Aluminum-lithium alloy micro-arc oxidation method and electrolyte adopted by same

A technology of micro-arc oxidation and aluminum-lithium alloy, applied in anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., to achieve good stability, promote continuous growth, and reduce processing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

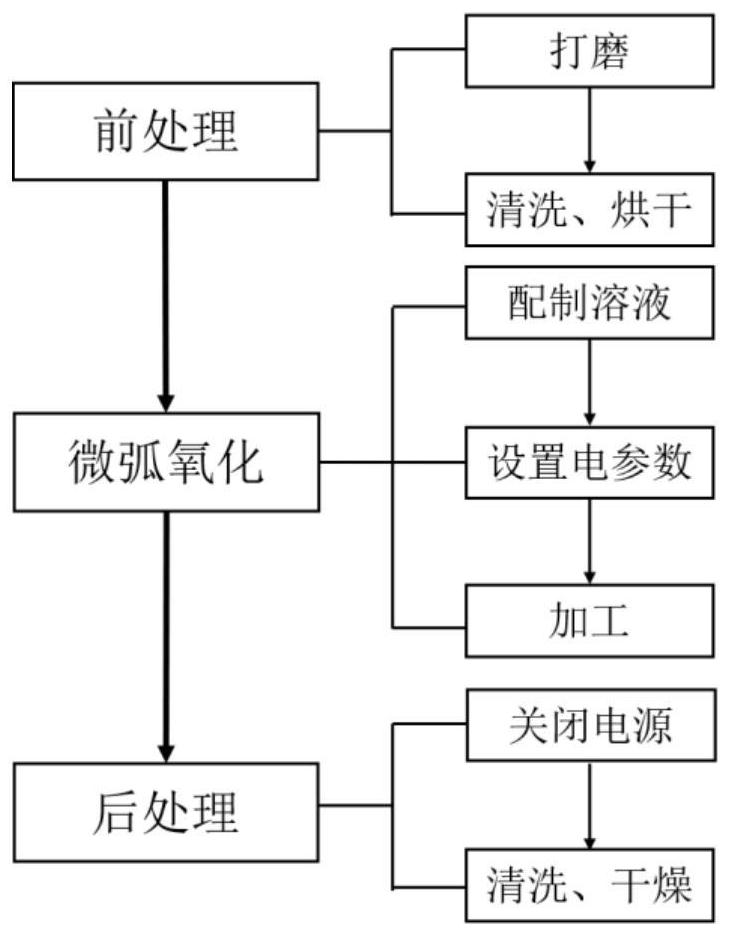

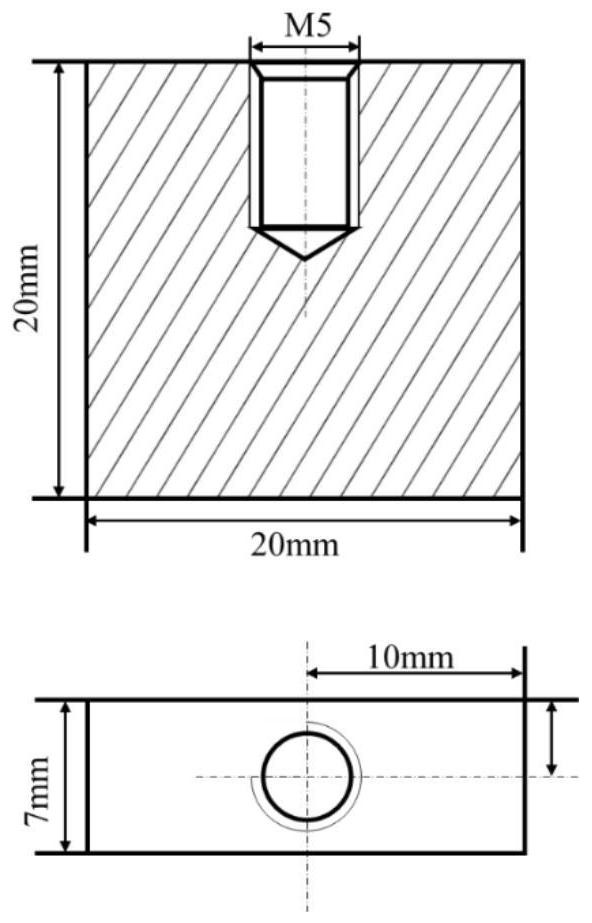

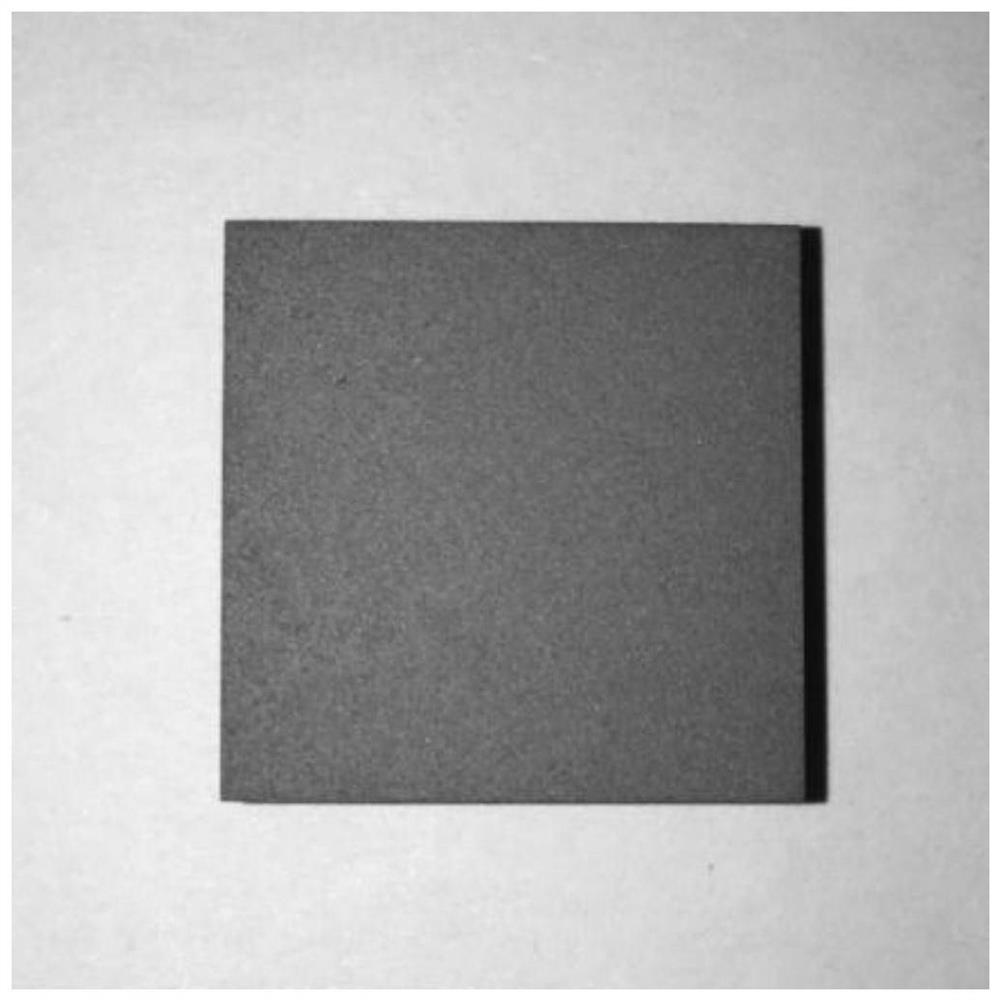

[0045] This embodiment relates to an aluminum-lithium alloy micro-arc oxidation method and a method for preparing a micro-arc oxidation electrolyte. The process of the method is as follows figure 1 As shown, the schematic diagram of the aluminum-lithium alloy micro-arc oxidation sample is as follows figure 2 shown. The micro-arc oxidation method is specifically:

[0046] 1. Prepare the sample Al-2Li-2Cu-0.2Zr cast aluminum-lithium alloy, the size is 20×20×7mm block. Perform surface mechanical pretreatment on the alloy: use 320# sandpaper to polish the oxide, and then further polish it on 1500# sandpaper. Rinse with distilled water, then alcohol, and dry with hot air. The cleaning solution is distilled water and alcohol, the operating temperature is kept at 30-40°C, and the processing time is about 10 minutes.

[0047] 2. Make a threaded hole on the surface of 20×7mm, with a diameter of 5mm and a depth of about 7mm, and connect the aluminum wire wrapped with insulation.

...

Embodiment 2

[0071] This embodiment relates to a method for micro-arc oxidation of an aluminum-lithium alloy and a method for preparing a micro-arc oxidation electrolyte. The micro-arc oxidation method is specifically:

