Patents

Literature

77results about How to "Reduce routine maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

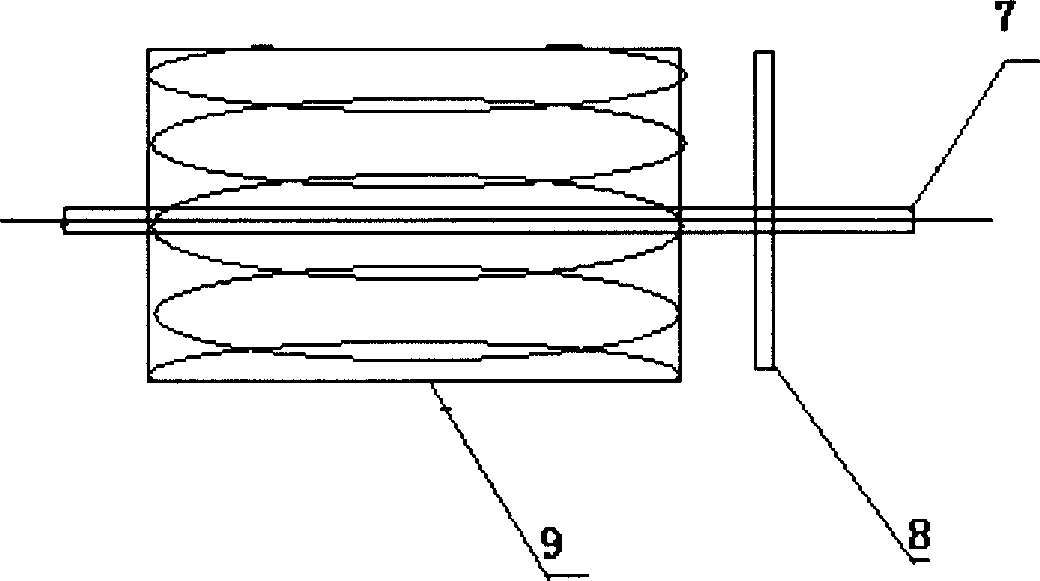

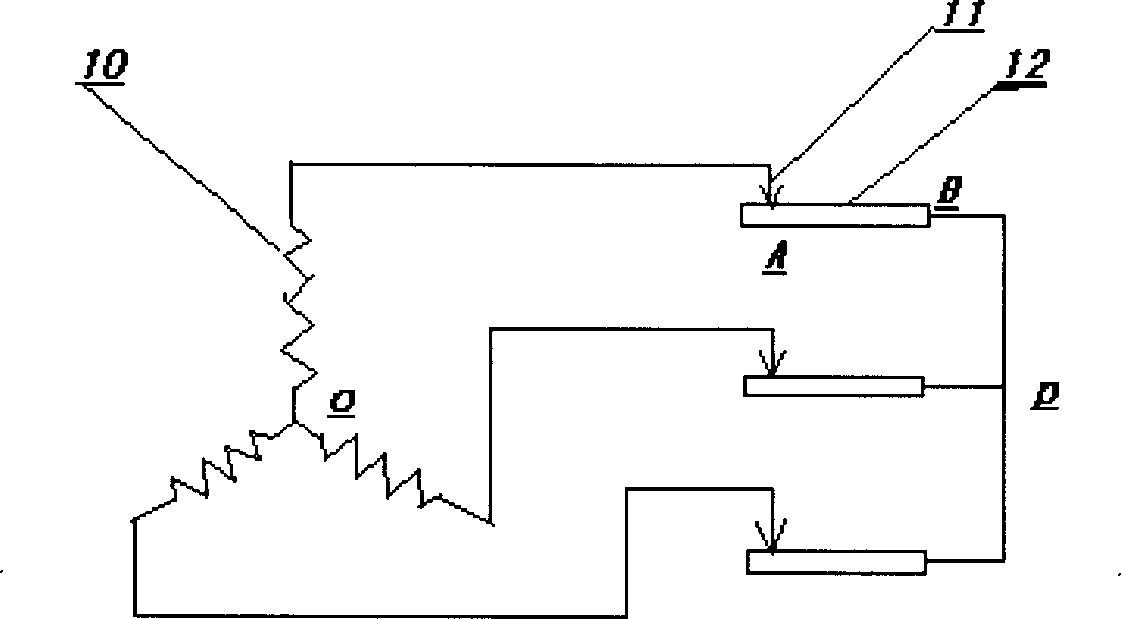

On-line monitoring method of content of formaldehyde in environmental air and device

PendingCN109459401AGuaranteed stabilityHigh detection sensitivityWithdrawing sample devicesPreparing sample for investigationData acquisitionLength wave

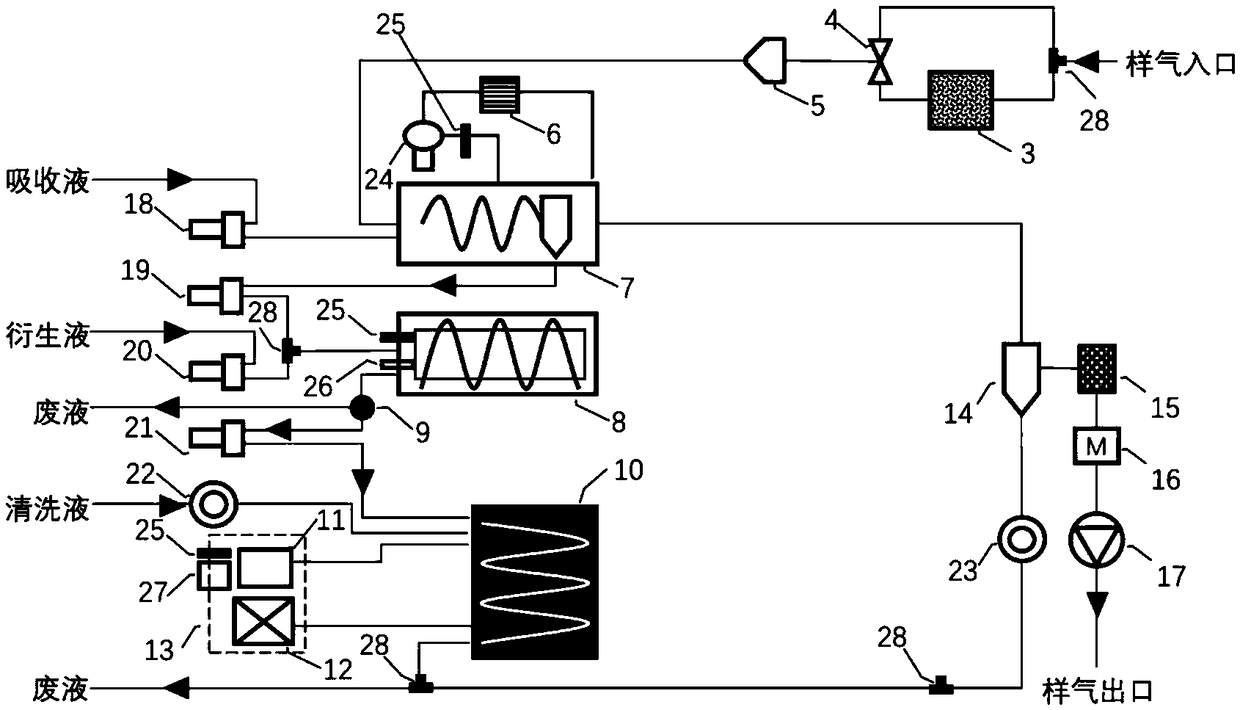

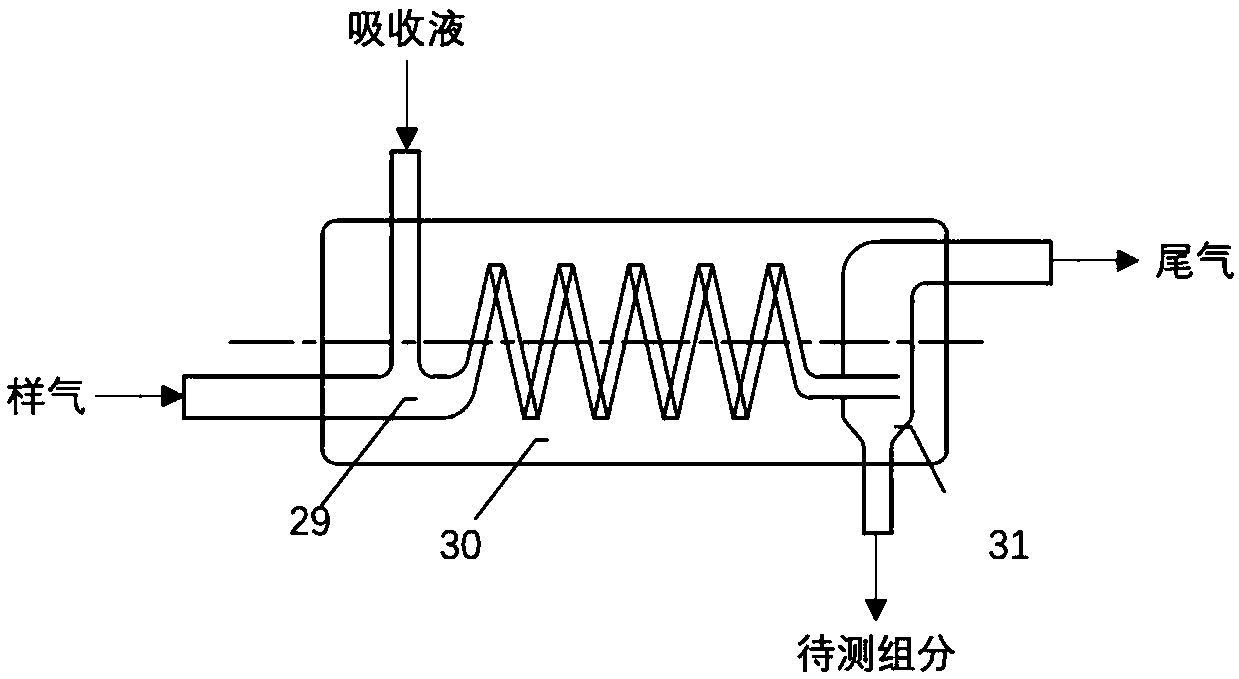

The invention discloses an on-line monitoring method of content of formaldehyde in environmental air and a device. The on-line monitoring method comprises measurement processes including a sampling process, a reaction process and a detection process of the formaldehyde in the environmental air. The method is characterized by comprising the following steps: converting formaldehyde in the environmental air into a formaldehyde solution and taking the formaldehyde solution as a liquid-phase sample to be detected; enabling the liquid-phase sample to be detected and acetylacetone to carry out derivatization reaction under the high-temperature condition to generate a yellow compound DDL, wherein absorption in a wavelength of 415 nm is the highest; enabling a solution to repeatedly reflect and absorb light in a total-reflection flow cell by using a total-reflection long-optical-path on-line flow cell; and calculating the content of formaldehyde to obtain the content of formaldehyde in the environmental air. The on-line monitoring device comprises a machine shell, a sampling module, a reaction module, a detection module, a solution conveying module, a control and data collection circuit anda display screen. Through the method and the device, the sensitivity and the detection limit of detection of formaldehyde are improved by the long-optical-path on-line flow cell; the method and the device are applied to on-line continuous monitoring of formaldehyde in the low-concentration environmental air.

