Nickel-saving high-nitrogen austenitic stainless steel gas-shielded flux-cored wire and preparation method thereof

A high-nitrogen austenitic and flux-cored welding wire technology, which is applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of low-temperature impact toughness of welded joints, improve the ability of stress corrosion resistance, improve stability, The effect of excellent welding processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

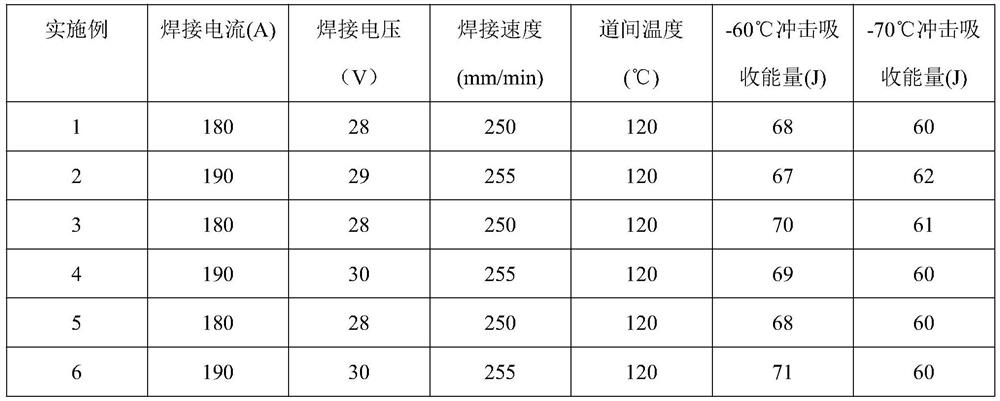

Examples

Embodiment 1

[0027] Embodiment 1: A kind of nickel-saving high-nitrogen austenitic stainless steel gas-shielded flux-cored welding wire of the present embodiment is made of core powder and a stainless steel sheath wrapped outside the core powder (thickness is 0.4mm, width is 430 low carbon Stainless steel strip, in which impurity elements and their mass content are P≤0.020%, S≤0.005%); the drug core powder is composed of rutile: 17%, potassium feldspar: 2%, zircon sand : 1.2%, fluorite: 0.5%, cryolite: 1%, copper powder: 8.8%, aluminum-iron alloy: 0.5%, electrolytic manganese: 35.5%, atomized ferrosilicon: 2%, silicon-calcium alloy: 1.3%, metal Nickel: 10%, ferromolybdenum: 1.2%, ferro-niobium: 1%, ferro-titanium: 1%, metal chromium nitride: 17% mixed; the nitrogen content in chromium nitride metal is 9%, and the drug core powder The particle size of the flux-cored wire is 60-80 mesh, and the filling rate of the core powder in the flux-cored wire is 24%.

[0028] The method for preparing ...

Embodiment 2

[0034] Embodiment 2: A kind of nickel-saving high-nitrogen austenitic stainless steel gas-shielded flux-cored welding wire of the present embodiment is made of core powder and a stainless steel sheath wrapped outside the core powder (thickness is 0.4mm, width is 430 low-carbon Stainless steel strip, in which impurity elements and their mass content are P≤0.020%, S≤0.005%); the drug core powder is composed of rutile: 17.0%, potassium feldspar: 2%, zircon sand : 1%, fluorite: 0.5%, cryolite: 1%, copper powder: 8.9%, aluminum-iron alloy: 0.5%, electrolytic manganese: 36%, atomized ferrosilicon: 2%, silicon-calcium alloy: 2.4%, metal Nickel: 9%, ferromolybdenum: 1.2%, ferro-niobium: 1%, ferro-titanium: 1%, metal chromium nitride: 16.5% mixed; the nitrogen content in chromium nitride metal is 9%, and the drug core powder The particle size of the flux-cored wire is 60-80 mesh, and the filling rate of the core powder in the flux-cored wire is 24%.

[0035] The method for preparing a...

Embodiment 3

[0041] Embodiment 3: A kind of nickel-saving high-nitrogen austenitic stainless steel gas-shielded flux-cored welding wire of the present embodiment is made of core powder and a stainless steel sheath wrapped outside the core powder (thickness is 0.4mm, width is 430 low-carbon Stainless steel strip, in which impurity elements and their mass content are P≤0.020%, S≤0.005%); the drug core powder is composed of rutile: 17.5%, potassium feldspar: 2%, zircon sand : 1.5%, fluorite: 0.5%, cryolite: 1%, copper powder: 8.5%, aluminum-iron alloy: 0.5%, electrolytic manganese: 35%, atomized ferrosilicon: 2%, silicon-calcium alloy: 1.6%, metal Nickel: 10%, ferromolybdenum: 1.4%, ferro-niobium: 1%, ferro-titanium: 1%, metal chromium nitride: 16.5%; the nitrogen content in chromium nitride metal is 9%, and the core powder The particle size of the cored wire is 60-80 mesh, and the filling rate of the core powder in the flux-cored wire is 25%.

[0042] The method for preparing a nickel-savin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com