High-toughness titanium alkaline type seamless flux-cored wire suitable for full-position welding

A seamless flux-cored wire, high toughness technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problem of decreased welding quality, mechanical properties of welded joints, difficult to obtain weld metal, and inability to apply all Position welding and other problems, to achieve the effect of arc stability, preventing molten iron from falling, and improving arc stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

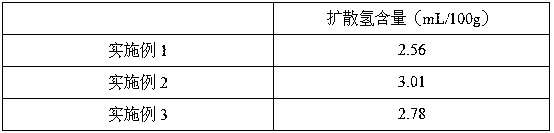

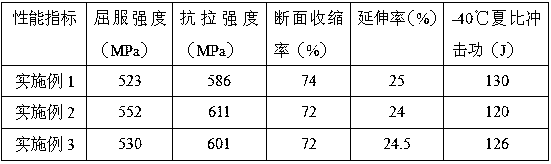

Embodiment 1

[0040] A high-toughness titanium-alkaline seamless flux-cored welding wire suitable for all-position welding. The welding wire is composed of a low-carbon steel strip on the periphery and core powder inside, wherein the core powder accounts for 15% by weight of the total weight of the wire. , The wire diameter is Ф1.2mm.

[0041] The composition of the drug core powder is: rutile: 33%, alumina: 1.5%, dehydrated feldspar: 3.5%, quartz: 2%, zircon sand: 2.5%, rare earth oxide: 1.2%, silicon powder: 14%, Iron boron: 0.2%, nickel powder: 6.5%, metal manganese: 10%, magnesium powder: 7%, the balance is iron powder and unavoidable impurities.

Embodiment 2

[0043] A high-toughness titanium-alkaline seamless flux-cored welding wire suitable for all-position welding. The welding wire is composed of a low-carbon steel strip on the periphery and core powder inside, wherein the core powder accounts for 15% by weight of the total weight of the wire. , The wire diameter is Ф1.0mm.

[0044] The composition of the drug core powder is: rutile: 39%, alumina: 1.5%, dehydrated feldspar: 3%, quartz: 1.5%, zircon sand: 2%, rare earth oxide: 1%, silicon powder: 15%, Iron boron: 0.2%, nickel powder: 6.5%, metal manganese: 8%, magnesium powder: 8%, the balance is iron powder and unavoidable impurities.

Embodiment 3

[0046] A high-toughness titanium-alkaline seamless flux-cored welding wire suitable for all-position welding. The welding wire is composed of a low-carbon steel strip on the periphery and core powder inside, wherein the core powder accounts for 15% by weight of the total weight of the wire. , The wire diameter is Ф1.0mm.

[0047] The composition of the drug core powder is: rutile: 35%, alumina: 1%, dehydrated feldspar: 2.5%, quartz: 2.5%, zircon sand: 2.5%, rare earth oxide: 1%, silicon powder: 16%, Iron boron: 0.2%, nickel powder: 6.5%, metal manganese: 12%, magnesium powder: 6%, the balance is iron powder and unavoidable impurities.

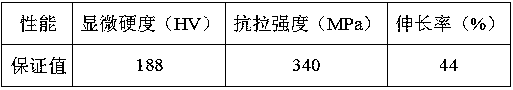

[0048] The manufacturing method of the high-toughness titanium-alkaline seamless flux-cored wire welded in all positions of the present invention is as follows: the outer skin is selected from SPHC steel strip, and the composition and properties are shown in Table 1 and Table 2; the chemical composition and mechanical properties of the welding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com