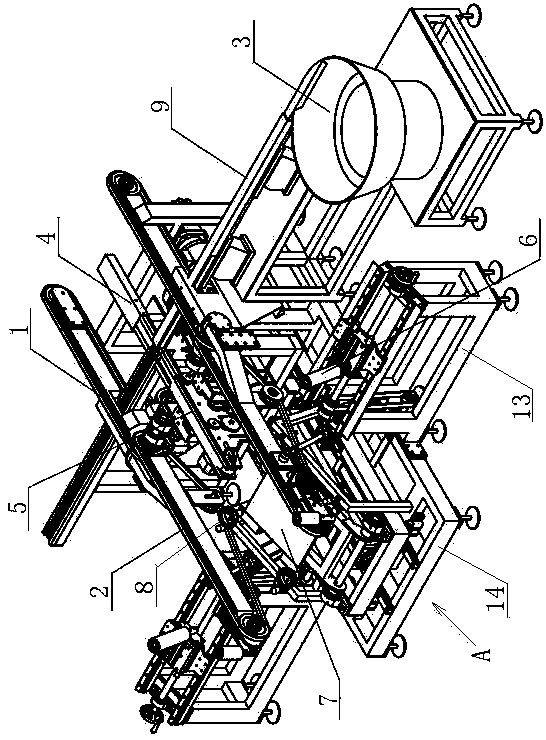

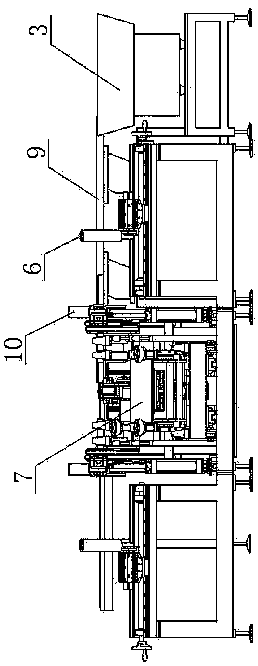

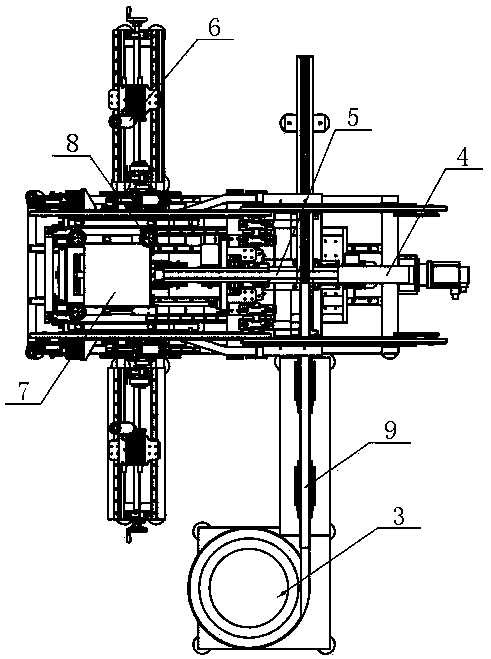

Automatic dismounting and stacking device for front windshield of car

A front windshield and stacking device technology, applied in the stacking, transportation, and packaging of objects, can solve the problems of high scrap rate and complicated manual unloading operation process, so as to reduce labor costs and labor intensity , The effect of design simplification and innovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The center positioning rod 10 is installed on the front end of the overturning transmission device 2, the rear end of the overturning transmission device 2 is in contact with the transition transmission device 1, and the high-voltage clamp vibration tray 3 is connected with the linear feeder 9 automatically, and the transmission motor 12 is connected with the overturning transmission device 2. The servo motor 11 is connected with the stacking turning device 7, the tapered positioning rod 6 is installed on the tapered positioning rod bracket 13, the tapered positioning rod bracket is located on both sides of the main frame 14, the linear feeder 9 is connected with the high-voltage clip pushing mechanism 4, The high-voltage clip pushing mechanism 4 is in contact with the high-voltage clip installation mechanism 5 , and the stacking device 7 has a glass sucker 8 .

[0023] The structure of the overturning transmission device 2 is that one end of the positioning overturning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com