Circulating fluidized bed hot-water boiler free of abrasion and corrosion

A circulating fluidized bed and hot water boiler technology, applied in fluidized bed combustion equipment, fluid heaters, water heaters, etc., can solve high temperature oxidation, fly ash erosion, low temperature dew point corrosion, boiler heating surface thickness reduction Thickness, shortening the service life of the boiler and other problems, achieving the effect of reducing the number of routine maintenance, simple installation and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

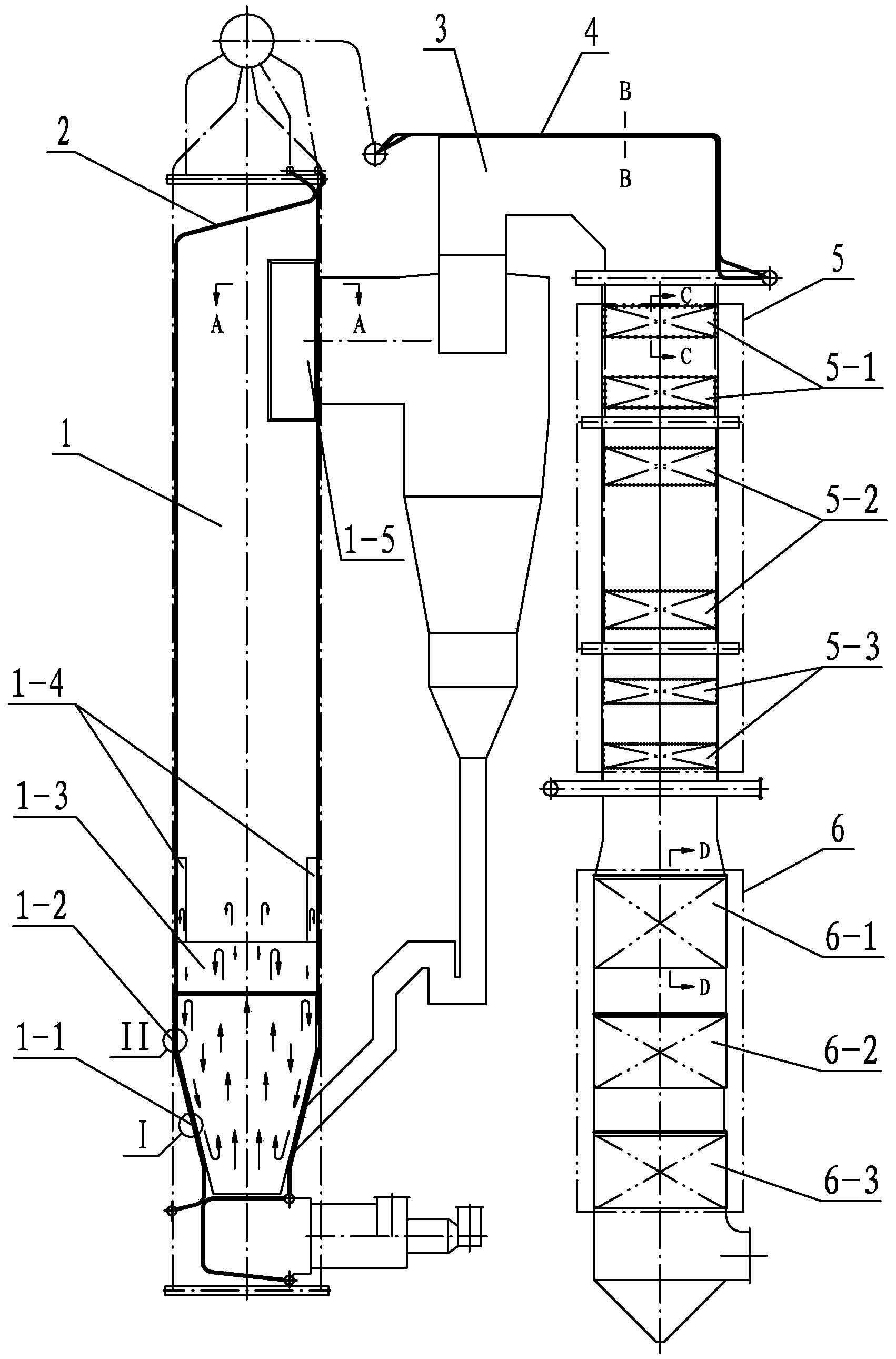

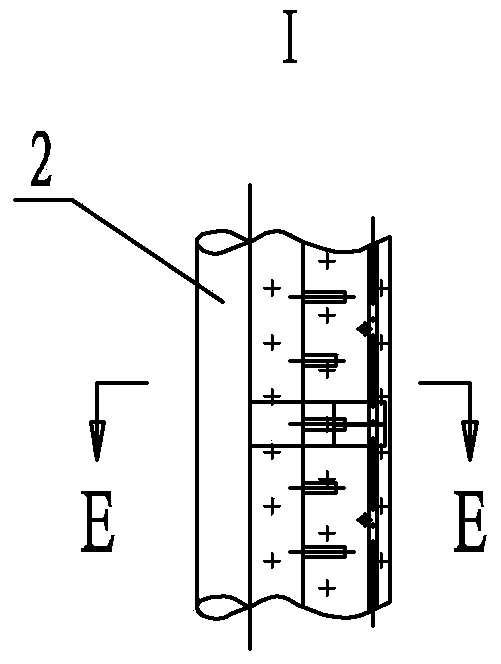

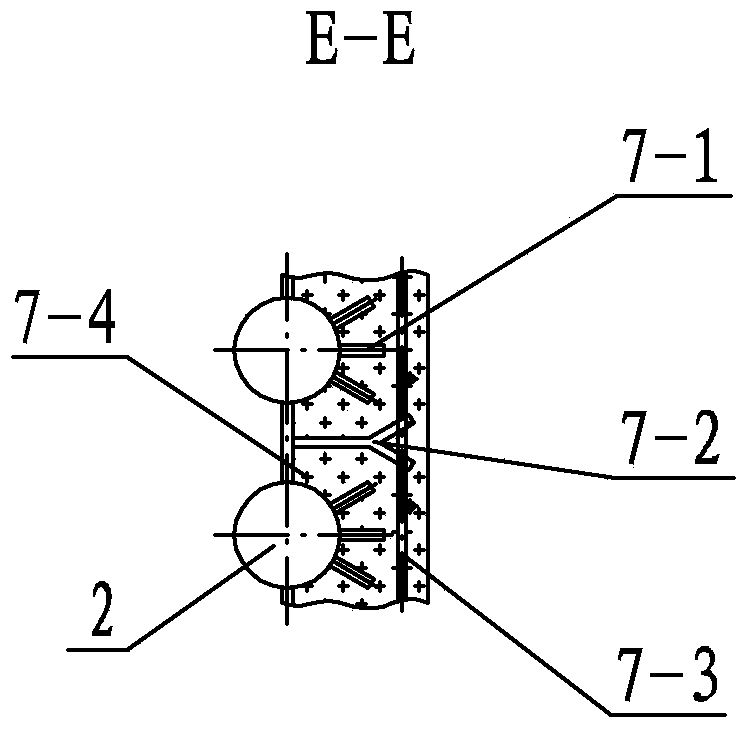

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment, a circulating fluidized bed hot water boiler for preventing wear and corrosion in this embodiment, which includes a furnace 1, a water wall 2, a flue 3, an economizer coating pipe 4, an economizer 5 and The air preheater 6, the furnace 1 is vertically arranged, and the interior of the furnace 1 is sequentially divided into a dense-phase zone 1-1, a dilute-dense phase transition zone 1-2 and a dilute-phase zone 1-3 from bottom to top, and in the furnace 1 A furnace outlet window 1-5 is arranged on the side wall of the upper end, the water-cooled wall 2 is arranged on the inner wall of the furnace 1 along the vertical direction, and one end of the flue 3 is arranged on the furnace outlet window 1-5 to communicate with the furnace 1, The other end of the flue 3 is set on the upper end of the economizer 5 and connected to the economizer 5, the economizer coating pipe 4 is fixed on the inner surface...