Owner:PEKING UNIV

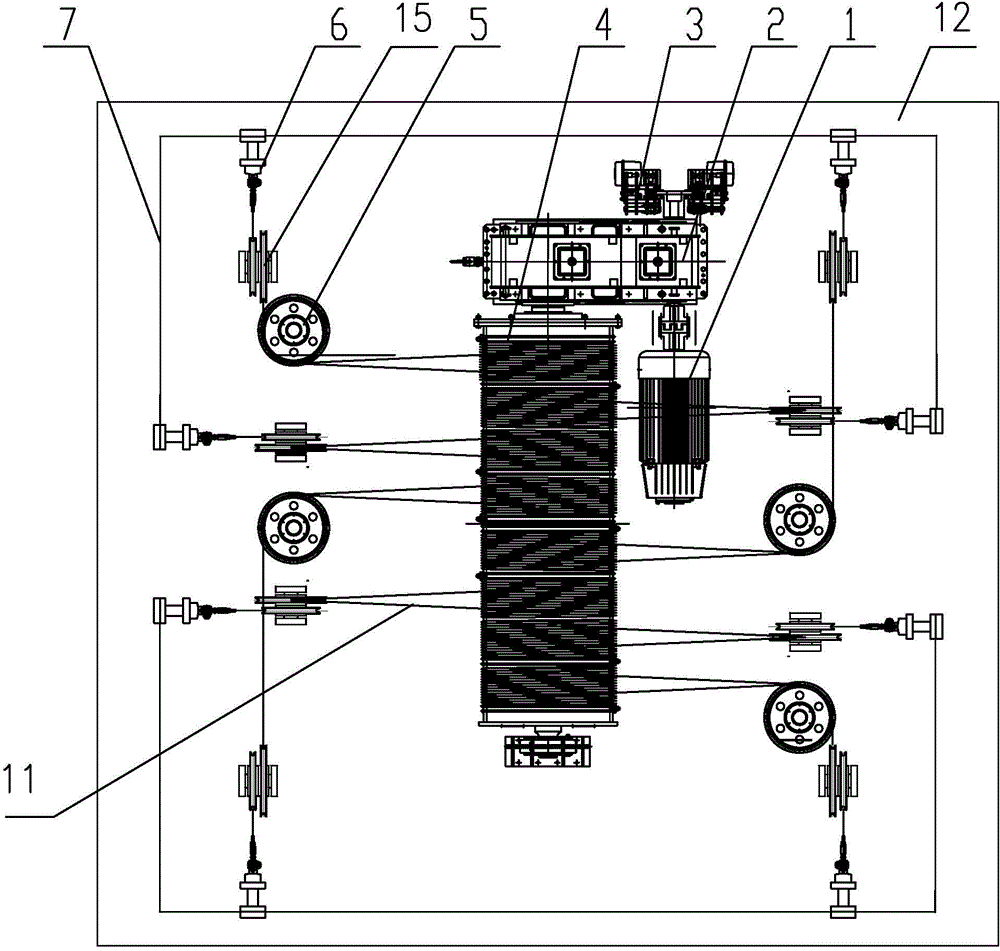

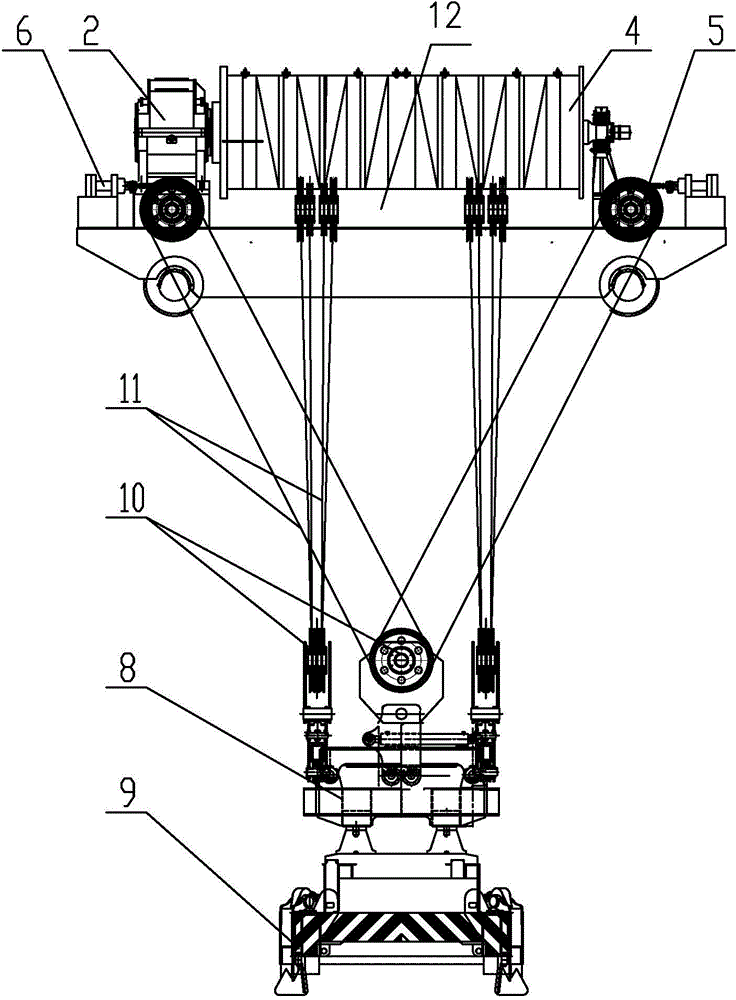

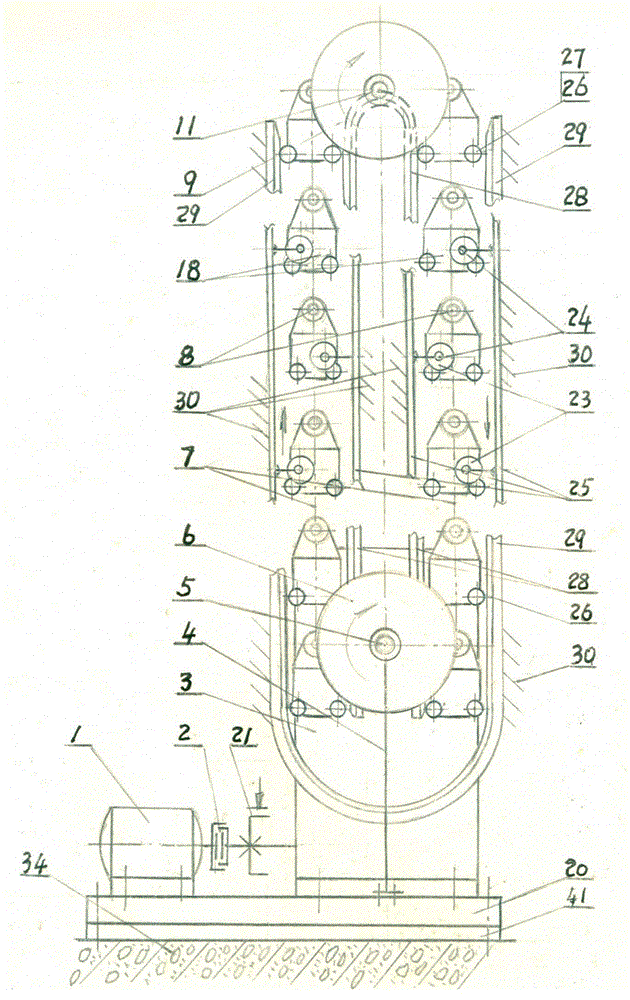

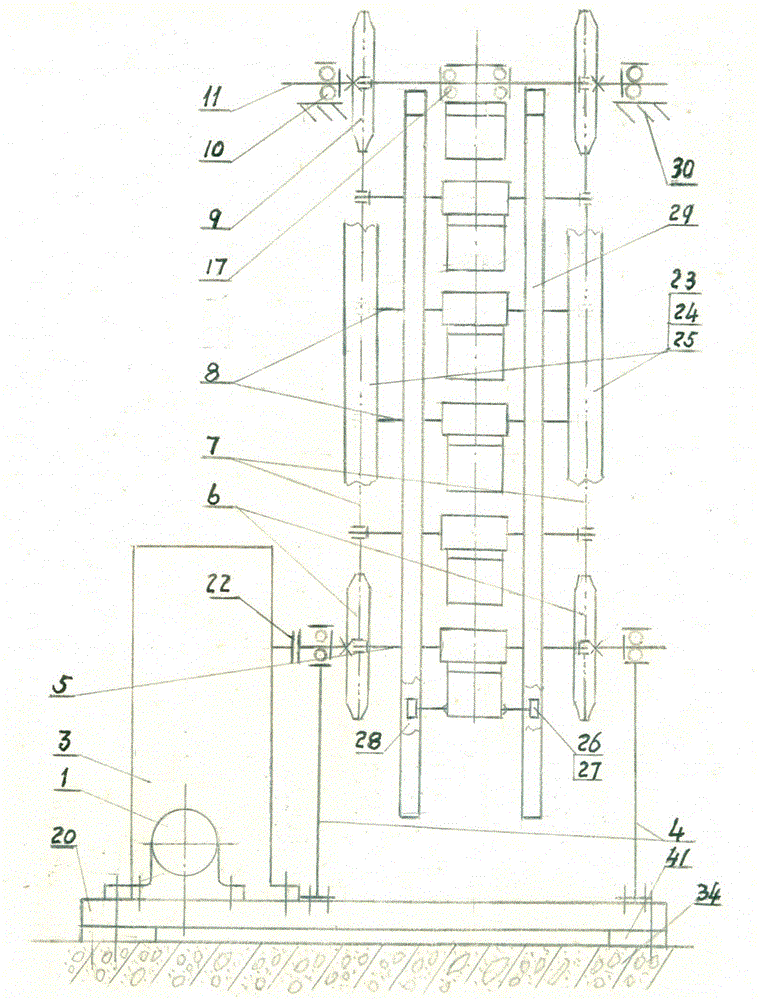

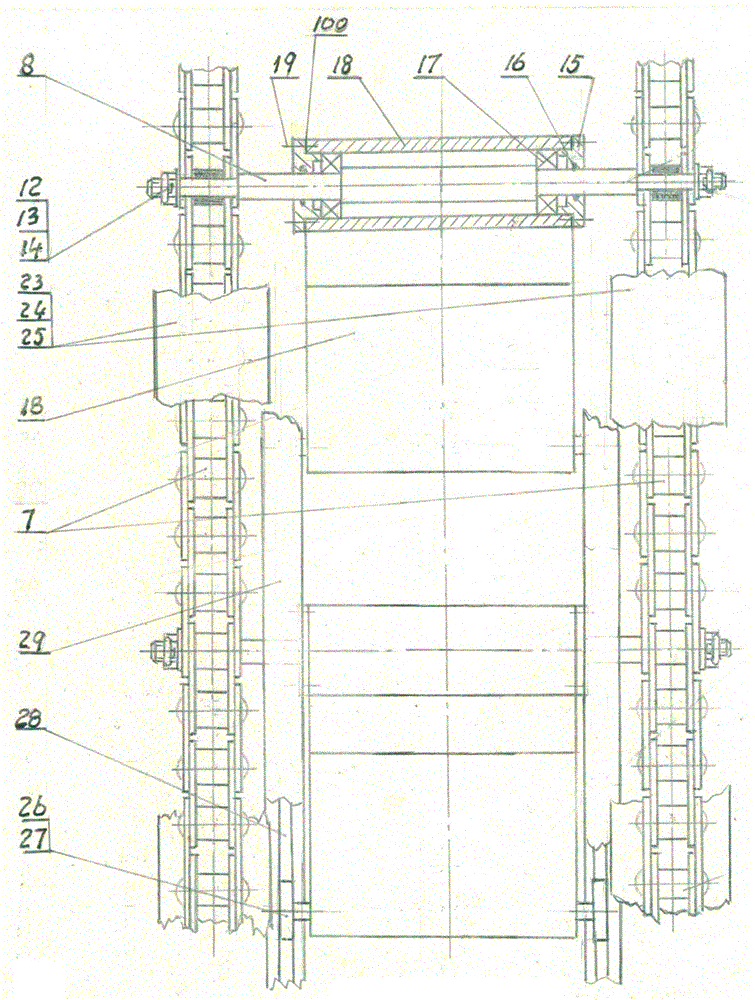

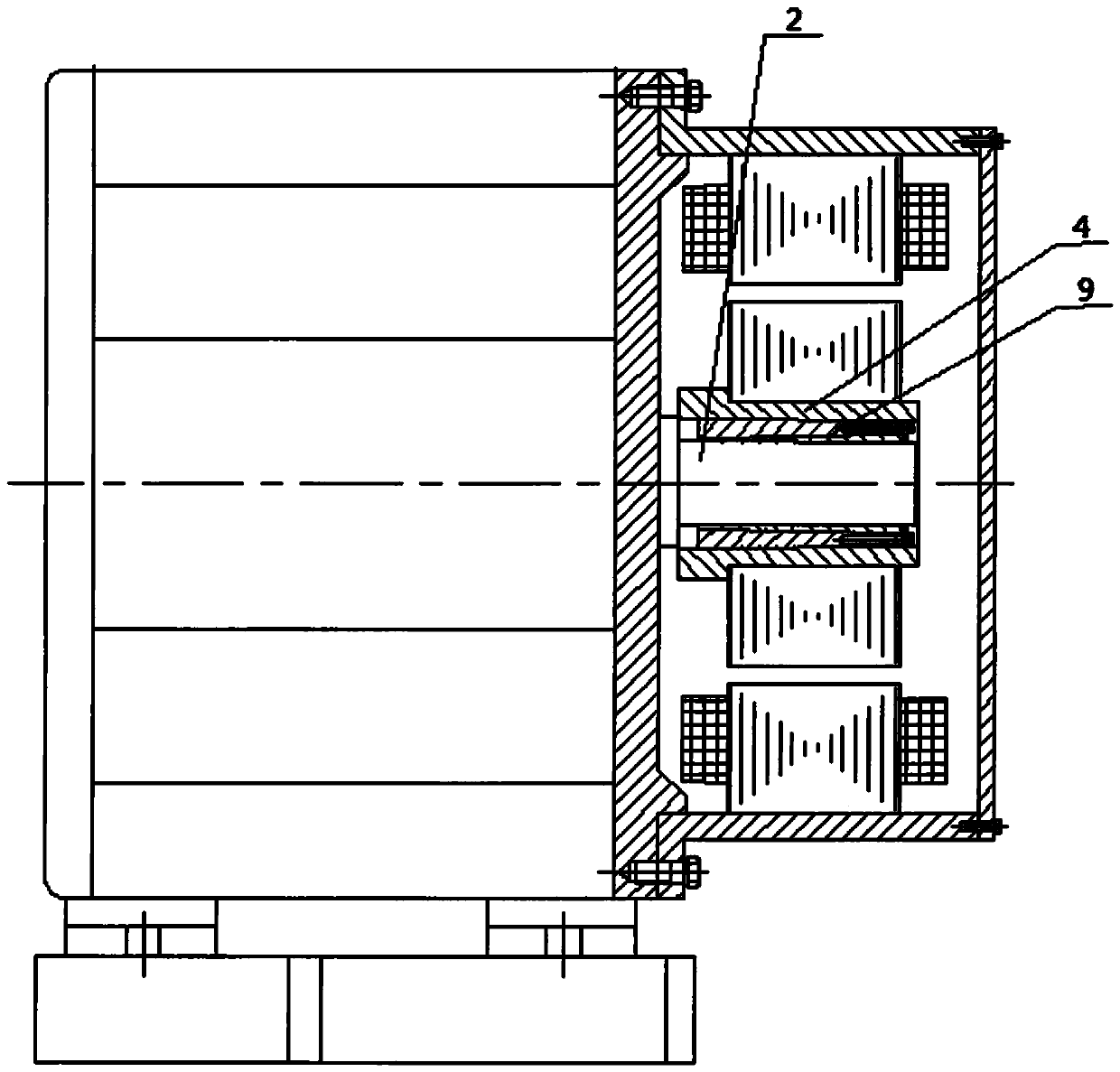

Crane steel wire rope anti-swing system

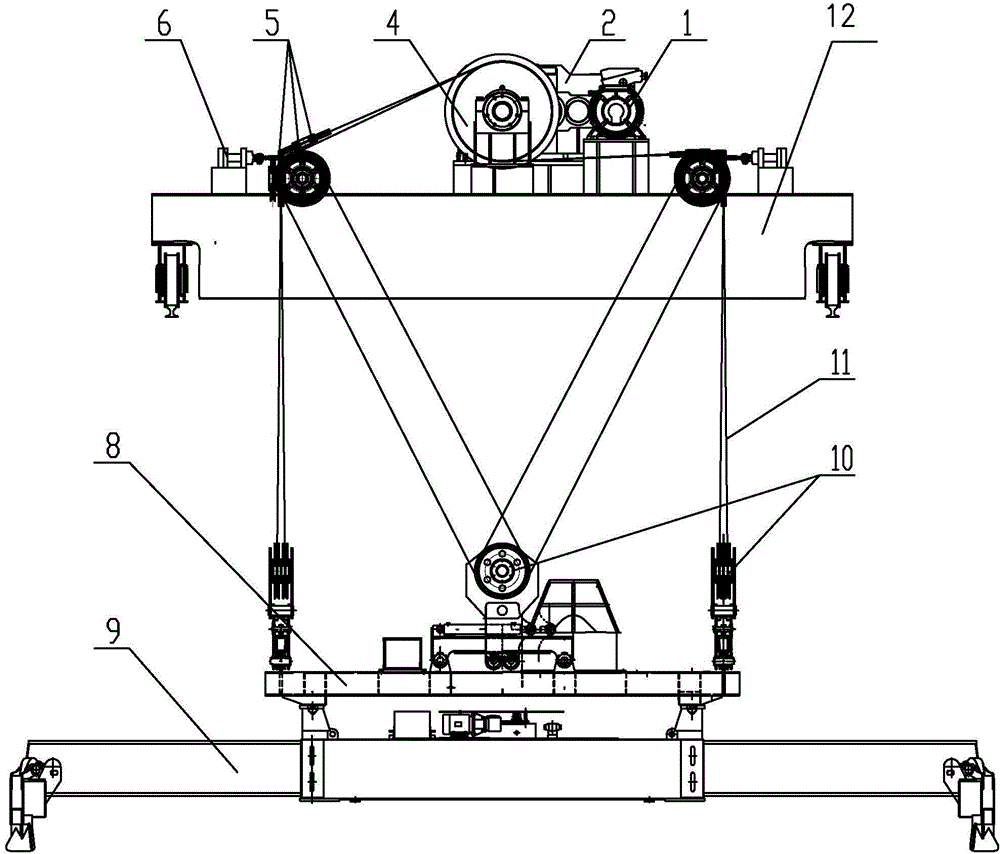

InactiveCN104477774ASignificant anti-sway effectSimple structureLoad-engaging elementsManufacturing cost reductionHydraulic cylinder

The invention discloses a crane steel wire rope anti-swing system. The crane steel wire rope anti-swing system comprises a motor, a reducer, a brake and a winding drum, which are mounted on a trolley frame and sequentially connected, wherein the lower parts of hoist ropes are twisted on a lower pulley block on an upper sling rack; the crane steel wire rope anti-swing system is characterized in that the eight hoist ropes twisted on the winding drum pass through an upper pulley block and a steering wheel, and steel wire rope lantern rings at the ends of the hoist ropes are respectively connected with piston rods of eight hydraulic cylinders which are symmetrically and uniformly fixed on the four sides of the trolley frame; the eight hydraulic cylinders are divided into two groups; every four hydraulic cylinder blocks are connected in series through hydraulic cylinder connecting pipelines. With the adoption of the technical scheme, the crane steel wire rope anti-swing system disclosed by the invention is simple in structure, the anti-swing effects of the steel wire ropes are obvious, the service life of the steel wire rope is effectively prolonged, and conveniences are brought to routine maintenance and repair of the equipment; the steel wire ropes are twisted in a multi-magnification manner, and the magnification factor is two, so that the pull of the steel wire ropes is only half of that in the prior art, and the torque of the winding drum can be reduced. Therefore, the specification of the reducer can be reduced, and the manufacturing cost can be lowered.

Owner:DALIAN HUARUI HEAVY IND CRANE CO LTD +1

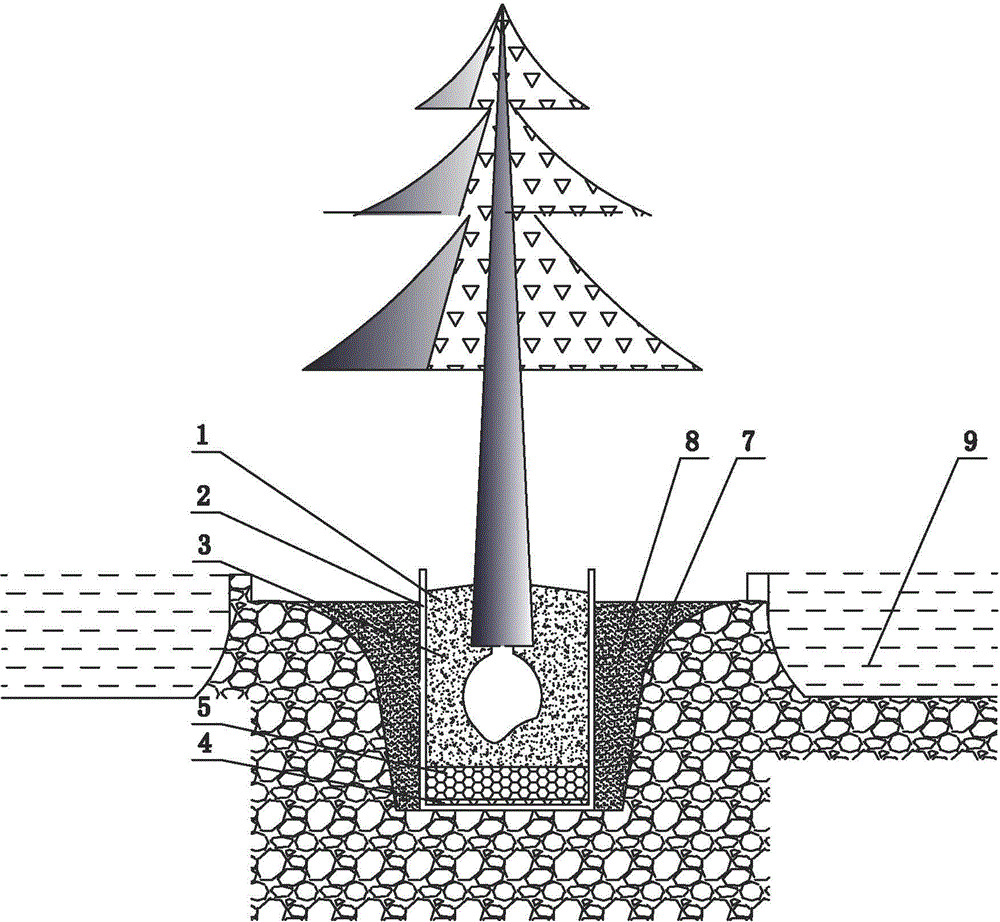

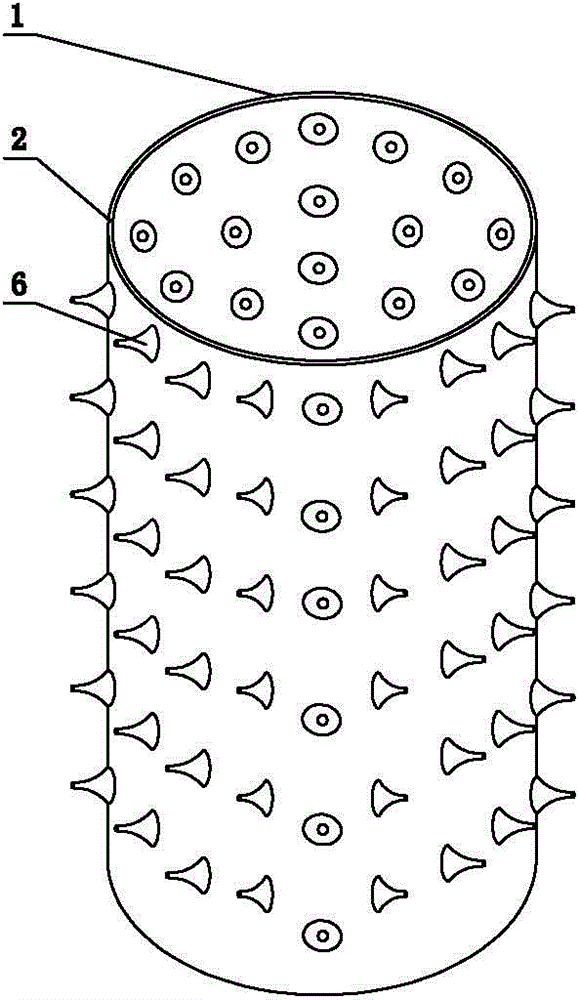

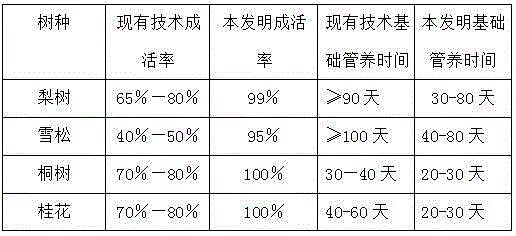

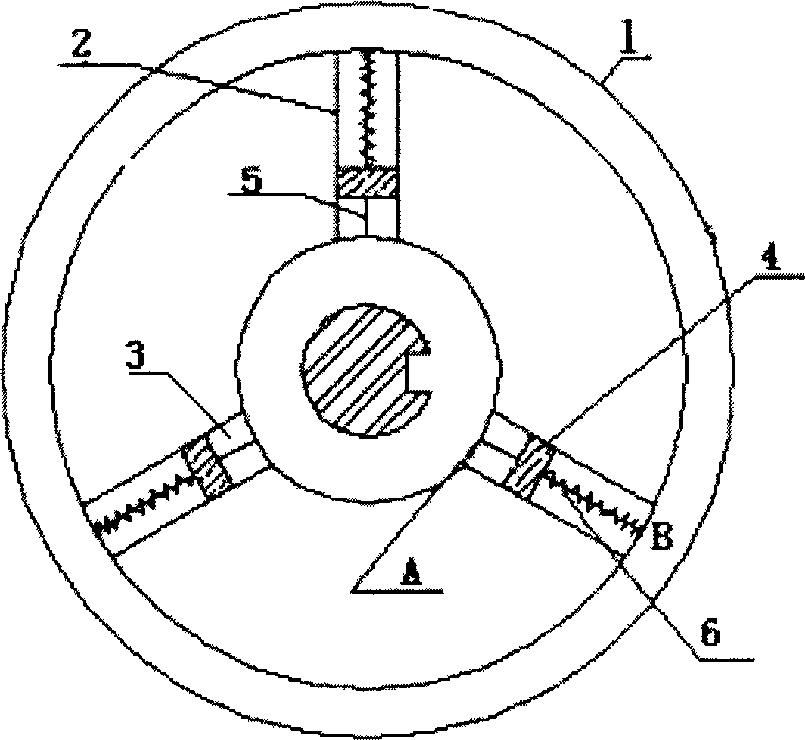

Root promoting seedling culturing method for woody plants

ActiveCN104303933AEasy to root and surviveImprove breathabilityCultivating equipmentsHorticulture methodsWoody plantWater filter

A root promoting seedling culturing method for woody plants uses a root controller. The root controller comprises an enclosing shell. Modified composite dressing soil is disposed in the enclosing shell. Geotechnical cloth and water filter particles are sequentially disposed at the bottom of the enclosing shell. A plurality of water seeping openings are formed in the enclosing shell. The root controller is convenient to carry, simple in structure, convenient to use, and the like. The method has the advantages that a pit is dug before seedling planting, the planted seedling can be connected to earth atmosphere after planting, and the seedling can take root and survive easily by the aid of a rooting agent; the seedling is planted into the root controller with pores distributing in the periphery, the seedling can breathe well, root breathing is benefited, seedling rooting and root aerobic respiration after rooting are benefited, and daily maintenance after planting is reduced.

Owner:湖北天蓝地绿生态科技股份有限公司

Torque adaptive winding type motor

InactiveCN1604433AReduce weightSimple structureAsynchronous induction motorsConductor CoilMotor load

This invention discloses a winded motor suitable to large torque starting, which comprises stator and rotor. The torque self-adapting winded motor cascades rotor coil circuit pre-set when starting. When rotor achieves the limit or set rotation speed, the centrifugal controller automatically gradually eliminates the resistance from rotor circuit to achieve the large torque starting. When motor load increases and speed reduces, the centrifugal automatically cascades the proper resistance into the rotor to increase torque.

Owner:史可德

Circulating lifting device

ActiveCN105545040AImprove work efficiencyNo major lossParkingsReciprocating motionMechanical equipment

Provided is a circulating lifting device. A transmission device is installed on ground, a reversing device is installed on another fixed object, and two chains connect the transmission device and the reversing device. A rotating shaft is connected with the two chains. A moving box is installed on the middle part of the rotating shaft in a vertical oscillating manner. Driven by the transmission device, the device realizes circulation, roundtripping, carrying, loading and unloading, and storage of personnel, materials and goods, and materials. The device is formed by the transmission device, the reversing device, a carrying device, and a stabilizing device. The circulating lifting device has four types. The types are a basic circulating lifting device, an energy-efficient circulating lifting device, a comprehensive circulating lifting device, and an efficient circulating lifting device. The common characteristics are that through changing the structure, the number, and operating methods (circulating or reciprocating motion), circulating paths of the moving box, and changing placing methods (vertical, inclined, horizontal, reversed inclined, and reversed) of the moving boxes, the device has new purposes and becomes a new product. Mechanical equipment manufactured according to principles of the equipment has characteristics of high efficiency, energy conservation, land saving, and cost saving, and the equipment is suitable for automation production in large batch.

Owner:BEIHANG UNIV

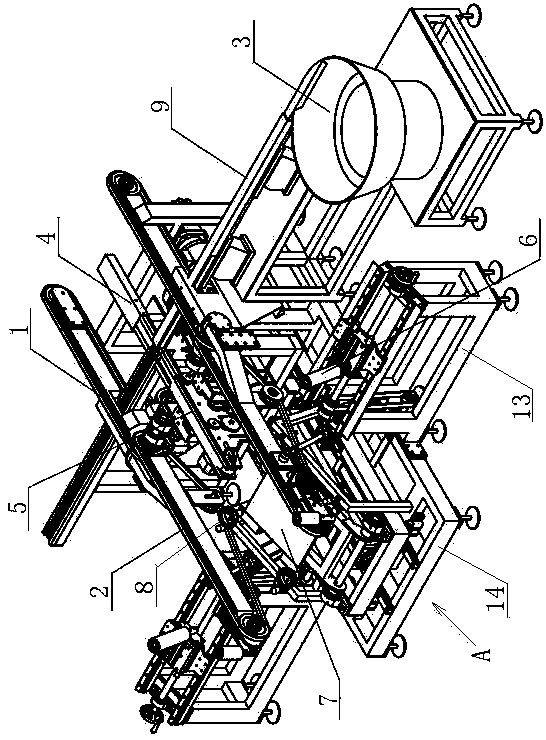

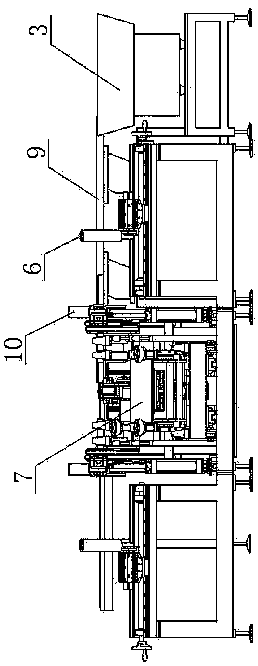

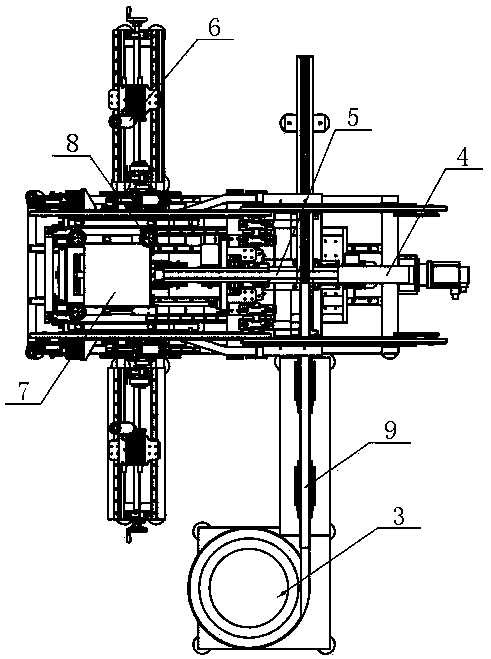

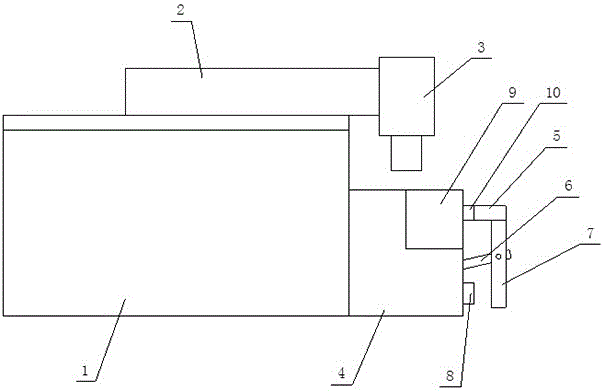

Automatic dismounting and stacking device for front windshield of car

The invention relates to an automatic dismounting and stacking device for the front windshield of an automobile, and belongs to the field of automobile glass production. A middle positioning rod is mounted at the front end of an overturning transmission device; the rear end of the overturning transmission device is in contact with a transitional transmission device; an automatic supply high-pressure clip vibration charging tray is connected with a linear feeder; a transmission motor is connected with the overturning transmission device; a servomotor is connected with a stacking and overturning device; a tapered positioning rod is mounted on a tapered positioning rod bracket; the tapered positioning rod bracket is positioned on two sides of a main frame; the linear feeder is connected with a high-pressure clip pushing mechanism; the high-pressure clip pushing mechanism is in contact and connection with a high-pressure clip mounting mechanism; a glass sucker is arranged on a stacking device. The device has the advantages that the structure is novel, the routine maintenance cost is reduced, the manufacturing cost is low, the application value is high, the popularization is strong, the full-automatic production can be achieved, the labor intensity of personnel is reduced, and the labor cost is reduced.

