Connecting structure of oil cylinder support base and pin roll as well as mechanical device

A technology of oil cylinder support and connection structure, which is applied to mechanically driven excavators/dredgers, etc., can solve the problems of shortened service life, troublesome service life, and high operating frequency of oil cylinders, and achieves improved service life, beautiful appearance and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

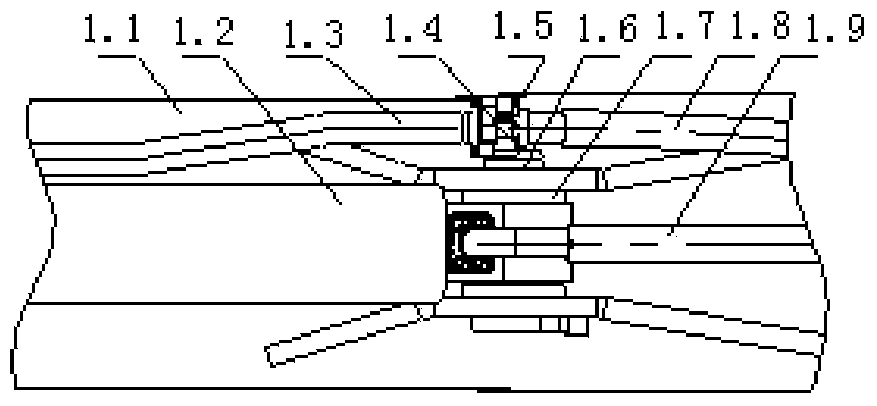

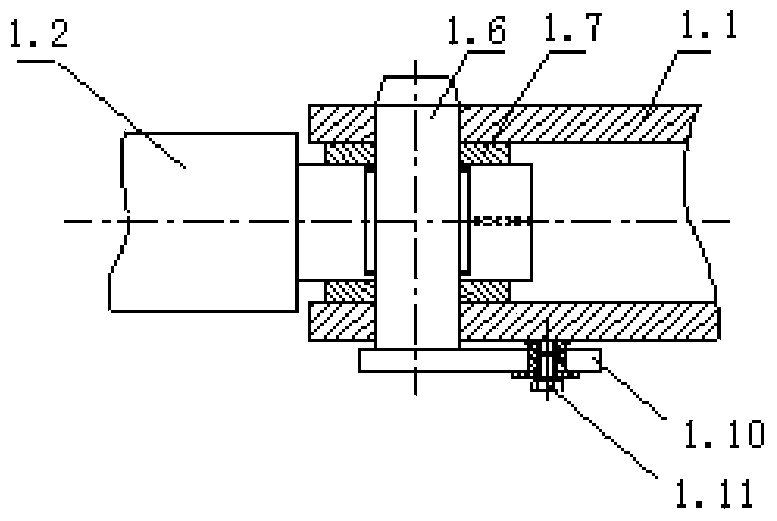

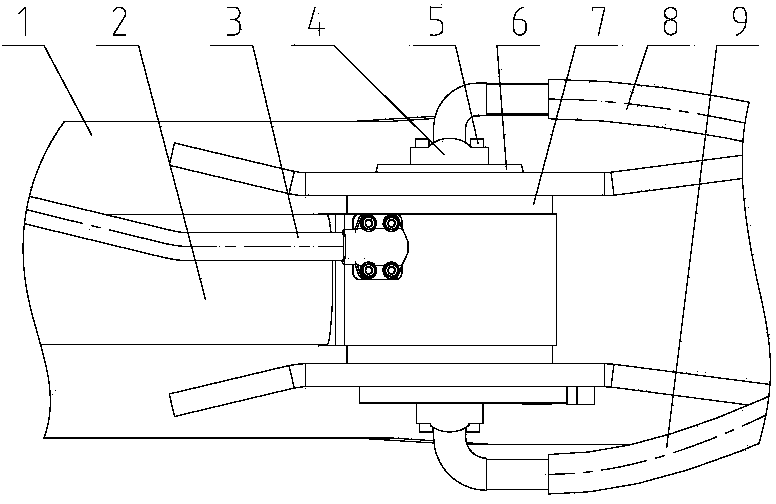

[0046] See Figure 3-6 Shown: a connection structure between a cylinder support and a pin shaft in an embodiment of the present invention, including a boom 1, a stick cylinder 2, a small cavity steel pipe 3, a flange 4, a screw 5, a pin shaft 6, Gasket 7, a small-cavity rubber hose 8, a large-cavity rubber hose 9, a limit plate 10, a positioning screw 11, an O-ring 12, the stick cylinder 2 is connected to the pin 6, and the stick cylinder 2 is connected to the pin 6 Connect to form an oil cylinder support 16, the pin shaft 6 is connected with the limiting plate 10, the positioning screw 11 is connected with the limiting plate 10, the two ends of the pin shaft 6 have two mounting screw holes 18, the small cavity rubber hose 8 and the large cavity rubber hose 9 They are respectively fixedly insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com