Vacuum switch contact

A vacuum switch and contact technology, applied in the electrical field, can solve the problems of high possibility of re-ignition and insufficient withstand voltage, and achieve the effect of reducing arc voltage, reducing the possibility of re-ignition, and satisfying high-voltage breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

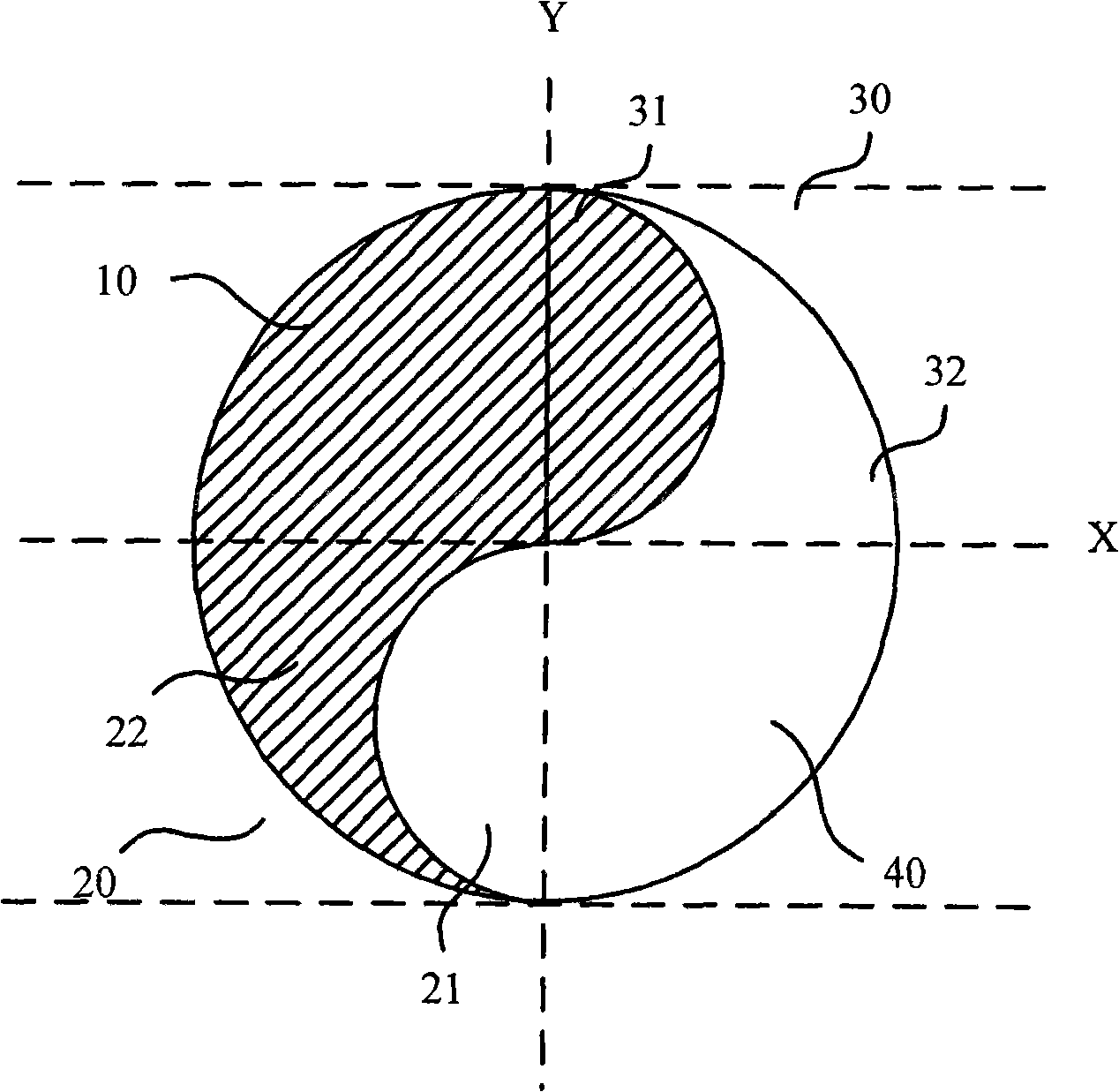

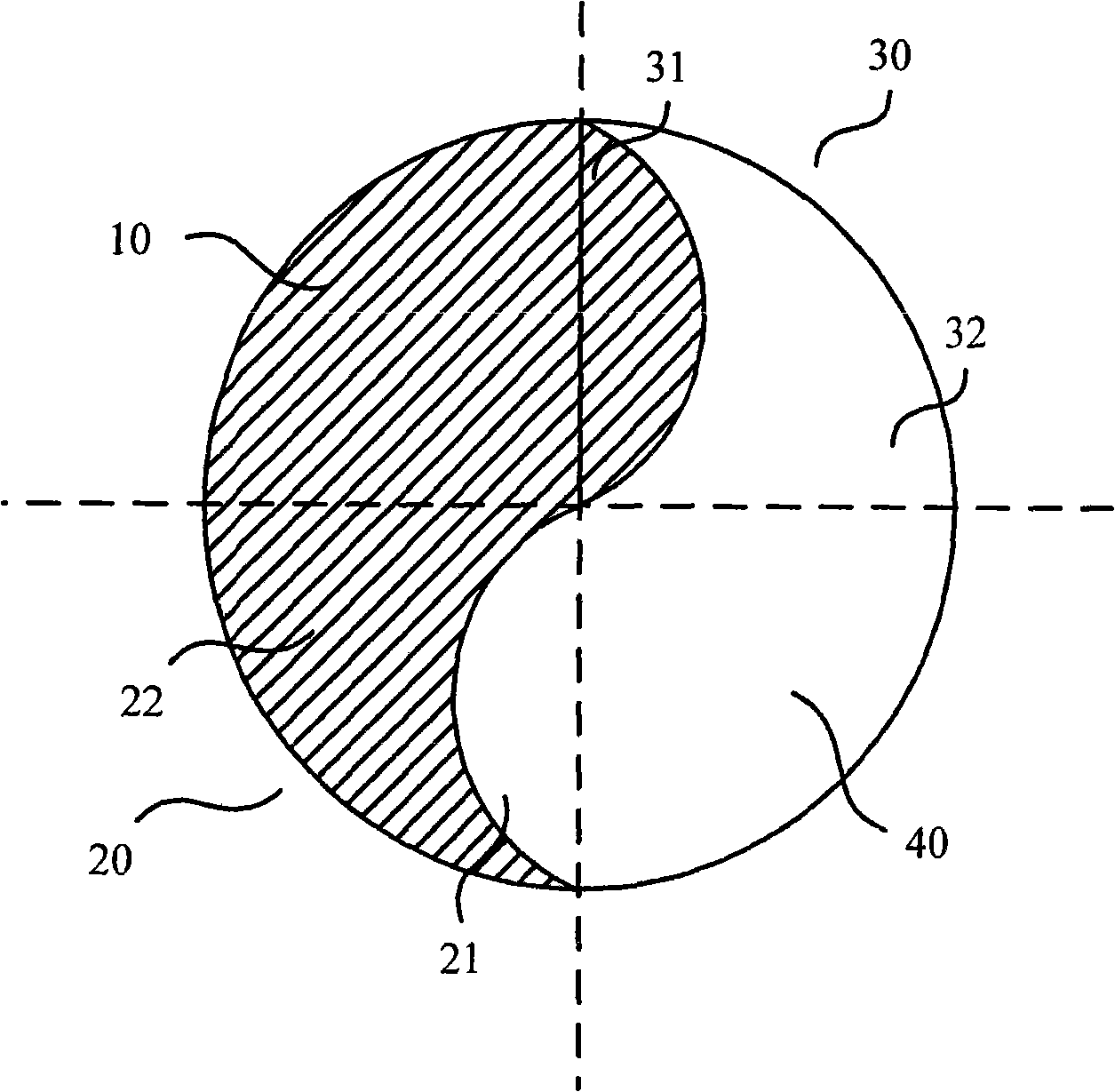

[0044] Such as figure 2 Shown is a cross-sectional view of the second embodiment of the vacuum switch contact of the present invention. The structure of this embodiment is roughly the same as that of the first embodiment, except that the first lower left area 21 and the first upper right area 31 are in the shape of a circular crown. And the straight long side of the first upper right area 31 is adjacent to the upper left area 10, and the straight long side of the first lower left area 21 is adjacent to the lower right area 40, as figure 2 shown.

[0045] The vacuum switch contact of this embodiment is similar to the working principle of the vacuum switch contact of Embodiment 1, which can provide an effective arc extinguishing longitudinal magnetic field, and the improvement of arc extinguishing ability is beneficial to reduce the possibility of restrike when the voltage is broken, and reduce the arc Therefore, it can meet the requirements of high-voltage breaking. The tech...

