Ladle breathable upper nozzle seat brick and method for controlling ladle slag

A technology for nozzle seat bricks and ladles, which is applied in the direction of manufacturing tools, metal processing equipment, casting melt containers, etc., can solve the problems of ineffective prevention, long length, and small diameter of air-permeable rods, so as to reduce production costs and prevent The effect of device air leakage and prevention of gas side leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

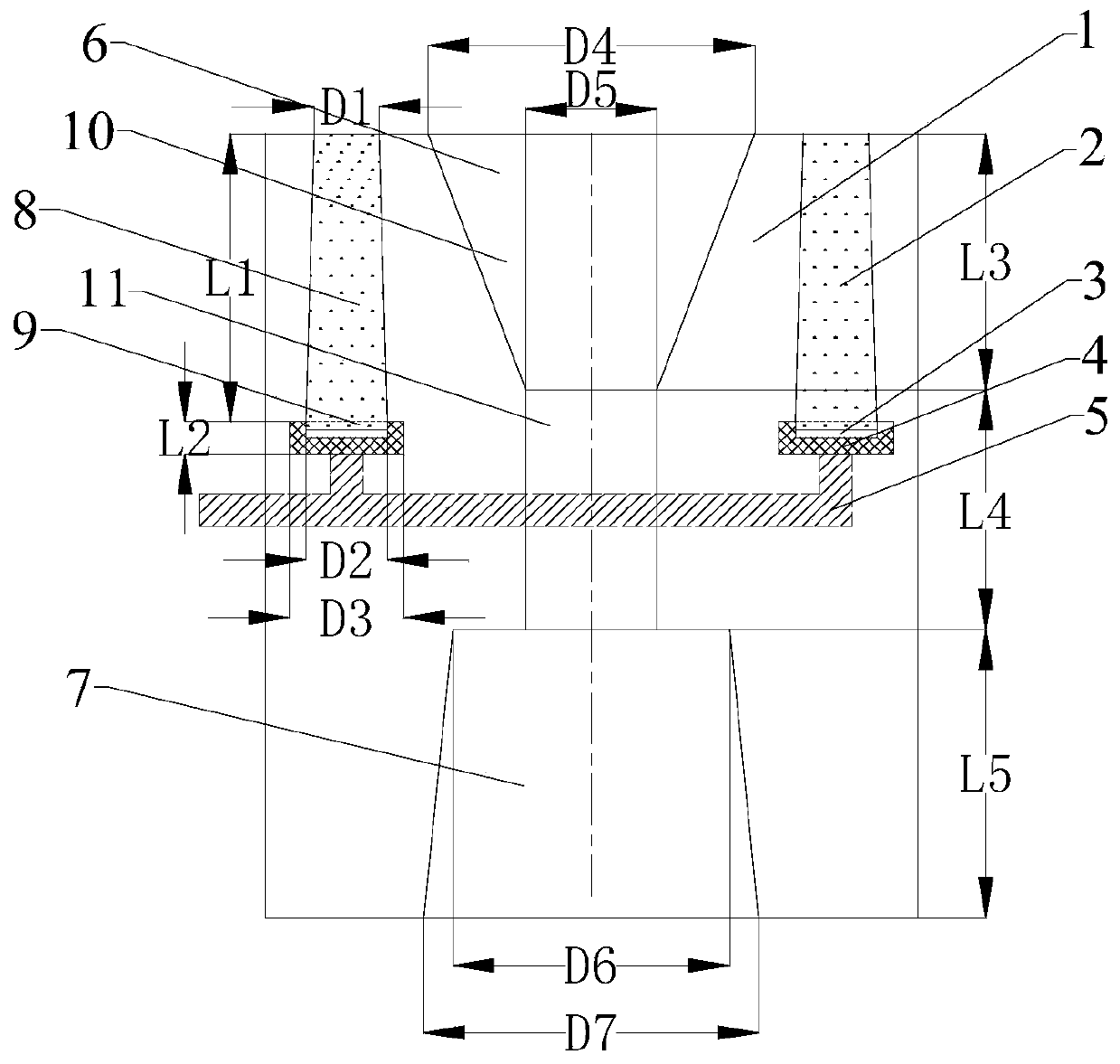

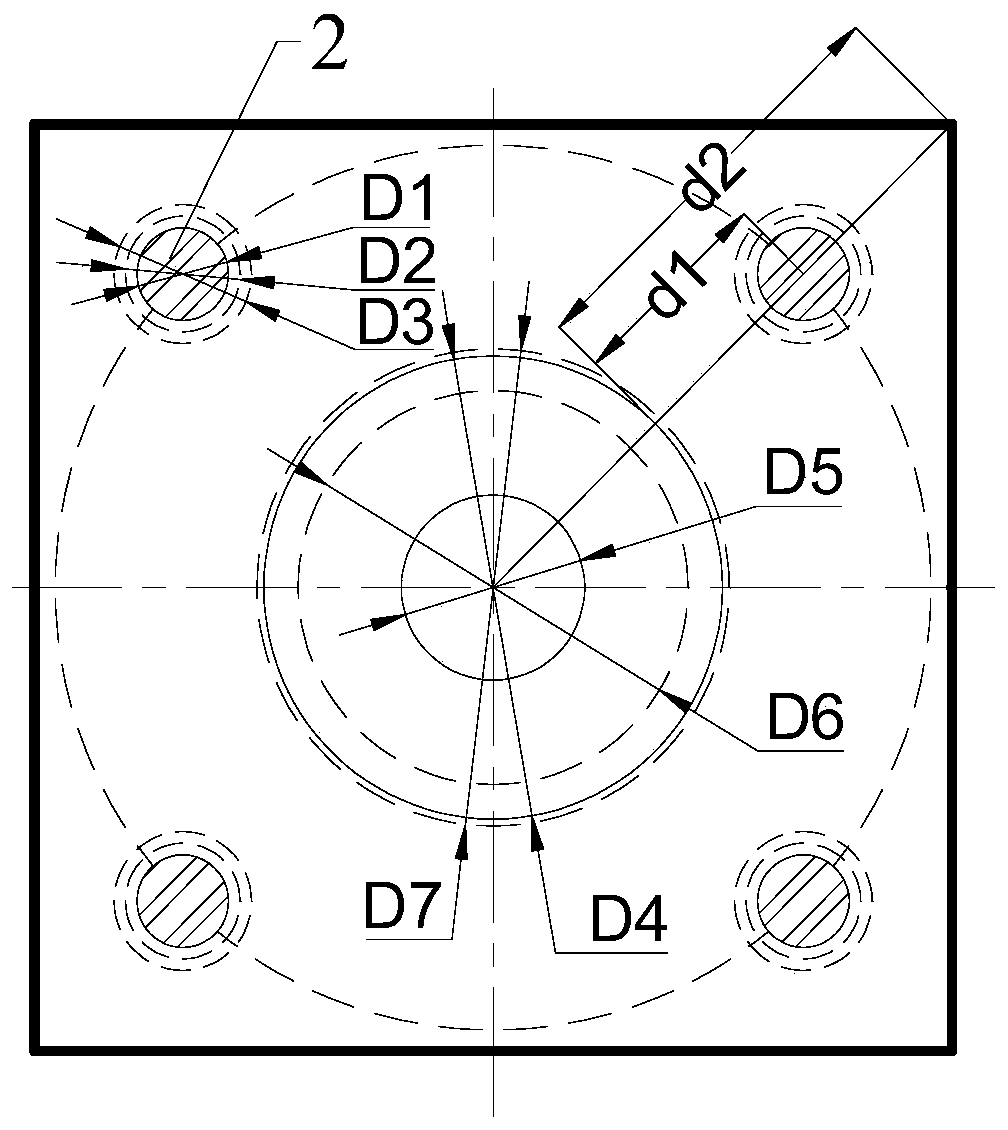

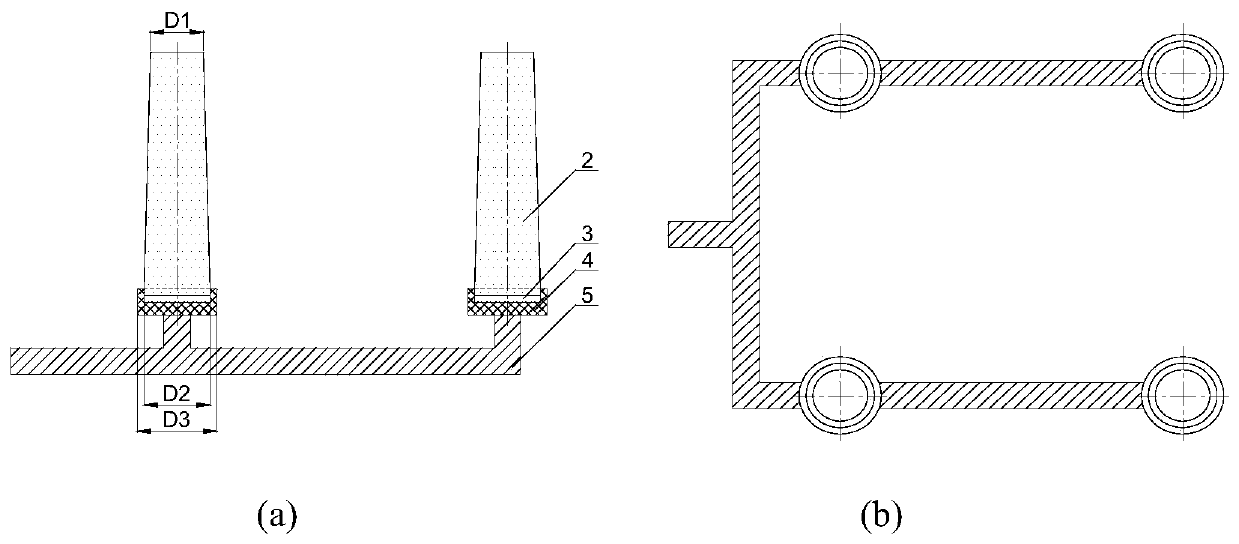

[0036] A kind of ladle breathable upper nozzle seat brick, such as figure 1 and Figure 4 As shown, it includes the ladle upper nozzle block body (1), vent plug (2), air chamber box (3), vent plug base (4), air blowing pipe (5), flow steel hole (6) and upper nozzle Mounting hole (7); the venting plug (2), air chamber box (3), venting plug base (4), flow steel hole (6) and upper nozzle installation hole (7) are all arranged on the ladle upper nozzle seat brick Inside the main body (1), the main body of the blowing pipe (5) is set inside the ladle upper nozzle block body (1), and passes