High-niobium high-chromium alloy cast ion self-protection flux-cored wire for grinding roller surfacing and preparation method thereof

A high-chromium alloy and flux-cored wire technology, which is applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problem of large fluctuations in the hardness of the deposited metal in the surfacing layer, unstable filling coefficient of welding wire powder, and reduction of the surfacing layer. Wear resistance and other issues, to achieve excellent welding process performance, improve moisture absorption ability, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

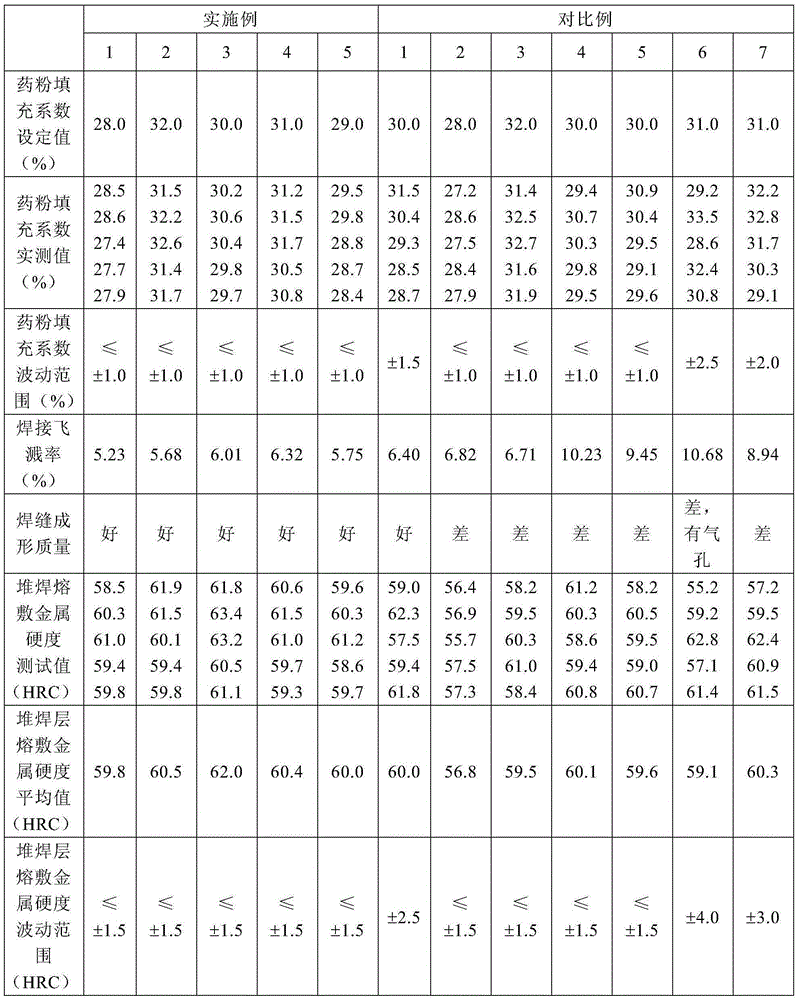

Examples

Embodiment 1

[0036] Select a ferritic stainless steel strip with a thickness of 0.6mm and a width of 14mm, and roll it into a U shape; 420g of high-carbon ferrochrome powder, 130g of ferro-niobium, 45g of graphite, 15g of ferrosilicon, 20g of electrolytic manganese, and 15g of medium-carbon ferroboron , 10g aluminum-magnesium alloy, 5g cryolite, 5g fluorite, 10g lithium carbonate, 5g zircon sand, 10g potassium titanate, 15g sodium titanate, 295g iron powder, a total of 1000g powder, potassium titanate, sodium titanate Carry out granulation and pre-sintering, and pass graphite, cryolite, fluorite, lithium carbonate and high-carbon ferrochrome through an 80-mesh sieve, then mix with other powders and stir for 110 minutes, then add to the U-shaped tank, the filling rate is 28%; After the mouth is closed, it undergoes four consecutive drawing and diameter reductions of φ4.0mm, φ3.65mm, φ3.41mm, and φ3.15mm, and the final diameter of the finished welding wire is 3.2mm.

Embodiment 2

[0038]Select a ferritic stainless steel strip with a thickness of 0.6mm and a width of 14mm, and roll it into a U shape; 480g of high-carbon ferrochrome powder, 160g of ferro-niobium, 50g of graphite, 20g of ferrosilicon, 30g of electrolytic manganese, and 20g of medium-carbon ferroboron , 20g aluminum-magnesium alloy, 10g cryolite, 10g fluorite, 15g lithium carbonate, 10g zircon sand, 15g potassium titanate, 20g sodium titanate, 140g iron powder, a total of 1000g powder, potassium titanate, sodium titanate Carry out granulation and pre-sintering, and pass graphite, cryolite, fluorite, lithium carbonate and high-carbon ferrochrome through an 80-mesh sieve, then mix with other powders and stir for 130 minutes, then add to the U-shaped tank, the filling rate is 32%; After the mouth is closed, it undergoes four consecutive drawing and diameter reductions of φ4.0mm, φ3.65mm, φ3.41mm, and φ3.15mm, and the final diameter of the finished welding wire is 3.2mm.

Embodiment 3

[0040] Select a ferritic stainless steel strip with a thickness of 0.6mm and a width of 14mm, and roll it into a U shape; 450g of high-carbon ferrochrome powder, 140g of ferro-niobium, 48g of graphite, 17g of ferrosilicon, 25g of electrolytic manganese, and 18g of medium-carbon ferroboron , 16g aluminum-magnesium alloy, 8g cryolite, 8g fluorite, 12g lithium carbonate, 8g zircon sand, 12g potassium titanate, 18g sodium titanate, 220g iron powder, a total of 1000g powder, potassium titanate, sodium titanate Carry out granulation and pre-sintering, and pass graphite, cryolite, fluorite, lithium carbonate and high-carbon ferrochrome through an 80-mesh sieve, then mix with other powders and stir for 120 minutes, then add to the U-shaped tank, the filling rate is 30%; After the mouth is closed, it undergoes four consecutive drawing and diameter reductions of φ4.0mm, φ3.65mm, φ3.41mm, and φ3.15mm, and the final diameter of the finished welding wire is 3.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com