Embodiment 3

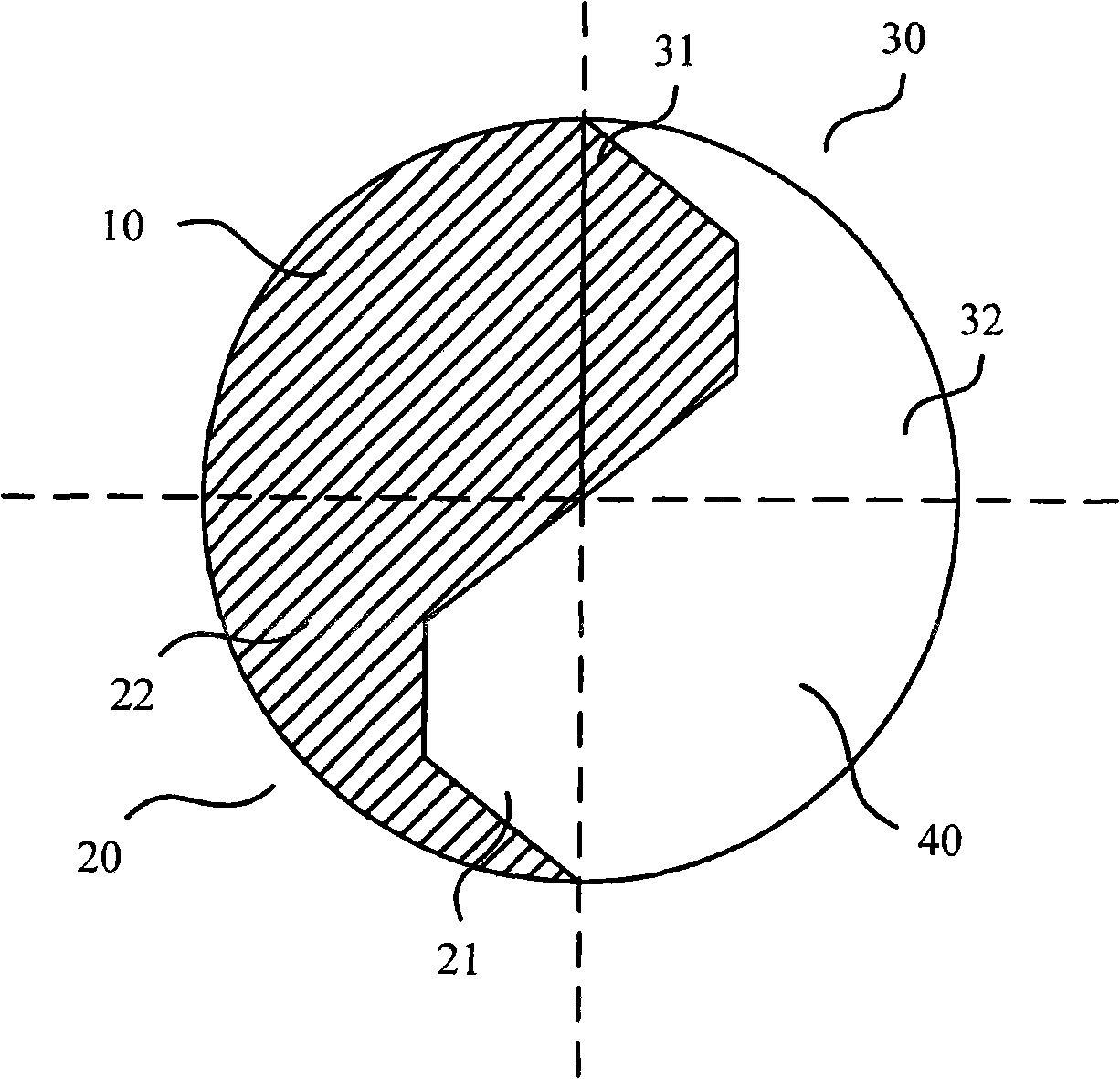

[0047] Such as image 3 Shown is the cross-sectional view of the third embodiment of the vacuum switch contact of the present invention. The structure of this embodiment is roughly the same as that of the first embodiment, except that the first lower left area 21 and the first upper right area 31 are trapezoidal in shape, and the first The bottom edge of the trapezoid of the upper right area 31, that is, the long side is adjacent to the upper left area 10, and the bottom edge of the trapezoid of the first lower left area 21, that is, the long side is adjacent to the lower right area 40, as image 3 shown.

[0048] The vacuum switch contact of this embodiment is similar to the working principle of the vacuum switch contact of Embodiment 1, which can provide an effective arc extinguishing longitudinal magnetic field, and the improvement of arc extinguishing ability is beneficial to reduce the possibility of restrike when the voltage is broken, and reduce the arc Therefore, it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com