Polyborosiloxane fire retardant for polycarbonate and preparing method thereof

A polysilaboroxane and polycarbonate technology, which is applied in the field of flame retardants and their preparation, can solve the problems of uneven dispersion and difficult compounding of compositions, and achieves high transparency, good mechanical properties, and no environment and human body. harmful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 70g of water and a small amount of acetic acid in a 500ml three-necked flask. Pour the mixture of 0.2 mol of diphenyldimethoxysilane and 0.1 mol of methyltrimethoxysilane into the constant pressure dropping funnel, add drop by drop into the above flask, finish the drop within 10 minutes, adjust the pH value to 3.0, control the temperature at 80°C, and react for 2 hours to obtain the intermediate product silanol. Then the synthesized silanol was dissolved in 70g of xylene, allowed to stand to separate layers, and the water layer was removed. The silanol xylene solution was then reacted with 7g of boric acid at 100°C for 7 hours, and the solvent xylene was distilled off under reduced pressure. Finally, a white solid is obtained, which is polysiloxane flame retardant.

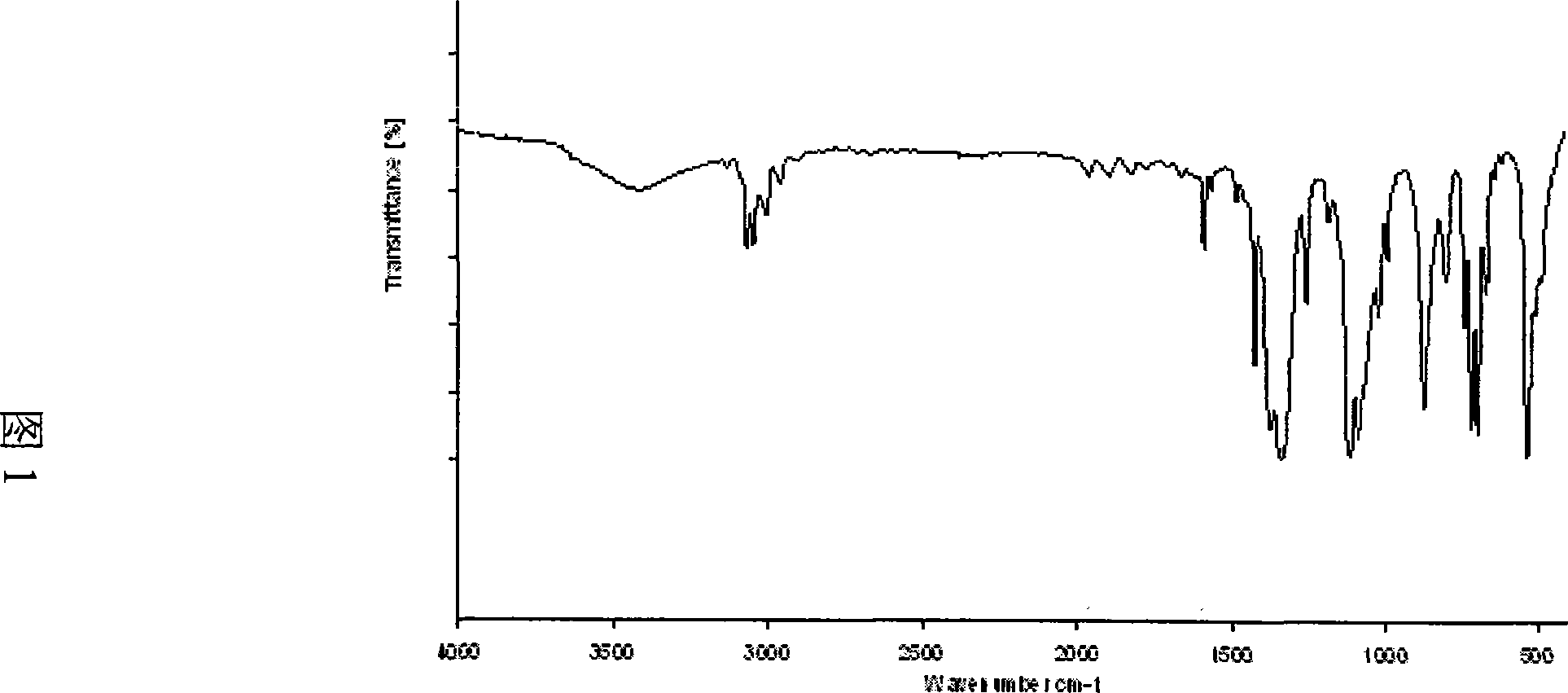

[0016] Its infrared spectrum is shown in Figure 1, and its specific structure is as follows: 3421cm -1 It is the stretching vibration peak of O-H; 3071cm -1 、1592cm -1 They are the stretching vibrat...

Embodiment 2

[0018] Add 80g of water and a small amount of acetic acid in a 500ml three-necked flask. Pour a total of 0.225mol of diphenyldimethoxysilane and 0.075mol of dimethyldimethoxysilane into the constant pressure dropping funnel, add dropwise to the above flask, and complete the dropwise addition within 10 minutes, adjust the pH value to 4.5, the temperature was controlled at 85°C, and the reaction was carried out for 1.5 hours to obtain the intermediate product silanol. Then the synthesized silanol was dissolved in 60g xylene, left to stand for stratification, and the water layer was removed, the silanol xylene solution continued to react with 6g boric acid for 7 hours, and the solvent xylene was distilled off under reduced pressure to finally obtain a white solid, i.e. Polysilaboroxane flame retardant.

Embodiment 3

[0020] Add 80g of water and a small amount of acetic acid in a 500ml three-necked flask. Pour the mixture of 0.18mol dimethyldimethoxysilane and 0.12mol diphenyldimethoxysilane into the constant pressure dropping funnel, add it dropwise to the above flask, complete the dropwise addition within 10min, and control the temperature at 80 °C, adjust the pH value to 2.8, and react for 2 hours to obtain the intermediate product silanol. Then dissolve the synthesized silanol in 70g of toluene, let the layers stand, remove the water layer, continue to react the silanol toluene solution with 7g of boric acid for 8.5 hours, distill off the solvent toluene under reduced pressure, and finally get a white solid, namely polysilicon boron Oxygen flame retardants.

[0021] The flame retardant and polycarbonate obtained in this example were added into a high-speed mixer at a weight ratio of 1:20 and mixed at a high speed for 15 minutes at 70° C., and then melted and extruded on a twin-screw ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com