Vacuum switch tube

A vacuum switching tube and contact technology, which is applied in the electrical field, can solve the problems of insufficient withstand voltage and high possibility of restrike, and achieve the effect of reducing the possibility of restrike, reducing arc voltage, and satisfying high-voltage breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

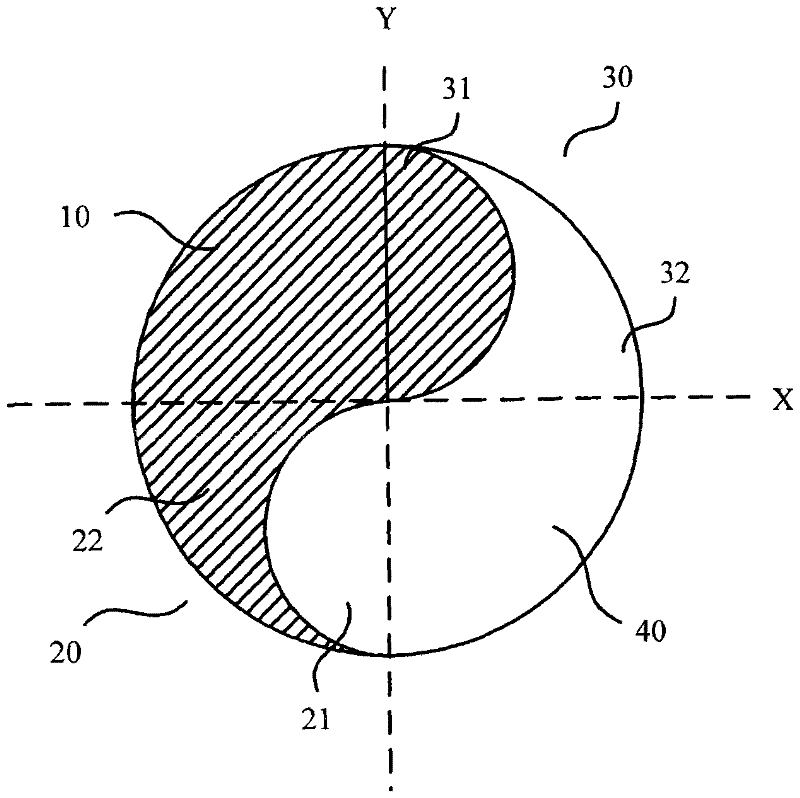

[0027] Such as image 3 Shown is a side view structural schematic diagram of the contact body in the second embodiment of the vacuum switch tube of the present invention. In this embodiment, the contact bodies of the first contact and the second contact are composed of several sheets stacked one after another. Taking the first contact as an example, each sheet is adjacent to a conductive sheet and a magnetically conductive sheet. Combined structure, several conductive sheets form a conductive part, and several magnetically conductive sheets form a magnetically conductive part, the cross-sectional shape of the conductive sheet and the magnetically conductive sheet and the structural relationship between the conductive part and the magnetically conductive part can adopt the above-mentioned embodiment. The technical solution is for the cooperation of yin and yang fish, and all the sheets are stacked together to form the outer contour shape of the main body of the contact, such as...

Embodiment 3

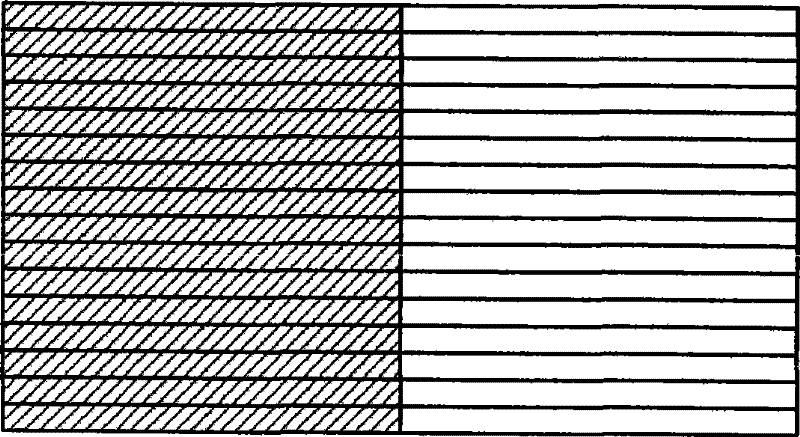

[0029] Such as Figure 4 Shown is a schematic diagram of the cross-sectional structure of the contact body in Embodiment 3 of the vacuum switch tube of the present invention. On the basis of the second embodiment above, in order to fix the relative position of the conductive part and the magnetic permeable part before the sheet body is melted and solidified, it is also possible to further set up a fixing mechanism that runs through several sheets on the conductive sheet 300 and the magnetically conductive sheet 400. hole 200, the fixing column 100 is inserted in the fixing hole 200, such as Figure 4 As shown, and one end of the fixing column 100 is fixed at the bottom inside the metal casing. The material of the fixing post 100 may be the same as that of the conductive component, such as copper metal.

[0030] The technical solution of this embodiment can simplify the production and manufacture of the contact body. After a plurality of sheet bodies are prepared by a simple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com