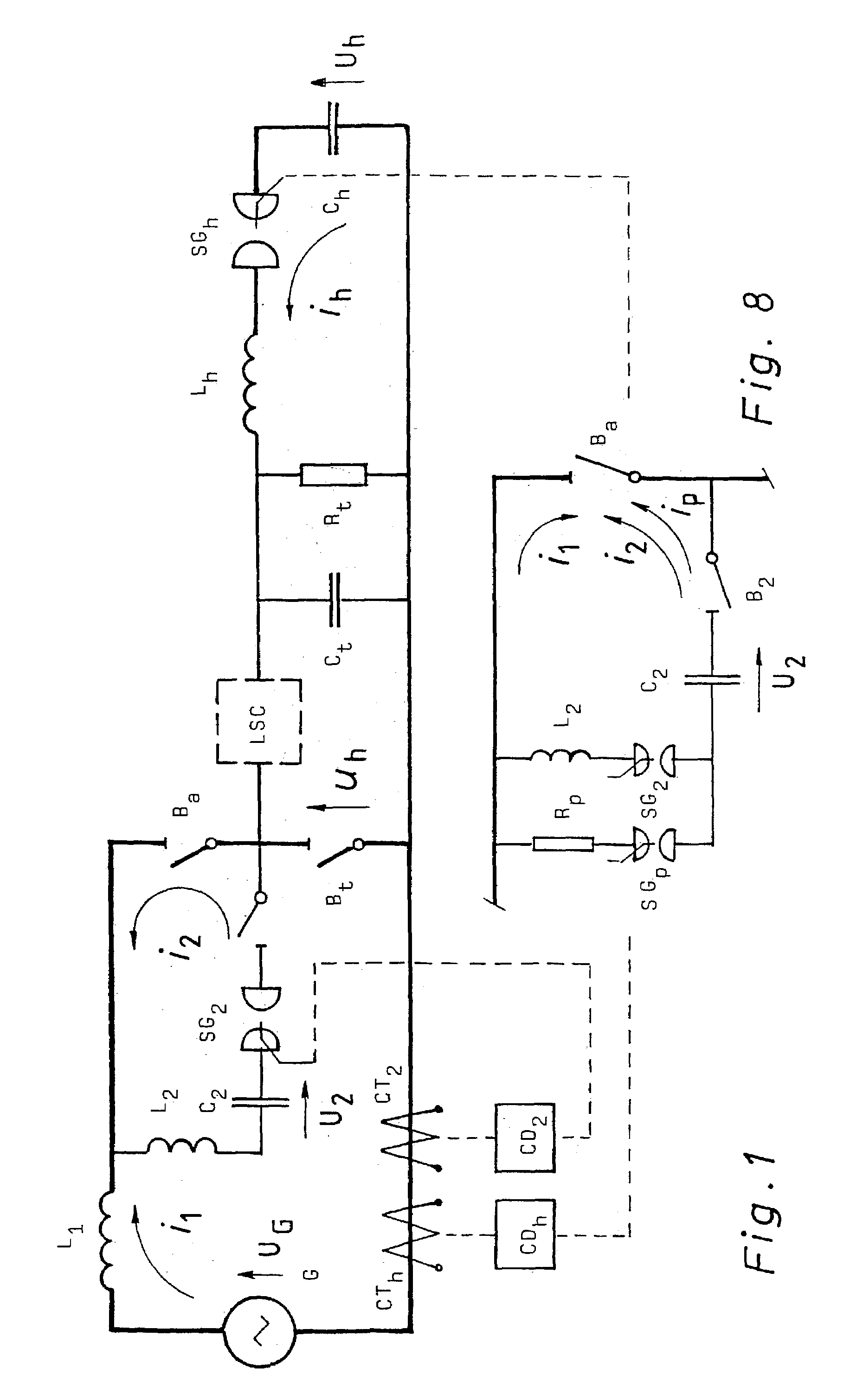

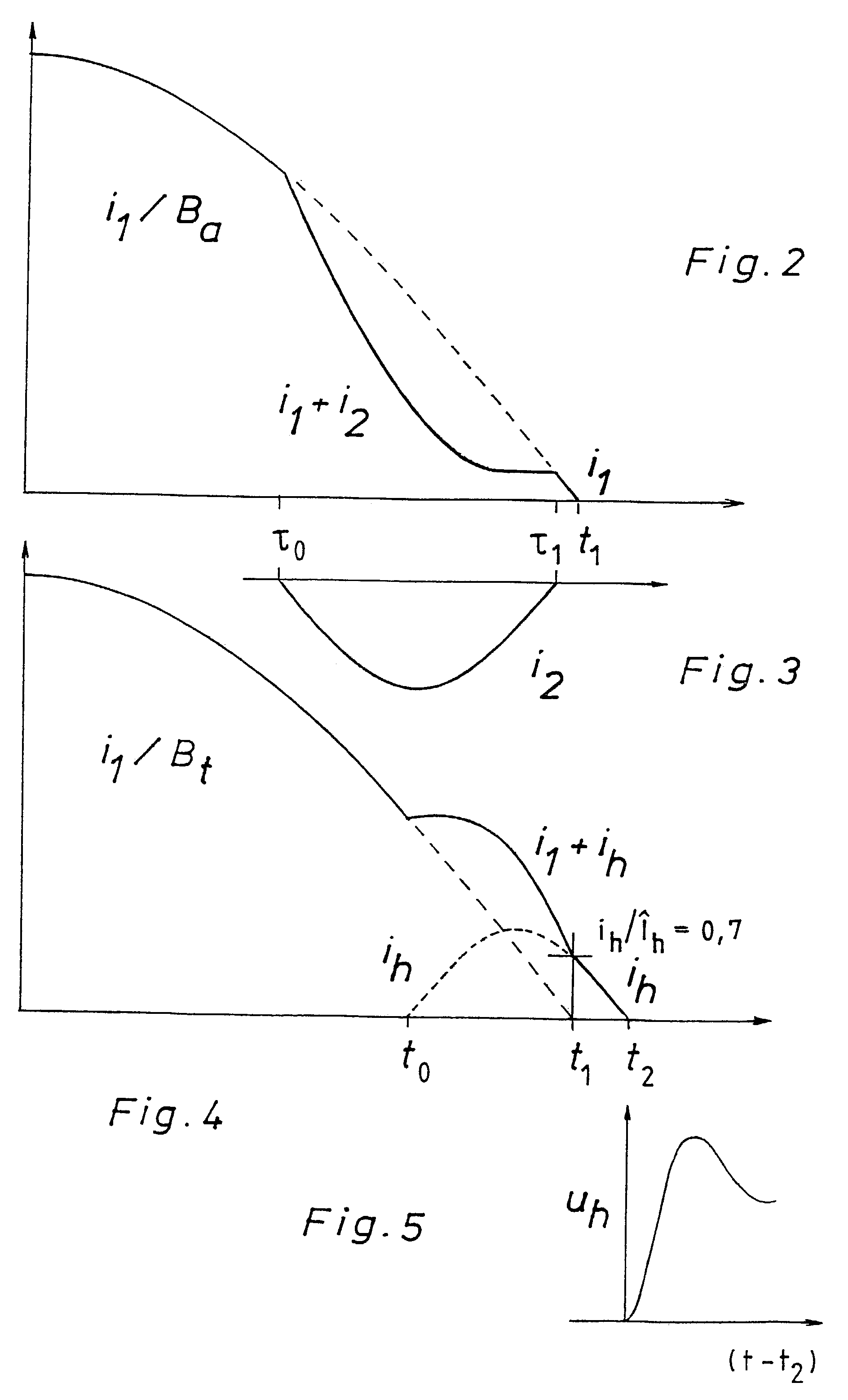

A method for testing high-voltage alternating-current power switches in a synthetic test circuit has the step of connecting a high-voltage oscillating circuit in parallel to a test switch Bt in a time interval before the current zero of an interruptible high current, which is determined by a half-cycle duration (Th / 2) of the oscillating current (ih) less the duration of equivalence (Δtse) of the sole flow of the oscillating current as sequential current in the test switch with a stress exerted upon the switch by the homogeneous current in a direct test circuit. The sequential-current flow duration of the equivalence results, at least approximately, from the comparison of the values of common physical stress parameters acting in the test switch during the test, on the one hand, in the synthetic test circuit and, on the other hand, in the direct test circuit.

Owner:SLAMECKA ERNST

Switchgear

InactiveCN1480968AReliable cut offImprove reliabilityContacts enclosures/screensElectromagnetic relay detailsMiniaturizationEngineering