Owner:FUYAO GRP CHANGCHUN

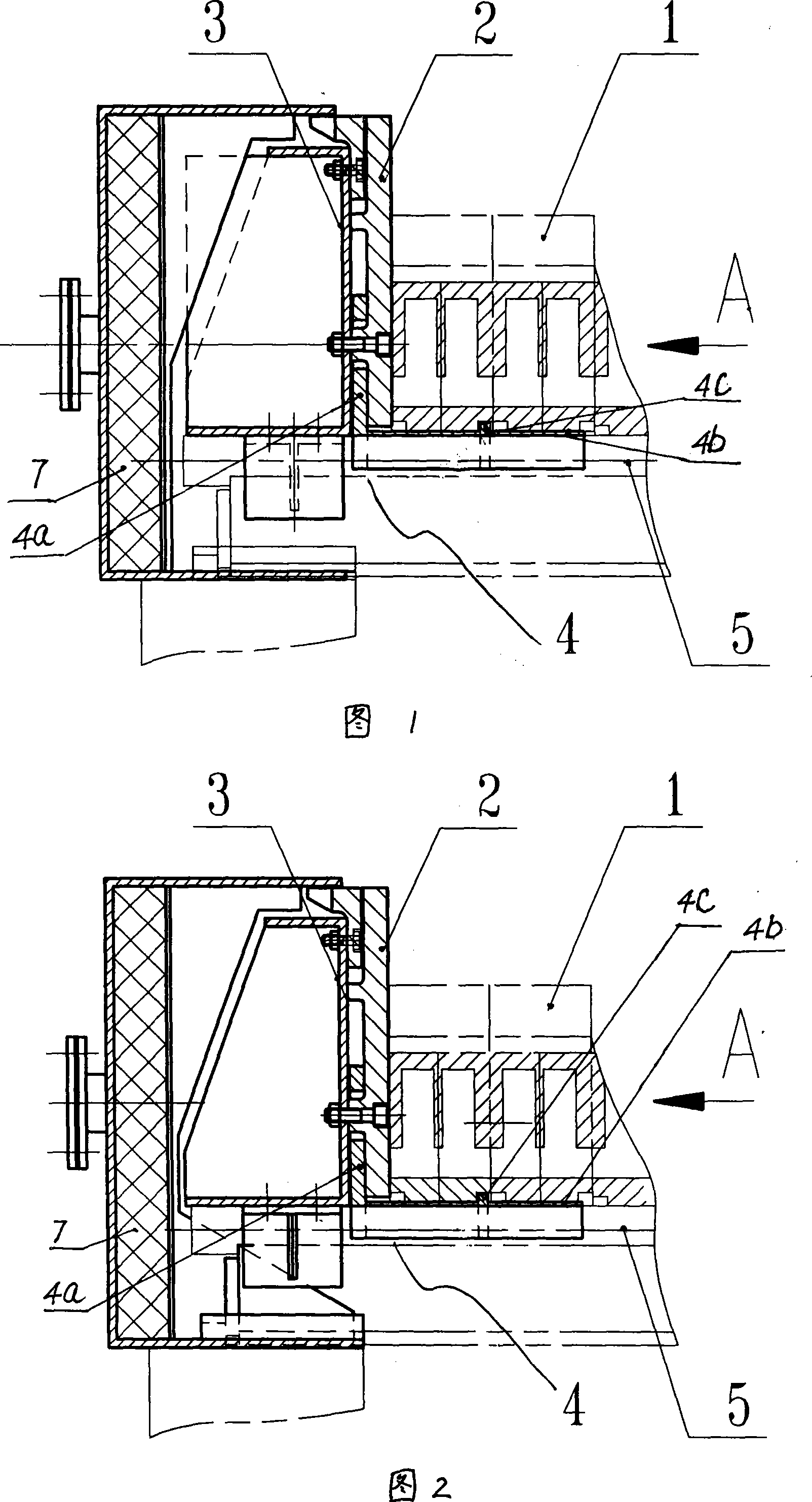

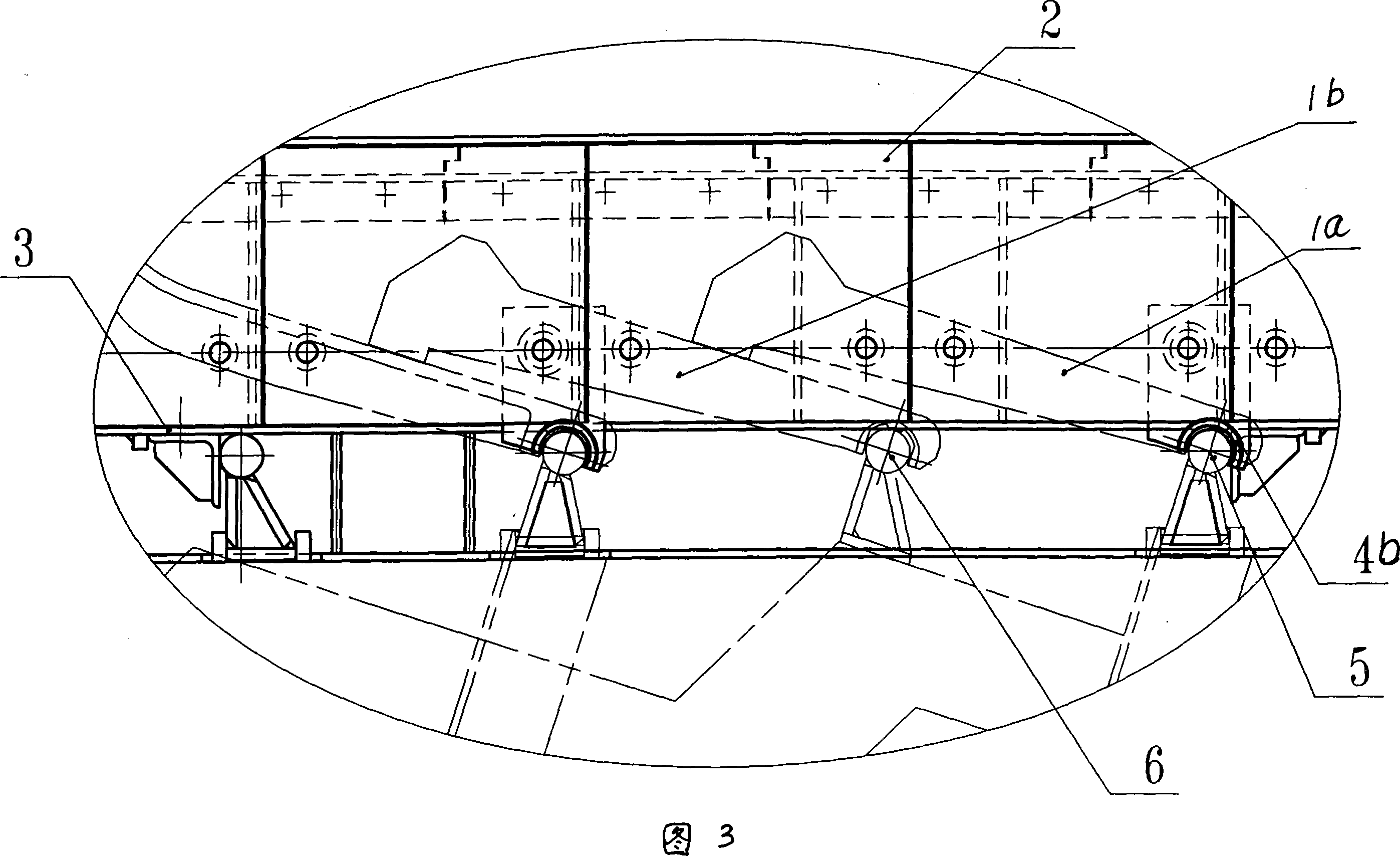

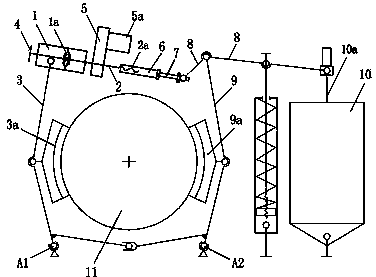

Mechanical compensating mechanism of incineration furnace grate

ActiveCN101178179AConstant ventilation areaEvenly ventilatedGratesIncinerator apparatusEngineeringForeign matter

The invention relates to a mechanical compensating device for a grate of an incinerator, in particular to a thermal expansion absorption device which avoids the ventilation gap change of the grate of the incinerator due to heat-expansion and cold-contraction. The invention comprises a fixed grate and a movable grate which are arranged crossly and one ends of which are fixed on the incinerator body. The invention is characterized in that the other end of each grate is provided with a sliding end which is used for sliding the grate when in expansion and extraction; and a supporting beam of the fixed grate positioned at the end is provided with a lateral compensating block, a connecting element and a sliding bracket in sequence, wherein, the connecting element comprises flat boards which are vertical to each other and a sliding block which takes the supporting beam of the grate as a guide rail and slides on the supporting beam; the sliding block is provided with a convex heave which can be circularly embedded inside a longitudinally inward groove of a grate sheet; and the sliding bracket is connected on the supporting beam of the fixed grate in a sliding way, thereby ensuring the grate gap of the incinerator to be constant and the wind feeding to be stable. Besides, as the grate sheet is always jointed with the lateral compensating block, the foreign objects are prevented from embedding into so as to avoid the short of burning and the local overheat of the grate, thereby reducing the ordinary maintenance amounts, increasing the burning efficiency and prolonging the service time of the incinerator.

Owner:HANGZHOU NEW CENTURY ENERGY ENVIRONMENTAL PROTECTION ENG CO LTD

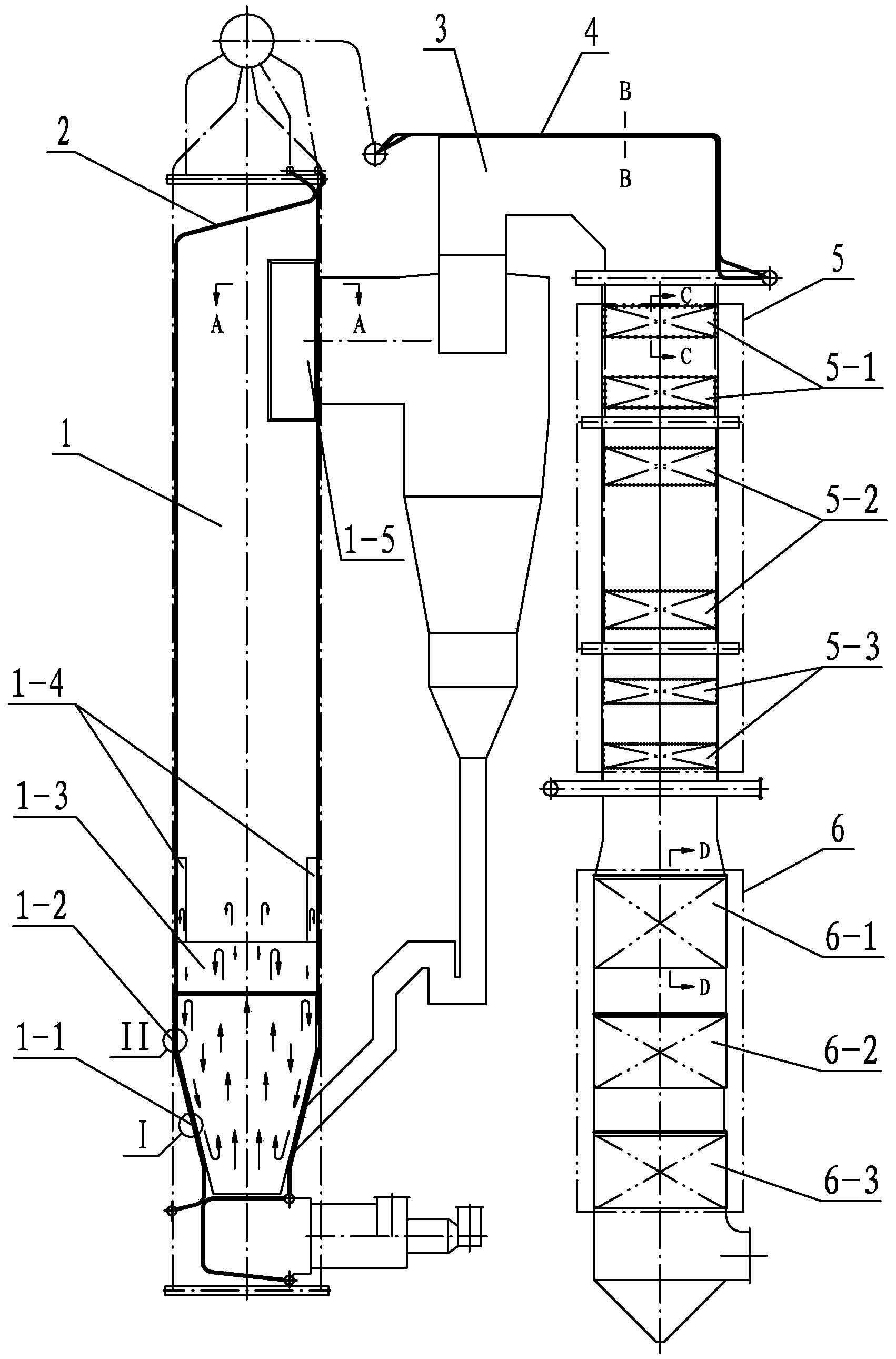

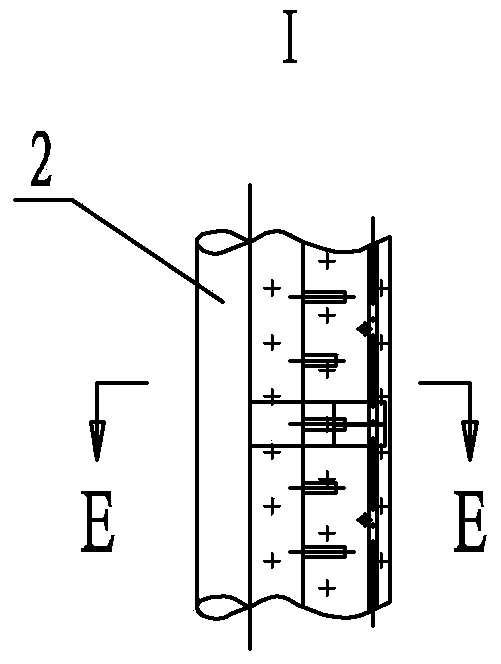

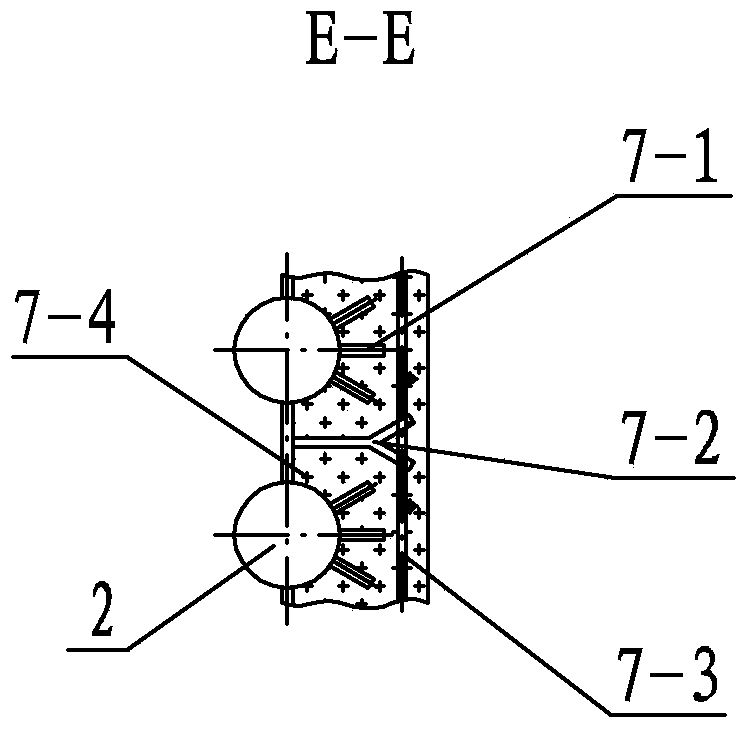

Circulating fluidized bed hot-water boiler free of abrasion and corrosion

ActiveCN103712205AReduce harmAvoid high temperature oxidationFluidized bed combustionWater heatersAir preheaterEngineering

The invention relates to a circulating fluidized bed hot-water boiler free of abrasion and corrosion, and relates to a circulating fluidized bed hot-water boiler. The circulating fluidized bed hot-water boiler solves the problem that pipe burst is generated because the heated surface of a boiler is reduced in thickness by suffering from the abrasion and the corrosion since fuel coal generates a high-temperature flue gas when being combusted in a furnace body, the flue gas contains sulfides, high-temperature high-pressure fuel particles and dust and the flue gas generate great impact accompanied by invasion, namely high-temperature oxidation, fly ash erosion and low-temperature dew-point corrosion, on the heated surface of a boiler in a boiler body in the using process of the traditional high-capacity circulating fluidized bed hot-water boiler. The circulating fluidized bed hot-water boiler free of abrasion and corrosion comprises a hearth, a water-cooled wall, a flue, a coal economizer cladding tube, a coal economizer, an air preheater, a plurality of pins, a plurality of clasp nails, a plurality of steel grids, composite material refractory concrete and an anti-abrasion cover. The circulating fluidized bed hot-water boiler disclosed by the invention is used for industrial and agricultural heating and urban centralized heating.

Owner:哈尔滨红光锅炉总厂有限责任公司

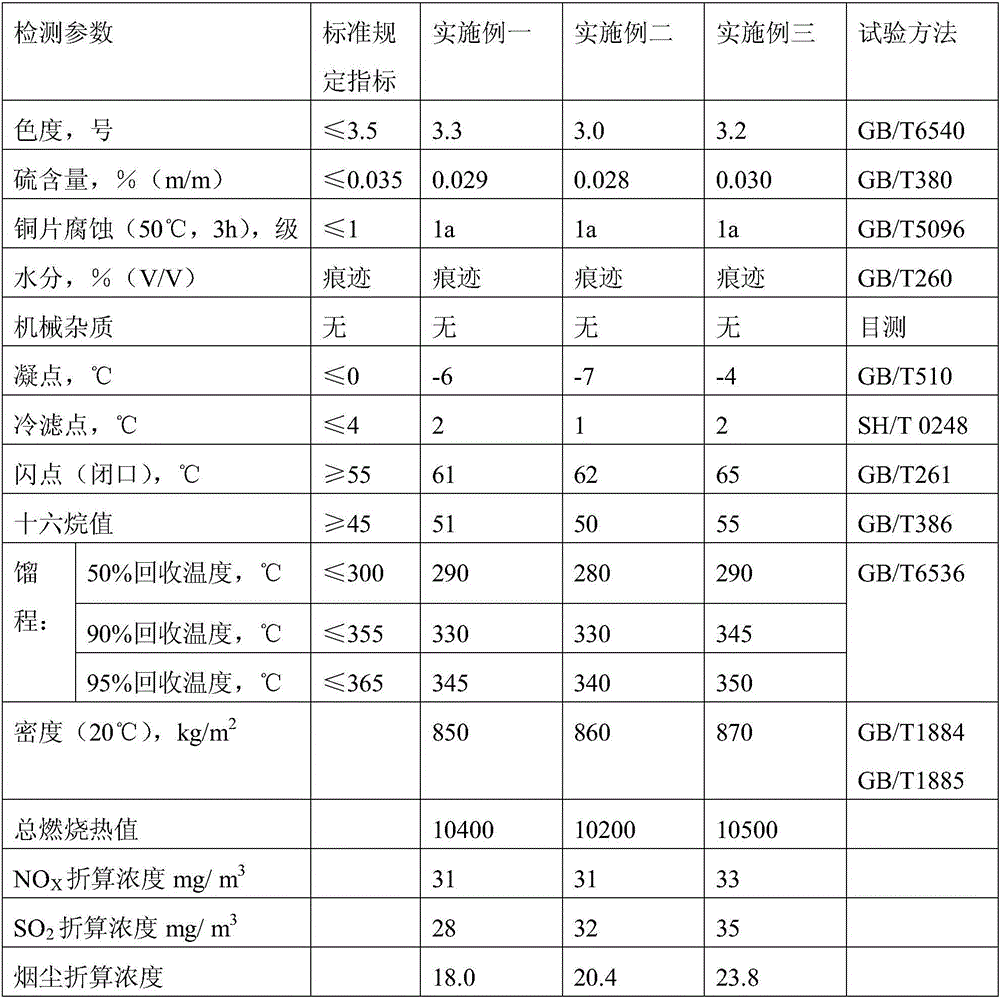

Composite fuel oil and preparation method thereof

InactiveCN105713682AHigh calorific valueImprove performanceLiquid carbonaceous fuelsOil and greaseMicrobial oil

The invention discloses composite fuel oil and a preparation method thereof. The composite fuel oil comprises components in parts by mass as follows: 5-15 parts of heavy oil, 10-40 parts of coal oil, 10-20 parts of coking light oil, 20-40 parts of vegetable oil, 5-10 parts of microbial oil, 3-6 parts of vegetable oleic acid or ethanolamine, 10-25 parts of methanol, 10-40 parts of distilled oil and 1-5 parts of additives, wherein the distilled oil is obtained from waste oil and / or diesel oil and / or illegal cooking oil through distillation, and the additives comprise a combustion improver, a dispersing agent and an anticorrosive agent. The composite fuel oil has the advantages of high heat value, stable performance and clean emission, is not prone to volatilization and is free of toxicity, smoke and odor, the requirement for ignition temperature in a use process can be met sufficiently, waste oil can be treated reasonably, and existing energy is saved.

Owner:NANJING LISHENG RECYCLE CO LTD

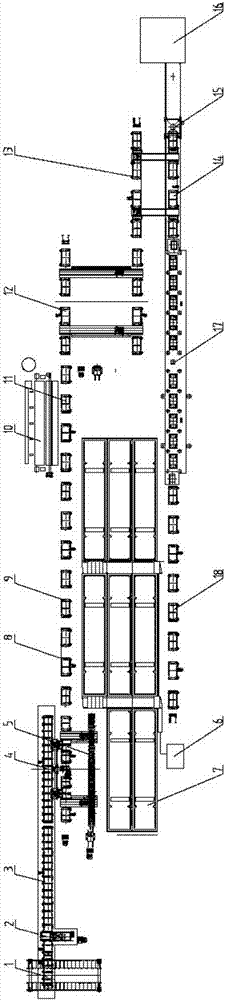

Production system for concrete sleeper suitable for high temperature and high humidity environment and method thereof

ActiveCN106945164AEasy to operateHigh degree of automationCeramic shaping plantsEast africaHigh humidity

The invention discloses a production system for a concrete sleeper suitable for high temperature and high humidity environment and a method thereof. The production system is formed by connecting sleeper gathering equipment, rebar cutting equipment, conjoined finished product transport equipment, turnover demoulding equipment, horizontal tension-releasing equipment, a steam curing system, die automatic cleaning equipment, an automatic spray-painting system, rebar wire-dividing fixed-length blanking equipment, rebar die-entering and penetrating equipment, rebar tensioning and stirrup mounting equipment, die traversing equipment, concrete production equipment, concrete pouring equipment, concrete vibrating and embossing equipment and edge cleaning and accessory removing equipment. The production system is capable of automatically producing the concrete sleeper applied to the corrosion environment of high temperature and high humidity in East Africa, and also can meet the requirements of eastern Africa in production efficiency and production quality and output, in particular to the requirements for Mombasa-Nairobi Railway track laying.