[0072] 1. Prepare a sample of Al-2Li-2Cu-0.2Zr aluminum-lithium alloy in a block shape of 20×20×7mm. Perform surface mechanical pretreatment on the alloy: use 320# sandpaper to polish the oxide, and then further polish it on 1500# sandpaper. Rinse with distilled water, then alcohol, and dry with hot air. The cleaning solution is distilled water and alcohol, the operating temperature is kept at 30-40°C, and the processing time is about 10 minutes.

[0073] 2. Make a threaded hole on the surface of 20×7mm, with a diameter of 5mm and a depth of about 7mm, and connect the aluminum wire wrapped with insulation.

[0074]3. Prepare the solution in the stainless steel tank. The contents of each reagent are: sodium silicate 14g / L, potassium hydroxide 6g / L, sodium tungstate 4g / L,...

Embodiment 3

[0084] This embodiment relates to a method for micro-arc oxidation of an aluminum-lithium alloy and a method for preparing a micro-arc oxidation electrolyte. The micro-arc oxidation method is specifically:

[0085] 1. Prepare a sample of Al-2Li-2Cu-0.2Zr aluminum-lithium alloy in a block shape of 20×20×7mm. Perform surface mechanical pretreatment on the alloy: use 320# sandpaper to polish the oxide, and then further polish it on 1500# sandpaper. Rinse with distilled water, then alcohol, and dry with hot air. The cleaning solution is distilled water and alcohol, the operating temperature is kept at 30-40°C, and the processing time is about 10 minutes.

[0086] 2. Make a threaded hole on the surface of 20×7mm, with a diameter of 5mm and a depth of about 7mm, and connect the aluminum wire wrapped with insulation.

[0087] 3. Prepare the solution in the stainless steel tank. The contents of each reagent are: sodium silicate 15g / L, sodium hydroxide 6g / L, sodium tungstate 3.5g / L,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com