Installation method of water injection pump station and corresponding motor and water injection pump integrated unit

An installation method and water injection pump technology, which are applied in the direction of pump devices, electric components, machines/engines, etc., can solve the problems of installation environment restrictions, installation accuracy cannot be guaranteed, etc., to improve work performance, improve work intensity, and facilitate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides an installation method for a water injection pump station. The installation method includes the following steps: firstly, process the end cap of the water injection pump with a shaft end to a stop, and install the water injection pump to the oil production place of the oil field; secondly, fix the motor The rotor sleeve of the rotor is coaxially fixed and installed on the shaft of the water injection pump; again, the end of the motor casing with the motor stator fixed inside is machined into a seam that matches the seam of the end cover, and the seam part of the end cover and the motor The spigot part of the casing is matched and fixedly connected; finally, the protective cover is fixed at the other end of the motor casing.

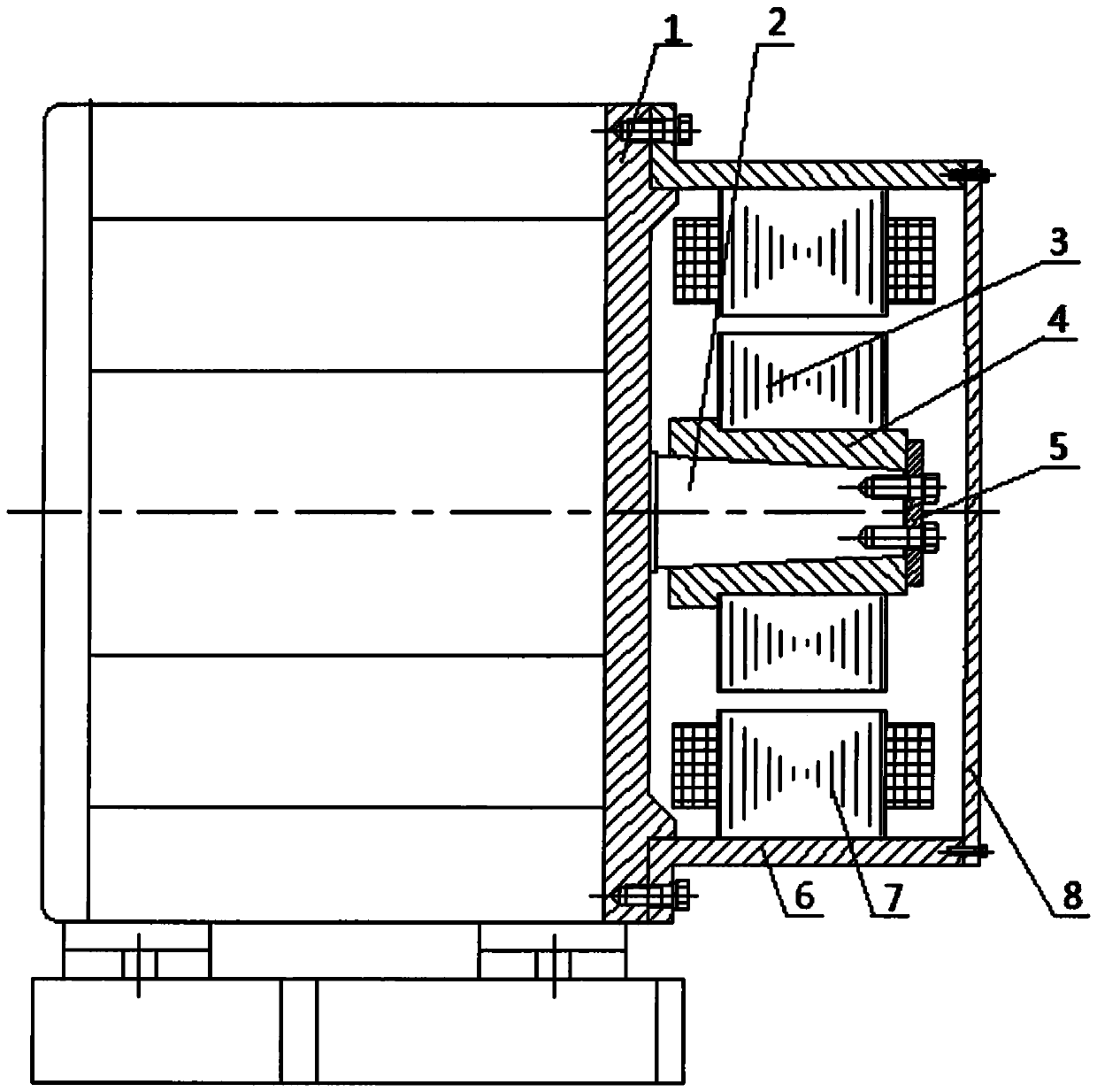

[0033] Corresponding to the installation method of the above-mentioned water injection pump station, this embodiment also provides an integrated motor and water injection pump unit, such as figure 1 As shown, it includes a ...