Owner:中交二公局铁路建设有限公司

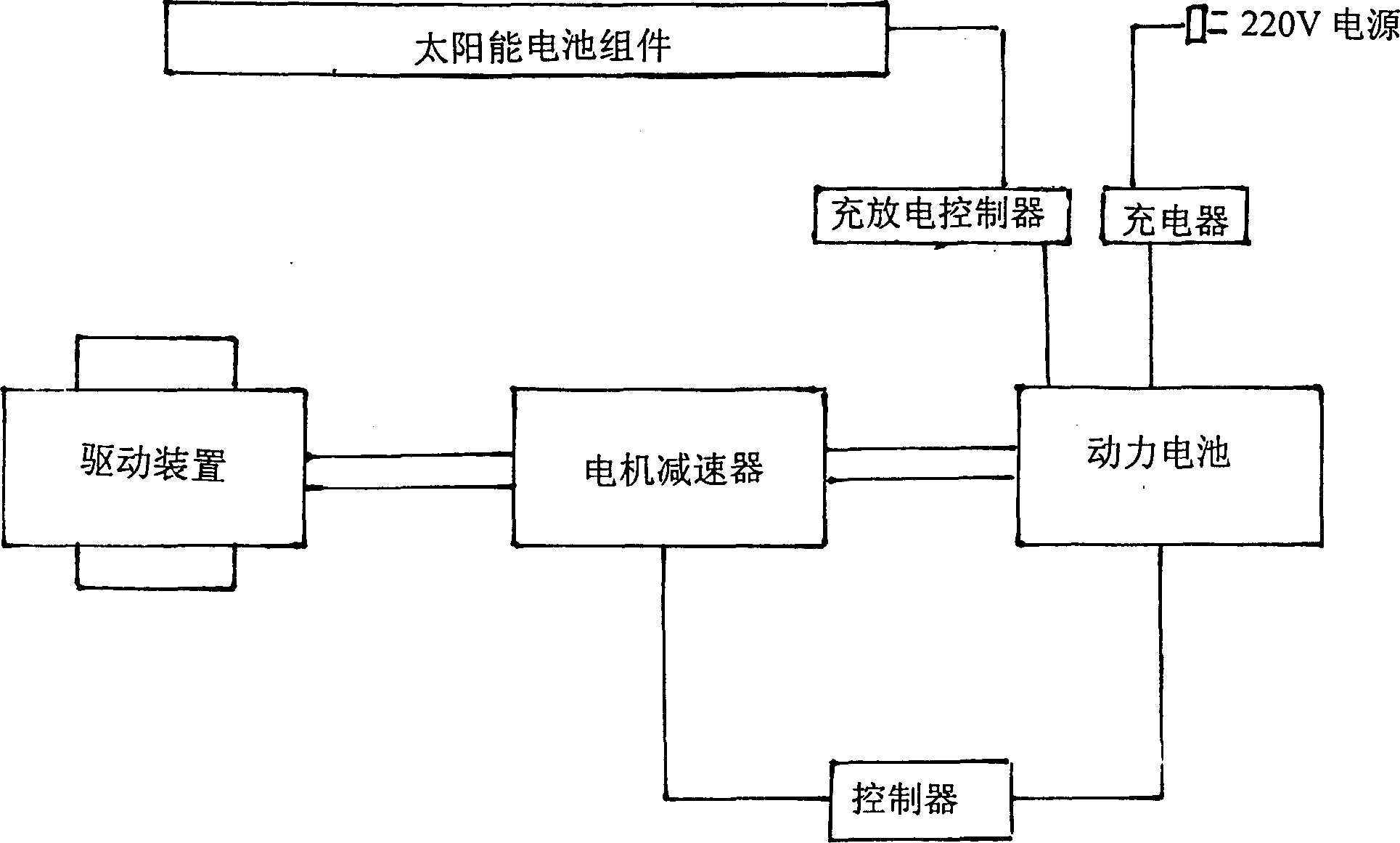

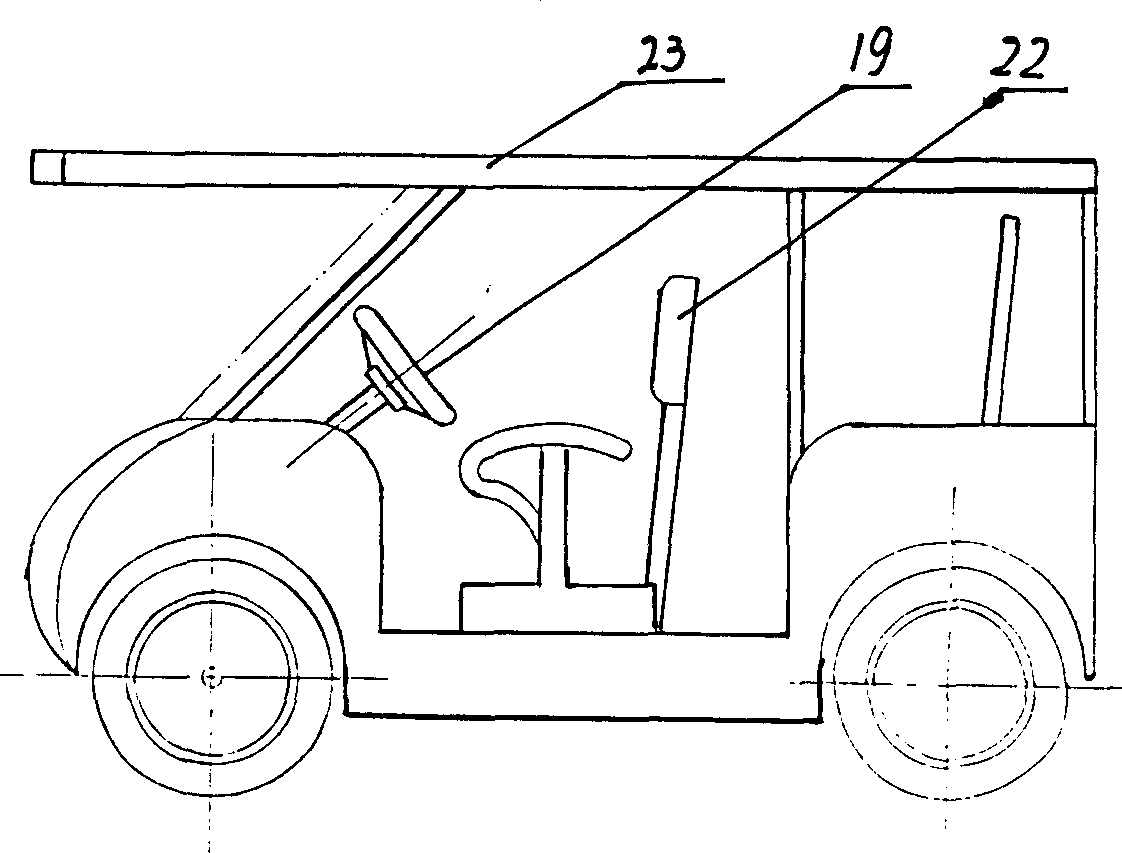

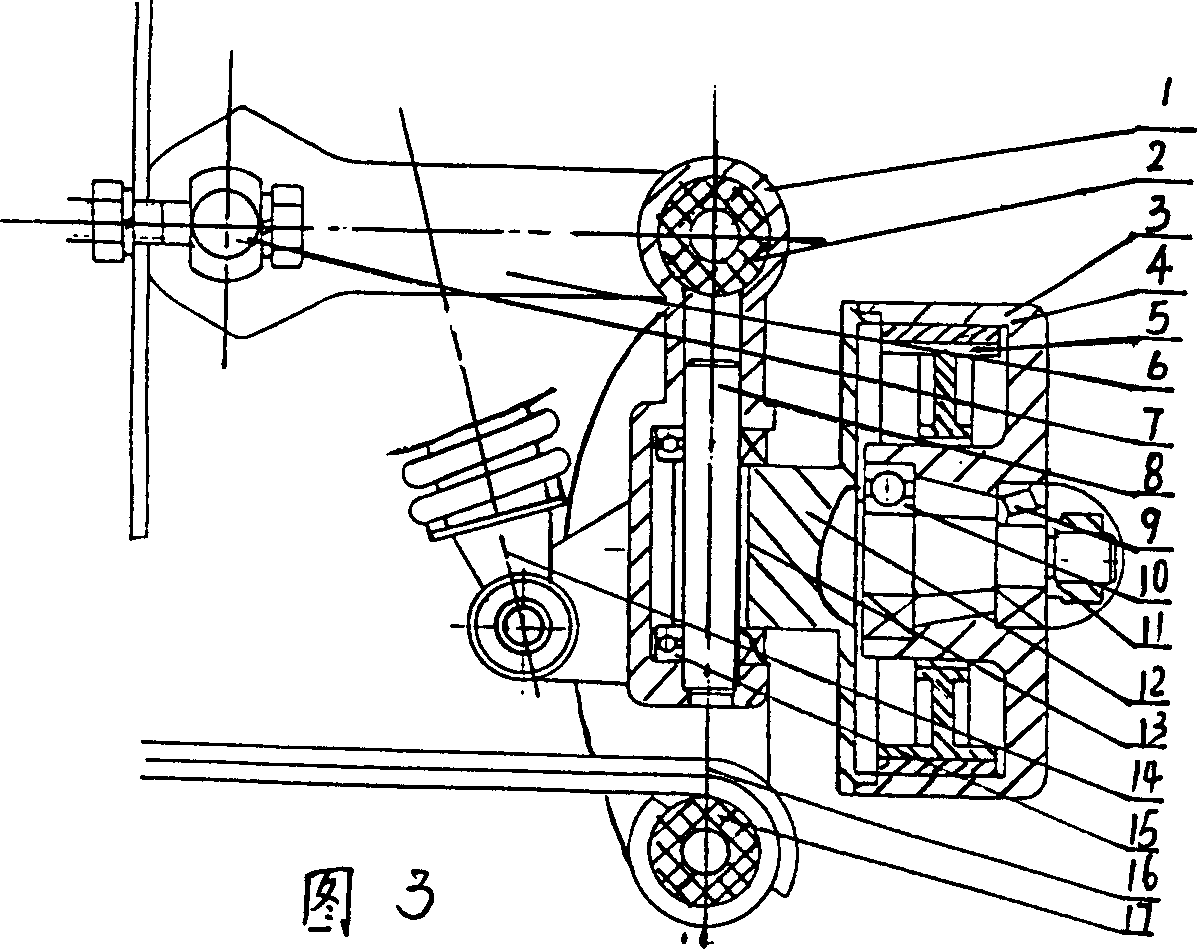

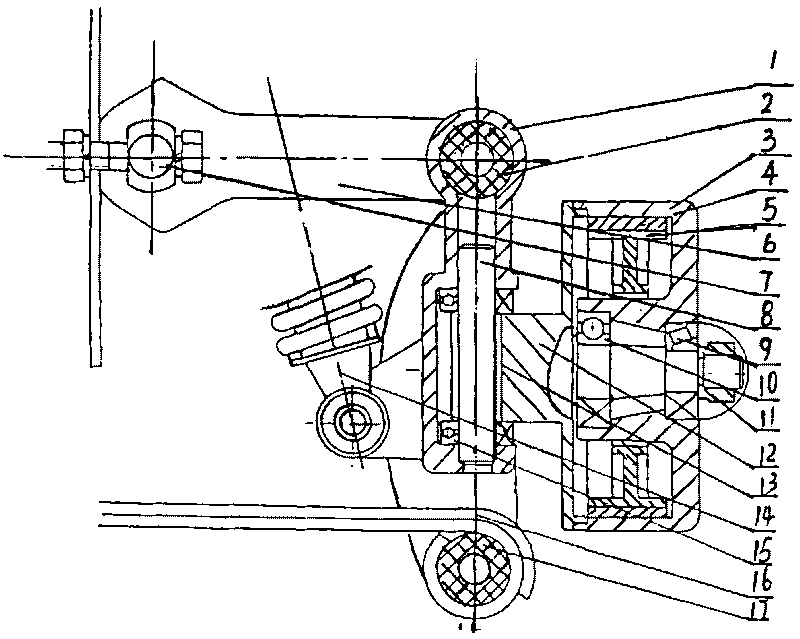

Solar electrically propelled vehicle

InactiveCN1448288ALose weightReduce consumptionElectric propulsion mountingPropulsion by batteries/cellsVehicle frameReduction drive

The solar energy electric car includes DC motor, solar cell assembly, charge / discharge controller, power cell, motor reducer, running system, driver, controller, steering system, car body, front wheels installed on the steering knuckle, main pin connected to the steering bearing seat, steering bearing seat connected to sheet spring in the lower part and the cradle and damper in the upper part andfixed to the lower part of the chassis, horizontal steering pull rod assembly, etc. The power cell is connected to the motor reducer, the motor reducer is connected to the driver, the controller is contained between the power cell and the motor reducer, and there are two power supplies, including 220 V power supply and solar cell assembly, charging the power cell.

Owner:熊国权

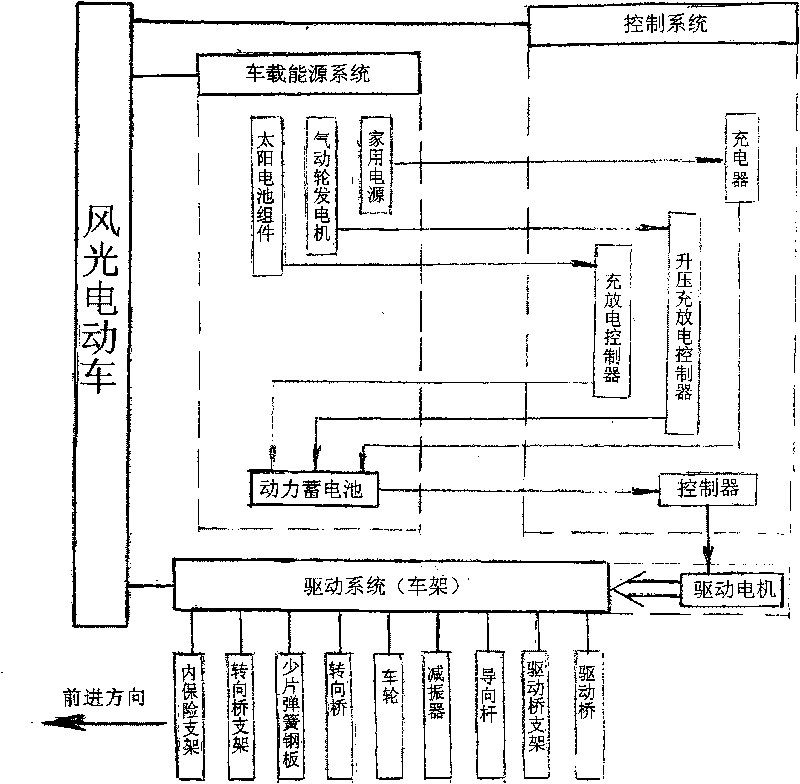

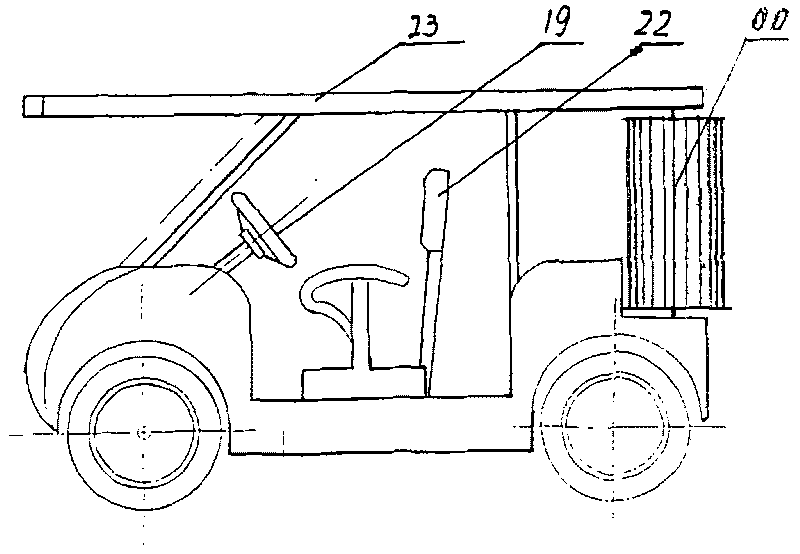

Wind-light electric vehicle

InactiveCN101746277ALose weightReduce consumptionSteering linkagesVehicular energy storageEngineeringCharge discharge

The invention is a wind-light electric vehicle, wherein a well-encapsulated solar module is arranged on the top of the electric vehicle, two wind wheel generators are respectively arranged at the right side and the left side of the vehicle body to form a vehicle-mounted energy system with a power battery, a DC motor is used for replacing a combustion engine and is assembled in a light weight driving system to substitute a heavy driving system, and a control system is used for coordinating each functional part to work and managing electric energy of the whole wind-light electric vehicle. The invention uses solar energy and wind energy resources to drive vehicles to run, and also uses a household power supply (220V) to charge the vehicles and enable the vehicles to run. Three household power supplies are used for charging the power battery or directly driving the wind-light electric vehicles to run, wherein the first path is used for charging the power battery by the solar module through a charging-discharging controller or directly driving the wind-light electric vehicles to run, the second path is used for charging the power battery by the wind wheel generator through a boost charging-recharging controller, and the third path is used for charging the power battery by a 220V power supply through a charger.

Owner:熊国权

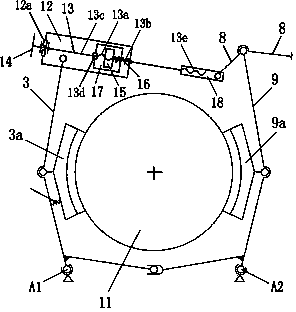

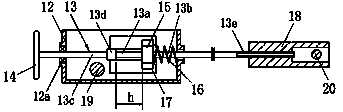

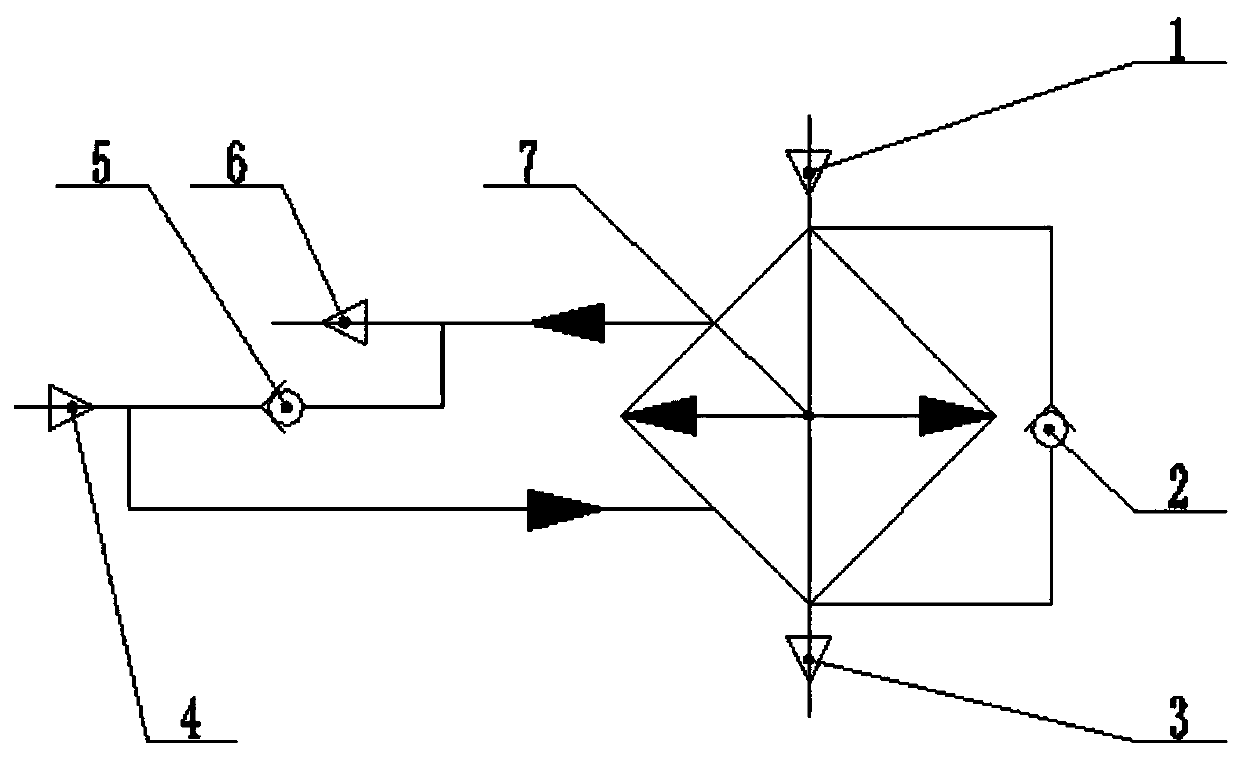

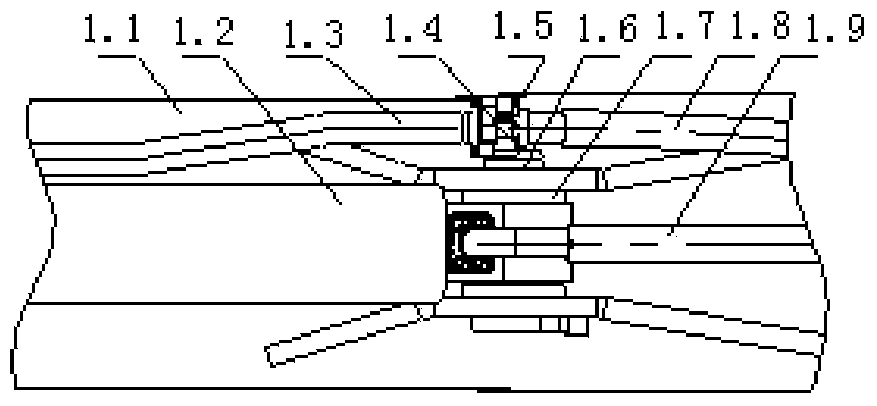

Friction braking clearance compensation device

ActiveCN104074896ARealize regulationAchieve compensationSlack adjustersAxial displacementEngineering

The invention discloses a friction braking clearance compensation device and relates to brakes. According to the friction braking clearance compensation device, an outer section of a rotary shaft (13) is located in a guide sleeve (12), a hand-operated wheel (14) is arranged at the outer end of the rotary shaft, and the guide sleeve is connected with a side brake arm hinged shaft of a brake; a first threaded section (13a) and a nut piece (15) which is matched with the first threaded section are arranged in the middle of the rotary shaft; a spring piece (16) used for pushing the nut piece to enter the first threaded section to achieve threaded fit is arranged on the guide sleeve; the diameter of a shaft section (13b) adjacent to one end of the first threaded section is equal to or smaller than the inner diameter of the first threaded section; a limiting component (13d) used for preventing the nut piece from moving in the axial direction is arranged at the other end of the first threaded section; a limiting block (17) used for preventing the nut piece from rotating is arranged on the guide sleeve; a second threaded section (13e) at the inner end of the rotary shaft is connected with one end of a connecting sleeve (18) in a threaded mode, and the other end of the connecting sleeve is connected with a hinged shaft at the inner end of a lever of the brake. The friction braking clearance compensation device has the advantages that the structure is simple, operation is convenient, and the clearance compensation precision is high.

Owner:长沙三占惯性制动有限公司

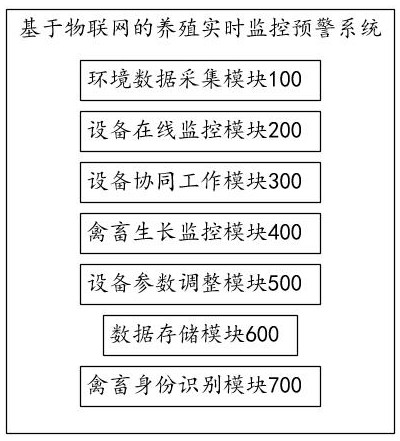

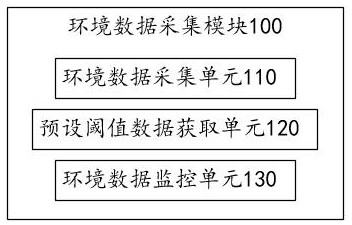

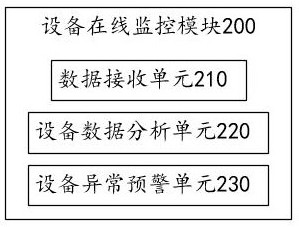

Breeding real-time monitoring and early warning system based on Internet of Things

PendingCN114693077ASuitable for growthReduce workloadMeasurement devicesOffice automationThe InternetData acquisition module

The invention belongs to the technical field of computers, and provides a real-time monitoring and early warning system for breeding based on the Internet of Things, and the system comprises an environment data collection module, an equipment online monitoring module, and an equipment cooperative work module. Wherein the environment data acquisition module is used for acquiring dynamic data in a breeding environment and controlling corresponding execution equipment to work according to the acquired dynamic environment data; the equipment online monitoring module is used for receiving monitoring data of the feeding equipment, the management equipment and the execution equipment from the monitoring equipment, and judging whether the current working operation state of the execution equipment or the feeding equipment is normal or not; when the operation state of the execution device or the feeding device is abnormal, early warning information is sent to the interaction end; and the equipment cooperative work module is used for coordinating cooperative work between the feeding equipment and the management equipment according to the feedback information. Cooperative joint debugging work of multiple devices is achieved, and workers are released from periodic and long-time-consuming daily maintenance work.

Owner:潍坊汇金海物联网技术有限公司 +1

Novel rack processing device

InactiveCN105834529AEasy to fixSimple structureGear-cutting machinesGear teethFerromagnetismMechanical engineering

The invention discloses a novel rack processing device, which comprises a base, a slider, a rack processing device, a fixture seat, a pressure bar, a support bar, a dowel bar and an electromagnet. The top of the base is slidably connected to the slider, and the slider The rack processing device is provided at the end of the base, the fixture seat is provided on the side of the base, and the fixture seat and the rack processing device are located on the same side of the base, and the corresponding rack processing device is provided with a gap for placing the rack to be processed on the fixture seat. One end is fixed on the fixture seat, the other end is rotatably connected to the middle of the dowel bar, the pressure bar is fixed on the top of the dowel bar, and the end of the pressure bar corresponds to the notch, and the bottom end of the dowel bar is a free end, corresponding to the bottom end of the dowel bar An electromagnet is installed on the side of the fixture seat, and the dowel bar has ferromagnetism. The invention has the advantages of simple structure, reasonable design and simple operation, which is beneficial to reduce production cost and daily maintenance, is convenient to fix the rack to be processed, and is beneficial to improving processing efficiency.