through the side of the ladle upper nozzle block body (1); the flow steel hole (6) is located on the upper The top of the nozzle installation hole (7) is connected with it, and the flow steel hole (6) and the upper nozzle installation hole (7) run through the ladle upper nozzle block body (1) from top to bottom as a whole; ) is provided with a vent plug (2), an air chamber box (3), a vent plug ...

Embodiment 2

[0049] A kind of ladle breathable upper nozzle seat brick, such as Figure 1-Figure 3 shown. Including the ladle upper nozzle block body (1), vent plug (2), air chamber box (3), vent plug base (4), air blowing pipe (5), flow steel hole (6) and upper nozzle installation hole ( 7); the vent plug (2), the air chamber box (3), the vent plug base (4), the flow steel hole (6) and the upper nozzle installation hole (7) are all arranged on the ladle upper nozzle block body (1 ) inside, the main body of the blowing pipe (5) is set inside the ladle upper nozzle block body (1), and passes through the side of the ladle upper nozzle block body (1); the flow steel hole (6) is located in the upper nozzle installation hole (7) above and connected with it, the flow steel hole (6) and the upper nozzle installation hole (7) run through the ladle upper nozzle block body (1) from top to bottom as a whole; set around the flow steel hole (6) Vent plug (2), air chamber box (3), vent plug base (4) a...

Embodiment 3

[0065] A kind of ladle breathable upper nozzle seat brick, such as Figure 1-Figure 3 As shown, it includes the ladle upper nozzle block body (1), vent plug (2), air chamber box (3), vent plug base (4), air blowing pipe (5), flow steel hole (6) and upper nozzle Mounting hole (7); the venting plug (2), air chamber box (3), venting plug base (4), flow steel hole (6) and upper nozzle installation hole (7) are all arranged on the ladle upper nozzle seat brick Inside the main body (1), the main body of the blowing pipe (5) is set inside the ladle upper nozzle block body (1), and passes through the side of the ladle upper nozzle block body (1); the flow steel hole (6) is located on the upper The top of the nozzle installation hole (7) is connected with it, and the flow steel hole (6) and the upper nozzle installation hole (7) run through the ladle upper nozzle block body (1) from top to bottom as a whole; ) is provided with a vent plug (2), an air chamber box (3), a vent plug base ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com