Polymer material for rapidly repairing asphalt pavement cracks and preparation method thereof

A technology of polymer materials and asphalt pavement, which is applied in the direction of building insulation materials, building structures, building components, etc., can solve the problems of high construction conditions, long road surface sealing time, and large temperature sensitivity, so as to meet the requirements of rapid repair and Operational requirements, promotion of compatibility, good effects of patching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

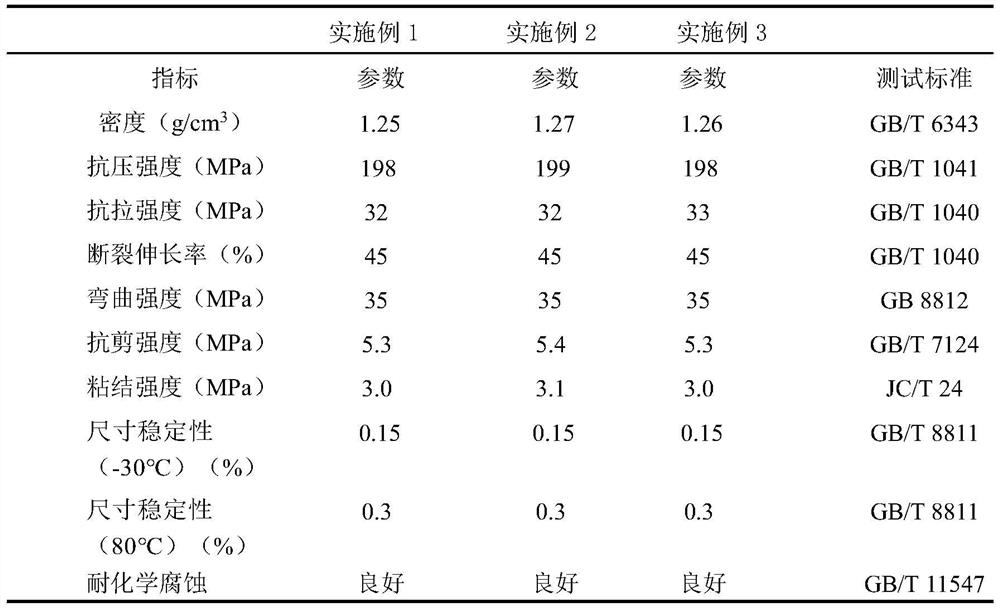

[0027] The present invention is a polymer material for quickly repairing cracks on asphalt pavement. The repairing material comprises the following raw materials in parts by mass: 80 parts of matrix asphalt, 3.5 parts of rubber, 25 parts of polypropylene glycol, 20 parts of curing agent, 10 parts of modifier, and dispersant 10 parts, 1 part of catalyst, 10 parts of water absorbing agent and 4 parts of tackifier.

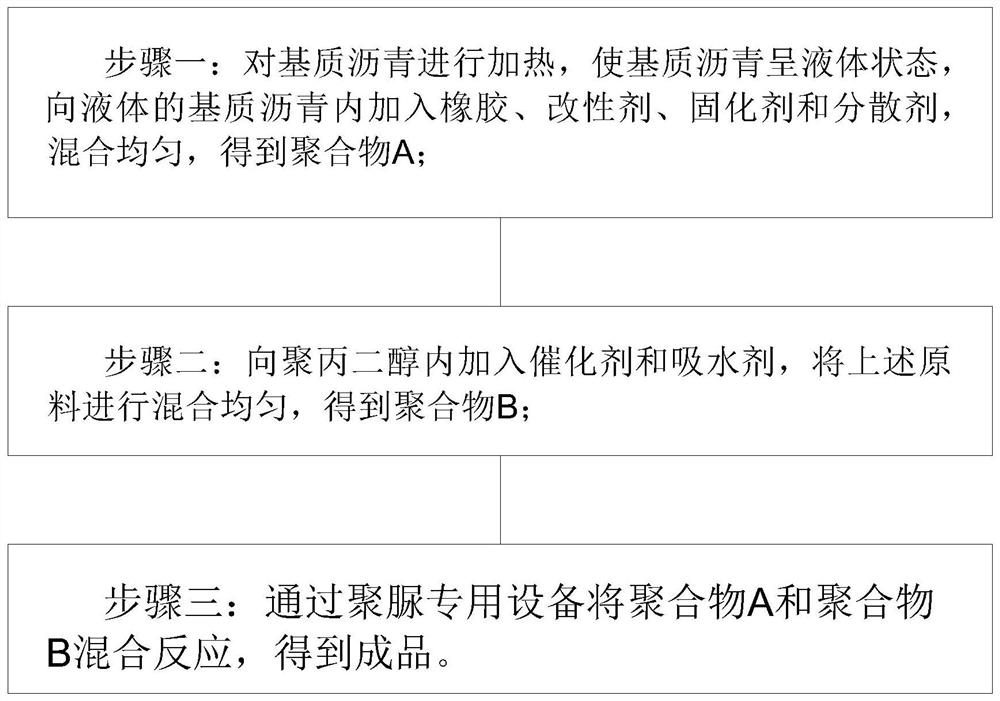

[0028] Such as figure 1 Shown, a kind of preparation method of the polymer material of quick repair asphalt pavement crack, comprises the following steps:

[0029] Step 1: heating the base asphalt to make the base asphalt in a liquid state, adding rubber, modifier, curing agent and dispersant to the liquid base asphalt, and mixing uniformly to obtain polymer A;

[0030] Step 2: adding a catalyst and a water-absorbing agent into the polypropylene glycol, and mixing uniformly to obtain polymer B;

[0031] Step 3: The polymer A and the polymer B are mixed and reacted ...

Embodiment 2

[0034] The present invention is a polymer material for quickly repairing cracks on asphalt pavement. The repairing material comprises the following raw materials in parts by mass: 88 parts of base asphalt, 4 parts of rubber, 27 parts of polypropylene glycol, 23 parts of curing agent, 12 parts of modifier, and dispersant 11 parts, catalyst 2 parts, water absorbing agent 30 parts and tackifier 6 parts.

[0035] Such as figure 1 Shown, a kind of preparation method of the polymer material of quick repair asphalt pavement crack, comprises the following steps:

[0036] Step 1: heating the base asphalt to make the base asphalt in a liquid state, adding rubber, modifier, curing agent and dispersant to the liquid base asphalt, and mixing uniformly to obtain polymer A;

[0037] Step 2: adding a catalyst and a water-absorbing agent into the polypropylene glycol, and mixing the above-mentioned raw materials evenly to obtain a polymer B;

[0038] Step 3: The polymer A and the polymer B a...

Embodiment 3

[0041] The present invention is a polymer material for quickly repairing cracks on asphalt pavement. The repairing material comprises the following raw materials in parts by mass: 96 parts of matrix asphalt, 4.5 parts of rubber, 30 parts of polypropylene glycol, 25 parts of curing agent, 15 parts of modifier, and dispersant 12 parts, catalyst 2 parts, water absorbing agent 40 parts and tackifier 9 parts.

[0042] Such as figure 1 Shown, a kind of preparation method of the polymer material of quick repair asphalt pavement crack, comprises the following steps:

[0043] Step 1: heating the base asphalt to make the base asphalt in a liquid state, adding rubber, modifier, curing agent and dispersant to the liquid base asphalt, and mixing uniformly to obtain polymer A;

[0044] Step 2: adding a catalyst and a water-absorbing agent into the polypropylene glycol, and mixing uniformly to obtain polymer B;

[0045] Step 3: The polymer A and the polymer B are mixed and reacted by speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com