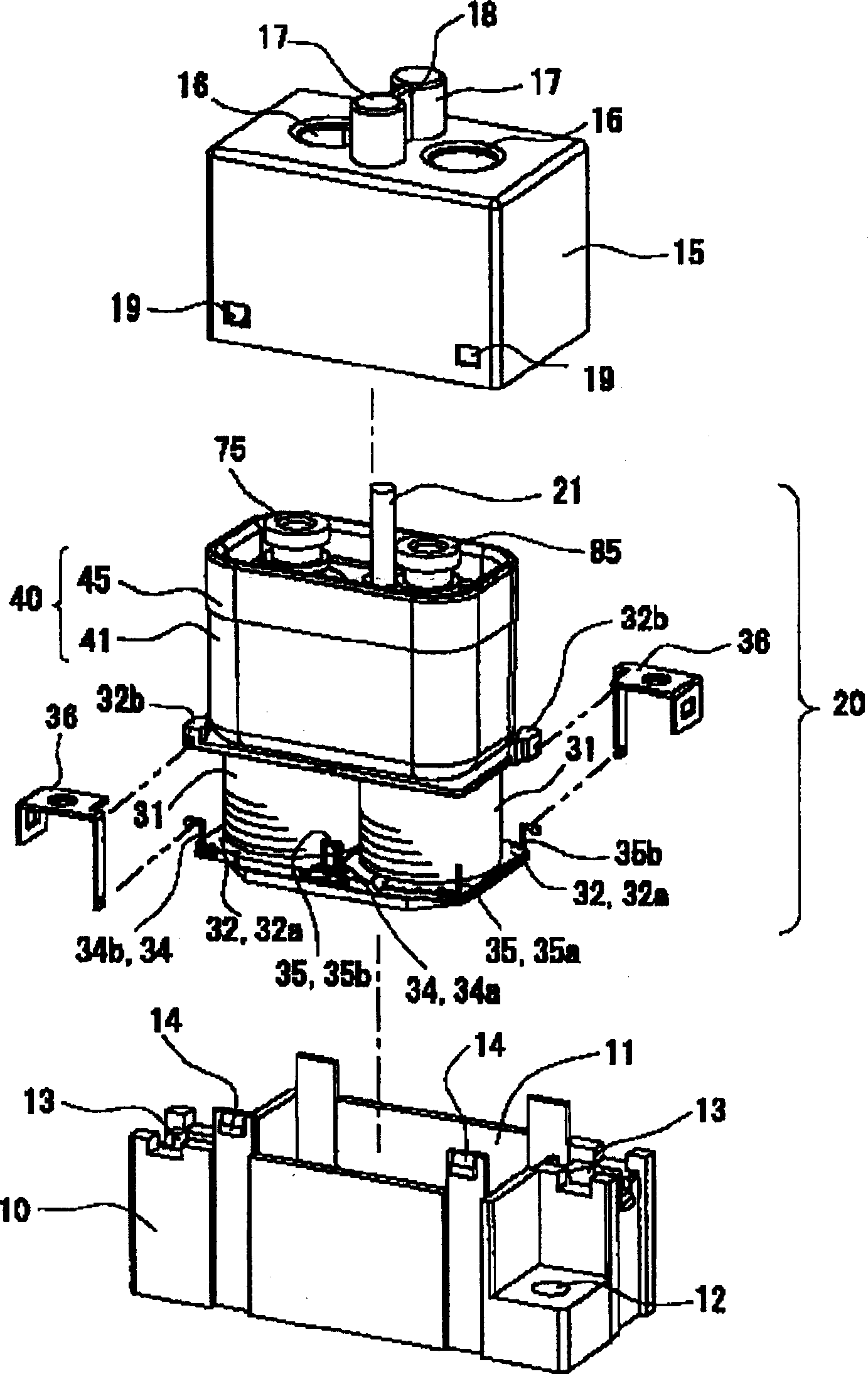

A switching device which can be small-sized by improving a shielding performance and can improve the reliability of switching characteristics. A permanent magnet disposed near stationary contacts is arranged in its pole-face perpendicularly of the axis of a moving contact member.

Owner:ORMON CORP

Method for controlling striations in a lamp powered by an electronic ballast

InactiveUS7719204B1Reduce arc voltageIncrease probabilityElectrical apparatusElectric light circuit arrangementOutput transformerBalanced circuit

A method for controlling striations in a lamp powered by an electronic ballast includes the steps of generating an asymmetric lamp current using an unbalanced circuit component in the electronic ballast and supplying that current to the lamp. The unbalanced circuit component may be an unbalanced output transformer or an unbalanced DC choke. The output transformer is unbalanced by offsetting the number of turns on each side of the tap on the primary winding of the transformer. In a similar manner, the DC choke is unbalanced by offsetting the number of turns in each winding of the choke.