Owner:TAICANG BAODA RACK

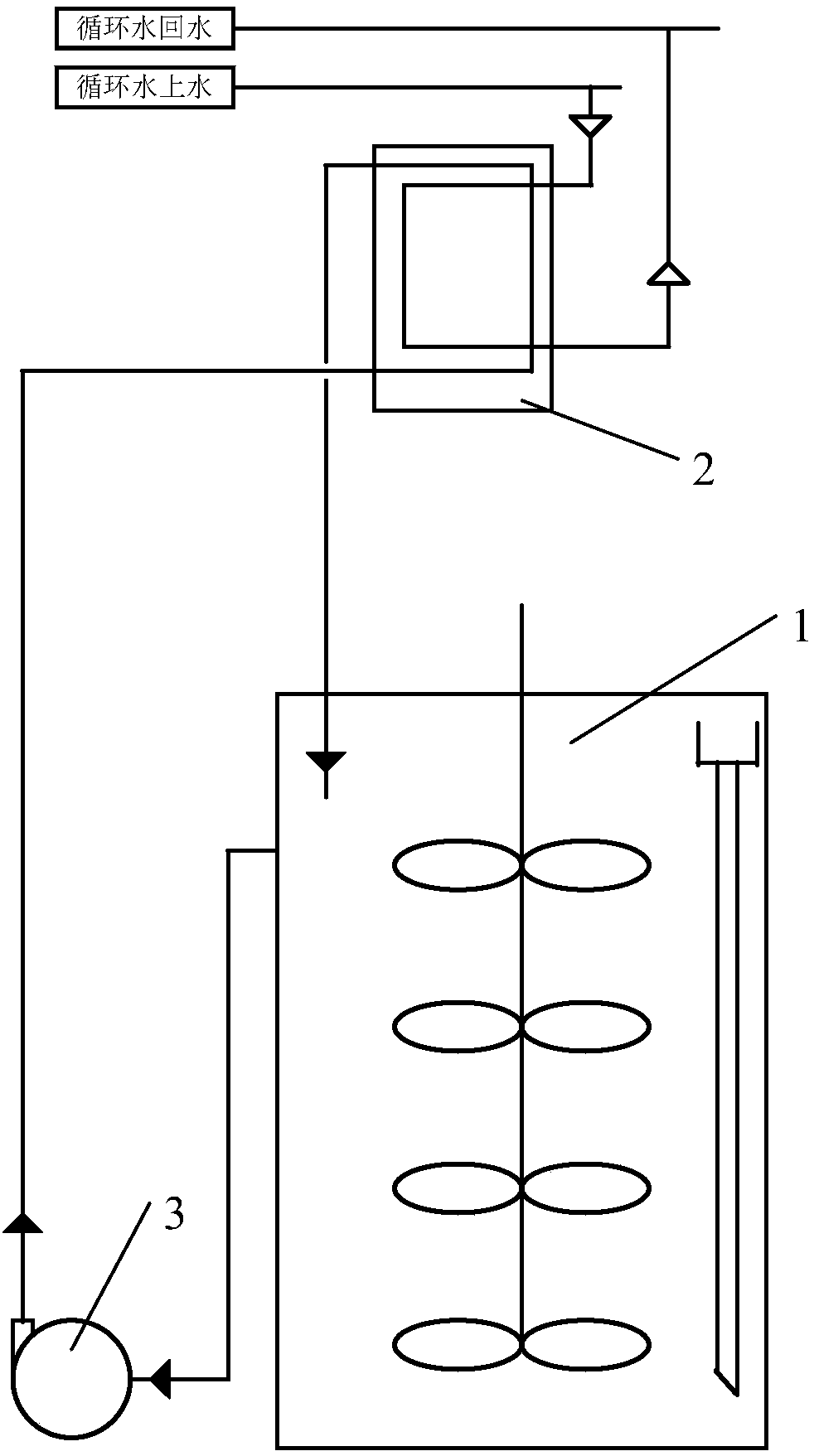

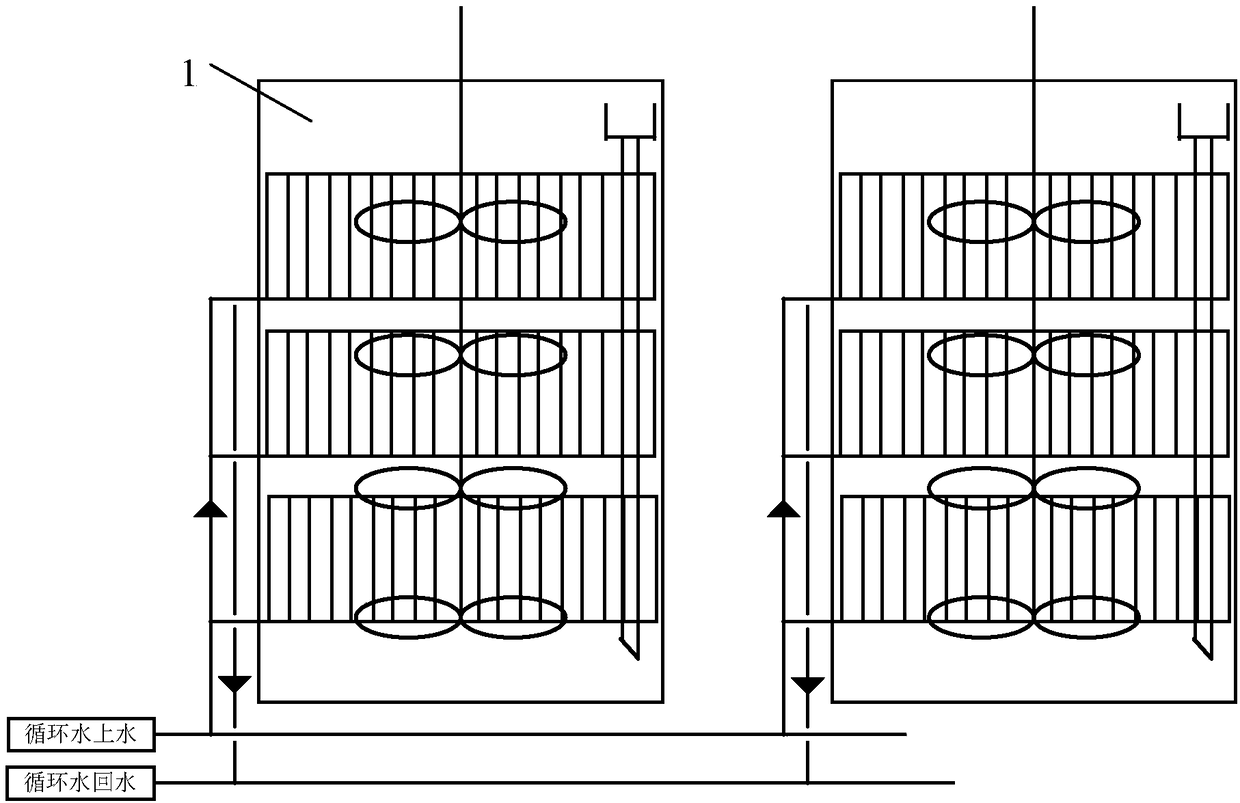

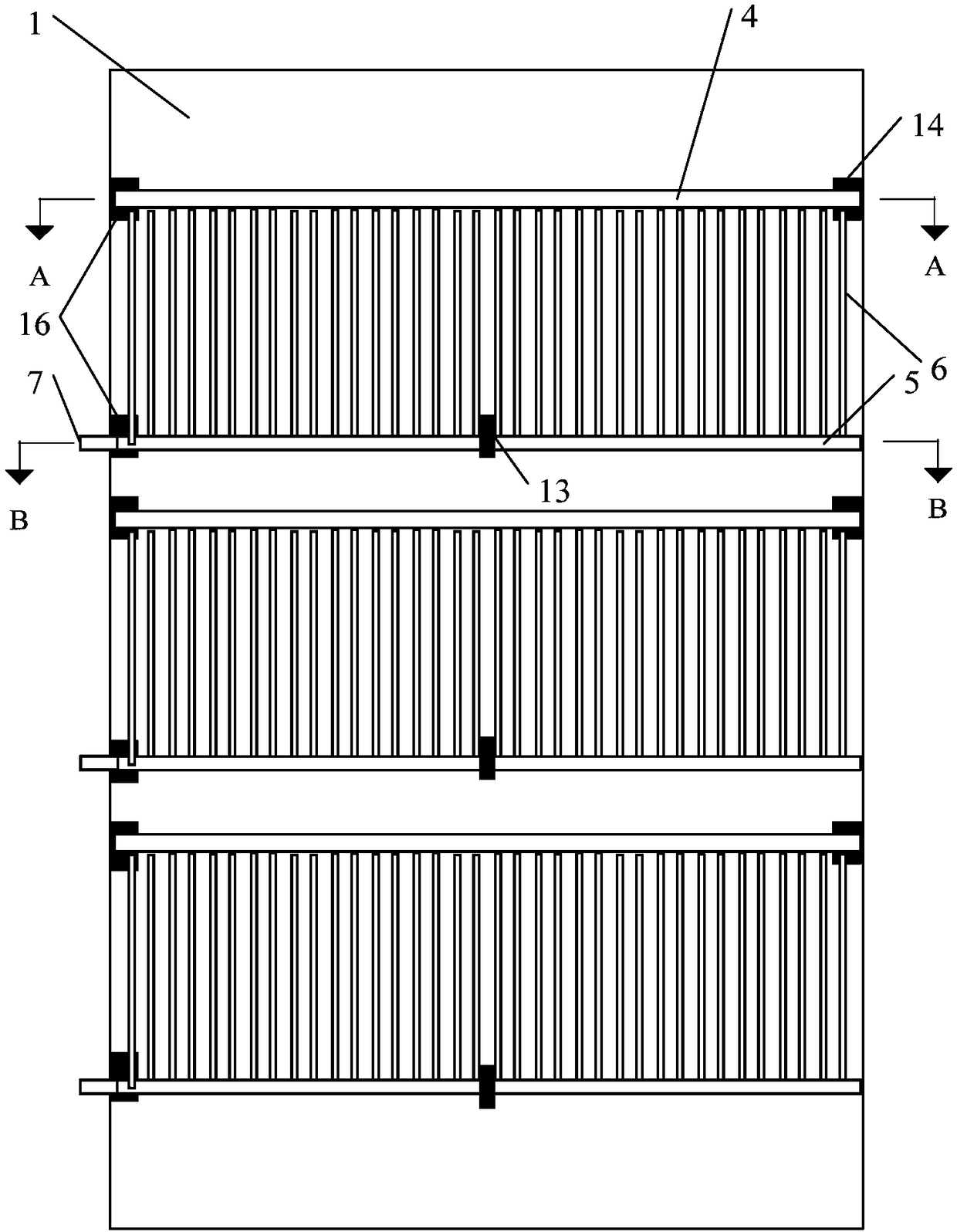

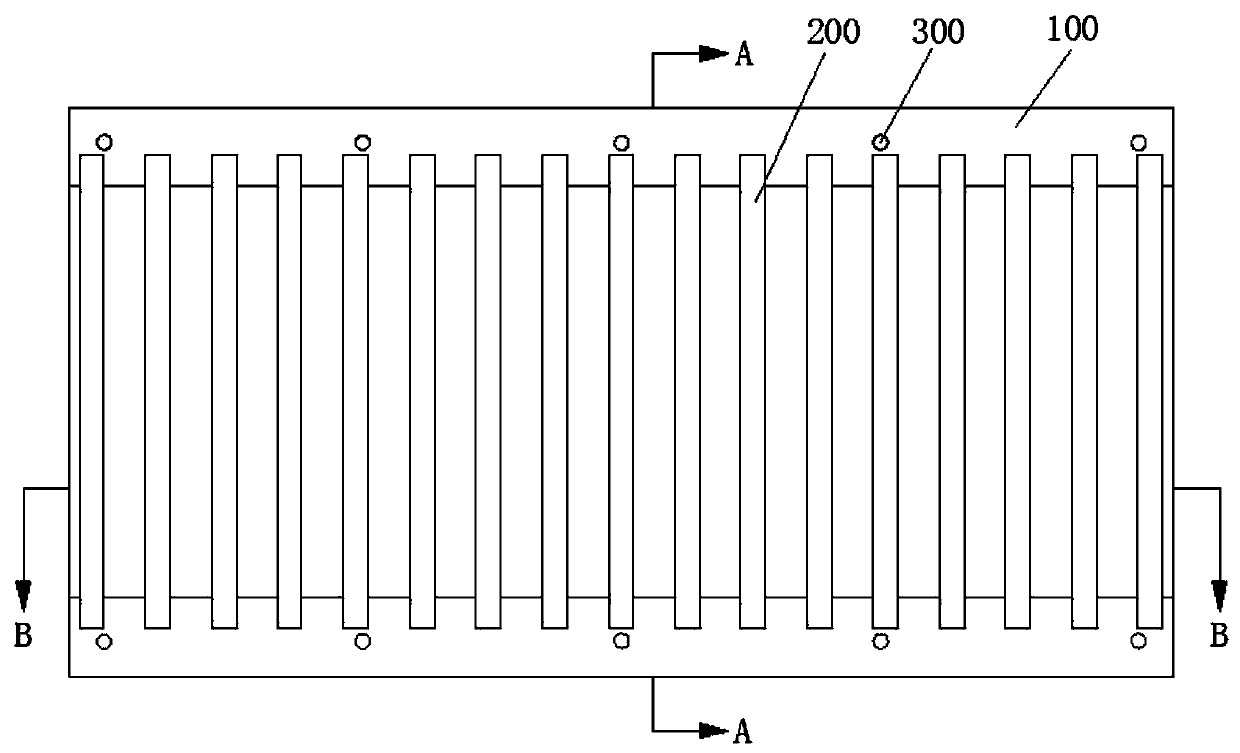

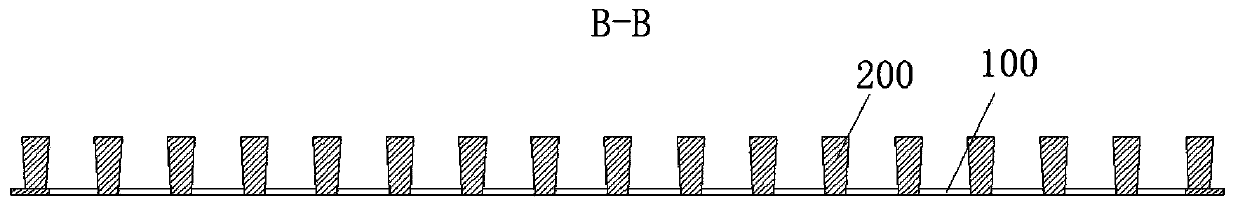

Sectional tube nest cooling device in decomposing tank

InactiveCN108131966AReduce power consumptionAccelerate evaporationStationary tubular conduit assembliesAluminium oxides/hydroxidesSlurryEngineering

The invention provides a sectional tube nest cooling device in a decomposing tank. The sectional tube nest cooling device is composed of multiple sections of cooling tube nests arranged in the decomposing tank, each decomposing tank is divided into multiple sections of heat exchange area from top to bottom, a section of cooling tube nest is arranged in each heat exchange area, and all sections ofcooling tube nests in the same decomposing tank are in parallel connection; each section of cooling tube nest is constituted by an upper annular pipe, a lower annular pipe and a tube nest cluster between the upper annular pipe and lower annular pipe, and the tube nest cluster is constituted by several vertical pipes parallel to the axis of the decomposing tank; water inlets of all sections of cooling tube nests are all communicated with a water inlet main pipe, and water outlets of all sections of cooling tube nests are all communicated with a water return main pipe. Decomposing slurry is directly cooled through sectional tube nest cooling devices in the decomposing tanks, the cooling procedure outside the tank is replaced, equipment investment and running cost are saved, and meanwhile, the work of the operating amount of workers and daily maintenance is reduced.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

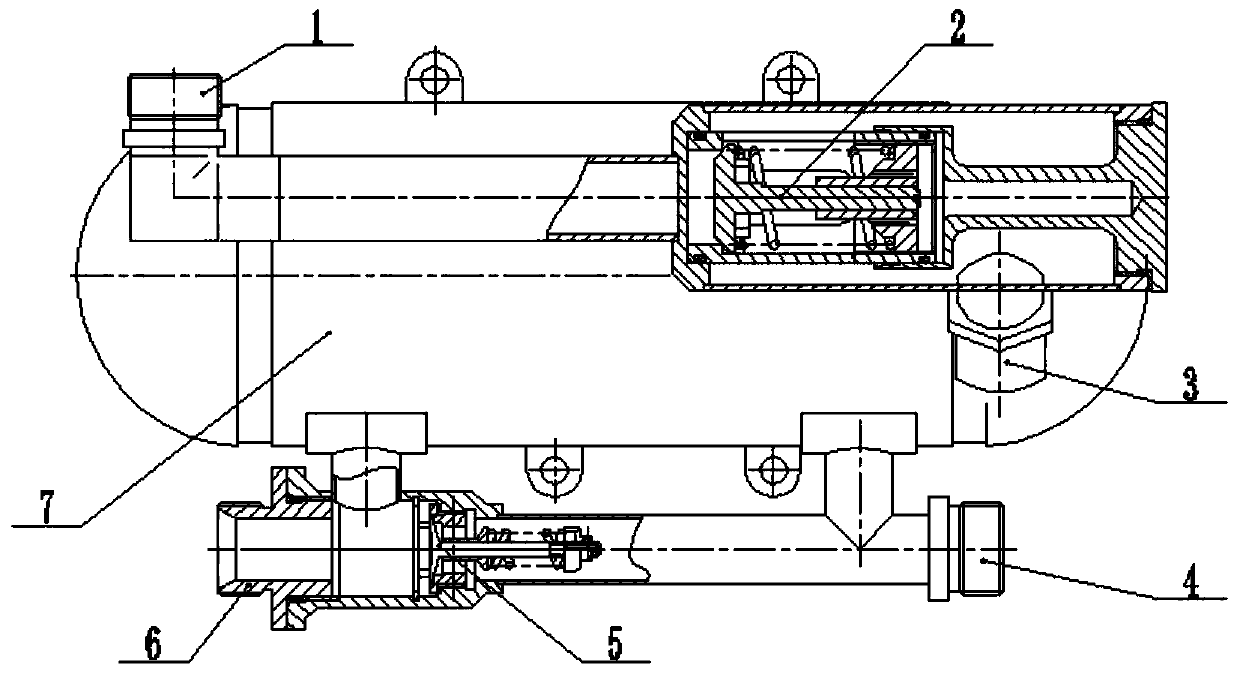

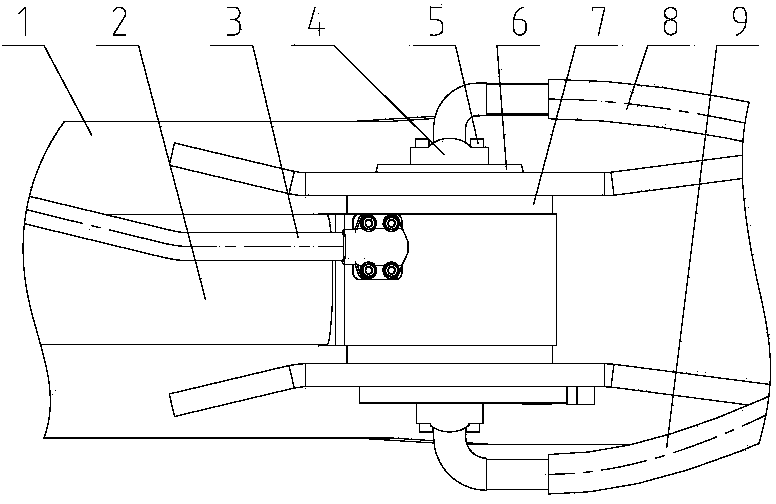

Oil filter double valve type fuel oil radiator

ActiveCN111535927AAdjust and control cracking pressureAvoid disassemblyTurbine/propulsion engine coolingTurbine/propulsion lubricationFuel oilLubrication

The invention discloses an oil filter double valve type fuel oil radiator, and belongs to the technical field of aero engine lubrication transmission systems. The oil filter double valve type fuel oilradiator comprises a fuel oil heat exchanger b and an oil control assembly, a fuel inlet b and a fuel outlet b are formed in the two ends of the fuel oil heat exchanger b correspondingly, the oil control assembly is connected to the lower end of the fuel oil heat exchanger b, an oil inlet b and an oil outlet b are formed in the two ends of the oil control assembly correspondingly, and the oil control assembly is internally provided with a heat exchanger oil safety valve b and an oil filter double valve assembly. According to the technical scheme, the oil filter double valve assembly is arranged at the oil outlet end of the oil control assembly, and an anti-siphon valve and an oil filter safety valve are arranged in the oil filter double valve assembly, so that the occurrence of oil loss caused by siphon phenomenon is effectively avoided; and meanwhile, the oil filter double valve assembly and an oil blocking cover are arranged into one assembly, the disassembly and connection of a pipeline are avoided, the disassembly and assembly procedures are reduced, and the maintenance work intensity is greatly reduced.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

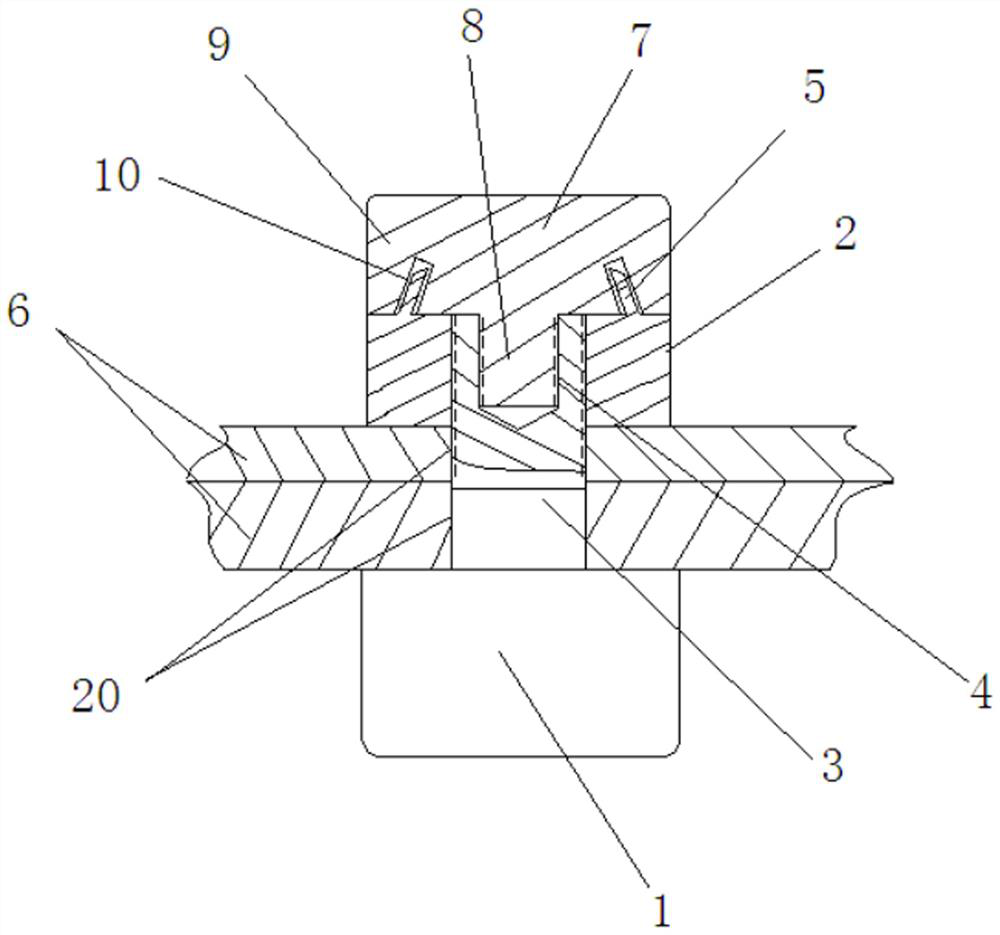

Connecting structure of oil cylinder support base and pin roll as well as mechanical device

InactiveCN103437388ASelf-lubricatingSmooth rotationMechanical machines/dredgersEngineeringLubrication

The invention discloses a connecting structure of an oil cylinder support base and a pin roll as well as a mechanical device. The connecting structure comprises a movable arm, a bucket rod oil cylinder, a small-cavity steel pipe, a flange, a bolt, a pin roll, a gasket, a small-cavity rubber tube, a large-cavity rubber tube, a limiting plate, a positioning bolt and an O-shaped sealing ring, wherein the bucket rod oil cylinder is connected with the pin roll; the pin roll is connected with the limiting plate; the positioning bolt is connected with the limiting plate; each of the two ends of the pin roll has two bolt installation holes; the small-cavity rubber tube and the large-cavity rubber tube are respectively arranged at the two ends of the pin roll; two inner holes are respectively vertically formed inside the pin roll; an oil slot is machined outside the pin roll; the inner holes are communicated with the oil slot; the oil slot is sealed by the O-shaped sealing ring; two connecting holes are formed in the oil cylinder support base; four small holes are formed in the surface of the oil cylinder support base; the small holes are connected with the small-cavity steel pipe. The connecting structure for the oil cylinder support base and the pin roll can be used for enabling the pin roll and the oil cylinder to have self-lubrication, so that the turning ability becomes better, and therefore, daily maintenance by coating the lubricating oil is cancelled; the rubber tubes do not move with the oil cylinder, so that the service lives of the rubber tubes are prolonged; the pin roll and the oil cylinder are compact in structure, convenient to maintain and attractive in appearance.