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the economizer 5 in this embodiment includes an upper economizer 5-1, a middle economizer 5-2 and a lower economizer 5-3, the upper economizer 5-1, the middle economizer The economizer 5-2 and the lower economizer 5-3 are arranged sequentially from top to bottom. With this setting, the sectioned economizer is convenient for maintenance and replacement of the wear-resistant cover inside the economizer and the wear of the economizer tube. Multi-section economizers work at the same time, which makes the heat exchange effect of the economizer more significant and the efficiency improved 10%. Other compositions and connection methods are the same as those in Embodiment 1.

[0025] In this embodiment, the economizer 5 adopts the design of variable pipe diameter, segmental variable cross-section, equal smoke velocity and no ash accumulation. Pipes with different diameters of Ф38, Ф42 and Ф6...

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1Describe this embodiment, the air preheater 6 in this embodiment includes an upper air preheater 6-1, a middle air preheater 6-2 and a lower air preheater 6-3, and the upper air preheater 6-1. The middle air preheater 6-2 and the lower air preheater 6-3 are arranged in order from top to bottom. In this way, the air preheaters are graded to facilitate maintenance and replacement of the wear-resistant cover inside the air preheater and the wear of the air preheater tubes. The multi-stage air preheaters work at the same time to make the heat exchange effect of the air preheater More significantly, the working efficiency is improved and the service life is extended. Other compositions and connection methods are the same as those in Embodiment 1.

[0027] In this embodiment, the air preheater adopts a horizontal structure, and the air and flue gas are arranged in countercurrent. The air preheater tube in the lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com