Owner:UNIVERSAL LIGHTING TECHNOLOGIES

Magnesium alloy micro-arc oxidation electrolyte

InactiveCN107287642ASolve surface preparation problemsSolving Micro-arc OxidationAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention belongs to the technical field of metal surface treatment, and particularly relates to a magnesium alloy micro-arc oxidation electrolyte. The magnesium alloy micro-arc oxidation electrolyte comprises materials including 5-15 g / L of sodium hydroxide, 3-20 g / L of sodium perborate, 4-15 g / L of potassium fluoride, 2-10 g / L of an additive ZX-1. The electrolyte meets the use requirements of magnesium alloy micro-arc oxidation, reduces the arcing voltage and solves the problems of surface treatment of complex workpieces, small workpieces and workpieces needing to be repaired. By means of addition of the additive ZX-1, the arcing voltage can be remarkably reduced, the voltage is controlled within a safe voltage range, meanwhile, the lower the arcing voltage, the thicker a micro-arc film layer is within the same time, and the corrosion resistance and the uniformity of a micro-arc oxidation film are enhanced.

Owner:HEBEI TAIHANG MACHINERY IND

Magnetization, decompression and cooling arc extinction line returning device of coal mine well ventilator electric power case

The present invention discloses a magnetization, decompression and cooling arc extinction line returning device of a coal mine well ventilator electric power case. The device comprises a fixed connection groove, a magnetization arc extinction device, a controller and an operation key. The fixed connection groove is inlaid and installed at the left end face of the magnetization arc extinction device. The air bag and a negative pressure cavity form a low pressure to allow an actuation block to be pasted to the surface of the electric power case for isolation from air and avoid that a lot of airpromotes arc recrudescence, the action force of a magnetic patch to arc electrons is employed to allow the arc to be close to an arc-shaped blocking plate gate, because a steel bar gate has a ferromagnetic feature to effectively absorb the arc and allow the arc to be stayed in a slit of an aperture and a laminated barb so as to reduce the arc voltage, a heat conductive pad and a condensation cavity are employed to absorb heat, the deformation of a balance rotation needle is employed to promote transmission of heat, The condensation and liquidation of distilled water in a water storage cavity are performed to consume and release the heat to reduce the arc temperature, prevent electrons from thermal ionization and allow the arc to be extinguished.

Owner:南京秦淮紫云创益企业服务有限公司

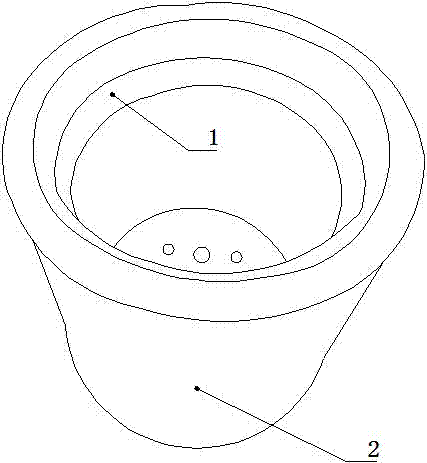

A quartz crucible forming mold

InactiveCN104402204BHigh strengthWon't burstGlass shaping apparatusGlass productionMetal alloyMetal impurities

The invention discloses a mold for forming a quartz crucible, which comprises a metal alloy mold, an outer mold, a porous alloy base, a rotating table, and a rotating shaft. The outer layer of the metal alloy steel mold is covered with an outer mold. The metal alloy steel mold The bottom of the mold is equipped with a porous alloy base, and the porous alloy base is placed on a rotating table, and a rotating shaft is arranged under the rotating table. The present invention has the advantages of high strength, long service life, efficient use of heat energy, and reduced power consumption. Advantages, the invention increases the melting temperature, can quickly remove metal impurities in the raw material, solves the disadvantage that the raw material can only rely on imported quartz sand, and improves the tightness between particles through high-temperature melting, reducing the number of bubbles, The product quality is improved, the production cycle is shortened, the production efficiency is improved, the energy is fully saved, and the production cost is reduced.

Owner:海盐华星标准件模具厂

Vacuum switch tube

ActiveUS8319137B2Reduce re-ignition possibilityReduce arc voltageHigh-tension/heavy-dress switchesAir-break switchesEngineeringVacuum switch

The present invention relates to a vacuum switch tube, which includes a first contact and a second contact disposed on conductive rods respectively. The two contacts are disposed facing each other. The two contacts are cylinders and include conductive members and magnetic members to form contact bodies. The cross section shape of the magnetic members is divided by a neutrality line into two unequal regions. The magnetic member of the first contact and the conductive member of the second contact are disposed corresponding to each other. The conductive member of the first contact and the magnetic member of the second contact are disposed corresponding to each other. The two vacuum switch contacts are anti-symmetrically disposed, such that a rotating magnetic field having rotating lines of magnetic force is formed, so that re-ignition possibility during voltage breaking is effectively reduced, and an arc voltage is decreased.