Owner:SHANGHAI SANY HEAVY IND

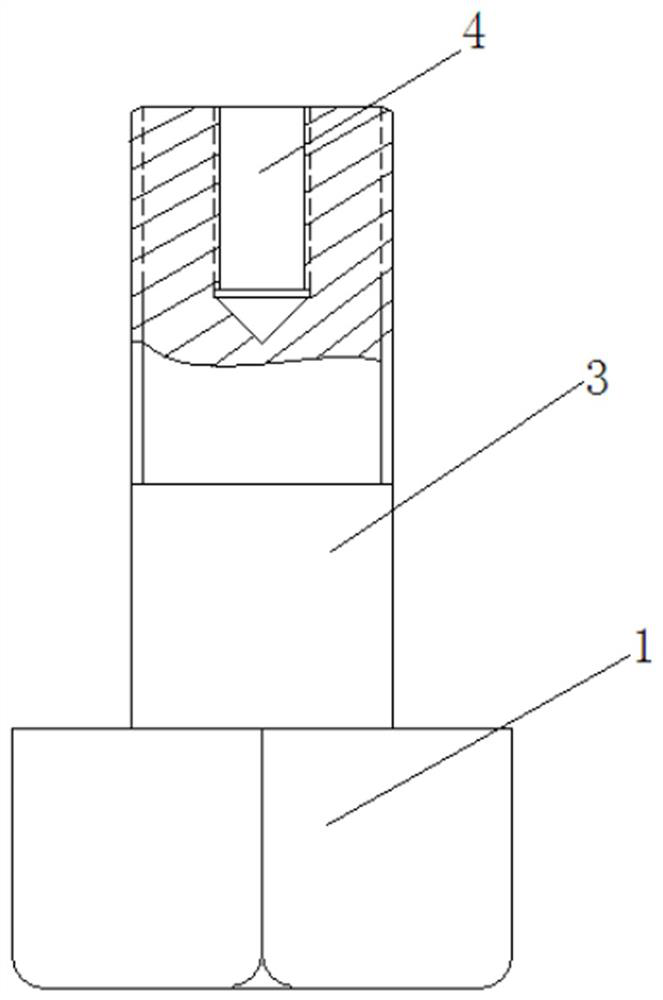

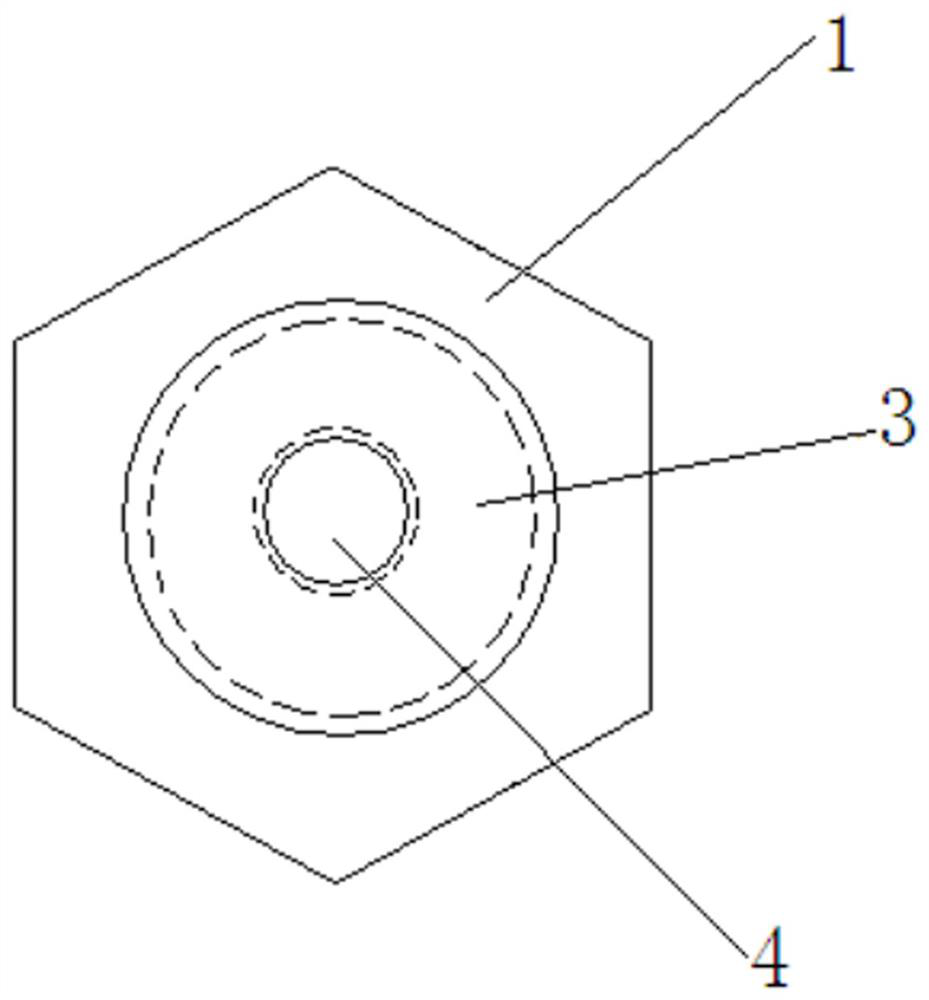

Two-bolt single-cap interlocking fastener

The invention designs a two-bolt single-cap interlocking fastener which comprises a main bolt and a lock head nut, an inner countersunk bolt hole is formed in the center of the end face of a bolt rod of the main bolt, the lock head nut is screwed on the bolt rod of the main bolt through a thread, a protruding thin-wall circular locking ring is arranged on one face of the lock head nut, and the center of circle of the thin-wall circular locking ring is concentric with the center point of the lock head nut; and an auxiliary bolt is arranged and composed of a bolt rod and a bolt head, an external thread on the bolt rod of the auxiliary bolt is matched with an internal thread of the inner countersunk bolt hole in the end face of the bolt rod of the main bolt, a ring groove is formed in the inner side face of the bolt head of the auxiliary bolt, and the ring groove corresponds to the thin-wall circular locking ring of the lock head nut. The two-bolt single-cap interlocking fastener has the advantages that the number of the parts is only three, the structure is simple, the machining process is simple, production is easy, mutual locking and fastening are conducted at three different point positions in the threaded connection mode and the hoop connection mode, therefore the performance of durable, stable and firm connection is achieved, and the connecting structure is of a non-open closed structure.

Owner:王子英 +1

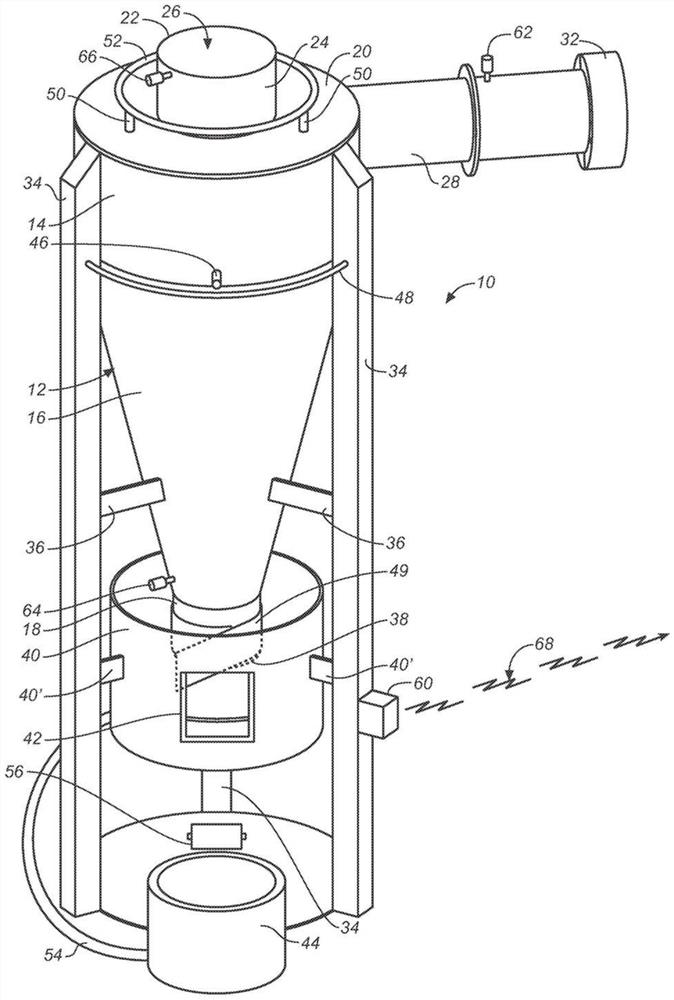

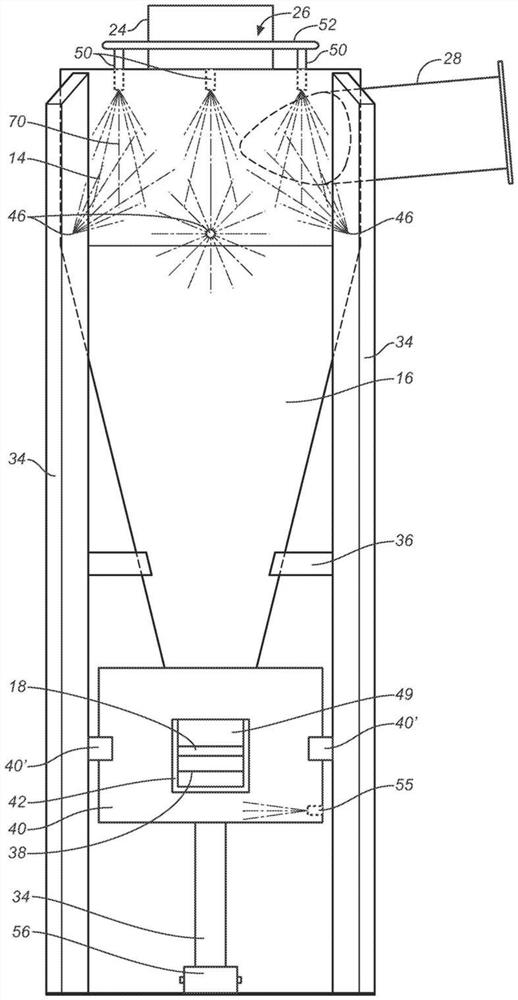

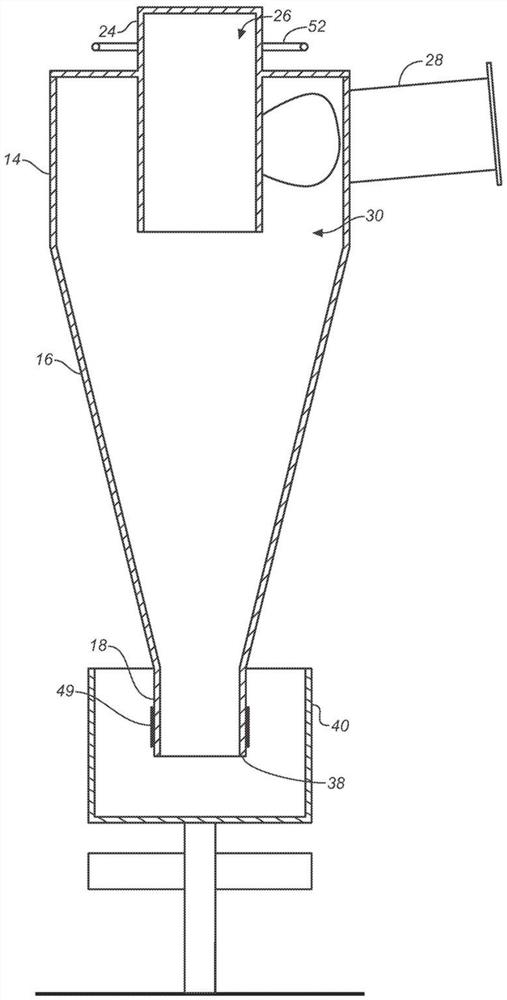

Temperature controlled exhaust stream water filter for coffee roasters

ActiveCN113438982AOdor suppressionVisible smoke reductionCombination devicesReversed direction vortexParticulatesWater filter

A cyclonic chiller-separator, including a vertically oriented treatment tower defining an interior space and having an exhaust inlet disposed in an upper portion, and a chimney with an exhaust outlet; an exhaust stream conduit in fluid communication with said interior volume of said treatment tower through said exhaust inlet, wherein said exhaust inlet is configured to induce cyclonic fluid motion in an exhaust stream entering said interior volume; a coolant water source; and a plurality of nozzles disposed about interior walls of said treatment tower and in fluid communication with said coolant water source for spraying cooling water into said interior volume above and into an exhaust stream introduced into said interior volume so as to cool, condense, and precipitate volatile organic compounds and organic acids, and to entrain and remove particulates from the exhaust stream.

Owner:VORTX KLEANAIR SYSTEMS

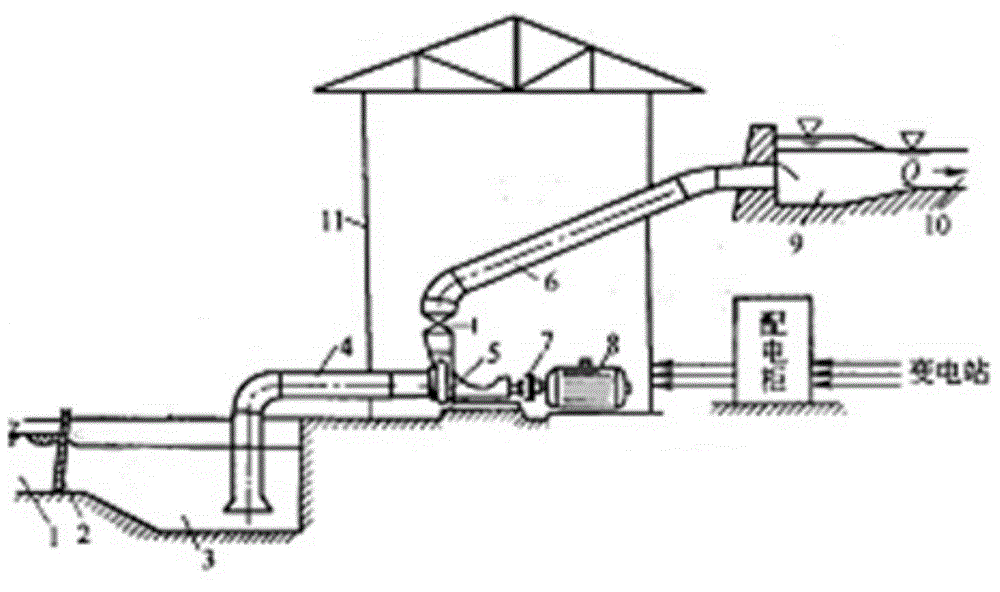

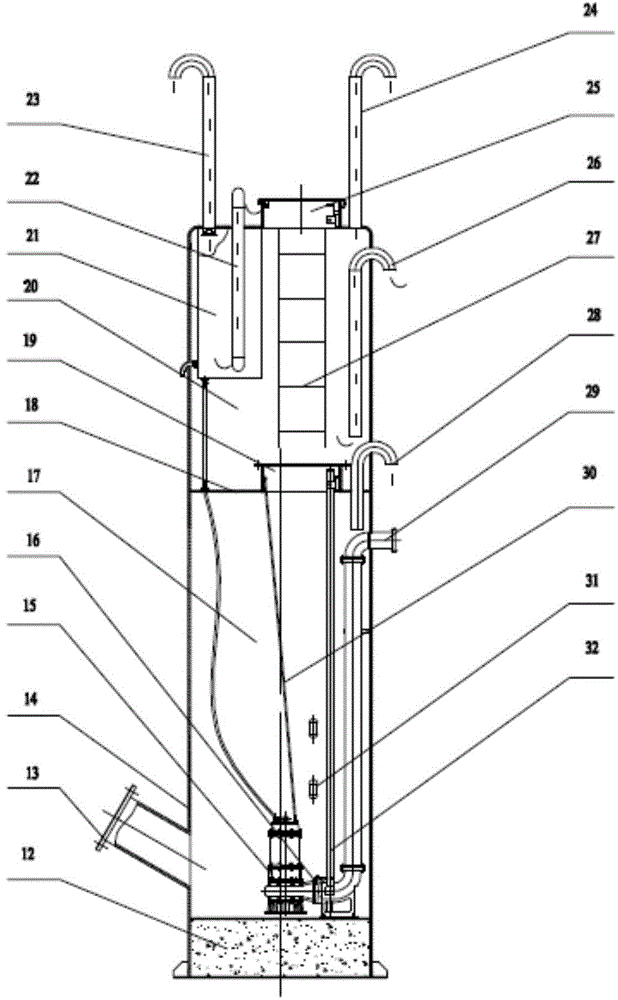

Integral water conveying pump station and mounting method thereof

The invention discloses an integral water conveying pump station. The pump station comprises a well barrel with a concrete base balance weight, wherein the well barrel is arranged below the ground and divided into a pump station electric control chamber and a pump station water chamber; a submersible sewage pump, a water feeding pipe, a water discharging pipe, a distribution cabinet, a guide rail for repair, a climbing ladder, a hydraulic controller and other parts are mounted in the pump station water chamber and the pump station electric chamber, so as to form an integral structure for the water conveying pump station. The invention further discloses a mounting method of the integral water conveying pump station. According to the method, a mounting hole of the well barrel is formed beside a water source; all parts mounted in the well barrel are buried underground at a time; therefore, a water pump station can be simply and quickly mounted; the field used is reduced; the integral structure greatly reduces the construction cycle; the construction cost can be reduced while the construction time is saved; the daily maintenance and repair can be reduced; the delay of irrigating due to repair can be avoided.

Owner:SHANDONG RUIQING ENVIRONMENT TECH DEV CO LTD

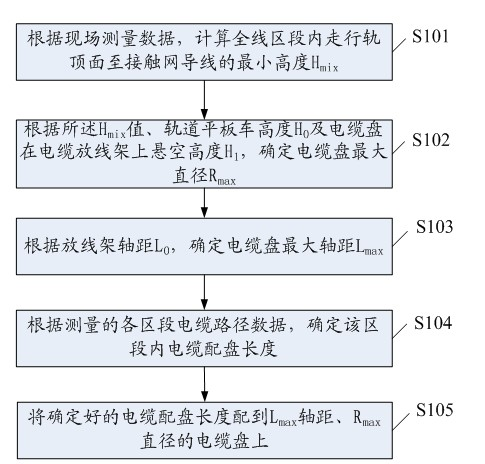

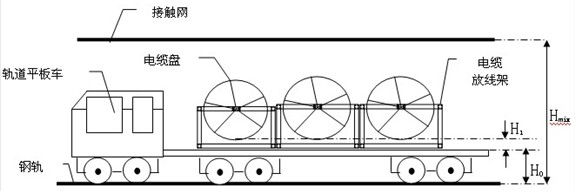

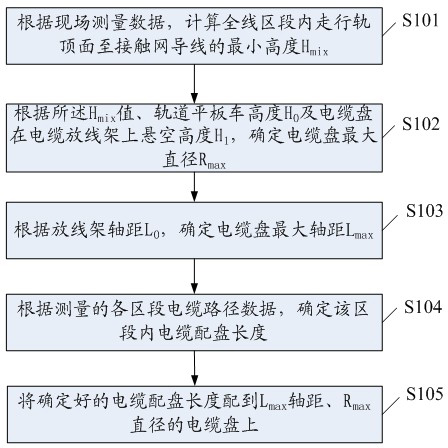

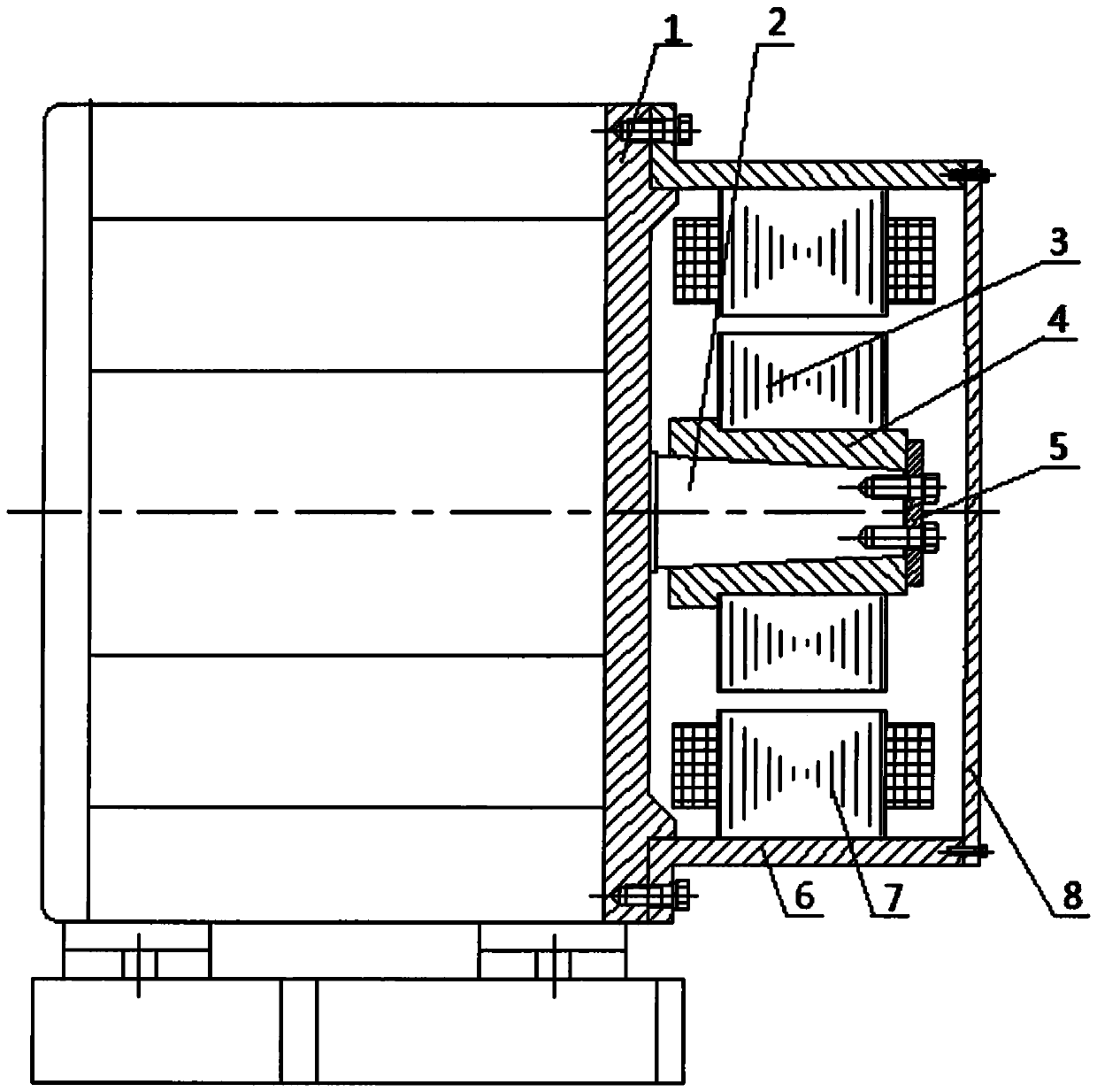

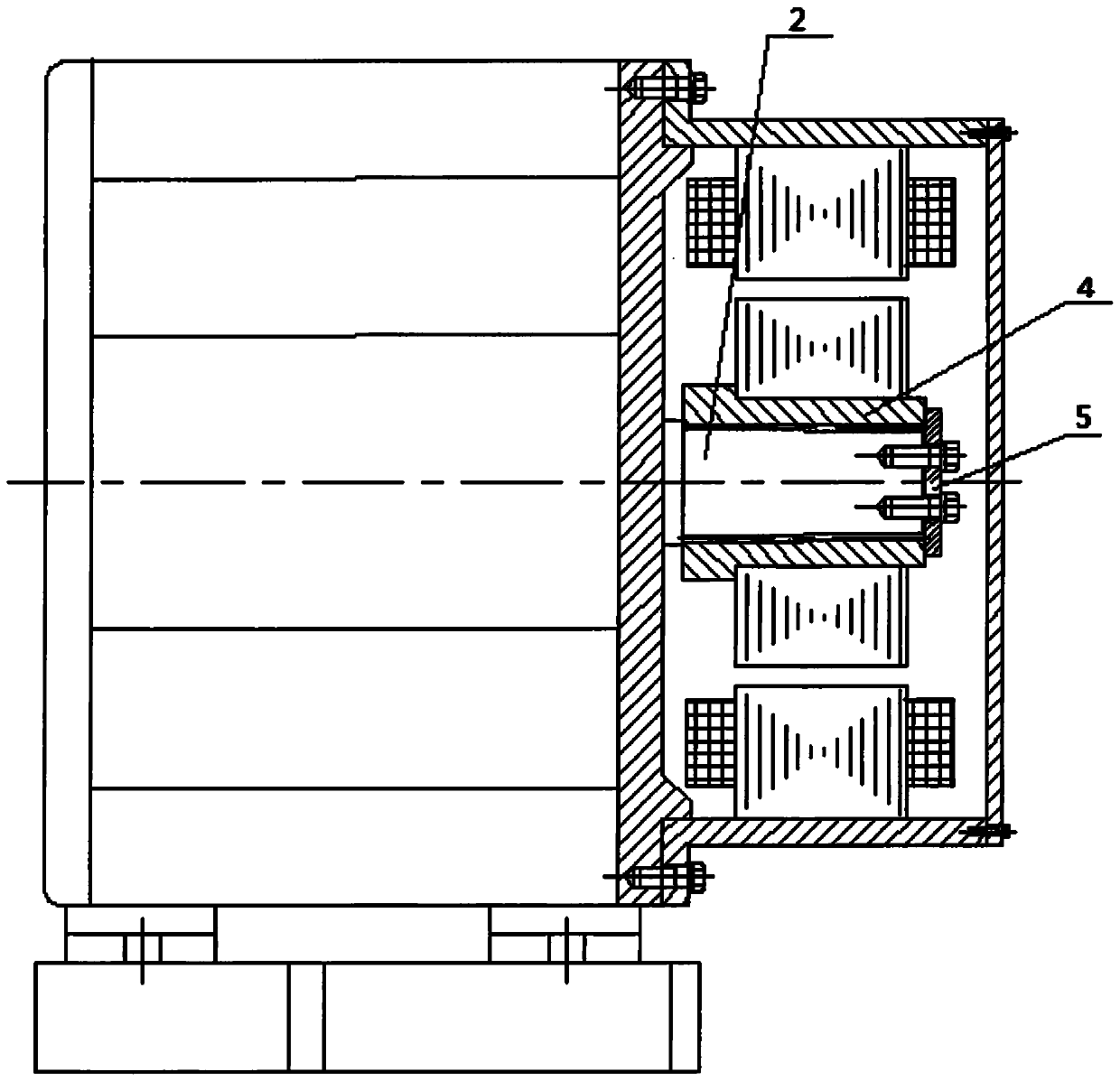

Ring network cable reel distribution process

ActiveCN102582469AReduce the number of platesReduce shipping costsTrolley linesRing networkEngineering

The invention discloses a ring network cable reel distribution process. The ring network cable reel distribution process includes steps of calculating the minimum height Hmix from the top of a traveling track to a lead of a contact net in a whole wire region according to field measured data; determining the largest diameter Rmax of cable reels according to the Hmix value, the height H0 of a track flat car and the suspension height H1 of the cable reels on a cable paying-off rack; determining the largest axle distance Lmax of the cable reels according to the axle distance L0 of the paying-off rack; determining cable reel distribution length in the region according to measured cable path data in various regions; and distributing the determined cable reel distribution length to the cable reels with the axle distance of Lmax and the diameter of Rmax, and increasing cable distribution quantity of each cable reel to the greatest extent. The quantity of the cable reels and utilization quantity of intermediate heads of cables can be reduced. As the utilization quantity of the intermediate heads of the cables is reduced, fault points of the cables after live operation are reduced, and safety of the ring network cables after live operation is improved.

