Crane steel wire rope anti-swing system

A technology for hoisting steel wire ropes and steel wire ropes, which is applied in the direction of load hanging components, transportation and packaging, etc. It can solve the problems of unbalanced force on the steel wire ropes, large torque of the reducer, inconvenient daily maintenance, etc., and achieves simple structure, reduced torque, Ease of repair and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

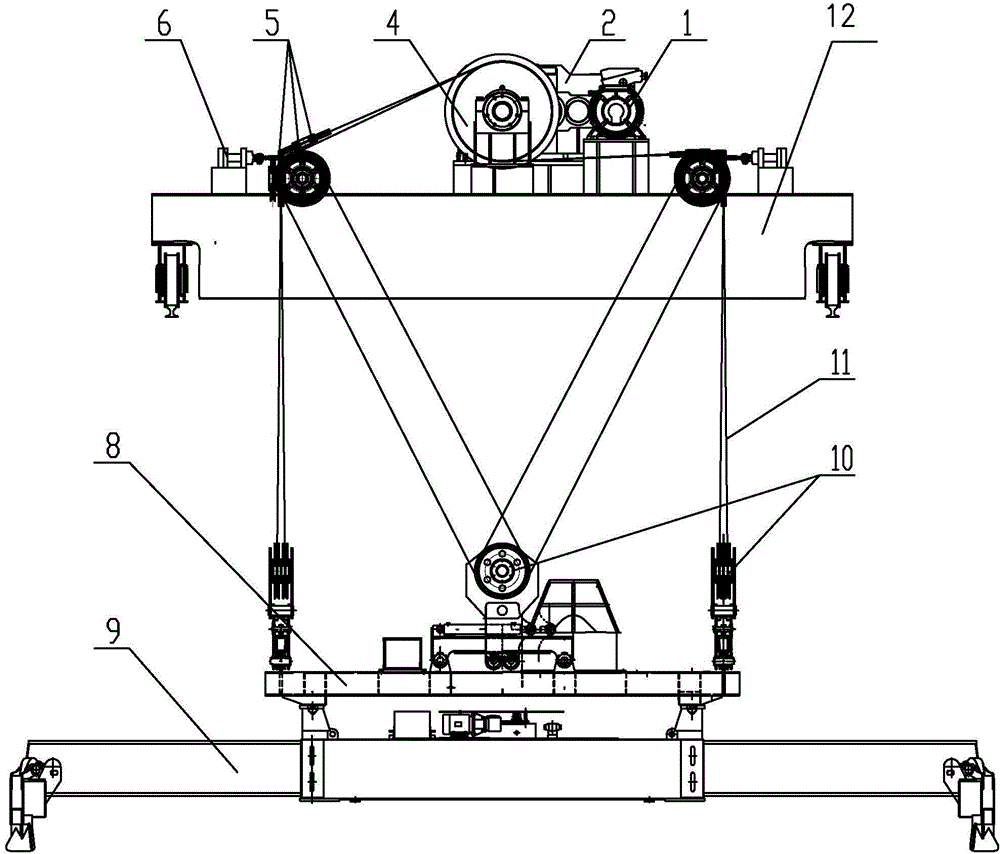

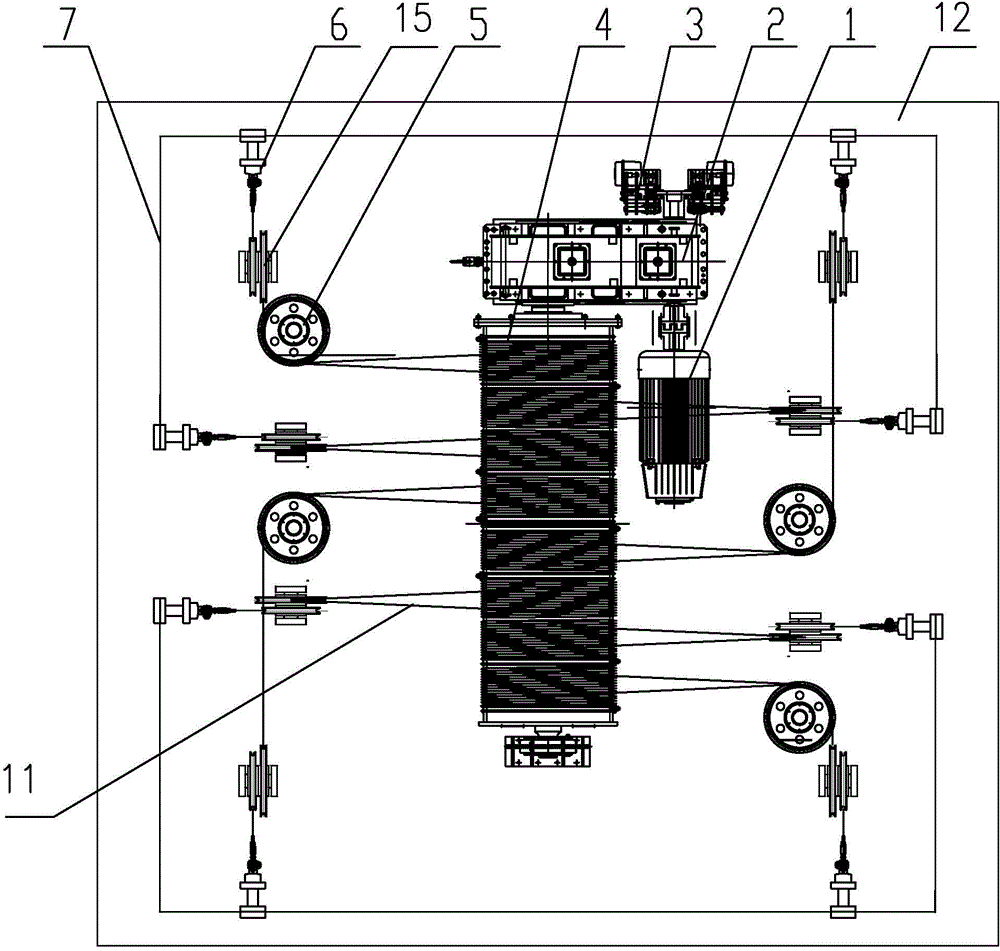

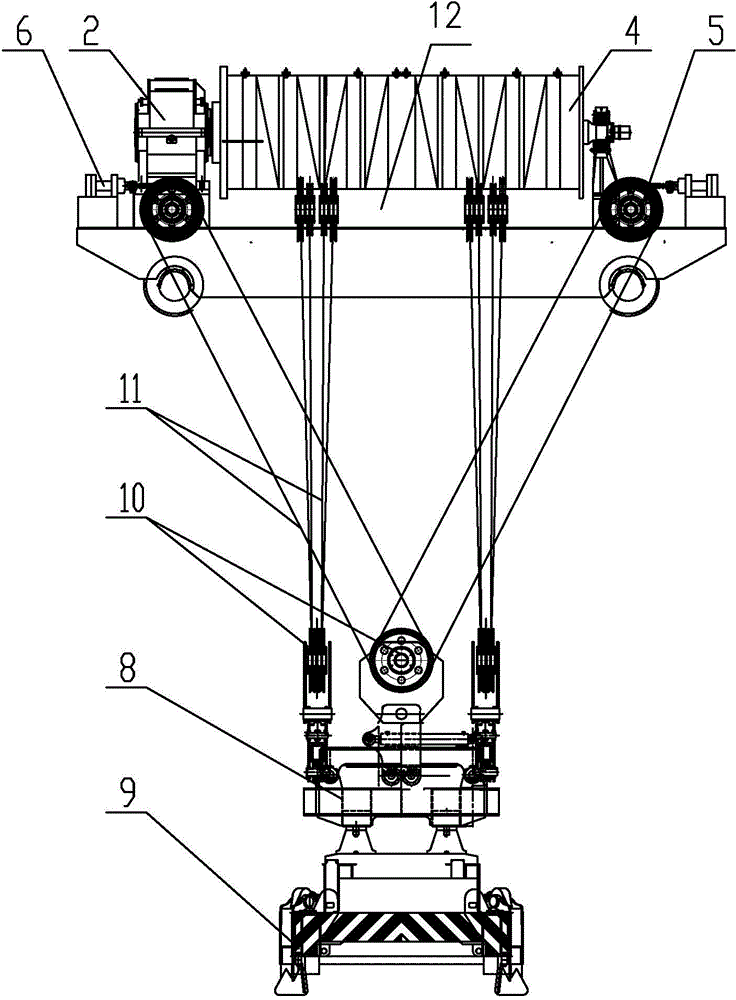

[0011] The crane wire rope anti-sway system of the present invention includes a motor 1, a reducer 2, a brake 3 and a reel 4 which are installed on the trolley frame 12 and connected in sequence. The bottom of the hoisting wire rope 11 is wound around the lower pulley group 10 on the upper frame 8 of the spreader. The spreader 9 is suspended below the upper frame 8 of the spreader. Its characteristics are: 8 hoisting wire ropes 11 wound on the drum 4 pass through the upper pulley block 5, and then guided by the steering wheel 15, the wire rope collar 14 at the end of the rope is fixed on the trolley evenly and symmetrically through the pin shaft 13 The piston rods of 8 hydraulic cylinders 6 on the four sides of frame 12 are connected, and 8 hydraulic cylinders 6 are divided into two groups, and every 4 hydraulic cylinders 6 cylinder bodies are connected in series with hydraulic cylinder connection pipelines 7. The upper pulley block 5 and the steering wheel 15 form the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com