Owner:BEIJING ORIENT VACUUM ELECTRIC

High-voltage switch transfer current device

InactiveCN101964271BReduce the destructive power of burningPrevent movementHigh-tension/heavy-dress switchesAir-break switchesPower flowLow voltage

The invention relates to a high-voltage, ultrahigh-voltage and extra-high voltage switch transfer current device for busbar transfer load current operation. The high-voltage switch transfer current device comprises a horizontally arranged vacuum switch, a switch operating box and a steering square box between the horizontally arranged vacuum switch and the switch operating box, wherein a fixed contact and a moving contact of the vacuum switch are coaxially arranged opposite to each other in a shielding case of a vacuum arc extinction chamber, a plurality of thread grooves are arranged on a columnar contact of the fixed contact from the columnar face to the end face of the contact at equal intervals, and the contact end of the moving contact is provided with a slot matched with the columnar contact of the fixed contact; a brake separating spring crank arm, a braking crank arm and a roller crank arm are arranged on a control main shaft of an operating mechanism of the switch operating box. By the technical scheme, an isolating switch is endowed with the capability of switching on and off busbar transfer current during double-busbar changeover operation, and thus, the technical purpose that power-frequency low-voltage great-current transfer current arcs produced in the busbar transfer can be switched on and off by the moving contact and the fixed contact of a 100-1100 KV outdoor AC high-voltage isolating switch can be achived.

Owner:LIAONING YIDE IND GRP CO LTD

High-pressure vacuum circuit breaker

InactiveCN100485844CShort electrical wear rateReduced service lifeHigh-tension/heavy-dress switchesAir-break switchesThree-phaseHigh pressure

Owner:瓦房店高压开关有限公司

Disc-type overlapping gyromagnetic longitudinal blowing vacuum arc extinguish chamber

ActiveCN102522259BHigh strengthShorten burn timeHigh-tension/heavy-dress switchesAir-break switchesConductor CoilArc column

The invention belongs to a vacuum circuit breaker field and especially relates to a disc-type overlapping gyromagnetic longitudinal blowing vacuum arc extinguish chamber. The vacuum arc extinguish chamber comprises: a conducting rod (1), a contact cup (5), an iron core (7) and an electrode (4) which is connected to the contact cup (5). The contact cup (5) is fixedly matched with the conducting rod (1). The iron core (7) is placed in the contact cup (5). The contact cup (5) is provided with a plurality of circulation side slots with equal intervals. The iron core (7) is provided with the winding slots (6) with the equal intervals. More than two groups of the coaxial coil windings (8) are stacked into the winding slots (6) and the coaxial coil windings are staggered with a certain angle theta successively. According to the invention, through a strong force of a rotating magnetic field and simultaneously under an effect of a vertical magnetic field, an arc voltage can be reduced; arc columns are impelled to be uniformly distributed on an anode surface; arc energy release can be accelerated; a breaking capacity of the vacuum circuit breaker can be increased.

Owner:SHENYANG POLYTECHNIC UNIV

A kind of preparation method of composite tungsten electrode material

The invention discloses a preparing method of a compound tungsten electrode material. The preparing method comprises the following steps of selection of oxides, prereduction, hydrogen gas reduction, high-energy mixing, forming and middle-frequency induction sintering. According to the preparing method of the compound tungsten electrode material, single-crystal ammonium paratungstate is subjected to clearance-type reduction to prepare blue tungsten oxide with a specific phase component, blue tungsten oxide is reduced to generate like-spherical tungsten powder, and the tungsten powder and one ormore of submicron-order oxides of cerium oxide, lanthanum oxide, yttrium oxide, zirconium oxide and the like are efficiently mixed in a high-energy powder mixing machine of a specific structure and subjected to isostatic compaction and low-temperature long-time middle-frequency induction solid-phase sintering; second-phase grains of obtained tungsten bars are fine and uniform, and the tungsten bars are free of segregation, high in rare earth retention rate and good in processing performance; the finished product rate reaches 87% or above, and the processing cost is reduced by 20% or above. Anexisting conventional technology is adopted for the tungsten bars for press working and machining, the finished product rate is high, and the compound tungsten electrode material which is low in arcing voltage, good in arc stability, low in burn-out rate, long in service life and environmentally friendly is obtained.

Owner:GANZHOU HONGFEI TUNGSTEN & MOLYBDENUM MATERIALS

A -70℃ low temperature steel welding rod

ActiveCN104551455BReduce segregationDecreased low temperature toughnessWelding/cutting media/materialsSoldering mediaSlagRare earth

The invention discloses a -70 degrees centigrade low-temperature steel welding bar. The -70 degrees centigrade low-temperature steel welding bar comprises a welding core and a coating, the coating of the welding bar is composed of 44-54% of marble, 15-24% of fluorite, 3-6% of barium carbonate, 2-5% of quartz, 2-5% of dehydration potassium titanate, 0.5-1.5% of borax, 1-3% of manganese metal, 3-6% of atomized ferrosilicon, 1-3% of rare earth ferrosilicon, 3-6% of ferrotitanium, 0.5-1.0% of silicon calcium alloy, 6.0-8.0% of nickel powder and 0.2-1.0% of Teflon. The -70 degrees centigrade low-temperature steel welding bar is featured with low nickel content, less splashing, good molten bath fluidity, uniform slag cover, soft electric arc sound, beautiful weld joint appearance, easiness in sediment separation and good welding technique, the content of diffusible hydrogen in the weld joint metal is within 5ml / 100 g (mercury process), and this meets the standard super-low-hydrogen welding bar requirement.