Owner:ELECTRICITY AFFAIR ENG COMPANY OF CHINA RAILWAY NO 8 ENG GRP

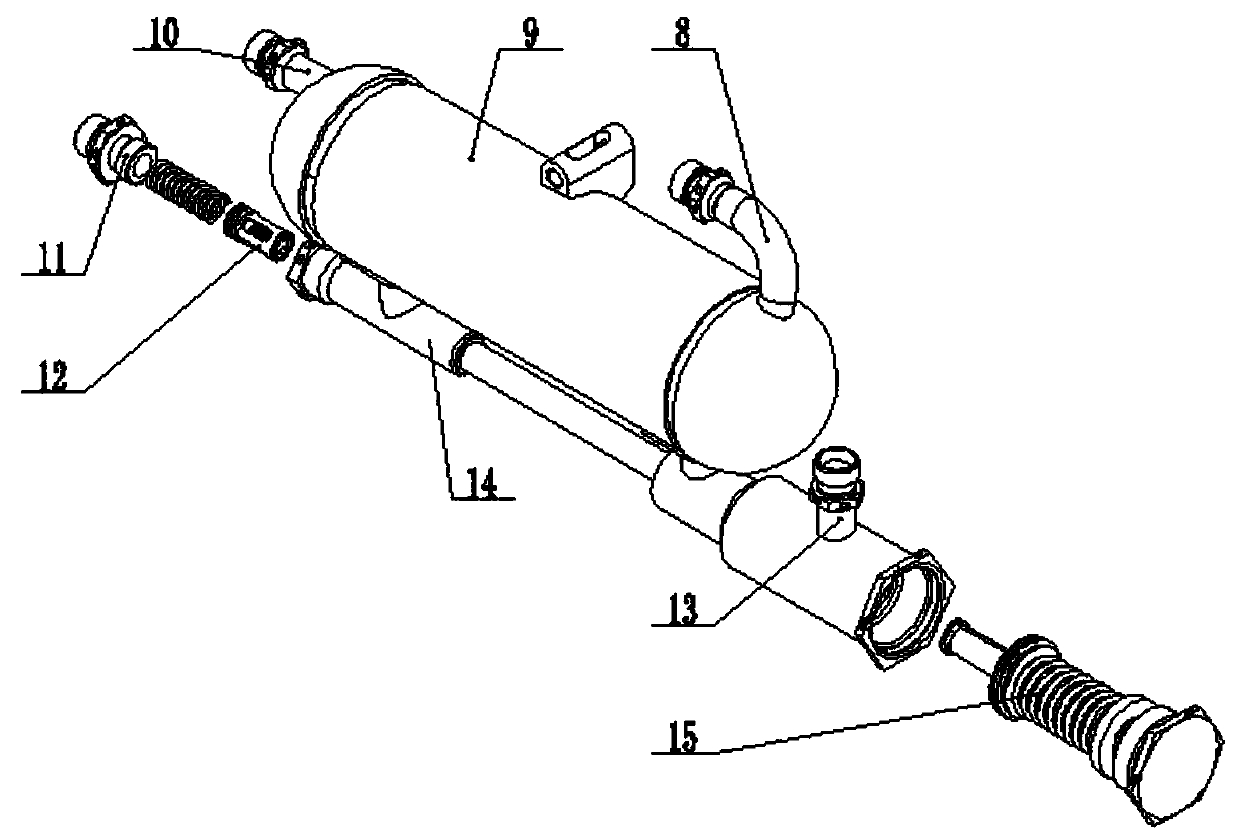

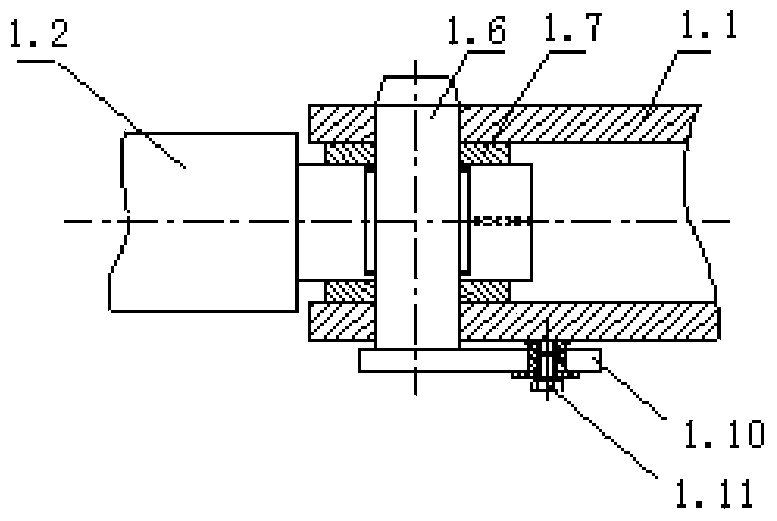

Installation method of water injection pump station and corresponding motor and water injection pump integrated unit

PendingCN110707869ASave spaceSimple structurePump componentsMechanical energy handlingElectric machineryControl theory

The invention provides an installation method of a water injection pump station and a corresponding motor and water injection pump integrated unit. The corresponding motor and water injection pump integrated unit comprises a motor and a water injection pump which are connected, the connecting end of the water injection pump is provided with an end cover and an outwards extending water injection pump shaft, and the motor comprises a case. Stators are annularly distributed and fixed to the inner wall of the case along the circumferential direction, a rotor sleeve is arranged at the position of amiddle shaft in the case, and rotors are annularly distributed and fixed on the outer wall of the rotor sleeve along the circumferential direction. The rotor sleeve is coaxially matched and fixedly connected with the water injection pump shaft, the case is fixedly connected with the end cover, a protective cover is further fixed to the non-connecting end of the case, and the rotor and the statorare installed respectively. According to the present invention, the problem that the double-positioning installation is difficult during overall installation of the motor is solved; meanwhile, the front and rear bearings of the motor and the front and rear end covers of the motor are saved, so that the structure of the whole unit is more simplified, the size is smaller, the occupied space is smaller, and space is saved for the pump station.

Owner:泰安阳光动力电机有限公司

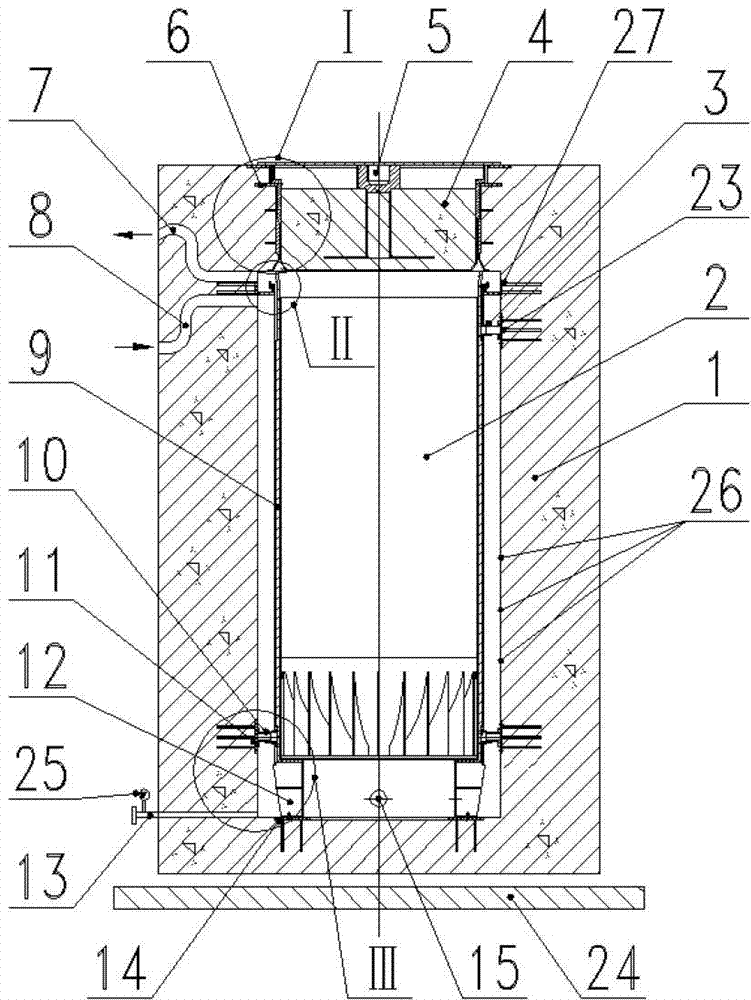

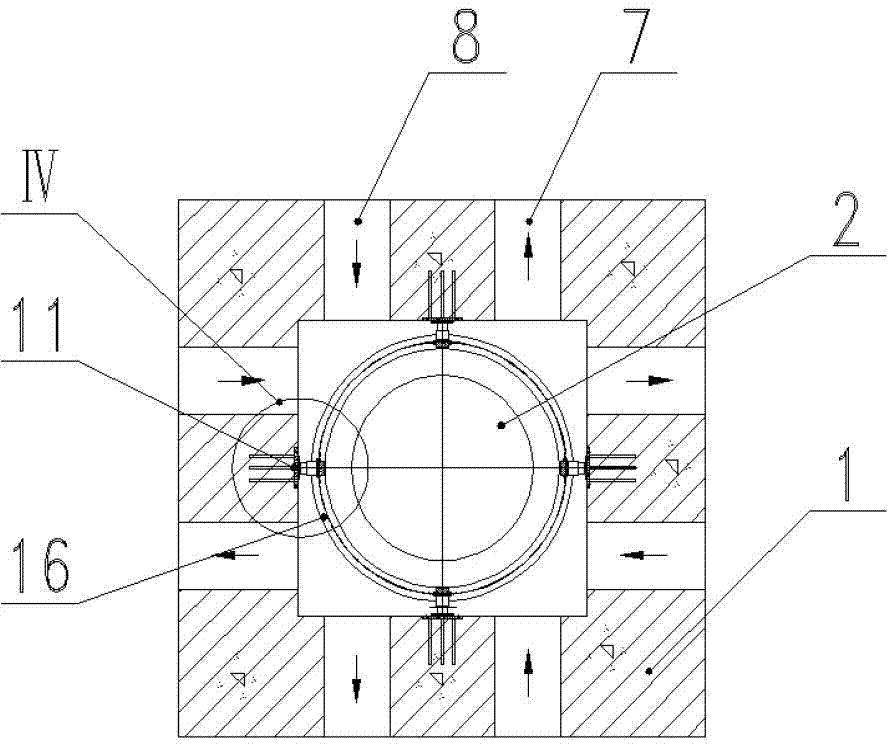

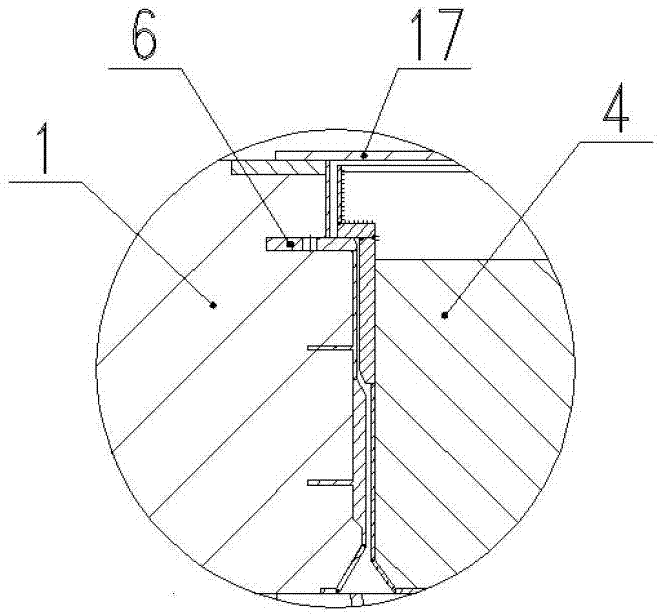

Spent fuel dry-type storage device

ActiveCN103065696BAchieving Radiation ShieldingEnsure safetyNuclear energy generationReactor fuel elementsInherent safetyNatural ventilation

Owner:CHINERGY CO LTD

Ore vibrating screen

PendingCN111359878AExtend your lifeEliminate stone inclusionSievingScreeningIsosceles trapezoidEconomic benefits

The invention relates to the technical field of mining mechanical equipment, in particular to an ore vibrating screen. The ore vibrating screen comprises a base plate and screen bars, wherein positioning holes are formed in the base plate, the screen bars are made of composite wear-resistant alloy through casting, the screen bars and the base plate are fixed through vacuum welding, and the screenbars are of isosceles trapezoid structures with upper edges longer than lower edges. The ore vibrating screen has the beneficial effects of long service life, specifically, a high-hardness wear-resistant alloy material is adopted, the wear-resistant life of the high-hardness wear-resistant alloy material is 5-10 times that of a common wear-resistant material; high efficiency, specifically, the stone clamping phenomenon in a using process of a traditional vibrating screen is basically eliminated, the operation load of vibrating equipment is reduced, daily maintenance of the vibrating equipmentis reduced, and the production efficiency is greatly improved; and high benefit, specifically, the abrasion of the vibrating screen is greatly reduced, the production cost of enterprises is directly reduced, meanwhile, maintenance personnel and maintenance frequency are reduced, the vibration maintenance management cost is reduced, and economic benefits are improved for the enterprises.

Owner:湖南海斯特材料科技有限公司

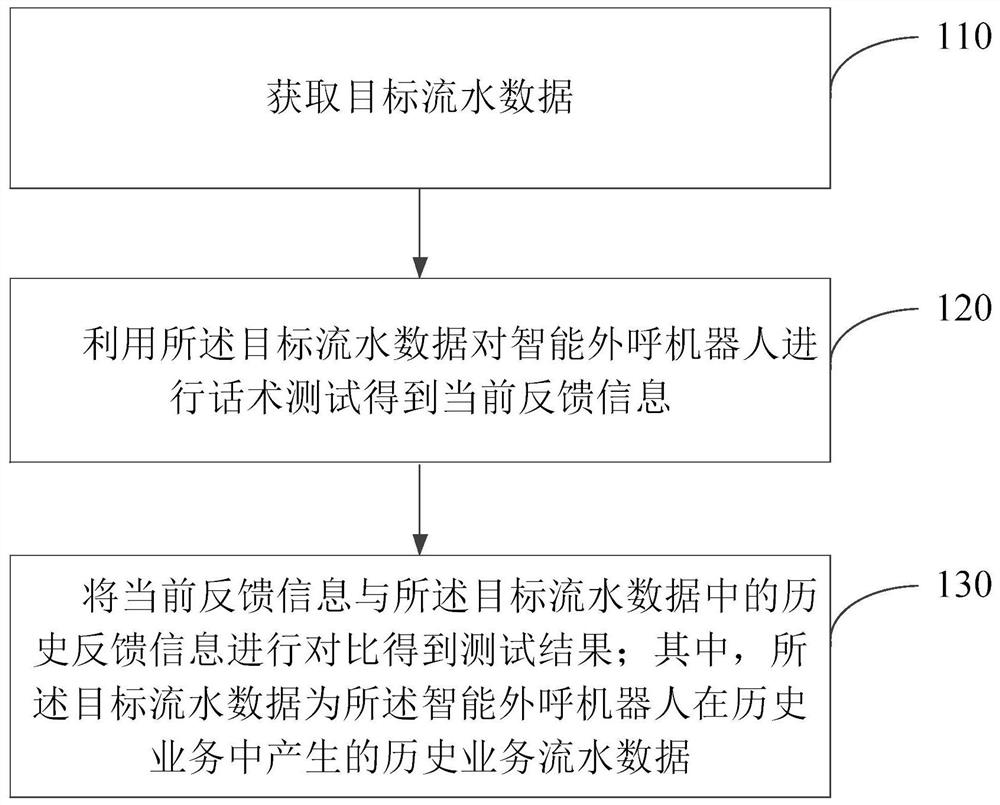

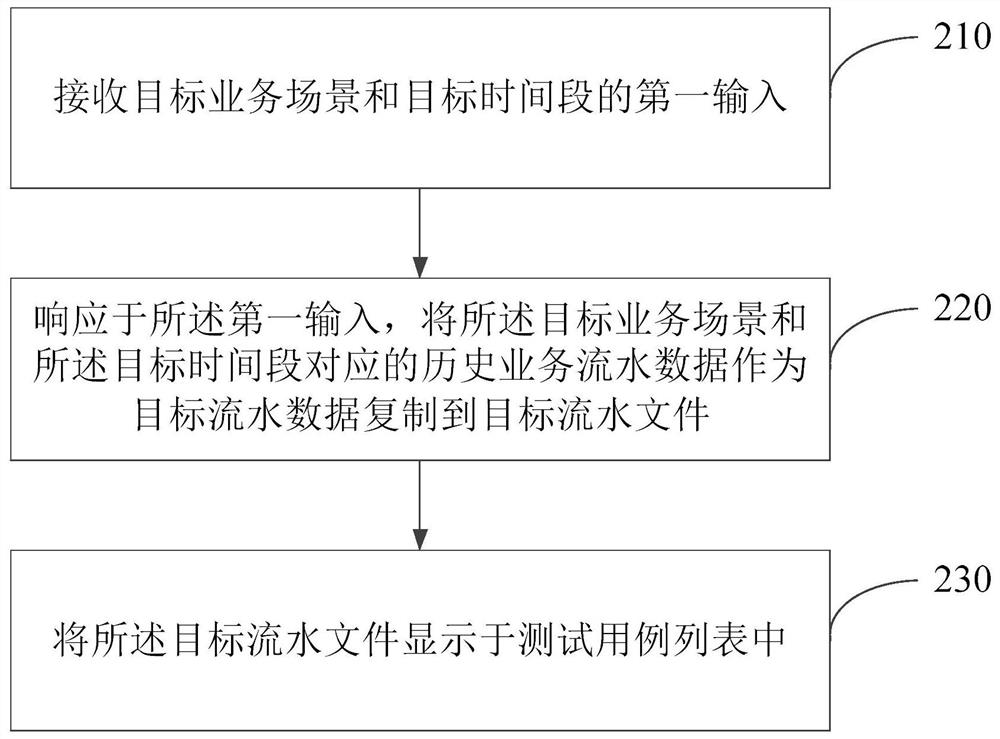

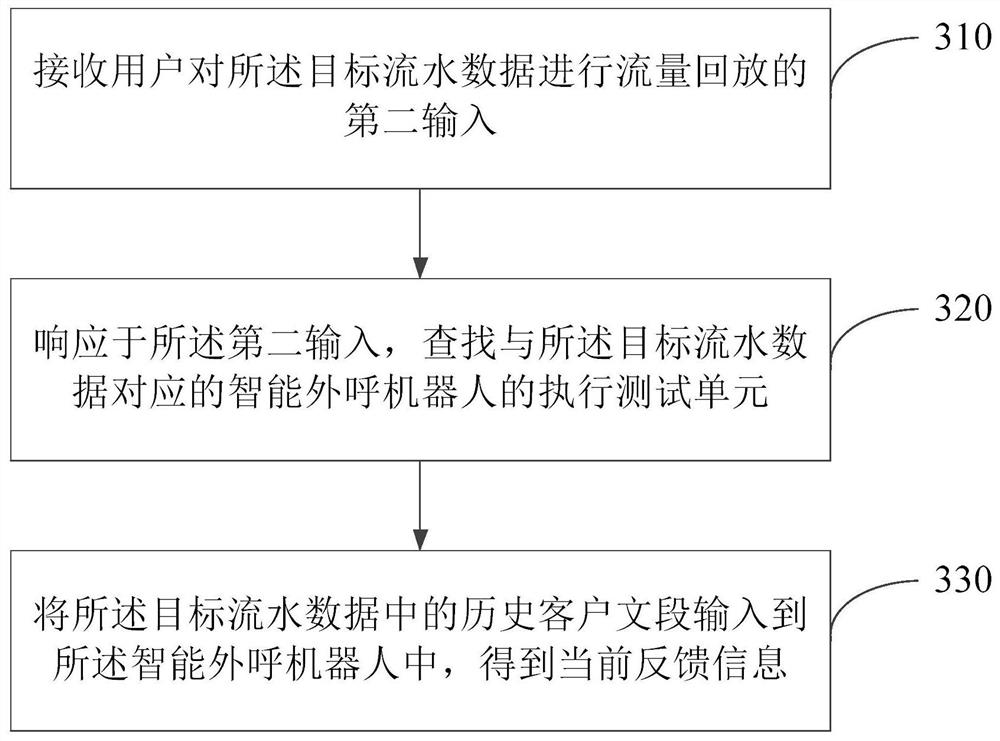

Typical skill test method and device for intelligent outbound robot

PendingCN113065850AReduce routine maintenanceImprove test efficiencyOffice automationSpeech recognitionTest efficiencySimulation

The invention provides a verbal skill test method and device for an intelligent outbound robot. The method comprises the following steps: acquiring target flow data; performing a verbal skill test on the intelligent outbound robot by using the target flow data to obtain current feedback information; comparing the current feedback information with historical feedback information in the target pipeline data to obtain a test result, wherein the target flow data is historical business flow data generated by the intelligent outbound robot in historical businesses, and the historical business flow data generated in the historical businesses is obtained to serve as the target flow data; compared with the scheme of manually simulating the problem of a customer for testing in the prior art, the method has the advantages that a large amount of daily maintenance can be reduced, the testing efficiency can be improved, and the labor cost can be reduced.

Owner:JD DIGITS HAIYI INFORMATION TECHNOLOGY CO LTD

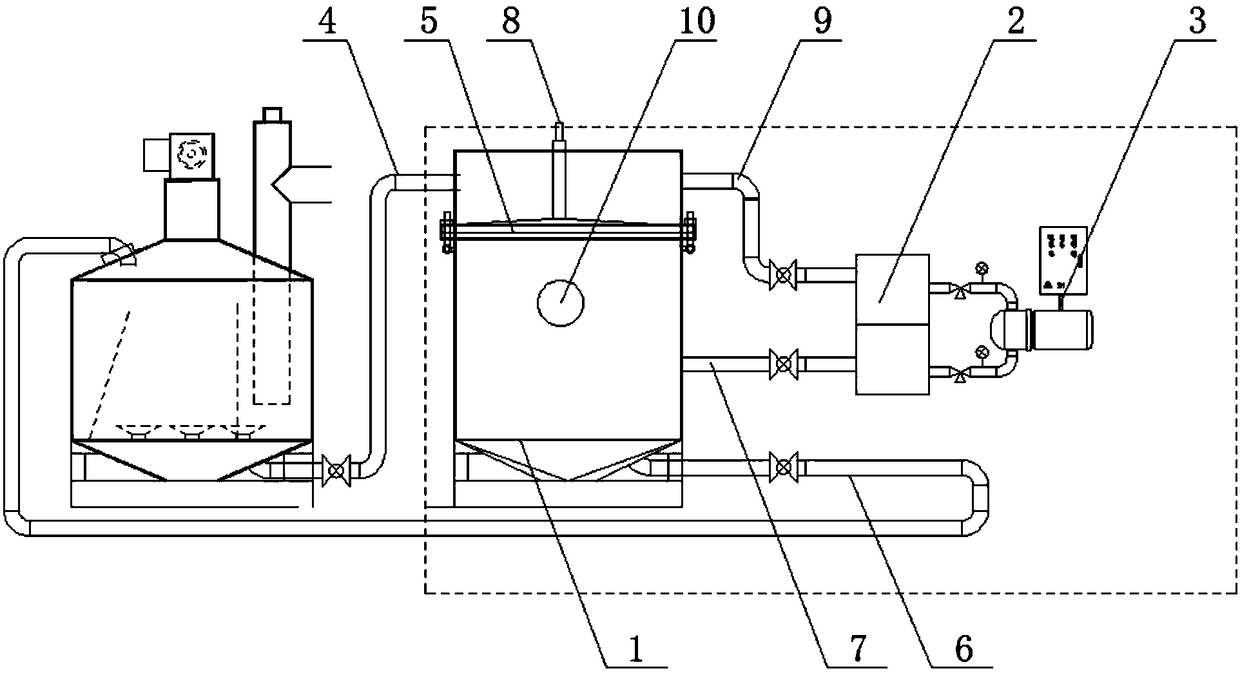

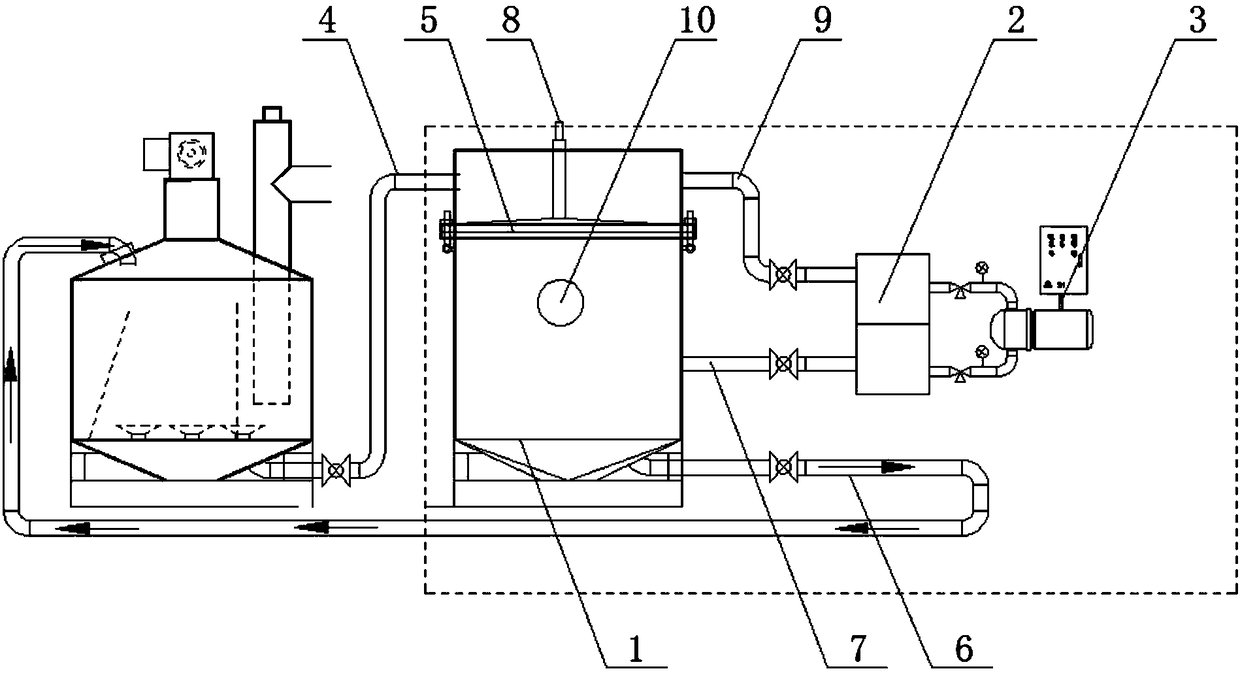

Vacuum treatment system used for cleaning kitchen oil insulation equipment, and vacuum treatment method thereof

ActiveCN108126385APromote refluxAchieve protectionStationary filtering element filtersVapor–liquid separatorSludge

The invention discloses a vacuum treatment system used for cleaning kitchen oil insulation equipment, and a vacuum treatment method thereof. The vacuum treatment system comprises a solid liquid separation tank, a gas liquid separator, a vacuum pump, a sewage suction pipe, a filter screen, a sewage discharge pipe, a vacuumizing pipe, a sludge scrapping machine, and a pressure increasing pipe; the solid liquid separation tank is connected with a sewage outlet of the kitchen oil insulation equipment through the sewage suction pipe; the filter screen which is used for filtering sewage flow in thesewage suction pipe is arranged in the solid liquid separation tank; and the sludge scrapping machine which is used for cleaning the filter screen is arranged in the solid liquid separation tank. Thevacuum pump is used for vacuumizing the internal part of the solid liquid separation tank using the gas liquid separator and the vacuumizing pipe, and is used for increasing the pressure in the solidliquid separation tank using the pressure increasing pipe; the bottom of the solid liquid separation tank is communicated with the kitchen oil insulation equipment through the sewage discharge pipe; impurities and waste water in the kitchen oil insulation equipment can be sucked into the solid liquid separation tank, and effective separation of the impurities with waste water is realized in the solid liquid separation tank. Compared with artificial cleaning, the advantages are that: labor intensity is reduced obviously, manpower and labor are saved, and the vacuum treatment system is convenient to use.

