Transmission liquid composition for stepless speed gear

A technology of composition and transmission fluid, which is applied in the field of CVT special transmission fluid composition, can solve the problems of inability to meet the special requirements of stepless variable transformers, low-temperature fluidity and viscosity difference, etc., and achieve excellent low-temperature fluidity and good low-temperature fluidity , the effect of normal viscosity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Get cumene (purity 99w%) 240 grams, formaldehyde (37% aqueous solution) 47.8 grams, sulfuric acid (concentration 98w%) 58.2 grams are raw materials. Among them, cumene and sulfuric acid were mixed and stirred in a four-necked bottle, and the temperature was raised from room temperature to 120°C. After reaching the set temperature, the formaldehyde solution placed in the dropping funnel was slowly dropped into the four-necked bottle. After the dropwise addition of formaldehyde is completed, after the heat preservation reaction for about 1 hour, the material is discharged into a separatory funnel, and extracted and washed with distilled water and n-butanol mixture (water:alcohol volume ratio is about 4:1) at about 80°C until pH=7. Cut out the upper oil phase product. After the oil phase products are collected, the unreacted raw material cumene is first distilled under the condition of residual pressure of 24-40mmHg, and then under the condition of residual pressure of le...

Embodiment 2

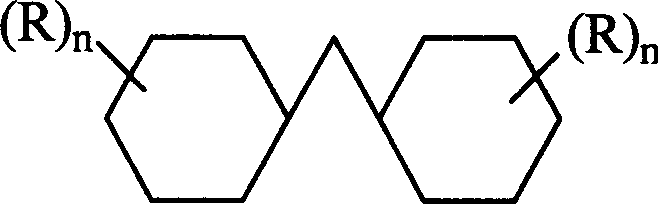

[0055] The synthesis process is the same as in Example 1, except that the raw material is changed to 268 grams of tert-butylbenzene, and the quality of formaldehyde and concentrated sulfuric acid remains unchanged. Condensation reaction was carried out at 120°C, followed by extraction, separation and vacuum distillation to obtain 125.5 grams of the intermediate bis(tert-butylphenyl)methane product. It was mixed with 6.7 g of 10% Pd / C catalyst and placed in an autoclave. Under the conditions of temperature 190° C., hydrogen pressure 7.0 MPa, and stirring speed 250 RPM, hydrogenation saturation was carried out. Product obtains 115.3 grams of final product after decompression head pulling, 1 The degree of hydrogenation saturation was determined to be 97.3% by H-NMR. 13 C-NMR molecular structure identification shows that bis(4-tert-butylcyclohexyl)methane is its main component.

[0056] The composition of table 3 embodiment and comparative example

[0057] components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com