Embodiment 2

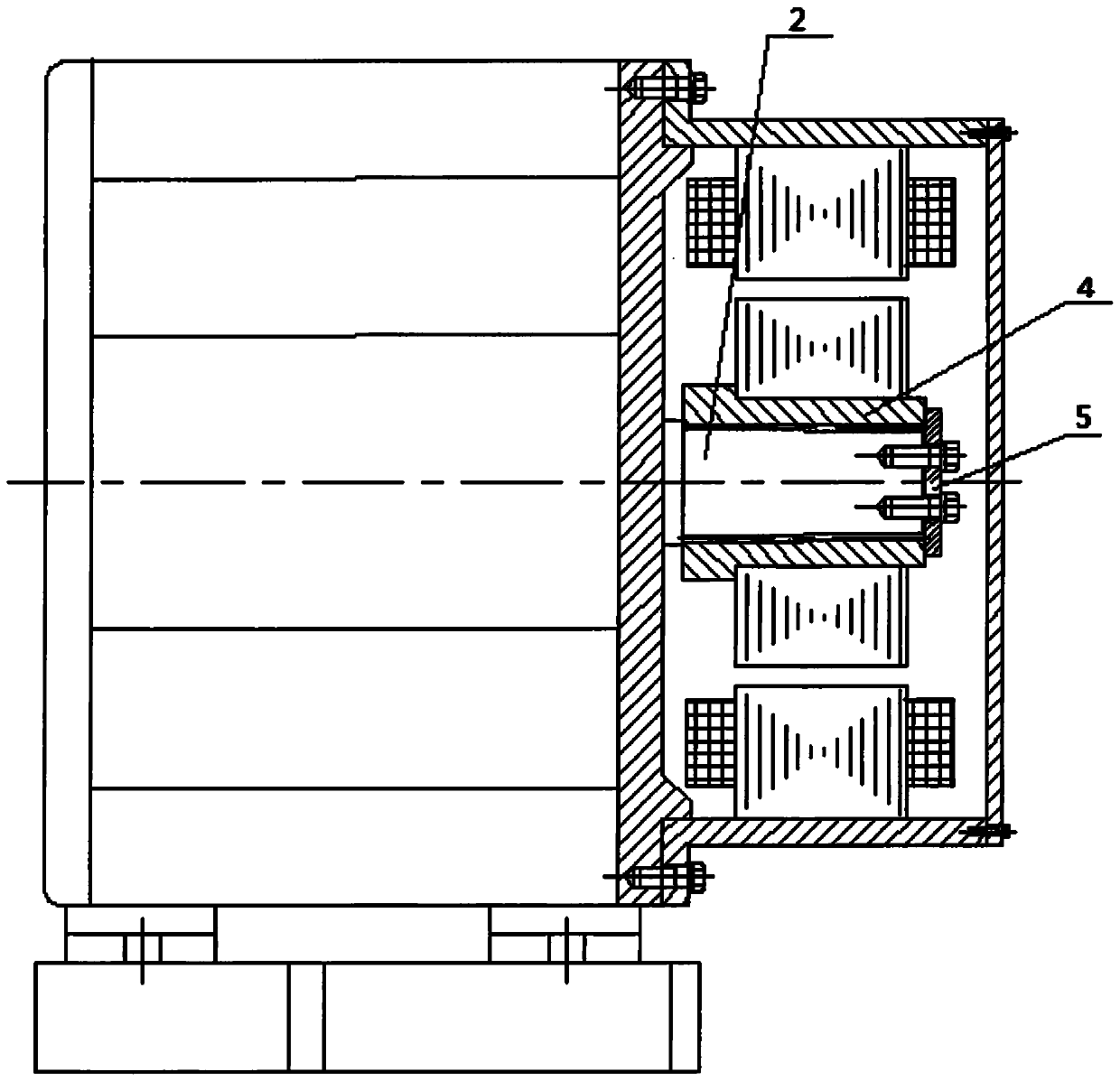

[0038] This embodiment provides another connection method between the water injection pump shaft 2 and the rotor sleeve 4 in Embodiment 1, such as figure 2As shown, the shaft 2 of the water injection pump adopts a spline shaft, and the hole of the rotor sleeve 4 adopts a spline hole that is coaxial with the spline shaft and cooperates with each other. In the hole, the error caused by the axis deviation during the installation process can also be avoided. There is a pressure plate 5 at the end of the rotor sleeve 4. The outer dimension of the pressure plate 5 is larger than the maximum aperture of the spline hole. The pressure plate 5 is fixedly connected with the water injection pump shaft 2 by screws. , so that the pressure plate 5 can press the rotor sleeve 4 on the water injection pump shaft 2, the rotor sleeve 4 and the water injection pump shaft 2 mesh with each other and transmit torque, and the weight of the rotor 3 is supported by the water injection pump bearing, maki...