Owner:JIANGSU JIUZHOU NEW MATERIAL TECH CO LTD

A kind of magnesium alloy micro-arc oxidation solution formula and its application method

InactiveCN103320841BImproved micro-arc discharge characteristicsFast growthAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention relates to a magnesium alloy micro-arc oxidation solution for carrying out micro-arc oxidation on a magnesium alloy to form a corrosion resistance layer on the surface of the magnesium alloy. The magnesium alloy micro-arc oxidation solution is characterized in that 1 L of the magnesium alloy micro-arc oxidation solution contains 1-9 g of caustic alkali, 2-12 g of a silicate, 1-9 g of an aluminate, 1-9 g of a fluoride, 0.3-1 g of a borate, and 2-6 mL of triethanolamine, wherein a solvent of the solution is water. The method for forming a corrosion resistance layer on the surface of a magnesium alloy by using the magnesium alloy micro-arc oxidation solution is characterized by comprising the following steps: preparing a magnesium alloy micro-arc oxidation solution, adding a certain mass of caustic alkali, a silicate, an aluminate, a fluoride, a borate and triethanolamine or hydrates of the compounds to water, carrying out stirring dissolving, adding water to achieve a certain volume, carrying out degreasing and washing on a magnesium alloy, placing the magnesium alloy in the micro-arc oxidation solution, carrying out micro-arc oxidation by adopting direct current pulse current, washing the magnesium alloy, and drying.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A Coal Mine Ventilator Power Box Magnetization Decompression Cooling Arc Extinguishing Line Device

The present invention discloses a magnetization, decompression and cooling arc extinction line returning device of a coal mine well ventilator electric power case. The device comprises a fixed connection groove, a magnetization arc extinction device, a controller and an operation key. The fixed connection groove is inlaid and installed at the left end face of the magnetization arc extinction device. The air bag and a negative pressure cavity form a low pressure to allow an actuation block to be pasted to the surface of the electric power case for isolation from air and avoid that a lot of airpromotes arc recrudescence, the action force of a magnetic patch to arc electrons is employed to allow the arc to be close to an arc-shaped blocking plate gate, because a steel bar gate has a ferromagnetic feature to effectively absorb the arc and allow the arc to be stayed in a slit of an aperture and a laminated barb so as to reduce the arc voltage, a heat conductive pad and a condensation cavity are employed to absorb heat, the deformation of a balance rotation needle is employed to promote transmission of heat, The condensation and liquidation of distilled water in a water storage cavity are performed to consume and release the heat to reduce the arc temperature, prevent electrons from thermal ionization and allow the arc to be extinguished.

