Phosphorus-doped core-shell ternary positive electrode material, preparation method thereof and lithium ion battery

A cathode material, phosphorus doping technology, applied in the direction of positive electrodes, secondary batteries, battery electrodes, etc., can solve the problems of material rate performance decline, failure to form, uneven shell distribution, etc., to achieve good rate performance and safety performance, Strong structural stability, good cycle performance and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

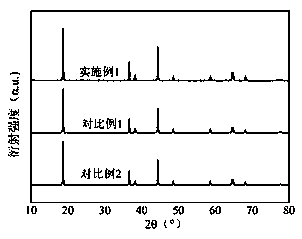

Embodiment 1

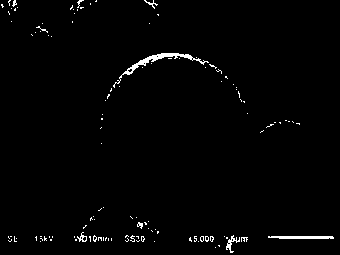

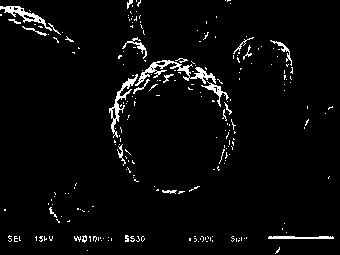

[0074] Weigh 1.19g of nickel nitrate, 0.63g of cobalt nitrate hexahydrate and 0.39g of manganese nitrate (the molar ratio of nickel:cobalt:manganese is about 6:2:2), 0.11g of sodium hypophosphite, 0.65g of urea, and 0.42g of sodium citrate g. Dissolved in 80 mL deionized water, stirred for 15 min, then added 100 g of ternary precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 Stir well to obtain mixed solution A. Pour the mixed solution A into the reaction kettle, and conduct hydrothermal heating at 200°C for 8 hours to obtain a phosphorus-doped core-shell ternary precursor, in which the shell is phosphorus-doped Ni 0.6 co 0.2 mn 0.2 (OH) 2 .

[0075] The core-shell structure obtained in the above steps was vacuum-dried, then mixed with 50.56 g of lithium hydroxide by ball milling, and sintered at 750° C. for 10 h in an oxygen atmosphere to obtain a phosphorus-doped core-shell ternary positive electrode material.

Embodiment 2

[0086] Weigh 7.02g of nickel nitrate, 2.40g of cobalt nitrate hexahydrate and 3.09g of aluminum nitrate nonahydrate (the molar ratio of nickel:cobalt:aluminum is about 7:1.5:1.5), 0.26g of sodium pyrophosphate decahydrate, 3.30g of urea, hard Sodium fatty acid 0.17g. Dissolved in 80 mL deionized water, stirred for 15 min, then added 100 g of ternary precursor Ni 0.9 co 0.05 Al 0.05 (OH) 2 Stir well to obtain mixed solution A. Pour the mixed solution A into the reaction kettle. A phosphorus-doped core-shell ternary precursor was obtained by hydrothermal heating at a temperature of 180 °C for 12 hours, where the shell was phosphorus-doped Ni 0.75 co 0.15 Al 0.15 (OH) 2 .

[0087] The phosphorus-doped core-shell ternary precursor obtained in the above steps was vacuum-dried and mixed with 53.56 g of lithium hydroxide ball mill, and sintered at 700° C. for 12 hours in an oxygen atmosphere to obtain a phosphorus-doped core-shell ternary positive electrode material.

Embodiment 3

[0098] Weigh 4.73 g of nickel nitrate, 0.940 g of cobalt nitrate hexahydrate and 0.78 g of titanium sulfate (the molar ratio of nickel: cobalt: manganese is about 0.8:0.1:0.1), 1.20 g of sodium phosphite, 2.42 g of ammonia water, dodecylbenzene Sodium sulfonate 1.13 g. Dissolved in 80 mL deionized water, stirred for 15 min, then added 100 g of ternary precursor Ni 0.95 co 0.03 mn 0.02 (OH) 2 Stir well to obtain mixed solution A. Pour the mixed solution A into the reaction kettle. The phosphorus-doped core-shell ternary precursor was obtained by hydrothermal heating at 150°C for 15 hours, where the shell was phosphorus-doped Ni 0.8 co 0.1 Ti 0.1 (OH) 2.2 .

[0099] The phosphorus-doped core-shell ternary precursor obtained in the above steps was vacuum-dried and mixed with 47.34 g of lithium hydroxide ball milled, and sintered at 680°C for 16 hours in an oxygen atmosphere to obtain a phosphorus-doped core-shell ternary positive electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com