Water tap device for oil rig

A faucet and drilling rig technology, applied in earth-moving drilling, wellbore/well components, flushing wellbore, etc., can solve the problems of reduced equipment utilization, limited service life, limited bearing capacity, etc., to achieve strong bearing capacity and extended overhaul Cycle time, the effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

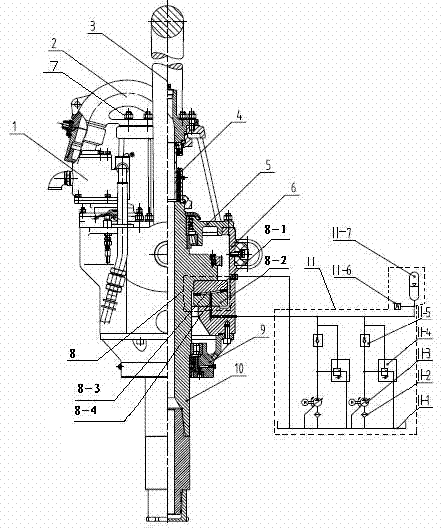

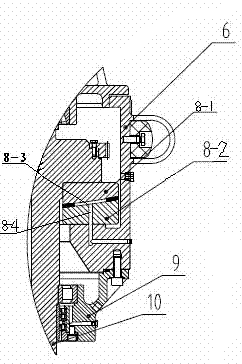

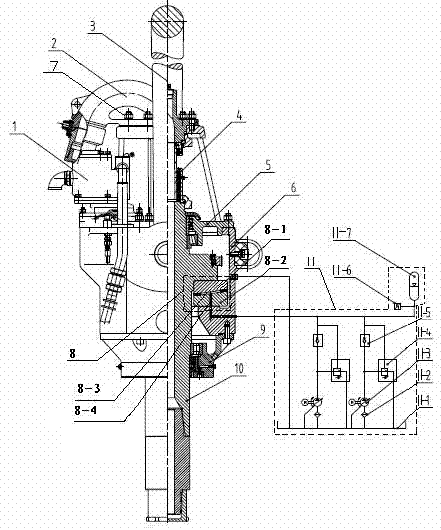

[0027] Such as figure 1 As shown, the new faucet device of the oil drilling rig mainly includes a hydraulic station device 11, a motor device 1, a gooseneck device 2, a lifting ring 3, a packing device 4, a center pipe 10, a casing upper cover 5, a casing 6, and a sliding bearing 8 And the bearing seat 9, the bearing seat 9 is installed on the outside of the center pipe 10 at the lower end of the shell 6.

[0028] The upper end of the lifting ring 3 is hung on the main hook of the hook, and the lower end is connected to the shell 6 by the lifting ring pin. The motor device 1 is installed on the top of the housing loam cake 5, and it drives the rotation of the central tube 10 by a pair of external gears. The casing upper cover 5 is connected with the casing 6 through screws, and the casing 6 is connected with the oil tank 11 through a pipeline. The gooseneck device 2 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com