Embodiment 3

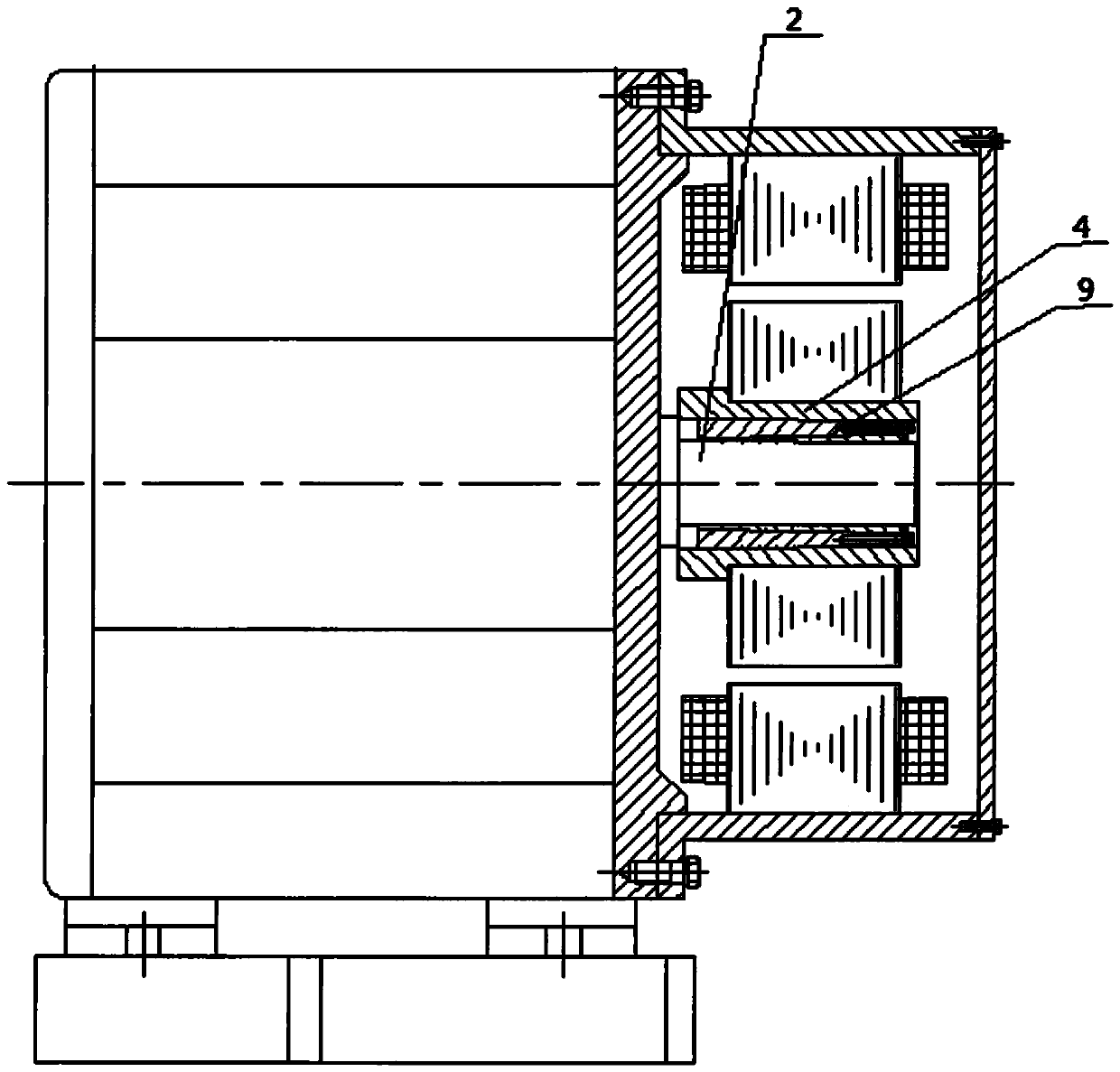

[0040] This embodiment provides another connection method between the water injection pump shaft 2 and the rotor sleeve 4 in Embodiment 1, such as image 3 As shown, the shaft 2 of the water injection pump adopts a cylindrical shaft, and the hole of the rotor sleeve 4 adopts a cylindrical hole that is coaxial with the cylindrical shaft and cooperates with each other. There is an expansion sleeve 9 inside the cylindrical rotor sleeve, and the two are installed in the cylindrical hole together. It can also avoid the error caused by the axis deviation in the installation process. By tightening the screws of the expansion sleeve 9, the inner diameter of the expansion sleeve 9 is reduced and the outer diameter is increased, so that the rotor sleeve 4 and the water injection pump shaft 2 are tightly connected together. At the same time The pressure plate 6 is also omitted, the rotor sleeve 4 is locked with the water injection pump shaft 2 and transmits torque, and the weight of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com