Mechanical compensating mechanism of incineration furnace grate

A compensating device and incinerator technology, applied in the direction of incinerators, grates, combustion types, etc., can solve the problems of difficult support design, affecting the ventilation gap of the grate, damage to springs and other components, and achieve the convenience of air intake and air pressure The effect of control, daily maintenance reduction, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

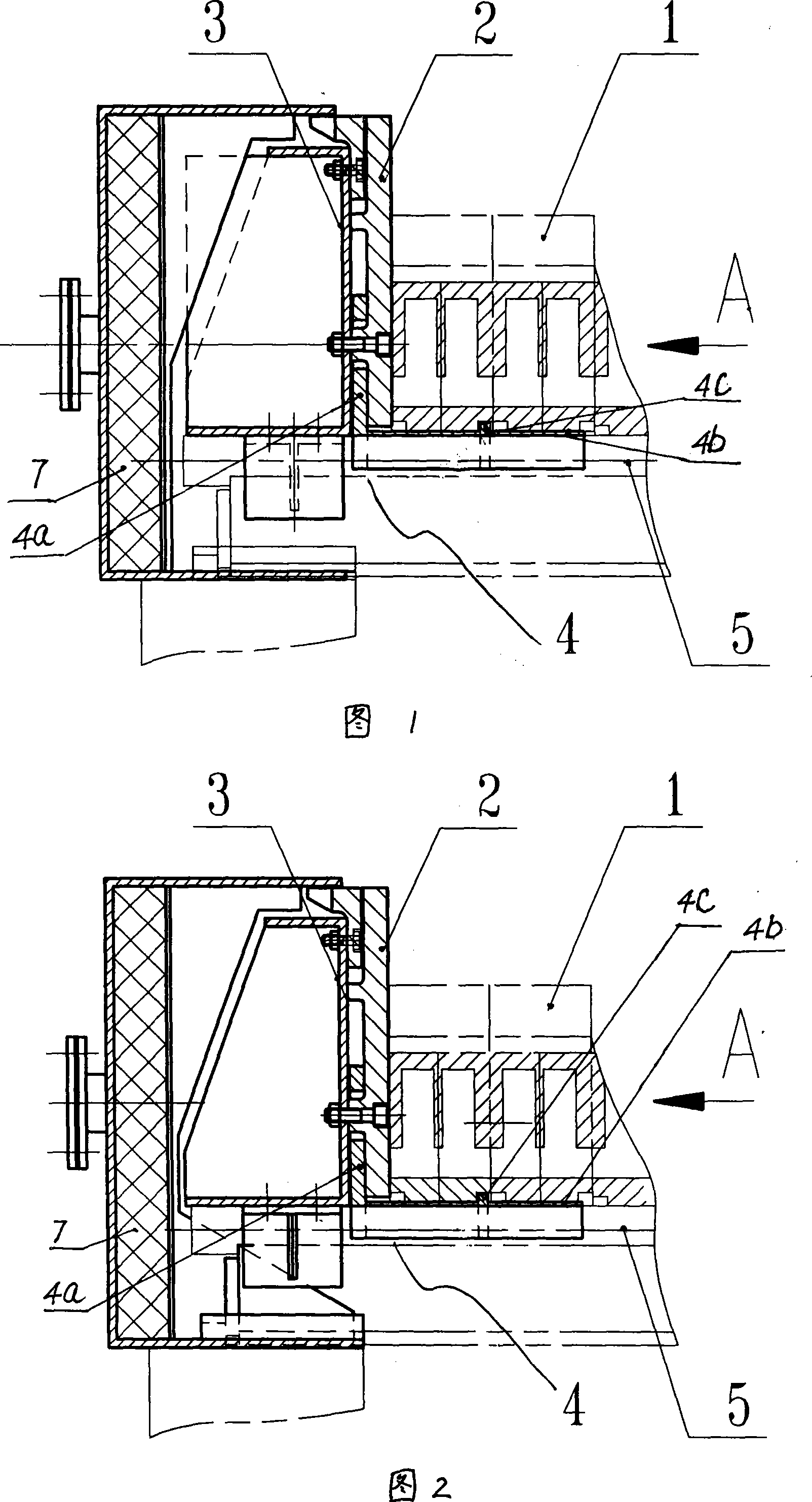

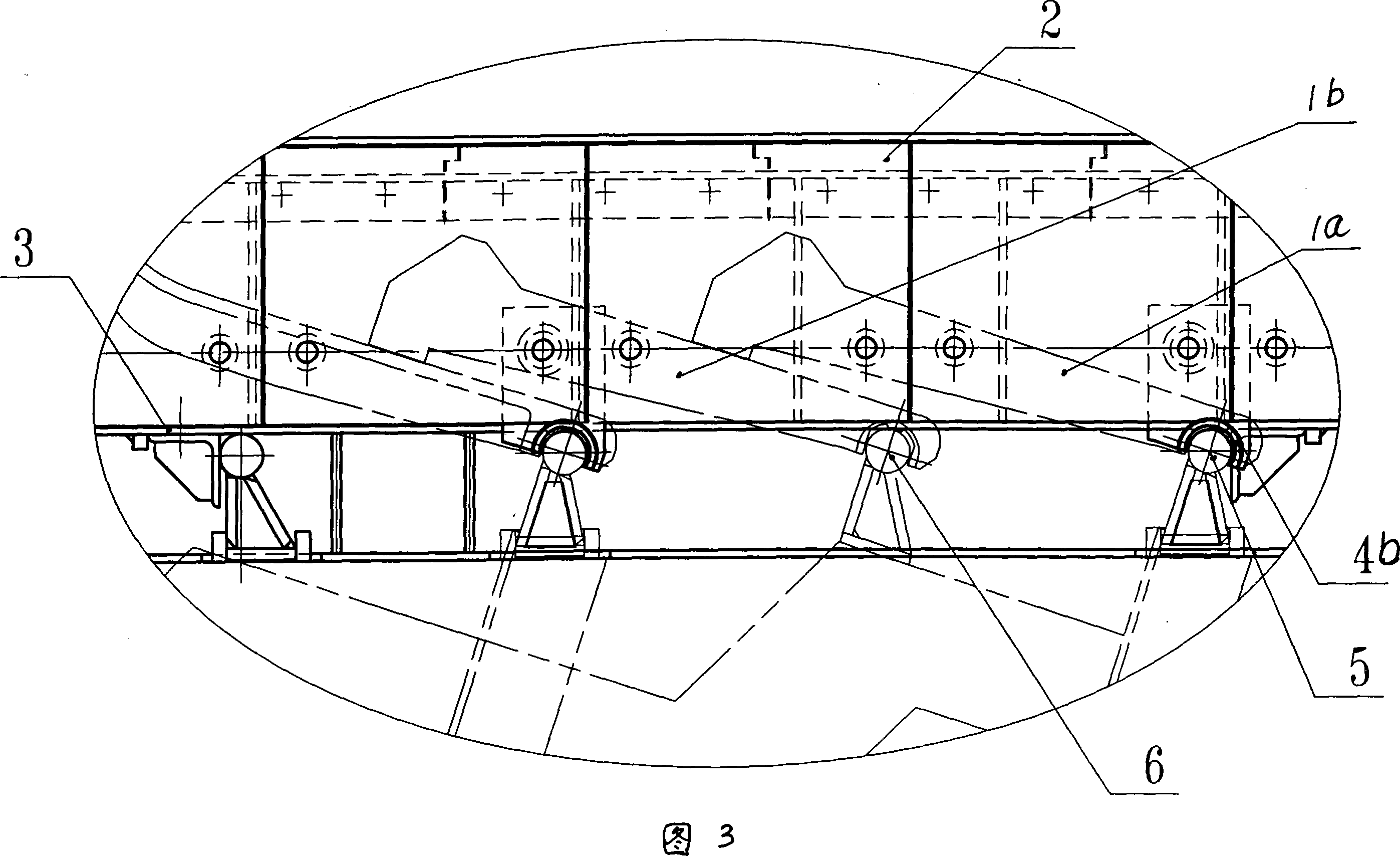

[0013] The structure of existing incinerator fire grate can refer to Fig. 1 or Fig. 2, Fig. 3, and it comprises the fixed fire grate support beam 5, the movable fire grate support beam 6 that are arranged on the body of heater 7 with insulation layer in a staggered manner, and Connect one group of fixed fire grate pieces 1a on each fixed fire grate beam 5 to form a row of fixed fire grates, and connect one group of movable fire grate pieces 1b on each movable fire grate beam 6 to form a row of movable fire grates (in Fig. 3 It only shows two-stage fixed fire grate and two-stage movable fire grate arranged in a staggered manner), wherein the movable fire grate is also connected to a component that can make it reciprocate through its movable fire grate beam 6 (this component is not shown in the figure). be expressed). This existing incinerator, no matter movable fire grate or fixed fire grate, all are fixed on the body of heater with insulation layer 7 by the both sides ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com