Owner:南京秦淮紫云创益企业服务有限公司

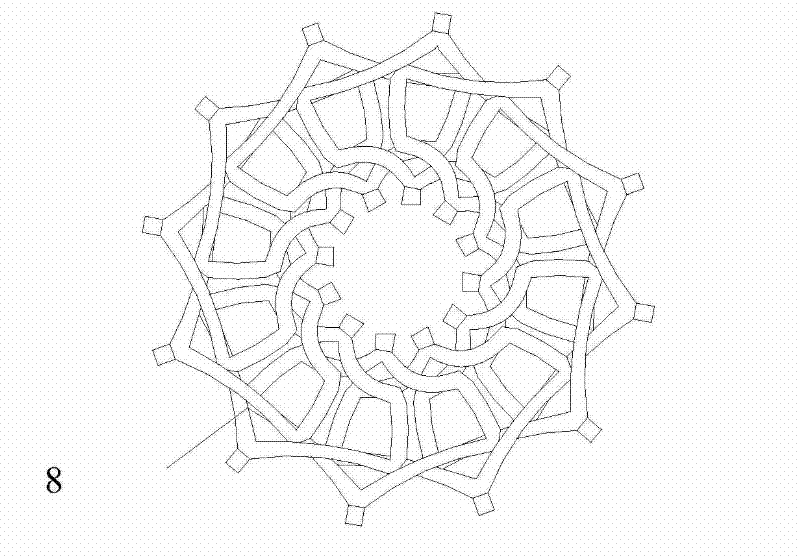

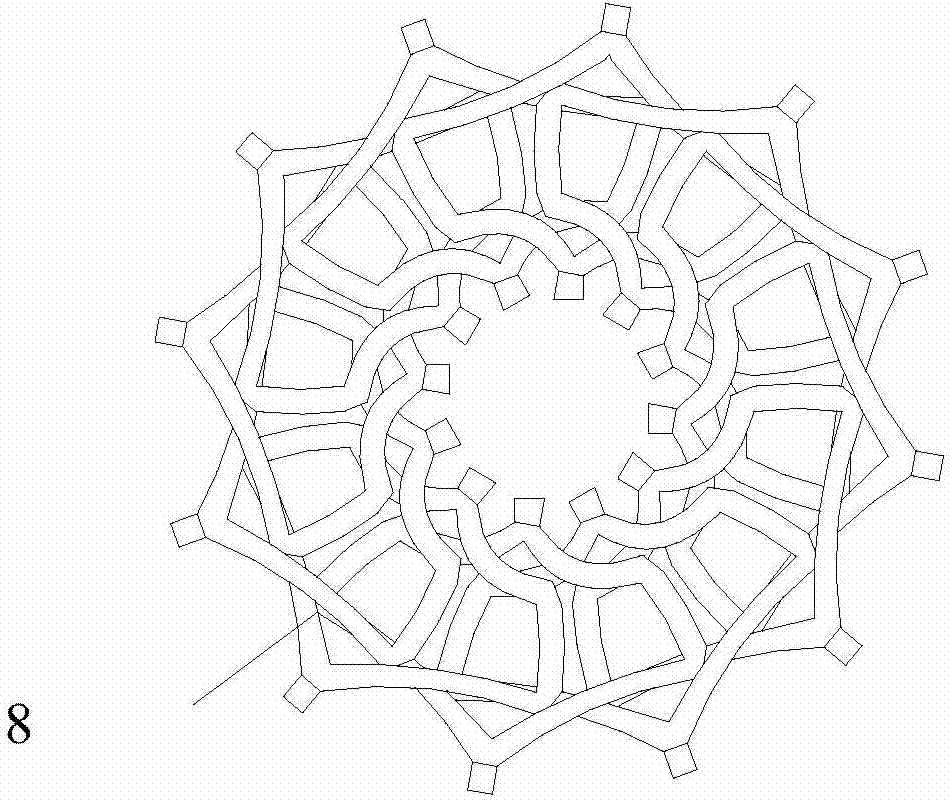

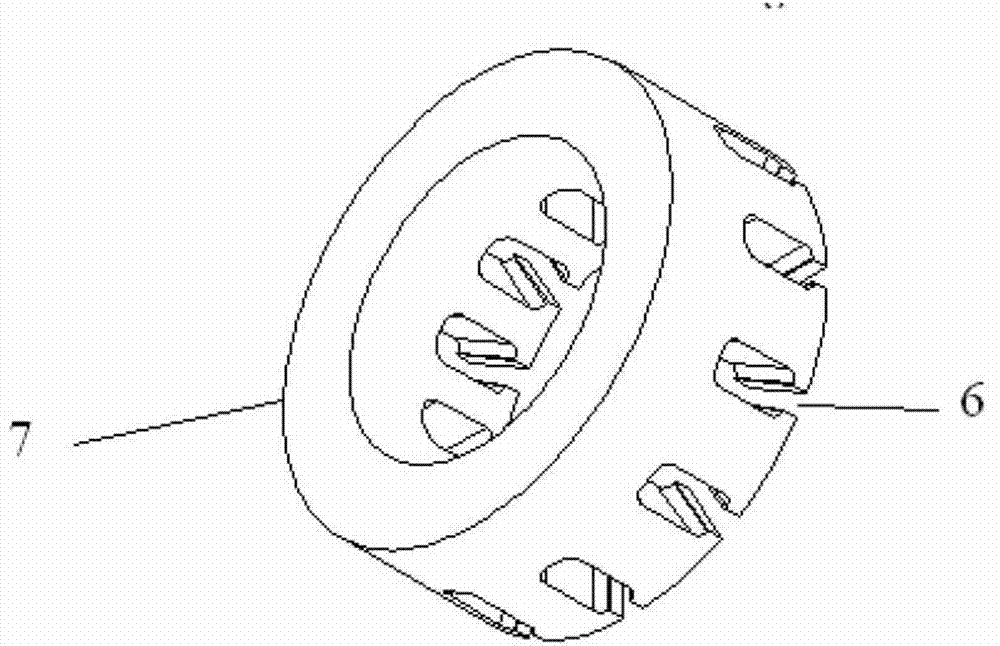

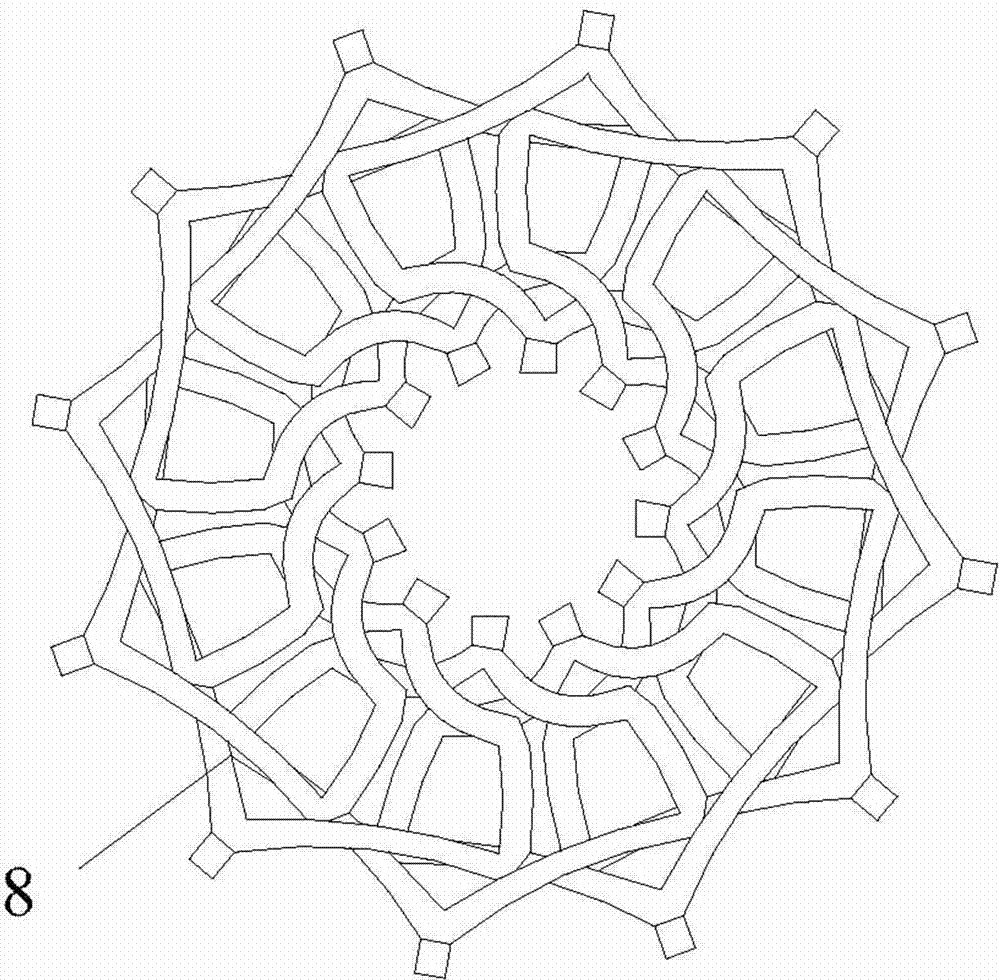

Disk-type gyromagnet longitudinal-blowing vacuum arc extinguish chamber

ActiveCN102522257BExtend your lifeProtective structureHigh-tension/heavy-dress switchesAir-break switchesBrute forceRing current

The invention belongs to the field of the vacuum circuit breaker, which particularly relates to a disk-type gyromagnet longitudinal-blowing vacuum arc extinguish chamber. The disk-type gyromagnet longitudinal-blowing vacuum arc extinguish chamber comprises a conducting rod (1), a contact cup (5), an iron core (7) and an electrode (4) connected with the contact cup (5), wherein the contact cup (5) and the conducting rod (1) are fixedly adapted; the iron core (7) is arranged in the contact cup (5); the contact cup (5) is equally provided with even ring current side channels; the iron core (7) is equally provided with winding channels (6); a coil winding (8) is arranged in each winding channel (6), wherein the number of the winding channels (6) is 12-30, and the width of the winding channel (6) is 2.5-3mm; and the coil windings (8) are distributed in a radiating mode to form a disk-type structure along the radial direction. In the disk-type gyromagnet longitudinal-blowing vacuum arc extinguish chamber, according to the brute force action of a rotary magnetic field and the action of a longitudinal magnetic field, the arc voltage can be lowered to drive the arc columns to be evenly distributed on an anode surface, the arc energy is accelerated to release, and the cut-off capability of the vacuum circuit breaker is improved.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com