Owner:ANHUI TIANJIAN ENVIRONMENTAL PROTECTION

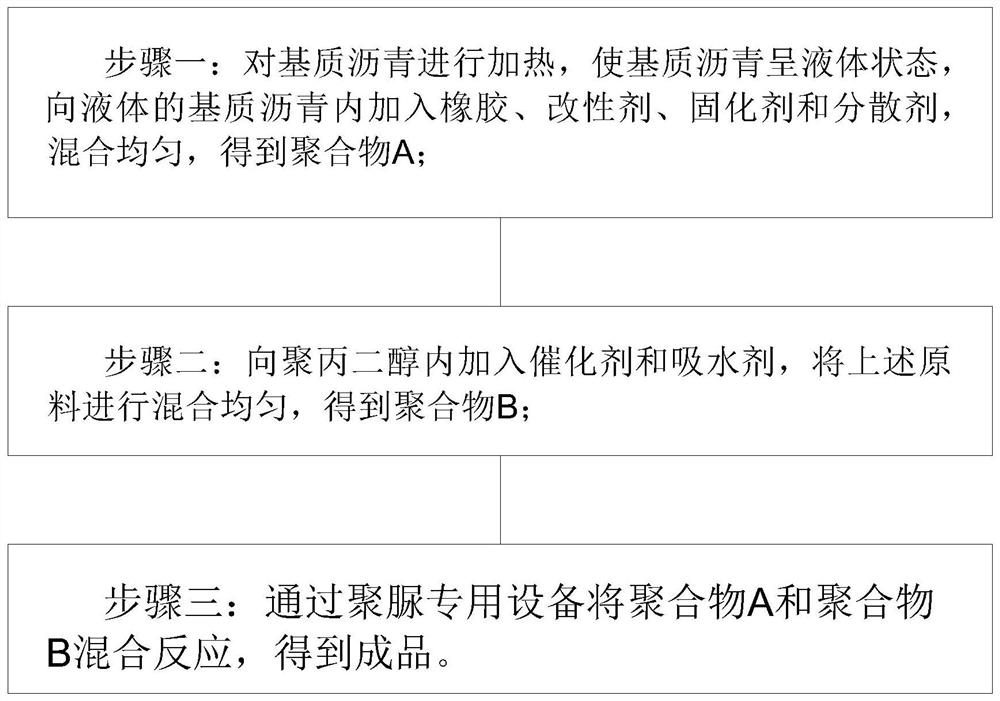

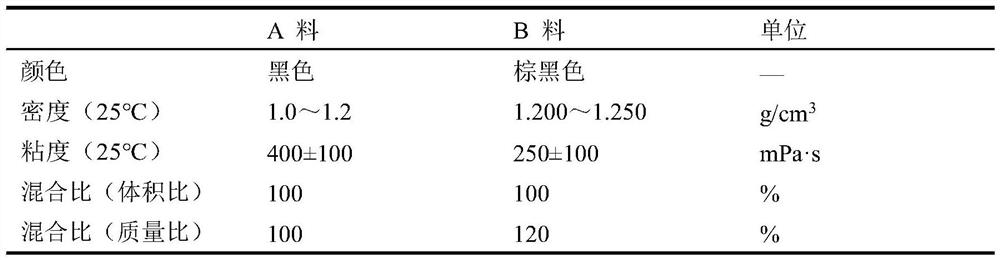

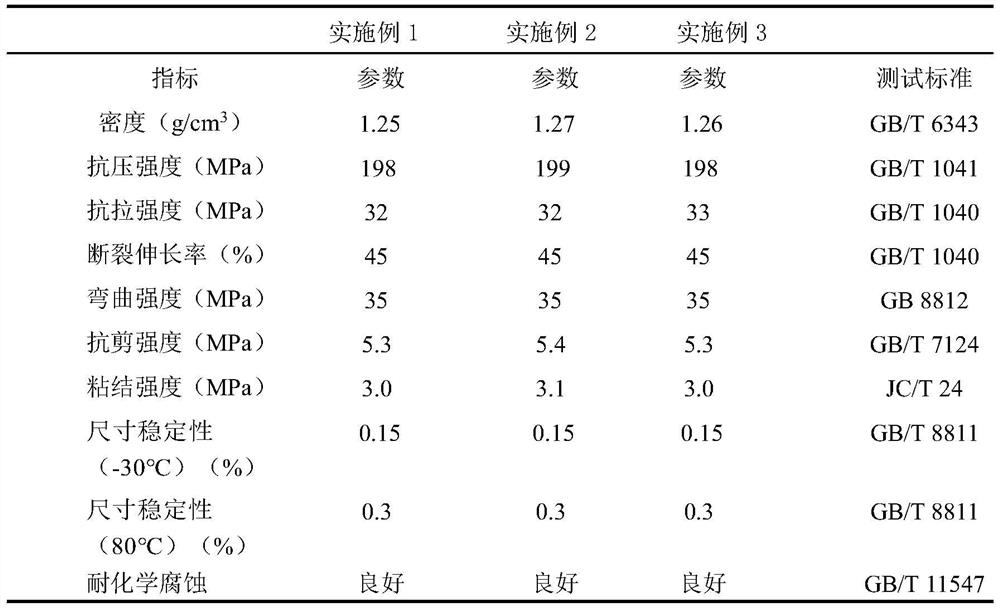

Polymer material for rapidly repairing asphalt pavement cracks and preparation method thereof

PendingCN114106571APromote swelling reactionGood compatibilityBuilding insulationsPtru catalystPolypropylene glycol

The invention discloses a polymer material for rapidly repairing asphalt pavement cracks and a preparation method of the polymer material. The repairing material is prepared from the following raw materials in parts by mass: 80 to 96 parts of matrix asphalt, 3.5 to 4.5 parts of rubber, 25 to 30 parts of polypropylene glycol, 20 to 25 parts of curing agent, 10 to 15 parts of modifier, 10 to 12 parts of dispersant, 1 to 2 parts of catalyst, 10 to 40 parts of water absorbent and 4 to 9 parts of tackifier. According to the polymer material for rapidly repairing the asphalt pavement cracks and the preparation method thereof, by adding the modifier, the swelling reaction of rubber and matrix asphalt can be effectively promoted, and light components in the asphalt can permeate in a rubber structure, so that the compatibility of the rubber and the matrix asphalt is efficiently promoted, and meanwhile, the polymer material also has relatively good high-temperature resistance; and the high-temperature self-repairing capability is also endowed, so that the tight protection of the steel bridge surface pavement structure layer on the lower-layer steel bridge panel is facilitated to a greater extent.

Owner:江苏争创磊固材料科技有限公司

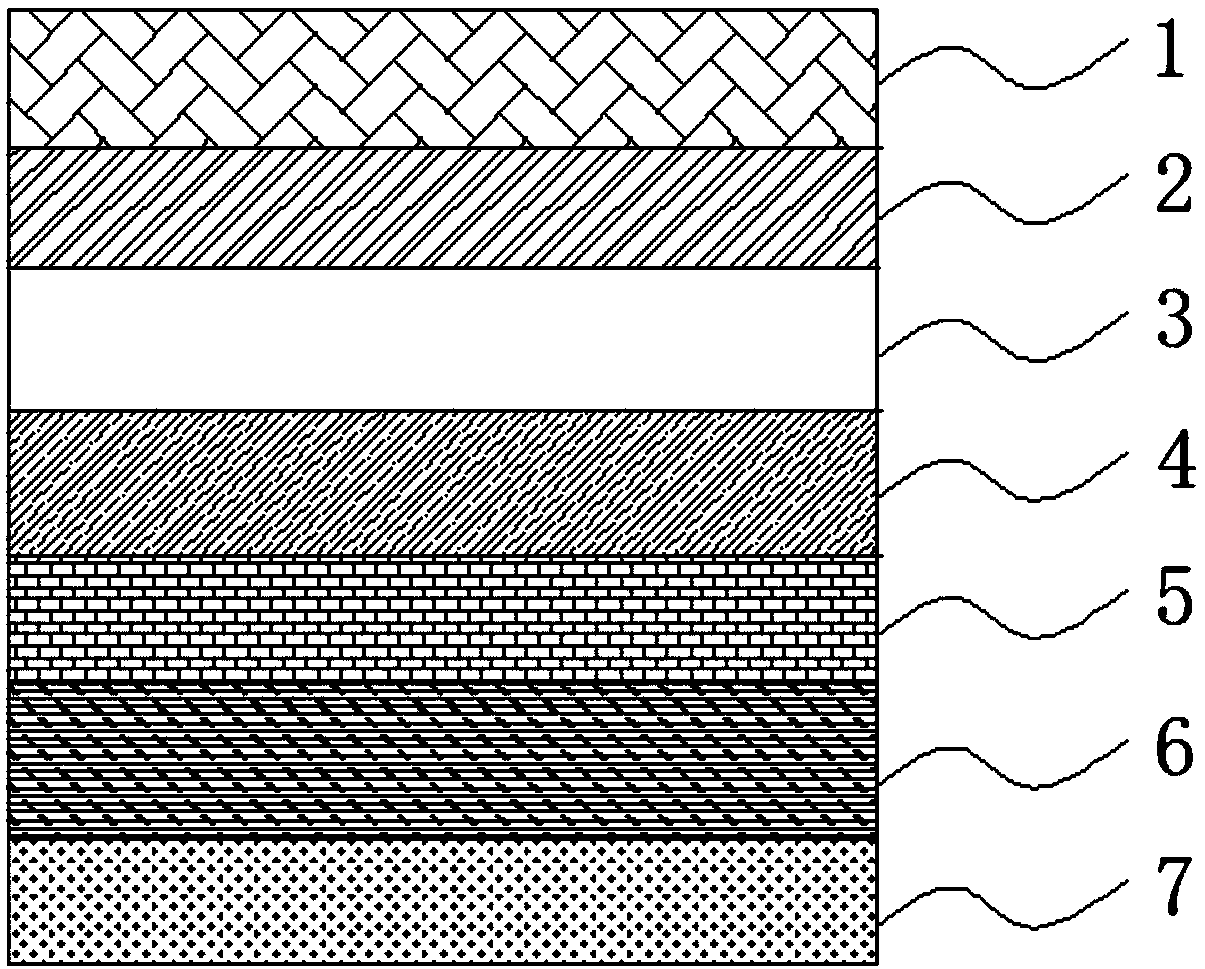

Composite type wallpaper and preparation method thereof

InactiveCN108222403AThe overall thickness is thinImprove fitFireproof paintsCovering/liningsActivated carbonUltimate tensile strength

The invention discloses composite type wallpaper and a preparation method thereof. The composite type wallpaper comprises a substrate layer, wherein a reinforced layer is arranged on any side of the substrate layer, a waterproof layer is arranged on the other side of the substrate layer, a fireproof layer is arranged on the other side of the reinforced layer, a sound absorbing layer is arranged onthe other side of the fireproof layer, a decorative layer is arranged on the other side of the sound absorbing layer, and a protective layer is arranged on the other side of the decorative layer; thereinforced layer is a polyarylester fiber layer; the sound absorbing layer is an activated carbon layer; and the protective layer is a polyvinyl resin layer. The composite type wallpaper disclosed bythe invention adopts green and environment-friendly materials, is excellent in tensile strength, integrates waterproof, fireproof, sound absorbing and dustproof functions into a whole and is optimized for interior decoration.

Owner:昆山市聚光装饰材料有限公司

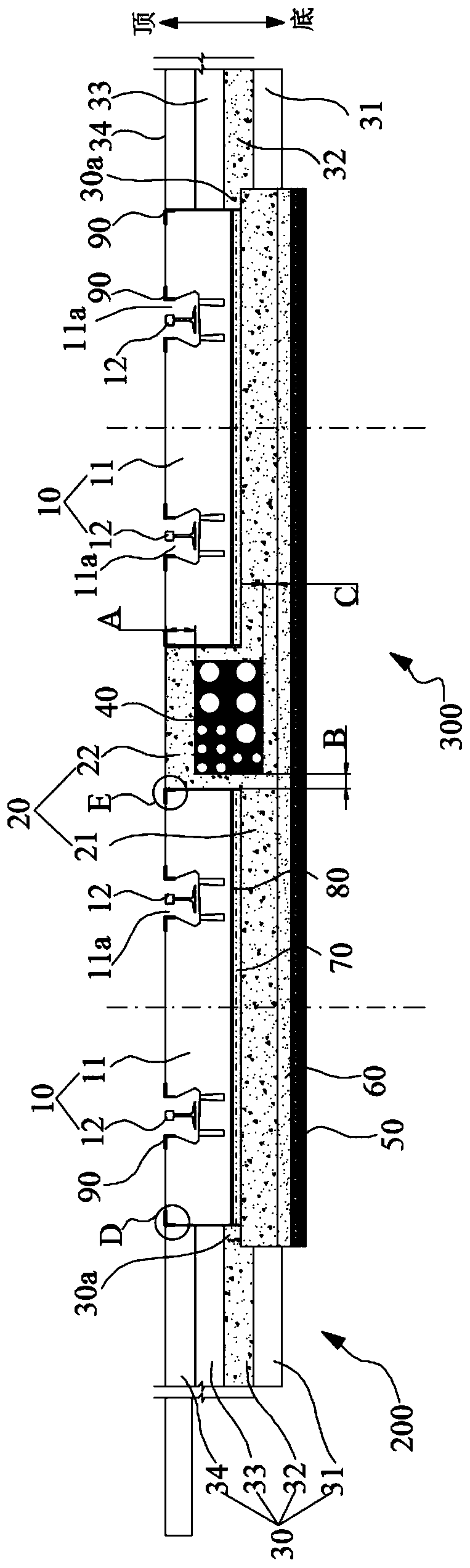

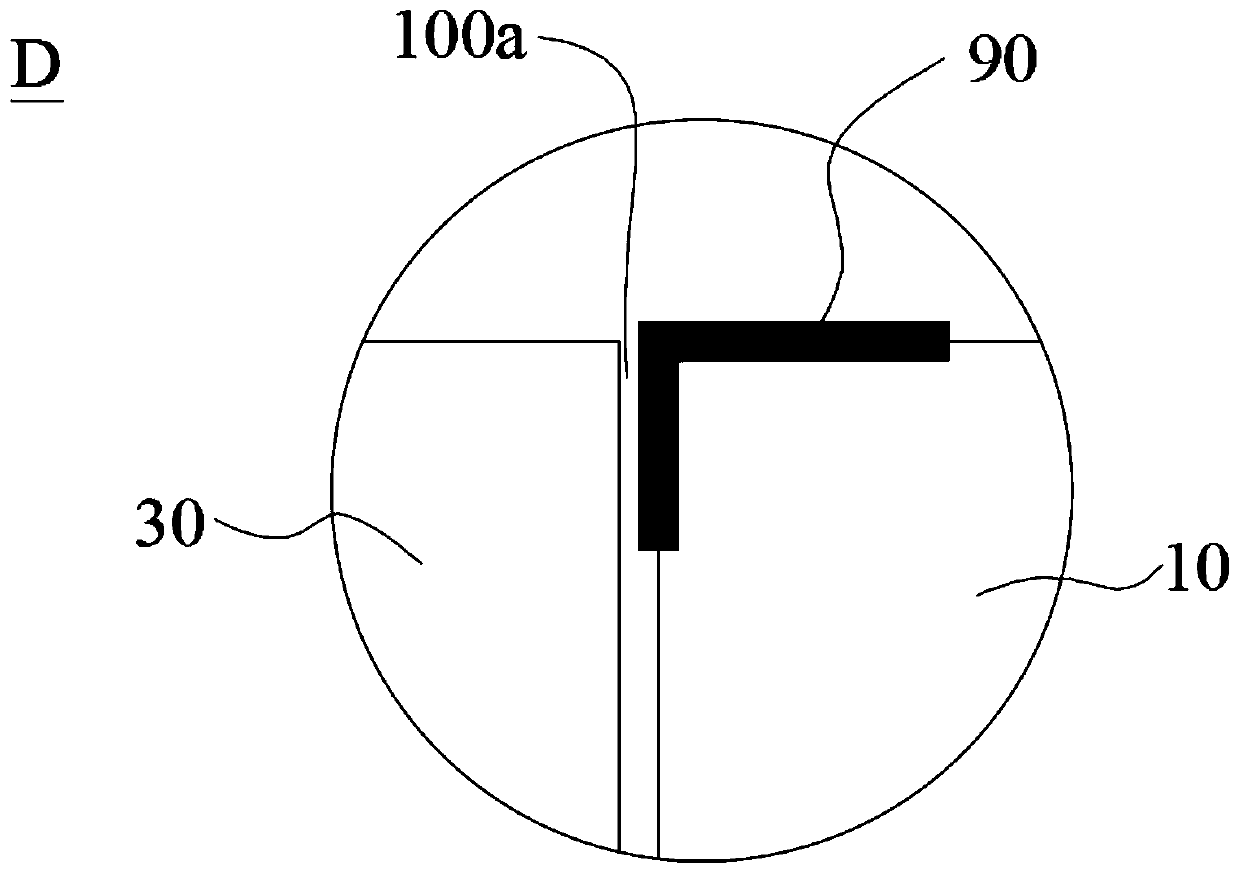

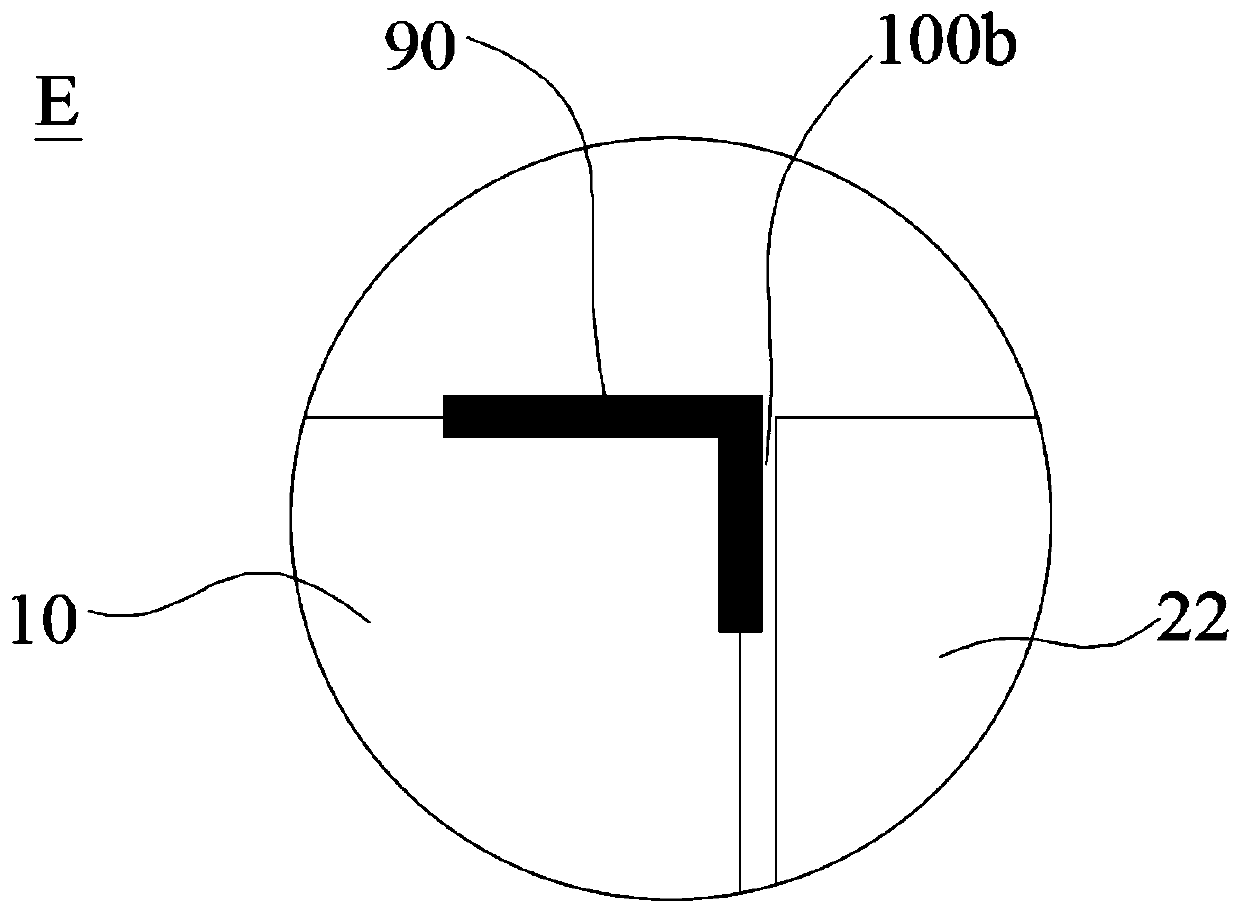

Level crossing structure of rail transit

PendingCN111549583AImprove mechanical performanceEven by forceBallastwayTrackwayArchitectural engineering

The embodiment of the invention provides a level crossing structure of rail transit. The level crossing structure comprises a track structure body and a foundation plate, the foundation plate comprises a first part and a second part, the first part is supported below the track structure body, the second part fills an inter-line area between every two adjacent track structure bodies, and the firstpart and the second part are integrally formed. Due to the fact that the first part and the second part are integrally formed, the second part can bear automobile loads and transmit the automobile loads to the first part, and then the first part evenly transmits the loads to a roadbed foundation bed of a track structure. In this way, it is guaranteed that the roadbed foundation bed under the double-line or multi-line track structure is evenly stressed, and uneven settlement caused by uneven stress of the roadbed foundation bed under the double-line or multi-line track structure is prevented.

Owner:CHINA RAILWAY SIYUAN GRP SOUTHWEST SURVEY & DESIGN CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com